Article Contents

Industry Insight: Led Driver For Led Strip

The unassuming LED driver remains the critical yet often overlooked cornerstone of successful commercial and industrial LED strip lighting installations. While the flexibility and aesthetic appeal of LED strips capture immediate attention, their long-term performance, energy efficiency, and overall system reliability are fundamentally dictated by the quality and suitability of the driver powering them. In demanding environments like retail spaces, warehouses, manufacturing facilities, office corridors, and hospitality venues, where lighting operates for extended hours under varying conditions, a substandard driver becomes a significant liability. Flicker, premature LED failure, inconsistent light output, and unexpected system downtime are not merely inconveniences; they translate directly into increased maintenance costs, operational disruption, and diminished return on investment. This makes selecting the right driver – one engineered for robustness, precise current regulation, thermal management, and seamless integration with control systems – a non-negotiable requirement for professional lighting specifications. Furthermore, compliance with stringent safety certifications like ETL for the North American market and CE marking for Europe is not optional paperwork; it is a fundamental prerequisite for legal installation, passing electrical inspections, and ensuring user safety. Specifiers and contractors demand these verifications as proof of adherence to rigorous safety and performance standards, avoiding costly project delays or rework due to non-compliant components. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to mastering this essential technology. We understand that in commercial and industrial settings, lighting is infrastructure, not decoration. Our core expertise lies in designing and manufacturing high-reliability LED drivers specifically engineered to meet the uncompromising demands of professional applications, consistently delivering the certified performance, longevity, and peace of mind that specifiers and facility managers require.

Technical Specs & Certifications

The LED driver for LED strip systems offered by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance, energy efficiency, and long-term reliability. Designed specifically to power LED strips in both residential and commercial applications, our drivers are optimized to ensure stable current output, consistent light quality, and seamless integration with dimming systems.

In terms of efficiency, Beauty STC’s LED drivers support power supplies that enable connected LED strips to achieve luminous efficacies of up to 120–140 lumens per watt, depending on the LED strip configuration and operating conditions. This high lumen-per-watt ratio ensures minimal energy waste and reduced operational costs, making the system ideal for energy-conscious installations.

To maintain excellent color rendering, our recommended driver and LED strip combinations are designed to work with LEDs that achieve a Color Rendering Index (CRI) greater than 90. This high CRI ensures that colors appear natural and vibrant under the illuminated environment, which is particularly critical in retail, hospitality, and residential lighting where visual accuracy and ambiance are essential.

Regarding environmental protection, Beauty STC offers LED drivers with various IP (Ingress Protection) ratings to suit different installation environments. Common models include IP20 for dry, indoor environments, while others are available in IP65, IP67, or even IP68 ratings for outdoor, damp, or exposed installations. These higher IP-rated drivers are fully sealed against dust and moisture, ensuring reliable performance in challenging conditions such as outdoor signage, landscape lighting, or bathroom and kitchen under-cabinet applications.

Beauty STC is committed to superior manufacturing standards, incorporating rigorous quality control, thermal management design, and durable components such as high-grade electrolytic capacitors and robust PCB layouts. Each driver undergoes extensive testing for electrical safety, surge protection, and long-term thermal stability, ensuring compliance with international standards including CE, RoHS, and UL certifications where applicable.

With over two decades of expertise in LED lighting solutions, Beauty (STC) Manufacturing Co., Ltd. delivers drivers that combine efficiency, durability, and precision, making them a trusted choice for professional lighting projects worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen factory serves as our primary manufacturing and engineering hub for LED lighting components, strategically located within the Jiangmen National High-Tech Industrial Development Zone in Guangdong Province. This modern facility spans over 20,000 square meters and is purpose-built for the efficient, high-volume production of LED drivers and associated lighting solutions, adhering strictly to ISO 9001 quality management standards. The factory layout emphasizes streamlined material flow from raw material intake through SMT assembly, aging, final testing, and packaging, supported by a workforce of over 300 skilled technicians and engineers.

Our SMT production lines represent a core strength of the Jiangmen facility. We operate multiple fully automated SMT lines equipped with state-of-the-art machinery from leading manufacturers including Yamaha YS series and Siemens X-series placement systems. These lines are capable of handling components down to 0201 package sizes with exceptional placement accuracy exceeding ±25 microns. The process integrates seamless solder paste printing using DEK printers, high-speed multi-head placement for rapid component insertion, and dual-lane reflow soldering ovens with precise thermal profiling. Each line incorporates sophisticated Automated Optical Inspection (AOI) systems positioned both post-solder paste application and post-reflow to detect defects like misalignment, tombstoning, or solder bridging in real-time, ensuring only flawless PCB assemblies proceed to the next stage. This advanced SMT capability is fundamental to producing the compact, high-density circuitry required for modern LED strip drivers.

Aging testing is a critical and rigorously implemented quality assurance step within our production flow, conducted in a dedicated environmental testing laboratory. All LED drivers, particularly those destined for LED strip applications, undergo mandatory aging tests before final shipment. We utilize large-capacity, temperature-controlled aging chambers capable of simultaneously testing thousands of units. Drivers are subjected to continuous operation at elevated temperatures, typically 60°C to 70°C, for a minimum duration of 24 hours, though 48-hour cycles are standard for higher-wattage or critical-specification units. During this burn-in period, units operate under full load conditions while sophisticated monitoring systems track key parameters such as output voltage stability, current ripple, efficiency, and thermal performance. This process effectively screens out early-life failures caused by component weaknesses or assembly issues, significantly enhancing product reliability and longevity for our customers.

Beauty STC possesses extensive OEM capabilities specifically tailored for LED drivers designed for LED strips, a core product category we manufacture at scale in Jiangmen. We offer comprehensive customization services starting from the conceptual phase. Our engineering team collaborates closely with clients to modify existing driver platforms or develop entirely new solutions based on specific requirements for output voltage (commonly 12VDC or 24VDC), wattage (ranging from 30W to 600W+), dimming protocols (including 0-10V, DALI, PWM, TRIAC, and smart protocols like Bluetooth Mesh), protection features (IP ratings from IP20 to IP67), and physical form factors. We manage the entire OEM process in-house, encompassing custom PCB design and layout, component sourcing meeting client specifications or preferred vendor lists, tailored firmware development for dimming and control, customized labeling and packaging, and securing necessary international certifications such as UL, ETL, CE, TÜV, SAA, and PSE for target markets. Our Jiangmen factory’s integration of SMT, stringent aging protocols, and flexible engineering support ensures we deliver reliable, high-performance, and market-ready LED strip drivers under the client’s brand.

Application Scenarios

LED drivers for LED strips are essential components in various commercial and hospitality environments including hotels, malls, and offices. They provide the necessary power conversion and regulation to ensure stable and efficient operation of LED strip lighting systems. In hotels, LED drivers are commonly used to power LED strips in guest rooms for under-cabinet lighting, cove lighting, headboard accents, and bathroom mirrors. They also support ambient lighting in lobbies, corridors, and stairwells, enhancing the overall guest experience with soft, energy-efficient illumination.

In malls, LED drivers are deployed to illuminate display shelves, signage, walkways, and architectural features. The flexibility of LED strips combined with reliable drivers allows for dynamic lighting designs that highlight retail spaces and create inviting atmospheres. In office environments, LED drivers power strip lighting in suspended ceilings, under desks, in partition walls, and along corridors. They support both functional task lighting and aesthetic design elements, contributing to improved visibility and a modern workspace ambiance.

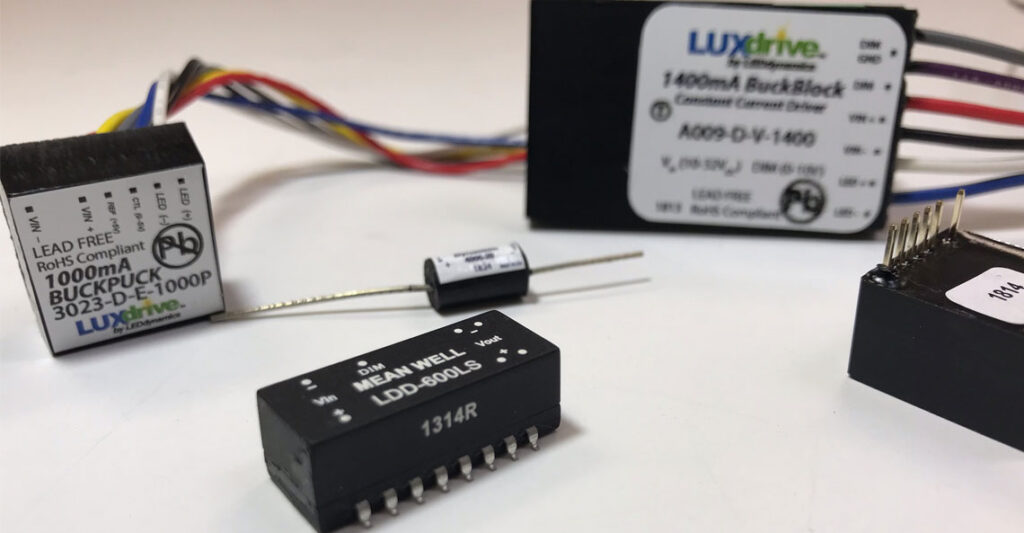

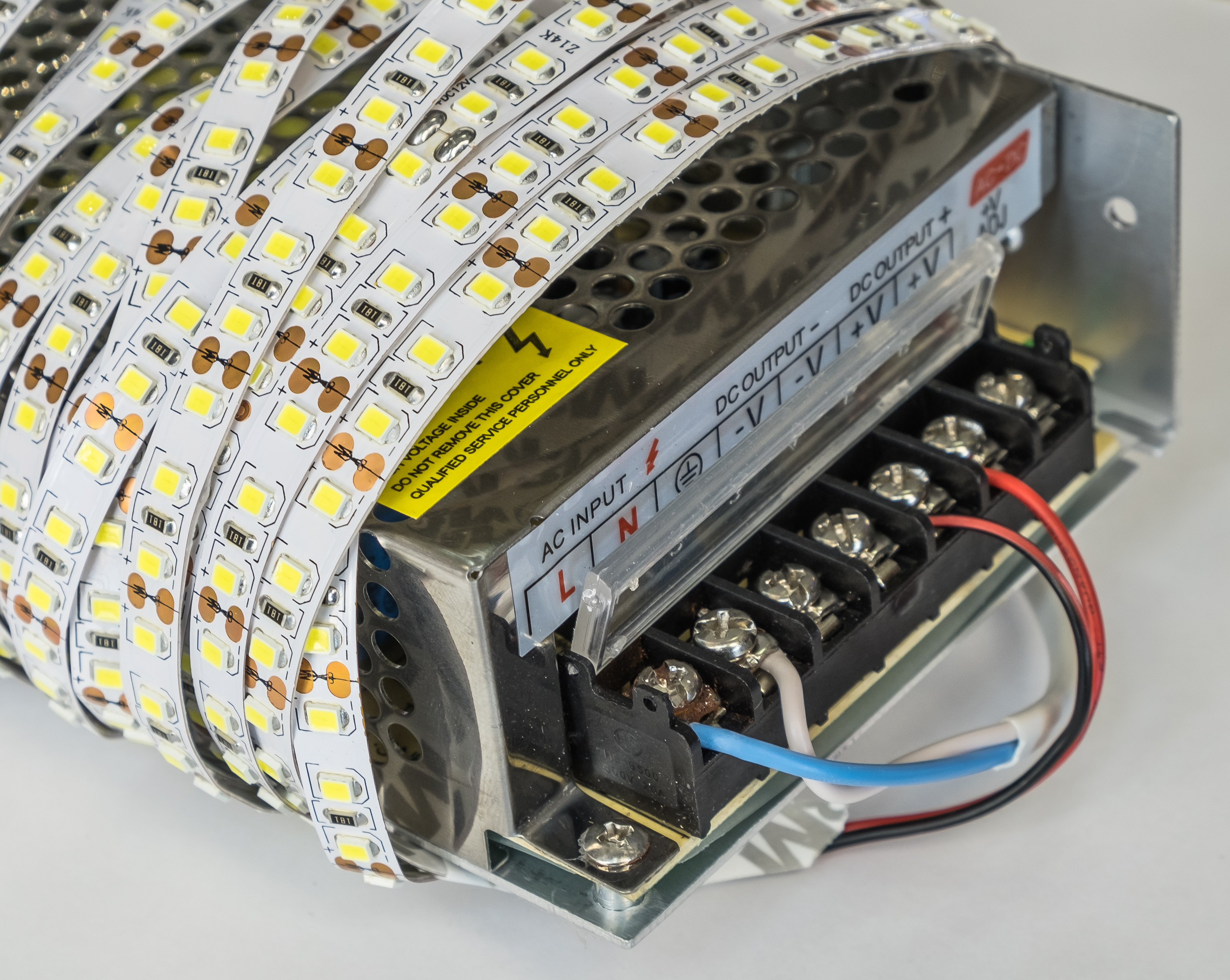

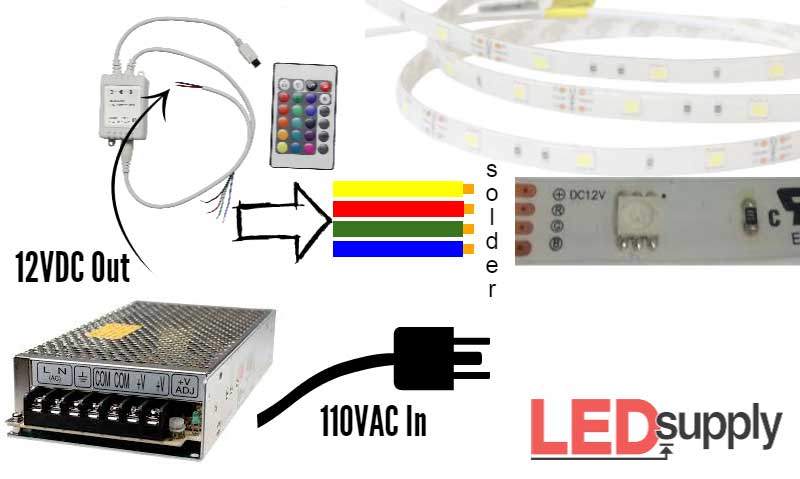

When installing LED drivers for LED strips, it is important to choose the right type of driver—either constant voltage (typically 12V or 24V DC) or constant current—based on the specifications of the LED strip. Ensure the driver’s output wattage exceeds the total power requirement of the LED strip by at least 20% to prevent overloading and ensure longevity. Mount the driver in a well-ventilated area away from direct heat sources and moisture, especially in high-traffic or humid environments like restrooms or kitchens. Use proper enclosures if the installation is in a damp or outdoor location.

Always follow local electrical codes and safety standards during installation. Connect wiring securely and use appropriate gauge wires to minimize voltage drop, especially for longer runs. For optimal performance, consider using dimmable drivers with compatible control systems to allow adjustable lighting levels, enhancing energy savings and user comfort. Regular inspection and maintenance will ensure reliable operation and extended service life of both the driver and the LED strip system.

Why Choose Beauty STC Lighting

Ensure flawless performance and extended lifespan for your LED strip installations with Beauty STC’s precision-engineered LED drivers. Our constant current and constant voltage solutions deliver stable power output, eliminating flicker and color shift while meeting rigorous global safety standards. Designed specifically for seamless integration with flexible and rigid LED strips, Beauty STC drivers provide reliable dimming compatibility and thermal management critical for professional lighting applications. Partner with Beauty STC to access tailored driver specifications, volume pricing, and dedicated technical support for your projects. Contact our lighting solutions manager directly at [email protected] to discuss your requirements and receive expert guidance on selecting the optimal driver for your LED strip system.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.