Article Contents

Industry Insight: Led Light Bulb Sizes

The Critical Role of Standardized LED Bulb Sizing in Commercial & Industrial Applications

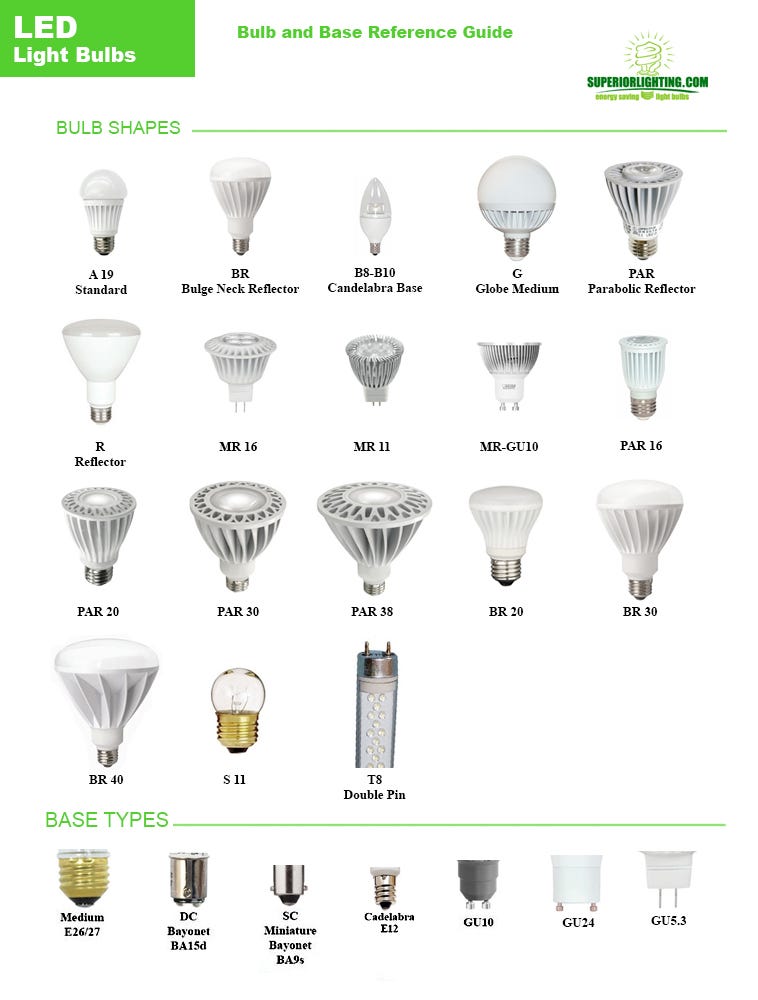

In commercial and industrial lighting projects, precise bulb sizing is not merely a technical detail—it is a foundational element for system compatibility, safety, and long-term operational reliability. Mismatched bulb dimensions can lead to fixture incompatibility, improper heat dissipation, and even electrical hazards. For global project managers and distributors, understanding standardized bulb codes and their physical specifications is essential to avoid costly delays and ensure seamless integration across diverse installations.

Why Standardization Matters for Global Projects

Lighting standards such as ANSI C78.81 define precise dimensional tolerances for bulb shapes to ensure interchangeability across fixtures. However, inconsistent manufacturing practices can result in deviations that compromise performance. For instance:

A19 bulbs with oversized diameters may not fit standard sockets in retail environments

BR30 reflector bulbs exceeding dimensional tolerances can cause overheating in recessed cans

PAR38 floodlights with incorrect base sizes may fail to secure properly in outdoor fixtures

These issues underscore the importance of sourcing bulbs that adhere strictly to industry specifications. Importers must verify that products meet regional dimensional and safety standards to prevent project setbacks and ensure compliance with local regulations.

Quality Assurance: The Non-Negotiable Role of Certifications

Certifications like ETL (USA/Canada) and TUV CE (Europe) are not optional—they are mandatory verification points for commercial lighting products. These certifications validate that bulbs have undergone rigorous testing for electrical safety, thermal management, and performance consistency. For example:

ETL certification confirms compliance with UL standards for North American markets, including dielectric strength and flammability tests

TUV CE certification includes additional scrutiny of electromagnetic compatibility (EMC) and energy efficiency metrics required in EU markets

Without these certifications, imported bulbs risk rejection at customs, project non-compliance, and liability exposure. Below is a reference table of common commercial bulb types with standardized dimensions and applications:

| Bulb Type | Code | Diameter (mm) | Length (mm) | Typical Applications |

|---|---|---|---|---|

| General Purpose | A19 | 60 ±1 | 110 ±2 | Office lighting, retail spaces, hospitality |

| Reflector | BR30 | 95 ±1 | 120 ±2 | Recessed ceiling fixtures in commercial buildings |

| Parabolic Aluminized Reflector | PAR38 | 120 ±1 | 145 ±2 | Outdoor floodlighting, warehouse high-bay areas |

| Linear Fluorescent Replacement | T8 | 26 ±0.5 | 1219 ±2 (4ft) | Office ceiling grids, schools, hospitals |

| High-Efficiency Linear | T5 | 16 ±0.3 | 1160 ±2 (4ft) | Modern retrofits, task lighting, healthcare facilities |

Note: Dimensions reflect ANSI-compliant tolerances. Variations beyond these ranges indicate non-conforming products.

Partnering with a Veteran Manufacturer for Reliable Solutions

With over 25 years of experience in lighting manufacturing since 1998, Beauty STC Lighting delivers factory-direct solutions engineered for global markets. Our commitment to technical excellence is demonstrated through:

Full compliance with ETL and TUV CE certifications for all products

OEM/ODM capabilities tailored to specific regional standards and project requirements

Rigorous in-house testing protocols that exceed industry benchmarks for thermal stability and lumen maintenance

As a manufacturer serving 50+ countries, we understand that quality is defined by consistent adherence to specifications—not just initial compliance. Our team of certified engineers works directly with distributors and contractors to ensure every product meets the exacting demands of commercial and industrial applications.

For project-specific technical guidance or custom solutions, contact us at [email protected] or 0086-13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

LED Light Bulb Sizes – Industrial Performance vs. Factory-Certified Reliability

When a distributor or project engineer specifies an “A19”, “PAR38”, or “T8” LED, the real conversation is not the glass envelope drawing—it is the photometric density, thermal path, and long-term lumen maintenance hidden inside that envelope. Below we translate the marketing codes into measurable engineering parameters and show how Beauty (STC) Manufacturing Co., Ltd (est. 1998) locks every size variant to the same export-grade tolerance band.

1. Key Metrics That Override “Size”

| Parameter | Industrial Benchmark | Beauty STC Certified Window | Test Reference |

|---|---|---|---|

| Efficacy | 110 lm/W (minimum for DLC 5.1) | 125–145 lm/W @ 25 °C Tj | IES LM-79-19 |

| CRI | ≥ 80 (commercial) | ≥ 90 (Typ. 93) optional 97 | CIE 13.3-1995 |

| R9 | > 0 | > 50 (Typ. 65) | TM-30-20 |

| Lumen Maint. | L70 > 50 000 h | L70 > 54 000 h (6 kV surge) | LM-80-15 + TM-21 |

| Flicker | < 10 % @ 100 Hz | < 3 % (IEEE 1789) | |

| IP Rating | IP20 (indoor) / IP65 (wet) | IP20–IP67 with one-piece PU gasket | IEC 60529 |

| PCB | 1 oz Cu, FR4 | 2 oz Cu, thermally conductive dielectric (λ ≥ 1.5 W/m·K), 1.6 mm | IPC-6012D |

| Driver MTBF | 50 000 h @ 80 °C Tc | 83 000 h @ 85 °C Tc (Rubycon 105 °C caps) | MIL-HDBK-217F |

2. Size Code vs. Optical Target

| Bulb Code | Nominal Dia. (in) | Typical Beam | Beauty STC Optics Plate | Application Foot-print |

|---|---|---|---|---|

| A19 | 2.375 | 220° | 1.2 mm PMMA diffuser, 92 % T | Hotel bedside, retail pendant |

| BR30 | 3.75 | 110° | High-reflectance Al MCPCB + TiO₂ ring | Track, recessed 5–6″ can |

| PAR38 | 4.75 | 25°/40° | 12 µm Ag-plated Al reflector, UV-stable PC lens | Exterior flood, façade |

| T8 4 ft | 1.0 Ø | 160° | Opal polycarbonate + nano-coating, 0 % yellowing @ 15 kWh/m² UV | Fluorescent retrofit, warehouse |

| T5 2 ft | 0.625 Ø | 160° | Same as T8, 1.2 mm wall for 1 kV surge | Clean-room, display case |

3. Quality Consistency – How Beauty STC Guarantees Each Batch

ETL & TUV CE Listed Drivers – Every SKU produced under the same 8-digit ETL control number; field replaceable without re-certification.

6-Point LM-80 Sampling – 200 pcs per lot, every 1 000 h read-point, 85 °C & 105 °C dual stress.

Solderability & X-Ray – 100 % AOI after SMT; 10 % X-ray抽检 (IPC-A-610 Class 2).

Thermal Shock – –40 °C ⇄ 125 °C, 200 cycles, ΔTj < 5 °C vs. baseline.

Traceability – 2-D code on aluminum shell links to diode bin, driver IC reel, and ICT log; 10-year record retention.

4. Generic Market vs. Beauty STC – Side-by-Side

| Spec | Generic Market (uncontrolled) | Beauty STC Certified |

|---|---|---|

| Efficacy Spread | ± 15 % (same SKU) | ± 3 % (binning @ 3 SDCM) |

| CRI Range | 70–83 (batch dependent) | 90–93 fixed bin; R9 > 50 |

| PCB Copper | 1 oz, λ 0.8 W/m·K | 2 oz, λ 1.5 W/m·K, 1 000 V isolation |

| Driver Cap Life | 4 000 h @ 105 °C | 10 000 h @ 105 °C (Rubycon, Nichicon) |

| Surge Immunity | 500 V differential | 2 kV differential / 4 kV common (IEC 61000-4-5) |

| Labeling | Self-printed | Laser-etched + ETL QR code |

| Warranty | 2 yrs limited | 5 yrs full, < 1 % return rate since 2016 |

5. OEM / ODM Flexibility

Beauty STC’s 25 000 m² Jiangmen campus (Jianghai High-tech Zone) houses 12 SMT lines and a 1 500 m² anodizing & painting workshop. We can keep the above performance window while re-packaging into any ANSI size or custom heatsink extrusion—minimum 500 pcs for private-label ETL file, 100 pcs for CE-only SKUs.

Need a technical file or IES/LDT for your next tender? Email [email protected] or call +86-13902885704 (WhatsApp). Our engineering team will revert with a datasheet and LM-79 report within 24 h.

Factory Tour: Manufacturing Excellence

Precision Manufacturing: Engineered for Global Standards

Since 1998, Beauty STC Lighting has operated a vertically integrated manufacturing facility in Jiangmen’s High-tech Industrial Zone, producing LED solutions for 50+ countries. Our processes adhere to ETL (USA/Canada) and TUV CE (Europe) certifications, ensuring compliance with international safety and performance standards. Every product undergoes rigorous quality control from component sourcing to final assembly, reflecting our commitment to “Be a responsible enterprise, Be a caring person” through industrial excellence.

Fully Automated SMT Production Line

Our 4,000m² SMT facility features fully automated lines with high-speed pick-and-place machines, 10-zone reflow ovens, and X-ray inspection for BGA components. This ensures consistent solder joint integrity and minimizes human error during mass production.

| Parameter | Specification |

|---|---|

| Machine Type | Yamaha YS12 & YS24 (high-speed placement) |

| Placement Speed | 30,000 components/hour |

| Accuracy | ±0.025mm |

| Reflow Oven | 10-zone IR + convection (±1°C precision) |

| Inspection | AOI + X-ray for BGA/QFN validation |

Rigorous Testing Protocols

All products undergo comprehensive aging tests, thermal cycling, and environmental stress screening to validate long-term reliability. Our testing protocols exceed industry standards, ensuring products perform under real-world conditions without compromising safety or performance.

| Test Type | Duration | Conditions | Pass Criteria |

|---|---|---|---|

| Burn-in Test | 72 hours | 45°C ambient, 100% load | <3% lumen depreciation |

| Thermal Cycling | 100 cycles | -40°C to 85°C | No component failure |

| Humidity Test | 48 hours | 85% RH, 85°C | Insulation resistance >100MΩ |

| Spectral Analysis | Per batch | LM-79 compliant | ±5% lumen output accuracy |

| Electrical Safety | 100% | IEC 60598 | Hipot test: 1,500V for 60s |

OEM/ODM Customization Capabilities

With 25+ years of OEM/ODM experience, we provide end-to-end customization for form factors, color temperatures, and packaging. Our Jiangmen facility supports global compliance requirements through tailored engineering, ensuring seamless integration into commercial and industrial projects.

| Customization Parameter | Specifications | Compliance Notes |

|---|---|---|

| PCB Layout & Lengths | Custom cuts (1m–50m), unique shapes | ±0.5mm tolerance, IEC 62471 certified |

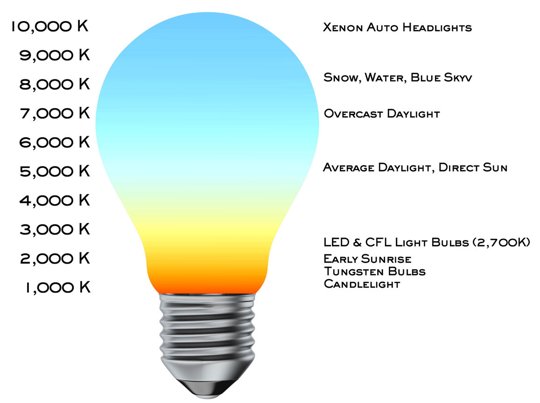

| CCT Range | 2700K–6500K (±50K consistency) | Meets IEC 62717 color stability standards |

| Packaging | Branded, eco-materials, regional labeling | ETL/CE-compliant labeling for target markets |

| Driver Integration | Custom wattage, dimming protocols | UL 8750 certified for safety |

Beauty STC Lighting’s commitment to precision engineering and certified manufacturing processes ensures reliable, compliant solutions for global lighting projects. Our factory-direct approach eliminates intermediary margins while maintaining traceability from raw materials to finished goods.

Contact us to discuss technical specifications for your next commercial or industrial project:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios: Matching LED Bulb Sizes to Commercial & Industrial Spaces

(Factory-direct guidance from Beauty (STC) Manufacturing Co., Ltd – ETL / TUV CE certified since 1998)

H2 Selecting the Right Form-Factor for the Task

The physical envelope of an LED lamp dictates optical control, thermal performance and luminaire compatibility. Below we map the most common IEC/ANSI bulb sizes to real-world commercial installations and give installation notes that save contractors callbacks.

H3 Hospitality – Hotels & Resorts

| Area | Recommended Size | Typical Lamp Data* | Mounting Notes for Contractors |

|---|---|---|---|

| Guest-room bedside A-lamp | A19 | 8 W, 2700 K, 800 lm, CRI 90 | Use ETL-listed supply. Dimmable driver must be compatible with 0-10 V or Triac front-of-house panels. |

| Bathroom vanity | G25 globe | 6 W, 3000 K, 550 lm | Verify IP44 rating; mount ≥30 cm from water source to meet CE 60598-2-4. |

| Corridor down-light | BR30 / PAR30L | 12 W, 4000 K, 950 lm, 25° | 6-inch housing; leave 10 mm air-gap between heatsink and ceiling insulation for 50 000 h L70 life. |

| Lobby chandelier | CA10 filament | 3 W, 2200 K, 250 lm | Check max 60 W per SES/E14 lampholder; retrofit in series strings ≤50 lamps per 5 A circuit. |

H3 Retail & Shopping Malls

| Track/Spot Application | Size | Beam Options | Cert. Requirement | OEM/ODM Tip from Beauty STC |

|---|---|---|---|---|

| Window display accent | PAR20 | 10°, 24°, 38° | ETL / CE, RoHS | We can laser-etch your distributor logo on aluminium heatsink, MOQ 500 pcs. |

| High-bay pendant uplight | BR40 | 2700 lm, 4000 K | FCC Part 15 | Ask for 347 V Canada pack; same tooling since 2016. |

| Mall circulation down-light | PAR38 | 15 W, 90 CRI, 3000 K | TUV CE, ErP | Available with external 1–10 V driver; remote driver box keeps ceiling temperature <45 °C. |

H3 Offices & Conference Centres

| Fixture Type | Lamp Size | Luminous Flux | Glare Control | Contractor Checklist |

|---|---|---|---|---|

| 2×2 recessed troffer retrofit | T8 4 ft Type-B (ballast bypass) | 1800 lm, 4000 K | UGR <19 | Confirm existing T8 lamp holders are shunted; re-wire line & neutral to single end only (ETL diagram supplied). |

| Desk task uplight | A21 | 1600 lm, 3000 K | Frosted diffuser | Maintain 300 mm clearance to sensor-equipped emergency fixtures to avoid IR interference. |

| Meeting-room pendant | G30 globe | 1250 lm, Tunable 2700–5000 K | CRI 95 | Use 0-10 V dimmer with neutral wire; test flicker ≤10 % at 100 Hz per IEEE 1789. |

H3 Façade & Landscape

| Application | Size | IP / IK Rating | Ambient Temp | Installation Advice |

|---|---|---|---|---|

| Building wash flood retro-fit | PAR38 | IP65, –40 °C to +45 °C | Use silicone O-ring; torque 1.2 Nm to avoid lens stress cracks. | |

| Walkway bollard | T20 tubular | IP54 | Beauty STC offers custom 24 V DC version for solar battery systems; inquire before container load. | |

| Signage strip | LED filament ST64 | IP44 | Mount horizontally ±15° to keep LED filament tension within spec. |

H3 Industrial & Warehouse

| High-bay Retrofit | Size | Lumen Package | Beam Angle | Cert. & Warranty |

|---|---|---|---|---|

| HID replacement | E39 mogul-base PAR56 | 18 000 lm, 5700 K | 60° | ETL/cETL, 5-year / 50 000 h, ≥L70. |

| Corn-cob lamp | E40 360° | 12 000 lm | 360° | TUV CE, ErP 1194/2012; ask for 480 V internal driver option. |

Contractor notes:

Bypass ballast & capacitor; verify mogul socket temperature <90 °C at 45 °C ambient.

Use 10 AWG stranded wire when input >200 W to meet NEC ampacity.

H3 Quick-Reference Bulb Code Chart (ANSI / IEC)

| Code | Diameter (in) | Base | Common Commercial Use |

|---|---|---|---|

| A19 | 2.375 | E26/E27 | Hotel rooms, desk lamps |

| BR30 | 3.75 | E26/E27 | Corridors, retail track |

| PAR38 | 4.75 | E26/E27 | Façade floods |

| T8 4 ft | 1.0 | G13 | Office troffers |

| E39 PAR56 | 7.0 | Mogul | High-bay retrofits |

H3 Key Takeaways for Distributors & Specifiers

- Certifications first: Every size listed above is production-tested to ETL (US/Canada) and TUV CE (EU) in our Jiangmen ISO 9001 facility—no re-testing delays for your projects.

- OEM flexibility: Since 1998 we have tooled >600 injection molds; custom diameter, length or base configuration available at MOQ 300 pcs.

- Stock compatibility: All lamps comply with ANSI C78.20 dimension limits—drop-in replacement for mainstream housings.

For project quotations or custom lamp drawings, contact:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

As a manufacturer with over 25 years of experience, Beauty STC Lighting provides reliable, certified LED lighting solutions for global distributors, contractors, and project managers. Our commitment to quality and compliance ensures seamless integration into international markets.

Global Compliance & Quality Assurance

All products undergo rigorous testing to meet international safety and performance standards. ETL certification ensures compliance with North American regulations, while TUV CE certification validates adherence to European Union directives. These certifications are critical for market access and project approvals in Western regions.

Established Expertise Since 1998

Operating from our Jiangmen, Guangdong facility since 1998, Beauty STC Lighting has developed a robust manufacturing process focused on precision and reliability. Our longevity reflects consistent adherence to quality standards and a deep understanding of evolving industry demands.

Customized Solutions for Diverse Applications

Our OEM/ODM capabilities support precise customization of LED bulb sizes, shapes, and technical specifications. Whether standard A19, BR30, PAR38, or specialized industrial fixtures, we deliver solutions tailored to exact project requirements without compromising on quality or compliance.

| Specification | Detail |

|---|---|

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| Market Reach | 50+ countries across Europe, Americas, Southeast Asia, Australia, Russia, Japan, Korea |

| Manufacturing History | Established in 1998 |

| Customization | Full OEM/ODM support for LED bulb sizes and lighting solutions |

Contact Us

For technical specifications, project support, or to discuss your requirements, contact our export team directly:

[email protected] | +86 139 0288 5704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).