Article Contents

Industry Insight: Led Flexible Led Strip

The LED flexible strip lighting market has experienced significant transformation over the past two decades, evolving from a niche decorative solution to a core component in commercial and industrial lighting design. Today’s demand for energy efficiency, design flexibility, and long-term reliability has propelled the adoption of high-performance LED strips across a wide range of applications—from retail displays and office ambient lighting to industrial task illumination and architectural integration. As facility managers and lighting designers prioritize sustainable and code-compliant solutions, certifications such as ETL and CE have become critical benchmarks, ensuring products meet rigorous North American and international safety and performance standards.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading innovator in flexible LED strip technology, delivering robust, code-compliant lighting solutions tailored for demanding commercial and industrial environments. Combining advanced thermal management, consistent lumen output, and rigorous quality control, Beauty STC’s LED strips are engineered to perform reliably under continuous operation, making them a preferred choice for professionals who value durability, efficiency, and regulatory compliance.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED flexible strips engineered for demanding commercial and premium residential applications where color fidelity, efficiency, and environmental resilience are critical. Our standard high-CRI flexible LED strips utilize top-bin, industry-leading 2835 or 5050 SMD LEDs mounted on rigorously tested flexible PCBs. Lumens per Watt (lm/W) efficiency is a core focus, with our typical high-CRI (Ra>90) strips delivering 130-140 lm/W under standard test conditions at 25°C ambient temperature. This efficiency is achieved through optimized driver circuitry, high-quality phosphor coatings, and superior thermal management inherent in our copper-heavy PCB designs, ensuring stable output even during sustained operation. It is important to note that real-world lm/W can vary based on drive current, ambient temperature, and specific binning; our engineering team provides detailed LM-79 reports for each product variant to ensure accurate system planning.

Color Rendering Index (CRI) performance is non-negotiable for Beauty STC. All strips marketed with CRI >90 consistently achieve Ra values of 95 or higher, with a strong emphasis on R9 (saturated red) values exceeding 50. This exceptional color accuracy is critical for applications in retail makeup counters, high-end apparel displays, luxury hospitality, and any environment where true-to-life color representation directly impacts customer experience and product perception. We achieve this through a proprietary multi-phosphor blend and strict binning protocols during manufacturing, ensuring batch-to-batch consistency that standard CRI>90 strips often lack. Our quality control includes spectroradiometric testing on every production batch to verify spectral power distribution and CRI metrics meet or exceed specifications.

Environmental protection is addressed through comprehensive Ingress Protection (IP) rating options. Beauty STC’s standard high-CRI flexible strips feature a robust dual-layer silicone encapsulation process, achieving an IP67 rating as standard. This provides complete protection against dust ingress and resistance to temporary immersion in water up to 1 meter for 30 minutes, making them suitable for demanding environments like retail display cases, under-cabinet kitchen lighting, cove lighting in humid climates, and outdoor architectural accents not subject to prolonged submersion. For marine or fully submerged applications, we offer IP68-rated variants with enhanced sealing, validated through 100% production-line testing per IEC 60529 standards, including extended salt spray testing to ensure long-term corrosion resistance.

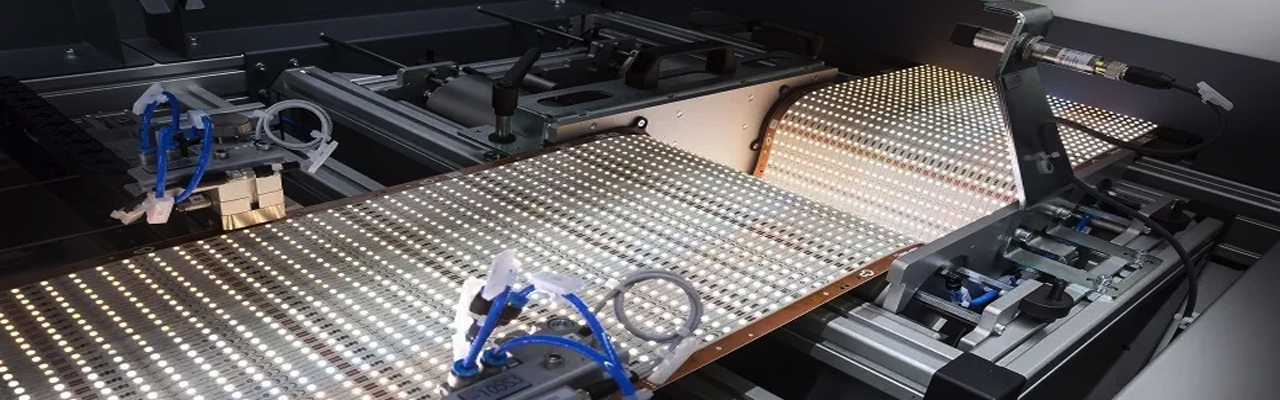

Beauty STC’s commitment to quality is embedded in every stage of production. Our Shenzhen manufacturing facility utilizes fully automated SMT lines with 3D solder paste inspection and automated optical inspection (AOI) to guarantee component placement accuracy and solder joint integrity. Every meter of high-CRI flexible strip undergoes a minimum 24-hour aging test at elevated temperature and full drive current before final calibration and packaging. We adhere strictly to IEC 60598 and IEC 62031 safety standards, with UL/cUL certification available for key product lines. Our rigorous quality management system, certified to ISO 9001:2015, ensures that the lm/W efficiency, CRI consistency, and IP rating claims are not just theoretical specifications but reliably delivered performance metrics backed by a standard 5-year warranty and proven field performance exceeding 50,000 hours at L70. This end-to-end control from chip selection to final testing is what distinguishes Beauty STC’s flexible LED strips in the high-fidelity lighting market.

Factory Tour: Manufacturing Excellence

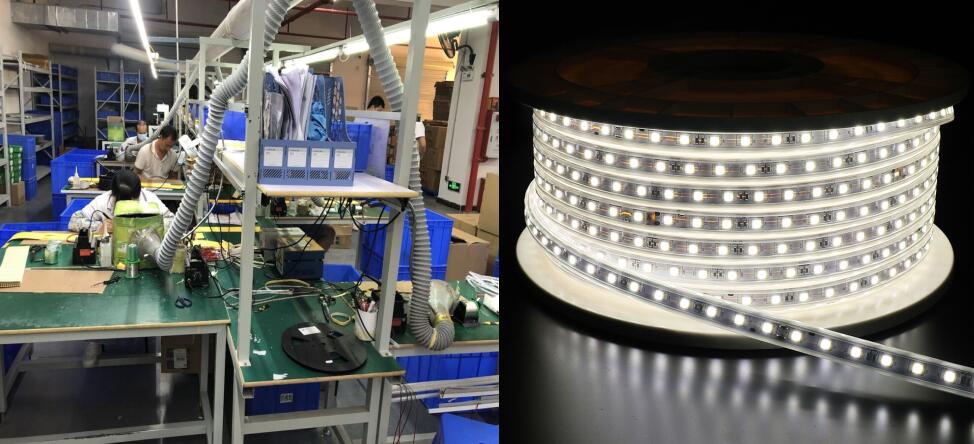

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility specializing in the production of LED lighting solutions, with a strong focus on quality, efficiency, and customization. Strategically located in the Jiangmen high-tech industrial zone, the facility benefits from advanced infrastructure and a skilled workforce, enabling it to support both domestic and international markets with reliable manufacturing output.

The factory is outfitted with state-of-the-art SMT (Surface Mount Technology) production lines, which are critical for the precise assembly of LED components onto flexible circuit boards. These SMT machines include high-speed pick-and-place units capable of handling a wide range of LED chip sizes, such as 2835, 3528, 5050, and 5730, with excellent placement accuracy and throughput. Automated optical inspection (AOI) systems are integrated into the SMT process to ensure component alignment, solder quality, and overall board integrity, minimizing defects and maintaining consistent product performance.

For LED flexible strip lights, the factory implements comprehensive aging tests as part of its quality assurance protocol. Finished strips undergo extended burn-in tests—typically 24 to 48 hours—at elevated temperatures and full operating voltage to identify early failures and verify thermal and electrical stability. This rigorous testing ensures long-term reliability and performance consistency, particularly important for applications requiring continuous operation.

Beauty STC has robust OEM and ODM capabilities tailored specifically for LED flexible strip lights. The company supports full customization including LED density, color temperature, color rendering index (CRI), input voltage (12V or 24V DC), IP ratings (from IP20 to IP68), and special features such as RGB, RGBW, or tunable white. Clients can also customize packaging, labeling, cut lengths, and reel sizes. The engineering team works closely with clients to develop prototypes, provide photometric testing reports, and ensure compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines advanced automation, stringent quality control, and flexible manufacturing processes to deliver high-performance, customizable LED flexible strip lighting solutions for a global customer base.

Application Scenarios

Flexible LED strips offer exceptional versatility for commercial lighting applications due to their thin profile, bendability, and ability to integrate seamlessly into diverse architectural elements. Within hotels, malls, and offices, their primary value lies in creating ambient layers, highlighting features, and providing functional task lighting where traditional fixtures are impractical. In hotels, focus on enhancing guest experience through subtle illumination. Install strips within ceiling coves in lobbies and corridors to provide soft, indirect ambient light that defines space without glare. Use them under reception desks and bar counters for a premium, inviting glow that improves visibility for staff interactions. Bed headboards benefit from integrated strips for convenient night lighting, while niche lighting within feature walls or behind headboards adds sophisticated depth. Bathroom mirror perimeters are ideal for glare-free, shadow-reducing illumination, and under-cabinet lighting in minibars or service areas enhances usability. For malls and retail environments, flexible strips are indispensable for visual merchandising and atmosphere. Employ them to backlight large-scale signage and wayfinding elements, ensuring consistent brightness without hotspots. Wrap strips around the edges of display cases and shelving to dramatically highlight merchandise, drawing the eye and creating visual interest. Integrate them into curved architectural features like columns or atrium railings to sculpt space with light. Cove lighting in high-ceilinged atriums or along escalator soffits provides essential ambient illumination while maintaining clean sightlines. Accent lighting for art installations or seasonal displays becomes effortless with the strip’s adaptability. Offices utilize flexible strips to improve both functionality and well-being. Implement under-cabinet lighting in kitchenettes and pantries for practical task illumination. Create subtle, modern cove lighting in executive offices or conference rooms to reduce eye strain during presentations while projecting a contemporary image. Use them within partition systems or suspended ceiling features to define collaborative zones without visual barriers. Task lighting under desk overhangs provides localized illumination for detailed work, reducing overhead light dependency. Accent strips along stair treads or within handrails enhance safety in low-light conditions.

Installation demands careful planning to ensure longevity and optimal performance. Always calculate voltage drop meticulously, especially for runs exceeding 5 meters; use 24V strips for longer continuous installations or incorporate periodic power feeds from both ends to maintain consistent brightness. Never install strips directly onto flammable surfaces like wood or drywall without proper thermal management; aluminum mounting channels are essential as they act as heat sinks, significantly extending LED lifespan and preventing lumen depreciation. Verify the required IP rating for the specific location—IP65 or higher is non-negotiable for bathroom perimeters, outdoor soffits, or areas exposed to cleaning splashes, while IP20 suffices for dry, enclosed coves. Before final mounting, thoroughly test the entire circuit including drivers and controllers to catch any defects or wiring errors early. Apply thermal adhesive paste between the strip and the aluminum channel when using high-density or high-output strips to maximize heat transfer. Ensure all connections are secure and soldered or use high-quality waterproof connectors for outdoor or high-moisture zones; never rely solely on friction-fit connectors in commercial settings. Finally, adhere strictly to local electrical codes regarding driver placement, circuit loading, and low-voltage wiring practices—this is not optional for commercial compliance and safety. Proper installation transforms these strips from simple light sources into reliable, high-performance architectural elements.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED flexible LED strips designed for versatility and performance. Partner with Beauty STC, a trusted leader in innovative LED solutions. For personalized support and collaboration, contact us today at [email protected] and let us illuminate your next success together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.