Article Contents

Industry Insight: Led Floor Lighting

The evolution of commercial and industrial lighting has moved far beyond basic illumination, demanding intelligent, durable, and purpose-built solutions that enhance safety, guide movement, and optimize operational efficiency within demanding environments. LED floor lighting has emerged as a critical infrastructure component in this landscape, transitioning from a niche aesthetic feature to an essential element for wayfinding in warehouses, defining safe pathways in manufacturing facilities, highlighting hazards in logistics hubs, and creating intuitive customer journeys within retail and hospitality spaces. Unlike residential applications, these settings impose rigorous requirements: luminaires must withstand heavy foot traffic, forklift impacts, chemical exposure, extreme temperatures, and continuous operation while maintaining consistent photometric performance. Crucially, compliance is non-negotiable. Products deployed in commercial and industrial settings must demonstrably meet stringent safety and performance benchmarks, making certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) fundamental prerequisites, not optional extras. They are the bedrock of liability protection, insurance compliance, and successful project specification.

Beauty STC Manufacturing Co., Ltd. has been at the forefront of meeting these exacting demands since our establishment in 1998. Over two and a half decades of focused engineering and manufacturing excellence have positioned us as a trusted partner for commercial and industrial clients globally. We understand that in these high-stakes environments, floor lighting is never merely decorative; it is a vital safety system and operational tool. Our deep expertise lies in developing robust, certified LED floor lighting solutions engineered specifically for the harsh realities of commercial and industrial use, where reliability, adherence to international standards like ETL and CE, and long-term performance are paramount to our customers’ success and safety.

Technical Specs & Certifications

LED floor lighting from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance, durability, and visual accuracy, making it ideal for architectural, commercial, and high-end retail applications. Our LED floor lights are designed with a strong emphasis on efficiency, color quality, and environmental protection.

In terms of efficiency, our LED floor lighting achieves a luminous efficacy of 90 to 120 lumens per watt, depending on the specific model and configuration. This high lumen-to-watt ratio ensures optimal energy savings without compromising light output, supporting sustainable lighting solutions in both indoor and outdoor installations.

Color Rendering Index (CRI) is a critical factor in premium lighting, and all our LED floor lights deliver a CRI greater than 90. This ensures accurate and natural color representation, which is essential in environments where visual clarity and aesthetic appeal are paramount—such as retail displays, museums, and hospitality spaces. High CRI performance is achieved through the use of premium-grade LEDs and advanced phosphor coatings, rigorously tested during production.

Regarding environmental protection, Beauty STC’s LED floor lighting typically features IP65 to IP68 ratings. IP65 provides complete dust protection and resistance to low-pressure water jets, suitable for indoor and semi-outdoor installations. For fully outdoor or wet location applications—such as stair treads, pool surrounds, or exterior walkways—our IP68-rated fixtures offer total dust ingress protection and submersion resistance, ensuring long-term reliability under harsh conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control throughout the production process. Our LED floor lights are constructed using high-strength materials such as die-cast aluminum and tempered glass, with robust sealing systems to maintain IP integrity. Each unit undergoes thermal, electrical, and waterproof testing to ensure compliance with international standards, including IEC and RoHS. With over two decades of lighting innovation, Beauty STC is recognized for delivering reliable, high-quality LED solutions that combine technical excellence with elegant design.

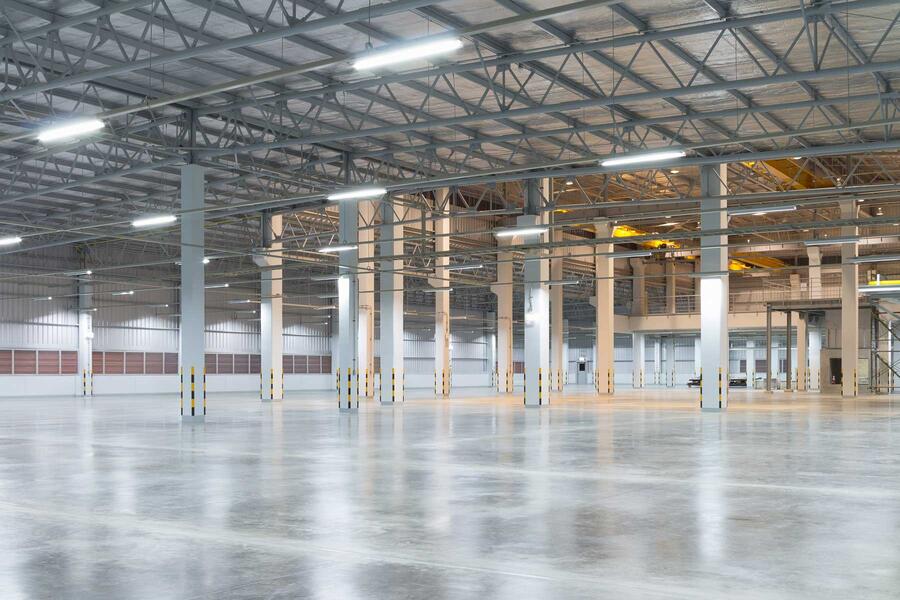

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a core production hub for our LED lighting solutions, strategically located within the Pearl River Delta’s advanced manufacturing ecosystem. This modern plant integrates specialized processes critical for high-reliability LED products, with particular expertise in architectural and specialty lighting applications such as LED floor lighting.

The surface mount technology (SMT) production lines within the Jiangmen factory utilize multiple high-precision Yamaha YS series placement machines. These systems handle components down to 0201 metric package sizes with micron-level accuracy, essential for densely populated LED driver and control boards used in slim-profile floor luminaires. Each SMT line incorporates fully automated solder paste inspection (SPI) and 3D automated optical inspection (AOI) stations immediately post-placement and post-reflow. Our nitrogen-controlled reflow ovens maintain precise thermal profiles to ensure solder joint integrity for components subjected to thermal cycling in floor installations. The entire SMT process operates under strict ESD controls and real-time statistical process monitoring to maintain yield rates above 99.5%.

Aging and reliability testing for LED floor lighting products follows a rigorous multi-stage protocol at the Jiangmen site. All finished floor luminaires undergo a mandatory 72-hour continuous burn-in test at 1.2x rated voltage within temperature-controlled environmental chambers. During this period, photometric performance is monitored at intervals using integrated spectroradiometers to track lumen maintenance and chromaticity shift. Crucially, the test sequence includes thermal cycling between -20°C and +50°C to simulate real-world installation environments from cold storage facilities to heated retail spaces. Products destined for outdoor or wet-location floor applications additionally complete 1,000-hour IP68 validation under constant water immersion at operational voltage. Statistical process control data from these aging tests feeds directly into our Six Sigma quality management system.

Our OEM capability for LED floor lighting encompasses comprehensive turnkey manufacturing services. The Jiangmen facility supports full product customization from initial concept through to packaged goods, including custom optical engineering for specific beam distributions required in floor wash applications, structural modifications for unique architectural integrations, and tailored driver solutions for 0-10V, DALI, or proprietary control systems. We provide complete design for manufacturing (DFM) collaboration, enabling clients to optimize thermal management in constrained floor cavity spaces while meeting stringent IP and impact resistance requirements. The factory maintains dedicated clean-room assembly zones for high-end optical components and offers flexible production scaling from prototype batches to high-volume runs exceeding 50,000 units monthly. All OEM projects benefit from our integrated quality assurance system, which includes material traceability through ERP, in-process inspections at 12 defined checkpoints, and final verification against IEC 60598-1 and IEC 60598-2-22 standards for floor-mounted luminaires.

Application Scenarios

LED floor lighting is a versatile and impactful design solution that enhances both aesthetics and functionality in various commercial environments. Its application is most effective in spaces where safety, ambiance, and architectural enhancement are priorities.

In hotels, LED floor lighting is ideal for creating welcoming and luxurious atmospheres. It is commonly used in lobbies, hallways, stair treads, and along guest room corridors to provide subtle guidance during nighttime while adding a modern, high-end aesthetic. Step lighting in staircases and illuminated pathways leading to elevators or restrooms improve guest safety without compromising on design.

In malls and shopping centers, LED floor lighting serves both decorative and navigational purposes. It can be embedded in flooring near entrances, food courts, escalator landings, and feature displays to draw attention or guide foot traffic. When used in creative patterns or color-changing modes, it enhances branding and seasonal displays. Waterproof and high-impact rated LED floor lights are especially suitable for high-traffic public areas.

In offices, LED floor lighting is typically applied in conference rooms, executive suites, and along emergency exit paths. It offers minimalist illumination that supports wayfinding without disrupting the professional environment. Under-cabinet toe-kick lighting or low-level path lighting in open-plan offices can also reduce glare and support circadian lighting strategies.

For successful installation, several key tips should be followed. First, always select fixtures rated for the specific environment—IP67 or higher for wet or high-traffic zones, and impact-resistant models where foot or cart traffic is heavy. Ensure the lighting design complies with local building and safety codes, especially for emergency egress requirements. Proper spacing is critical; lights should be placed at consistent intervals to maintain uniform guidance, typically 1 to 2 meters apart depending on light output and beam angle. Use low-voltage LED systems for safety, and install drivers in accessible locations for maintenance. Finally, integrate controls such as motion sensors or dimmers to enhance energy efficiency and extend LED lifespan. Proper alignment and secure mounting in concrete, tile, or wood substrates will ensure long-term durability and optimal light distribution.

Why Choose Beauty STC Lighting

Elevate your architectural projects with precision-engineered LED floor lighting solutions designed for durability, safety, and seamless integration. At Beauty STC Manufacturing Co. Ltd. we specialize in high-performance LED floor luminaires that meet rigorous international standards including IP67 ingress protection and 50000-hour lumen maintenance. Our engineered systems ensure optimal light distribution thermal management and vandal resistance for commercial public and high-traffic environments.

Partner with Beauty STC to access OEM/ODM capabilities flexible customization and scalable production from our ISO-certified facility. We provide comprehensive technical support photometric validation and compliance documentation to streamline your project specifications and installations.

Contact our dedicated project management team at [email protected] to discuss your requirements receive tailored recommendations and initiate a collaboration built on engineering excellence and reliable delivery. Reach out today to integrate Beauty STC LED floor lighting into your next specification.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.