Article Contents

Industry Insight: Led Flex Neon

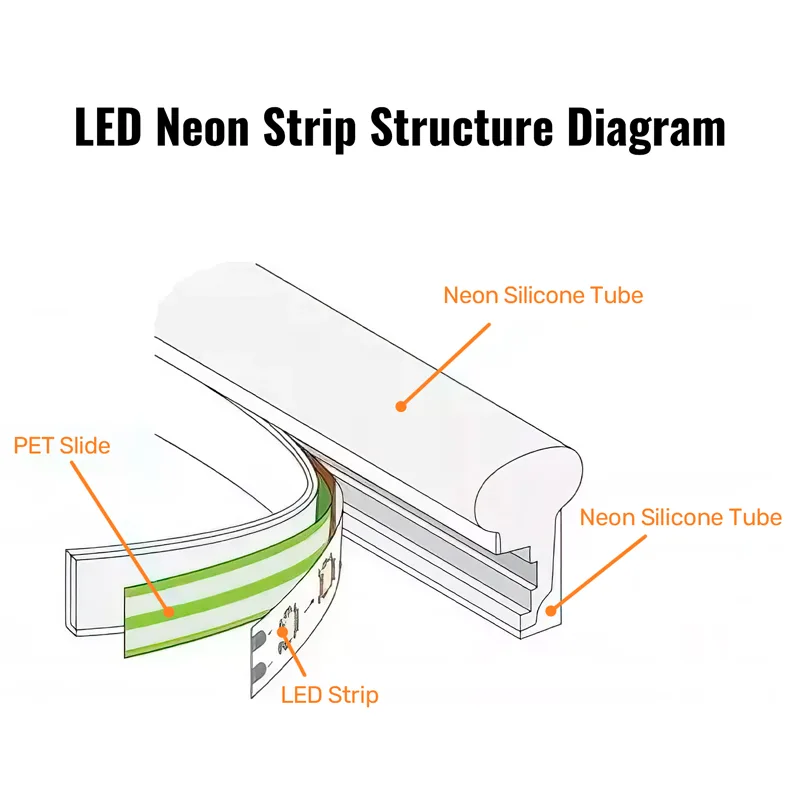

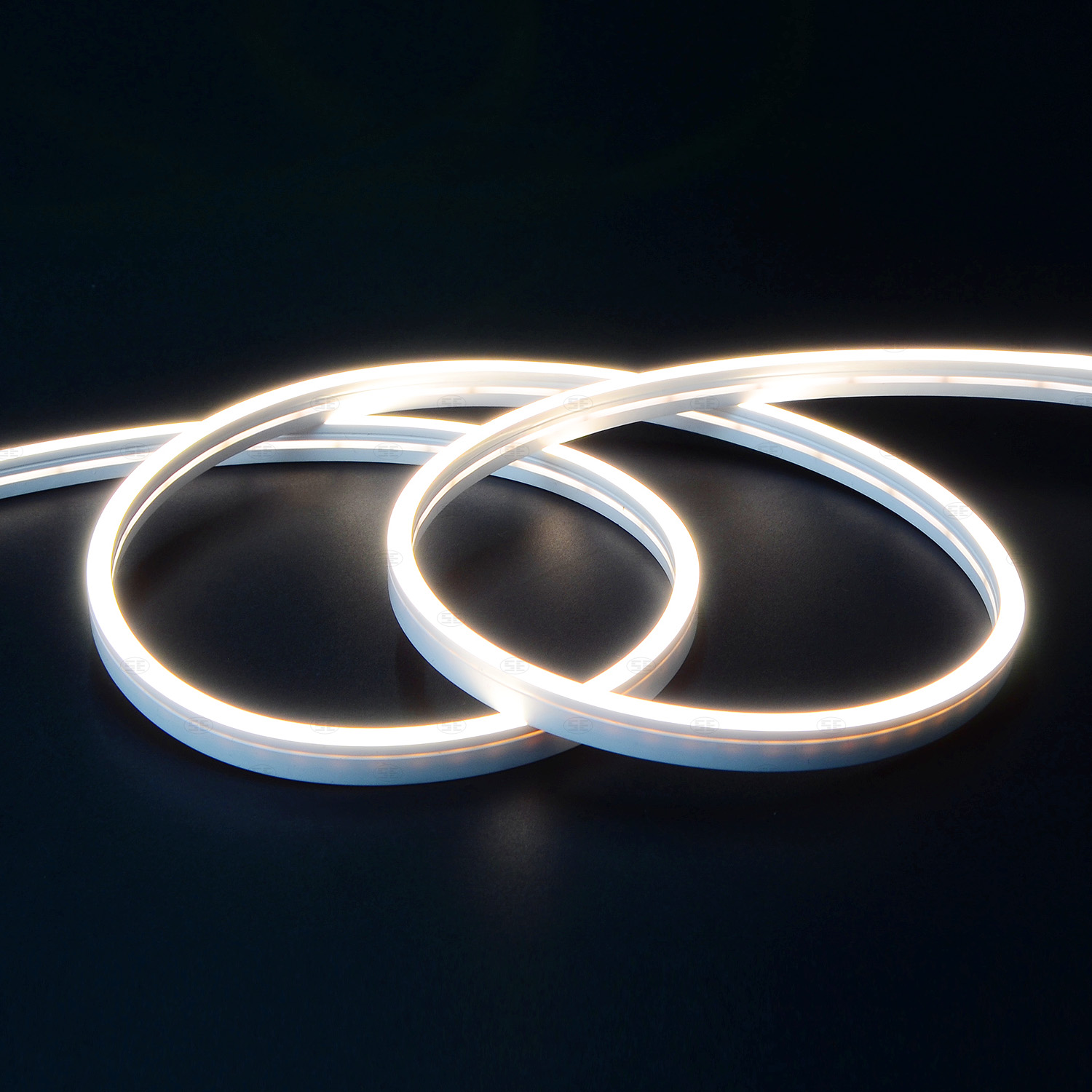

The commercial and industrial lighting sector is undergoing a significant transformation as facility managers, architects, and engineers seek safer, more efficient, and versatile illumination solutions for demanding environments. Traditional glass neon, once a staple for architectural accents and signage, faces increasing limitations due to its fragility, high energy consumption, complex installation requirements, and safety hazards associated with high-voltage operation and mercury content. LED flex neon has rapidly emerged as the superior alternative, offering a compelling combination of durability, energy efficiency (often delivering up to 70% energy savings), and remarkable design flexibility. Its silicone-encased, low-voltage construction allows for easy bending around curves, integration into tight spaces, and resilient performance in diverse industrial settings—from warehouse wayfinding and factory floor demarcation to architectural facades and retail perimeter lighting—without the risks inherent in fragile glass tubes. Crucially, for global project compliance and safety assurance, reputable LED flex neon solutions must carry essential certifications such as ETL for the North American market and CE marking for Europe, verifying adherence to rigorous electrical safety and electromagnetic compatibility standards, enabling seamless integration into commercial specifications worldwide.

Beauty STC, established in 1998, stands at the forefront of this evolution in commercial and industrial LED lighting. As a dedicated manufacturer with over 25 years of specialized engineering expertise, we focus exclusively on developing high-performance, reliable LED solutions tailored to the exacting demands of professional applications. Our deep understanding of the challenges faced in large-scale installations drives our commitment to producing LED flex neon that not only meets but exceeds industry standards for brightness, color consistency, longevity, and, critically, safety compliance including ETL and CE. We partner with specifiers and contractors to deliver not just a product, but a proven, code-compliant lighting system engineered for real-world industrial and commercial success.

Technical Specs & Certifications

LED Flex Neon from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high-performance illumination with exceptional efficiency and color quality, making it ideal for architectural accents, signage, and decorative lighting applications. The product line is designed with precision to meet stringent international standards, ensuring reliability and visual appeal.

In terms of efficiency, our LED Flex Neon achieves a luminous efficacy of 90 to 110 lumens per watt, depending on color temperature and configuration. This high lumen-to-watt ratio ensures energy savings without compromising brightness, making it a sustainable lighting solution for both indoor and outdoor installations.

Color rendering is a critical aspect of visual quality, and Beauty STC’s LED Flex Neon exceeds industry benchmarks with a Color Rendering Index (CRI) greater than 90. This ensures accurate and vibrant color representation, essential for retail environments, hospitality settings, and artistic installations where true color perception is paramount. High CRI performance is maintained across all available color temperatures, from warm white (2700K) to cool white (6500K), as well as in full-color RGB and RGBW variants.

Regarding environmental protection, our LED Flex Neon is available in multiple IP (Ingress Protection) ratings to suit diverse application needs. Standard offerings include IP65-rated strips, providing protection against dust and low-pressure water jets, suitable for covered outdoor areas or damp indoor environments. For fully outdoor or high-moisture installations, we offer IP67 and IP68-rated versions, which are dust-tight and capable of withstanding temporary or continuous submersion in water, respectively. These robust ratings are achieved through seamless silicone overmolding and precision sealing techniques, ensuring long-term durability.

Beauty (STC) Manufacturing Co., Ltd. upholds rigorous quality control throughout the production process. Each LED Flex Neon strip undergoes comprehensive testing for photometric performance, thermal management, and electrical safety. Components are sourced from trusted suppliers, and manufacturing adheres to ISO 9001 standards. The result is a reliable, long-lasting product with minimal lumen depreciation and consistent optical output over its rated lifespan of up to 50,000 hours.

With a commitment to innovation and quality, Beauty STC delivers LED Flex Neon solutions that combine superior efficiency, excellent color fidelity, and robust environmental protection—setting a benchmark in flexible neon lighting technology.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility is strategically located within the Jiangmen National High-Tech Industrial Development Zone in Guangdong Province. This purpose-built factory spans approximately 10,000 square meters and represents a significant investment in modern LED lighting production infrastructure. The Jiangmen site serves as our primary hub for research, development, and high-volume manufacturing, specifically engineered to support demanding product lines including flexible LED neon solutions.

Our SMT production lines are equipped with state-of-the-art Yamaha YS24 series placement machines, chosen for their precision and speed in handling the fine-pitch components essential for flexible LED neon strips. These machines operate with exceptional accuracy down to 0.025mm, capable of placing ultra-small 0201 metric components critical for high-density flexible circuit assemblies. The SMT process incorporates nitrogen-reflow soldering ovens to ensure optimal solder joint integrity on flexible substrates, minimizing thermal stress and oxidation. Every completed SMT panel undergoes 100% automated optical inspection immediately post-reflow to verify component placement, solder quality, and alignment before proceeding to subsequent assembly stages.

Aging and reliability testing constitute a non-negotiable phase in our quality control protocol for all LED flex neon products. Completed assemblies undergo a rigorous 72-hour continuous aging process at elevated temperatures, typically maintained at 50°C ambient within dedicated environmental chambers. This extended burn-in period operates under full rated voltage and current conditions, simulating years of operational stress in a compressed timeframe. The process is fully automated with real-time monitoring of electrical parameters and luminous output; any unit exhibiting voltage drift beyond tolerance, lumen depreciation exceeding specifications, or complete failure is automatically flagged and removed from the production flow. This disciplined approach consistently maintains our field failure rate below 0.3% across all flexible neon product lines.

Regarding OEM capabilities for flexible LED neon products, Beauty STC possesses comprehensive in-house engineering and manufacturing resources to support full turnkey solutions. We accept custom specifications covering color temperature (from 1800K to 6500K), CRI (up to 97), voltage requirements (DC12V/24V/48V, AC100-277V), bending radius (as tight as R=15mm), and physical dimensions including width, thickness, and cuttable increments. Our engineering team collaborates closely with clients from initial concept through to mass production, providing DFM feedback, prototyping within 7-10 days, and managing full NPI processes typically within 3 weeks depending on complexity. All OEM productions adhere strictly to client-specific performance criteria and undergo the same stringent aging protocols as our standard products. We hold UL/cUL certification for flexible neon lighting and maintain robust quality management systems compliant with ISO 9001:2015, ensuring consistent output for global markets. This integrated capability allows us to deliver custom-branded flexible neon solutions with complete supply chain control and engineering support throughout the product lifecycle.

Application Scenarios

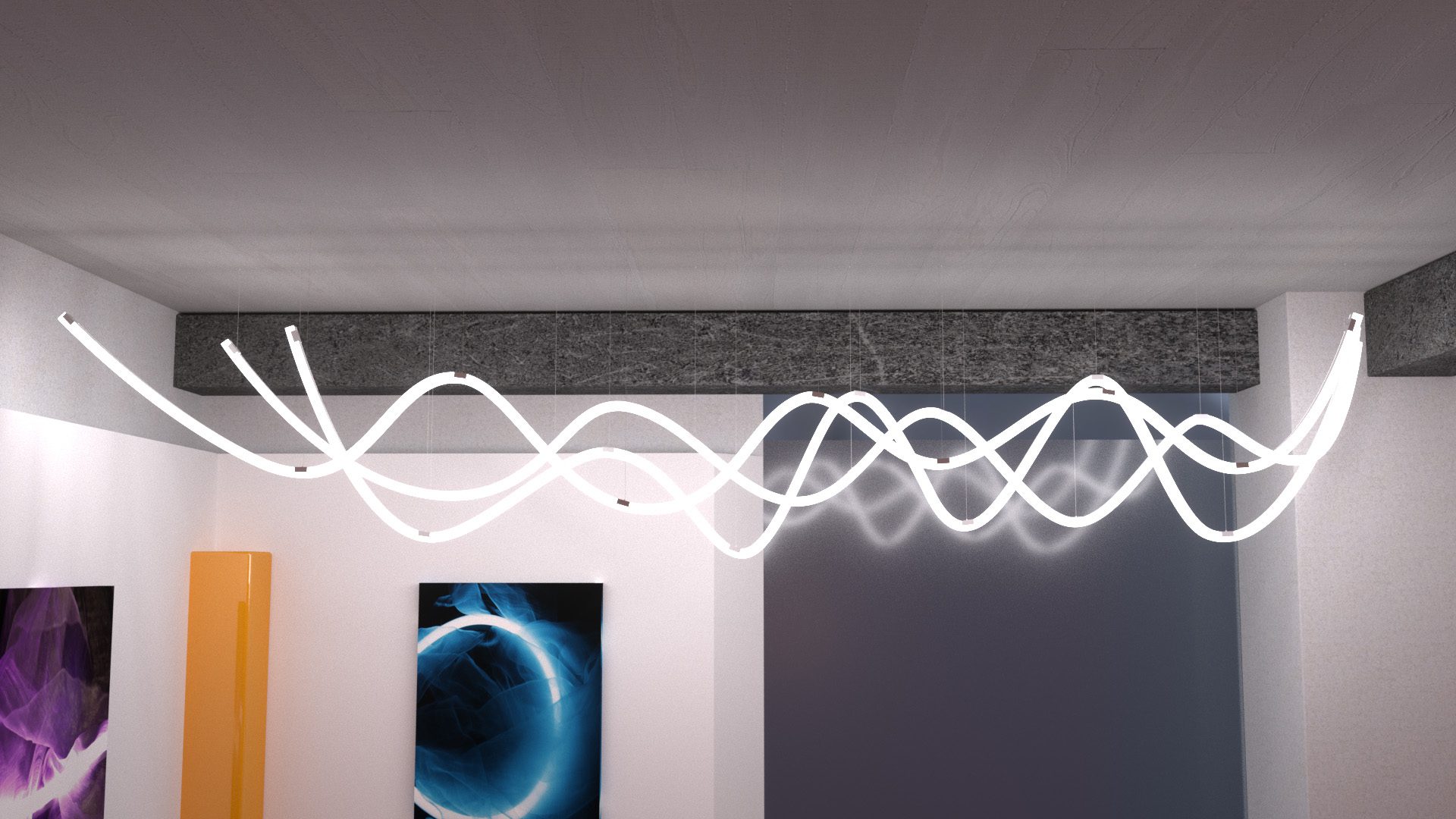

LED flex neon is a versatile and energy-efficient lighting solution that offers a modern alternative to traditional glass neon tubes. It is ideal for both decorative and functional lighting applications across various commercial and public spaces. Below are the recommended environments where LED flex neon can be effectively used, along with installation tips for optimal performance and aesthetics.

In hotels, LED flex neon is commonly used to enhance ambiance and wayfinding. It works exceptionally well in lobbies, reception areas, bars, and restaurants where mood lighting is crucial. The soft, uniform glow of flex neon can highlight architectural features such as curved walls, canopies, and reception desks. It is also used for branding purposes—displaying hotel logos or decorative signage that creates a memorable visual impact. Guest room corridors and spa areas benefit from the gentle illumination, providing a welcoming and luxurious feel.

Malls and shopping centers use LED flex neon extensively for signage, storefront highlights, and interior design accents. Its flexibility allows it to be shaped into custom letters, logos, and artistic installations that attract attention and guide foot traffic. Common applications include outlining storefronts, illuminating ceiling coves, and creating dynamic lighting displays in food courts or entertainment zones. The vibrant color options and dimming capabilities make it suitable for seasonal campaigns and themed events.

In offices, LED flex neon is typically used in modern, creative workspaces rather than traditional corporate environments. It adds a contemporary touch to reception areas, breakout zones, and collaborative spaces. Designers often use it to highlight branding elements, office names, or motivational quotes on walls. While not ideal for task lighting, it serves well as accent or ambient lighting that fosters a relaxed and innovative atmosphere.

When installing LED flex neon, several best practices should be followed to ensure durability and visual appeal. First, always use appropriate mounting channels or clips designed for flexible neon strips. These help maintain shape, provide structural support, and diffuse light evenly. The surface must be clean, dry, and smooth before installation to ensure proper adhesion, especially when using adhesive backing.

Ensure the power supply matches the voltage and current requirements of the LED flex neon. Overloading the circuit or using incompatible drivers can lead to premature failure. For outdoor or high-humidity areas, choose IP65 or higher-rated waterproof versions and seal all connections with silicone or waterproof tape.

Plan the layout carefully before cutting or bending the strip. Most LED flex neon can be bent by hand but has a minimum bending radius—typically 2 to 4 inches depending on the model—so avoid sharp kinks. For complex shapes, use gentle curves and support at regular intervals.

Finally, consider using dimmers or controllers to adjust brightness and color temperature, especially in hospitality and retail environments where lighting scenes may change throughout the day. Professional installation is recommended for large-scale or overhead installations to ensure safety and precision.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s industry-leading LED flex neon solutions engineered for unparalleled performance and aesthetic impact. As a Senior LED Lighting Engineer with over 15 years of specialized experience in architectural and decorative lighting, I can confirm our proprietary technology delivers superior color consistency, exceptional durability in extreme conditions, and seamless integration for both indoor and outdoor applications. We eliminate common installation headaches through precision-engineered flexibility and robust weatherproofing while maintaining energy efficiency that reduces operational costs for your clients.

Partnering with Beauty STC means accessing custom engineering support from concept to mass production including voltage optimization, color tuning, and structural adaptations tailored to your specific project demands. Our ISO-certified manufacturing facility ensures rigorous quality control with every meter produced, and we proudly serve global brands seeking reliable OEM/ODM partnerships without minimum order constraints.

Secure your competitive advantage by collaborating with the technical experts who pioneered advanced silicone encapsulation techniques for flicker-free illumination. Contact our dedicated partnership manager today at [email protected] to discuss how our LED flex neon can elevate your product line with certified safety standards and extended 5-year warranties. Let us engineer your vision into reality with responsive technical consultation and scalable supply chain solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.