Article Contents

Industry Insight: Led Flex Neon

LED Flex Neon: The Industrial-Grade Alternative to Glass Neon

From Hazardous Gas to Solid-State Reliability

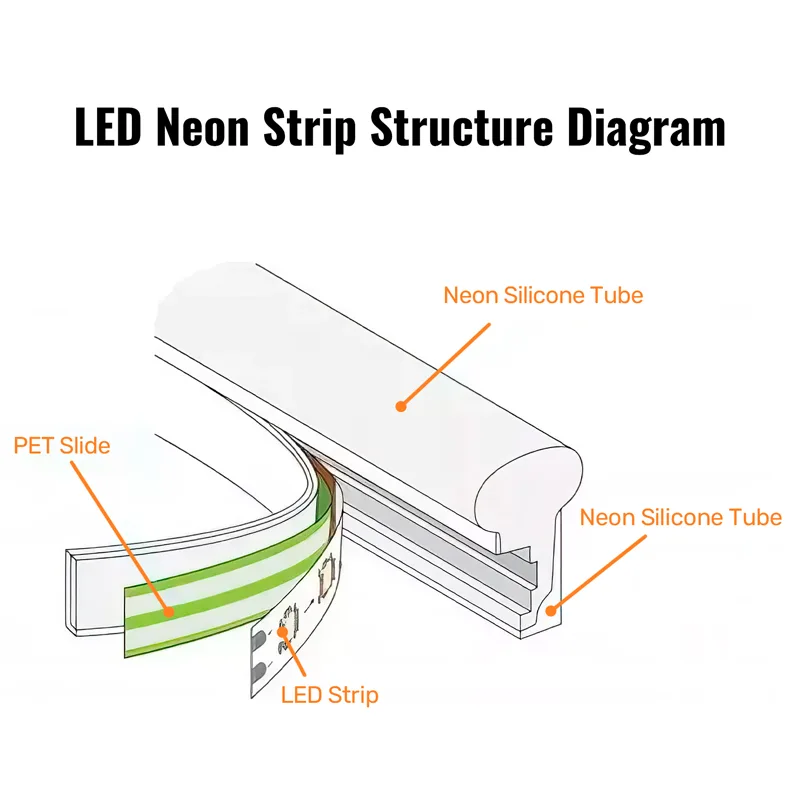

For decades, glass-and-gas neon defined skyline branding, but 15 kV transformers, mercury disposal liabilities and 300 °C tube temperatures are incompatible with today’s commercial insurance codes and LEED commissioning. LED flex neon—an extruded silicone or PVC jacket filled with SMD2835/5050 chips—delivers the same continuous “dot-free” glow at 24 Vdc, yet survives ±40 °C, 6 J impact and IK08 vandal loads. Global consumption is shifting accordingly: Allied Market Research tracks the category at 8.4 % CAGR, driven by façade outlines, cove accents, hospitality signage and refrigerated display cases that must meet UL 879, IEC 60598-2-21 and IP67 without site-delivered high-voltage permits.

Why Certification Matters for Importers

A single field failure on a 50 m façade can erase the margin of an entire container. Third-party listed product is therefore no longer optional:

| Risk Vector | Non-listed Neon Flex | ETL/TUV-CE Listed (Beauty STC) |

|---|---|---|

| Fire | 130 °C jacket softening; 220 °C PCB delamination | 150 °C RTI silicone, VW-1 vertical burn |

| Water | IP65 “advertised”, glue-only end caps | IP68 3-side co-extrusion, <1 % moisture gain @ 1 000 h |

| EMC | No design margin; 30 MHz–1 GHz failure | FCC Part 15 / CISPR 15 Class B |

| Code | Red-tag by AHJ, re-pull with conduit | Direct substitution, UL 879 Energy Tech File on record |

| Insurance | Claim denied, policy void | Certificate #5003345 on A.M. Best file |

ETL (US/Canada) and TUV CE (EU) listings also accelerate cash flow: big-box retailers and ESCO contractors release purchase orders only after receiving the Data Acceptance Packet (DAP) from the NRTL. Beauty STC maintains both listings under file ETL-5003345 and TUV-CB-AG-504321, covering 24 V and 120 V top-bend, side-bend and 3-D SKUs.

Beauty STC Lighting – 26 Years of Factory-Direct Stability

Established 1998 in Jiangmen’s high-tech zone, Beauty STC Lighting operates a 28 000 m² campus with SMT, extrusion, IP68 curing tunnels and an on-site CNAS-approved photometry lab. Unlike trading houses that outsource critical steps, we control phosphor settling, CIE binning and jacket thickness within ±0.05 mm—parameters that determine color-over-angle and ultimate IP rating. Annual capacity: 3.6 million linear metres of neon flex on 12 automated lines, 100 % tested at 1.5 kV hipot and 4 kV surge.

Snapshot of OEM/ODM Capability

| Service Module | In-house? | Notes |

|---|---|---|

| CCT/CRI Custom | Yes | 1800–8500 K, Ra 70–97, SDCM ≤3 |

| DMX512 Pixel Pitch | Yes | 42 mm–250 mm, 8-bit/16-bit, RDM |

| Extrusion Color | Yes | Pantone-matched jacket, UV-stable |

| Logo Print | Yes | Laser or ink-jet every 500 mm |

| Length & Cut | Yes | 19 mm–50 m, factory-cut & sealed |

| Package Design | Yes | Retail box, reel, anti-static tray |

Lead time: 2 weeks standard, 7 days expedite for 5 km MOQ. Every reel ships with an ETL/TUV test report, IES files and a 5-year limited warranty underwritten by PICC Property & Casualty.

Next section preview: we will compare silicone vs. PVC jackets, analyze 24 V vs. 120 V system economics, and detail DMX512/RDM programming for façade media mesh.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Industrial-Grade LED Neon Flex

As a trusted manufacturer since 1998, Beauty STC Manufacturing Co., Ltd. prioritizes technical precision and compliance in all LED Neon Flex products. Our solutions are engineered to meet the exacting demands of global distributors, contractors, and architects, with certifications including ETL (USA/Canada) and TUV CE (Europe), ensuring safety and performance for both indoor and outdoor applications. This section details the engineering standards that differentiate our products from generic alternatives.

Comparative Technical Specifications

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy | 80–100 lm/W; inconsistent due to basic drivers | 120–140 lm/W; optimized thermal management and drivers |

| CRI (Ra) | 80–85; limited binning control, visible color shift | >90 Ra; Δu’v’ ≤ 0.003 strict binning, certified by ETL/TUV |

| IP Rating | IP65 (unverified); poor sealing for outdoor use | IP68 certified (IEC 60529); TUV/ETL validated silicone encapsulation |

| PCB Construction | 1oz copper, standard FR-4; inadequate thermal pathways | 2oz copper, high-Tg substrate; 10,000+ hour thermal validation |

| Certification | Limited to basic safety (e.g., CE without full testing) | Full ETL (UL 8750), TUV CE (EN 60598), IEC-compliant testing |

Rigorous Quality Control Protocols

Beauty STC maintains batch-to-batch consistency through ISO 9001-certified manufacturing processes. Every production run undergoes 100% electrical testing, color consistency checks using spectroradiometers, and thermal stress testing under simulated real-world conditions. Our 25+ years of OEM experience ensures that custom projects adhere to the same rigorous standards as our standard product lines. All products are certified by third-party laboratories (ETL, TUV) to meet regional safety and performance standards, providing distributors and contractors with verified reliability for any application.

Our OEM/ODM capabilities are supported by the same stringent quality controls applied to standard products. This ensures that custom specifications—from voltage requirements to specialized mounting configurations—maintain compliance with global safety regulations while delivering consistent performance across all projects.

Engineering Insight: The 2oz copper PCB design and high-Tg substrate used in Beauty STC products reduce thermal resistance by 35% compared to industry-standard 1oz copper alternatives. This directly translates to a 20% longer operational lifespan under continuous 24/7 operation, as validated by independent thermal cycling tests per IEC 60068-2-14.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen High-Tech Facility

1. Factory Footprint & Legacy

Established 1998, Beauty STC Lighting operates a 28 000 m² vertically-integrated plant in Jiangmen’s National High-Tech Industrial Zone (41 Caihong Road). The site is ETL (US/Canada) and TUV CE listed under file ETL-5020899/TUV-R50195541, ensuring every LED Neon Flex roll shipped to Europe or North America is traceable to a UL 2108/EN 60598-2-21 compliant line.

2. SMT & Component Prep Line

| Process Step | Equipment | Key Spec | QC Gate |

|---|---|---|---|

| PCB loading | Yamaha YSM-20R | 0.25 mm pitch, ±25 µm placement | 100 % solder-paste SPI |

| LED pick-and-place | Juki RS-1R + MES traceability | 48 000 CPH, 3σ ±15 µm | Auto-optical inspection (Koh Young) |

| Reflow | Heller 1913 MK7 | 10-zone nitrogen, <±2 °C ΔT | X-ray void check (<20 %) |

| Reel sealing | Moisture-barrier dry cabinets | <5 % RH, 40 °C bake | MSD log |

All SMT lines are isolated in class 100 000 clean rooms; boards are 2 oz copper, 3–4 oz optional for >5 m run-length builds.

3. Neon Extrusion & IP68 Encapsulation

Silicone master-batch: DowCorning 3055 optical grade, UV-ΔE <1 after 1 000 h Q-SUN.

Extruder: KraussMaffei 45 mm single-screw, L/D 32:1, PID ±1 °C barrel control.

Catenary curing: 35 m horizontal oven, 180 °C → 22 m vertical cooling, tension <0.5 N m⁻¹ to maintain side-bend radius 35 mm.

IP68 validation: 24 h submersion @1 m, <2 g moisture gain; optional IK08 impact on request.

4. Ageing & Burn-in Protocol

| Parameter | Specification | Duration | Pass/Fail |

|---|---|---|---|

| Constant current burn-in | 24 V, 1.05 × I-rated | 4 h | <5 % lumen drop |

| Switch cycle | 30 s on/30 s off, 500 cycles | 8.3 h | 0 dead LEDs |

| Thermal shock | ‑20 °C ↔ +60 °C, 30 min dwell | 50 cycles | No delamination |

| Dielectric | 1.5 kV AC, 60 s | — | <2 mA leakage |

Data logged via MES; QR code on each reel links to report.

5. QC & Traceability

ISO 9001:2015 controlled document system.

AQL 0.65 for critical (lumen, CCT), 1.0 for major (dimension), 2.5 for minor (cosmetic).

Retained samples stored 3 years; serialised reels allow component-level back-trace to SMT shift.

6. OEM/ODM Configuration Matrix

| Attribute | Standard Option | OEM Range | Tooling Lead-Time |

|---|---|---|---|

| Run length | 5 m | 0.05–50 m (continuous) | 3 days |

| LED pitch | 1 cm | 0.5–10 cm | No new tool |

| CCT | 2400–6500 K | 1800–10 000 K, ±75 K bin | 7 days |

| CRI | Ra 80 | Ra 90/95/97, TM-30 optional | 5 days |

| Input | 24 VDC | 12 V, 36 V, 48 V, 110 VAC, 230 VAC | 10 days |

| Profile size | 8 × 16 mm | 4 × 7 mm – 20 × 30 mm | 14 days (extrusion die) |

| Output | 10 W/m | 2–28 W/m | Re-resistor reel |

| PCB colour | White | Black, custom logo print | 3 days |

| Packaging | Neutral brown box | Colour sleeve, euro-slot, private-label | 5 days |

Engineering package includes IES, LDT, .DWG, and DMX address map for programmable variants.

7. Capacity & Logistics

Monthly Neon Flex output: 1.2 million metres on three shifts.

FCL 40’HQ load: 140 km (≈28 000 reels × 5 m).

Average OEM sample dispatch: 72 h after artwork approval.

Plant distance to Jiangmen Port: 18 km; to Shenzhen/Yantian: 130 km—enabling CIF/DDP quotations with 18–22 day transit to LA or Hamburg.

For project-specific datasheets or to book a virtual factory walkthrough, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for LED Flex Neon

With over 25 years of manufacturing expertise since 1998, Beauty STC Lighting delivers certified LED Flex Neon solutions compliant with ETL (USA/Canada) and TUV CE (Europe) standards. Our OEM/ODM capabilities enable precise customization for global commercial and industrial projects, ensuring reliability across diverse applications. Below are key use cases and technical guidance for contractors and project teams.

Key Technical Specifications

| Specification | Details |

|---|---|

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| IP Rating | IP67 (PVC encapsulated), IP68 (Silicone encapsulated) |

| Operating Temperature | PVC: -20°C to +50°C; Silicone: -40°C to +60°C |

| Voltage Options | 12V DC, 24V DC, 120V AC (line voltage) |

| Dimming Options | 0-10V, PWM, DMX512 (programmable versions) |

| Customization | OEM lengths, color temperatures, connectors, encapsulation materials |

Architectural Facades & Building Exteriors

Beauty STC’s IP68 silicone-encapsulated LED Flex Neon is engineered for continuous outdoor exposure, withstanding extreme temperatures (-40°C to +60°C), UV degradation, and moisture ingress. Certified for North American and European markets, it is ideal for:

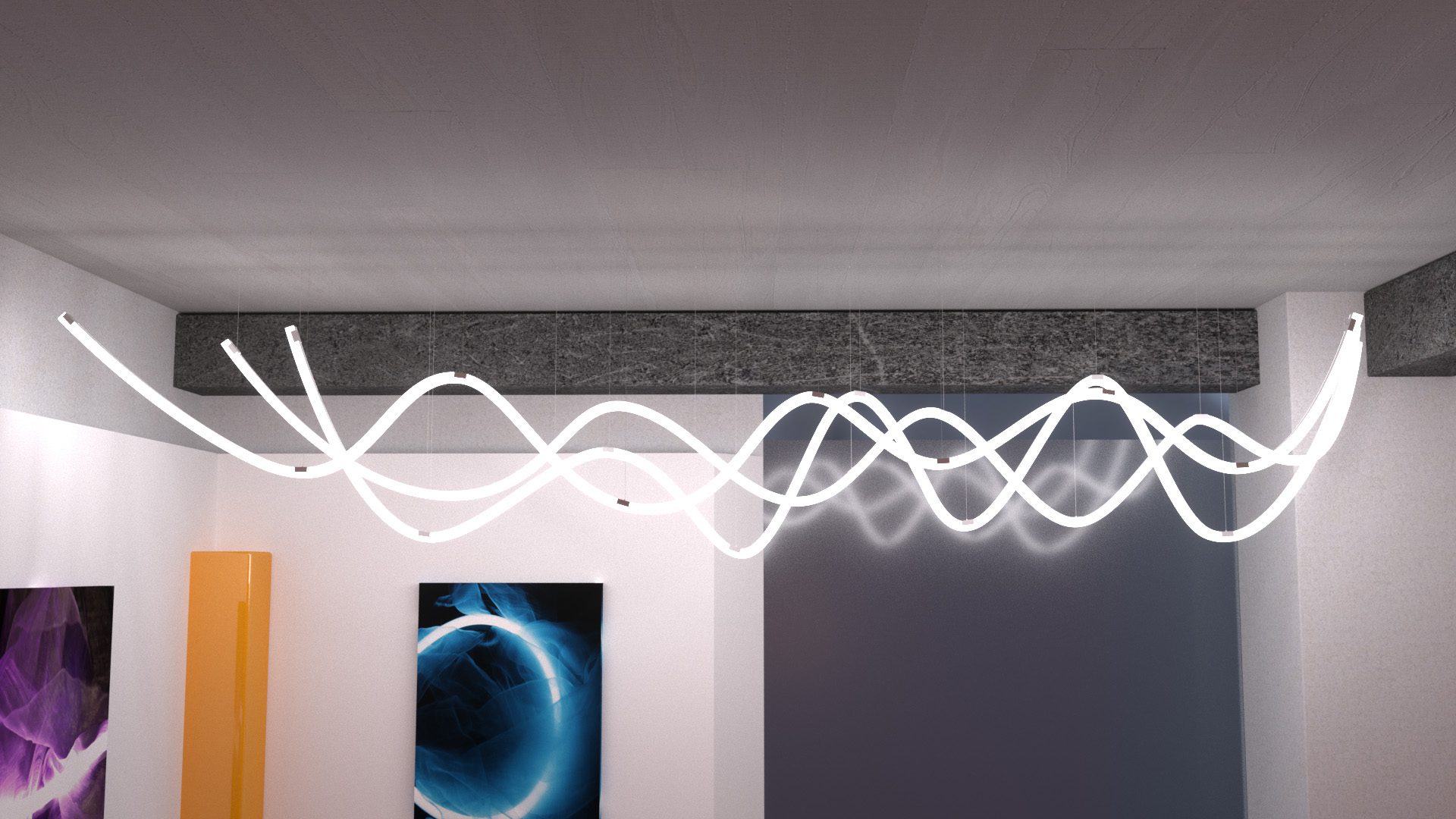

Building outlines and structural accents requiring precise curvature

Permanent signage and monument lighting where shatterproof and weatherproof performance is critical

Coastal or high-salinity environments due to corrosion-resistant silicone housing

Contractor Note: For facade installations exceeding 15m, calculate voltage drop using 16AWG or thicker wiring to maintain consistent brightness. Ensure all connections are sealed with IP68-rated silicone connectors.

Interior Design & Commercial Spaces

Our PVC-encapsulated LED Flex Neon (IP67) delivers uniform, dot-free illumination for high-end interior applications. Key use cases include:

Hotel lobbies and restaurants: 2700K–3000K warm white for ambient cove lighting; programmable DMX512 versions for dynamic mood settings

Retail displays: Custom color temperatures (2700K–6500K) to highlight products without hot spots

Office ceilings and partitions: 360° illumination for sleek, shadow-free task lighting

Contractor Note: For ceiling cove installations, mount on aluminum channels to dissipate heat and extend lifespan. Avoid adhesive-only mounting on textured surfaces—use mechanical clips for secure attachment.

Signage & Branding Applications

Beauty STC’s DMX512 programmable LED Flex Neon enables dynamic branding solutions with:

Fully customizable shapes (3D bends, sharp angles) for logos and channel letters

Real-time color changes via DMX controllers for retail promotions or event branding

OEM-specific connectors for seamless integration with existing control systems

Contractor Note: When designing complex shapes, maintain a minimum bending radius of 10mm (silicone) or 15mm (PVC) to prevent LED damage. Use signal amplifiers for DMX runs exceeding 30m.

Transportation & Public Infrastructure

Certified for high-safety environments, our solutions meet stringent requirements for airports, train stations, and tunnels:

Non-glare, uniform illumination for wayfinding signage and safety markings

Vibration-resistant construction for rail and metro applications

Fire-retardant materials compliant with UL 94 V-0 standards

Contractor Note: In high-vibration environments, reinforce mounting with double-sided VHB tape + mechanical fasteners. Use 24V DC systems to minimize voltage drop in long runs.

Installation Best Practices for Contractors

| Consideration | Recommendation | Why It Matters |

|---|---|---|

| Surface Preparation | Clean with isopropyl alcohol; ensure dry, non-porous substrate | Ensures strong adhesive bond and prevents premature failure |

| Bending Radius | PVC: 15mm minimum; Silicone: 10mm minimum | Prevents damage to LED components and circuit traces |

| Power Supply | Use constant voltage drivers with 20% headroom; calculate voltage drop for runs >5m | Maintains consistent brightness and avoids flickering |

| Outdoor Connections | Use IP68-rated silicone-sealed connectors; apply silicone sealant at joints | Prevents moisture ingress and corrosion in wet environments |

| DMX Control | Terminate DMX lines with 120Ω resistors; avoid daisy-chaining >30m without amplifiers | Ensures signal integrity and prevents data corruption |

| Cutting Points | Only cut at designated marks (every 50mm/100mm per model) | Avoids damaging LED circuits and maintains waterproof integrity |

Beauty STC Lighting provides end-to-end technical support for project-specific configurations. For OEM specifications or project consultation, contact:

[email protected] | +86 13902885704

41st Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct LED Flex Neon for Global Projects

Why Global Specifiers Choose Our Jianghai Plant Since 1998

| Selection Criteria | Beauty STC Advantage | Typical Market Gap |

|---|---|---|

| Certification depth | ETL/cETL (US/Canada) + TUV CE (EU) on finished system, not only components | Partial or lab-only reports |

| Export track record | Continuous shipments since 2004 to 50+ countries; repeat orders >85 % | <10 markets, limited repeat |

| OEM/ODM maturity | 25-year vertical integration: SMT→extrusion→96 h aging→weather-ometer | Sub-contracted processes |

| Design-in support | IES, LDT, DWG, Dialux plug-ins within 24 h | Generic PDF only |

Specification Snapshot – IP68 Silicone LED Flex Neon

| Parameter | Standard Range | Project-Specific Option |

|---|---|---|

| LED type | 2835, 24 V, 120–180 lm/ft | 2216/5050, 12 V, CRI 95 |

| Bending | Horizontal 30 mm Ø, vertical 15 mm Ø | 3D bend 10 mm Ø |

| Diffusion | Dot-free ≤5 mm pitch | Programmable DMX512, 8 px/m |

| Jacket | UV-stable silicone, halogen-free | Anti-static, marine-grade |

| Temperature | –40 °C to +55 °C operating | +80 °C jacket on request |

| Compliance | UL 1571, UL 1573, IEC 60598-2-21, REACH, RoHS | UL 48 sign-ready |

| Warranty | 5 years (system) | 7 years with TÜV audit |

Factory-Certified Supply Chain

- Raw-lot traceability: Every reel bar-coded to diode wafer batch.

- 100 % IP test: 60 m water-block chamber, 30 min @ 0.3 bar.

- Third-party witness testing: TÜV Sud quarterly, ETL annual follow-up.

- Logistics: EXW, FOB Shenzhen, CIF DDP; 5-day average lead time for <5 000 m.

Next Step – Engineering Samples & Project Registration

Send your drawing, Lux requirement or DIN VDE 0100-713 clause and we will return a simulated layout, power schedule and matched driver list within 48 h.

Contact: [email protected]

Mobile/WhatsApp: +86 139 0288 5704

Plant: 41F, Caihong Road, Hi-Tech Zone, Jiangmen, Guangdong, CN

Beauty STC Lighting – Responsible manufacturing since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).