Article Contents

Industry Insight: Led Driver For Led Lights

In the rapidly evolving landscape of commercial and industrial lighting, the LED driver has emerged as a critical component in ensuring the performance, reliability, and longevity of LED lighting systems. As facilities across warehouses, manufacturing plants, office complexes, and retail spaces transition to energy-efficient LED solutions, the demand for high-quality, code-compliant LED drivers continues to grow. These drivers not only regulate power to maintain consistent light output but also play a vital role in thermal management, surge protection, and system compatibility—factors that are paramount in demanding commercial and industrial environments.

Compliance with international safety and performance standards such as ETL and CE has become a baseline expectation, ensuring that LED drivers meet rigorous electrical, thermal, and electromagnetic requirements for safe operation in diverse applications. Specifiers and facility managers increasingly prioritize drivers that are certified to these standards, as they provide assurance of quality, reduce liability risks, and support seamless integration into larger lighting control systems.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of LED driver innovation, delivering robust, standards-compliant power solutions tailored for commercial and industrial lighting. With decades of engineering expertise and a commitment to performance and reliability, Beauty STC has established itself as a trusted partner for lighting manufacturers and project developers seeking drivers that combine efficiency, durability, and global certification.

Technical Specs & Certifications

LED drivers are critical power conversion components for LED lighting systems, but it is essential to clarify that specifications such as lumens per watt (lm/W) and Color Rendering Index (CRI) are characteristics of the complete LED luminaire or the LED light source itself, not the driver. The driver’s role is to provide stable, regulated power to the LEDs, and its performance directly influences the luminaire’s ability to achieve and maintain these optical specifications. Beauty STC designs and manufactures drivers to ensure optimal support for high-performance lighting applications.

Driver efficiency, measured as the ratio of AC input power to DC output power (typically expressed as a percentage), is the key metric related to system efficacy. Beauty STC drivers achieve industry-leading efficiencies of 88% to 95% across standard operating ranges. This high efficiency minimizes energy loss as heat within the driver, ensuring that a maximum portion of the input power is delivered to the LEDs. Consequently, this directly contributes to the overall luminaire efficacy (lm/W), as less energy is wasted in the power conversion stage. Drivers with higher efficiency also run cooler, enhancing system reliability and longevity. Beauty STC rigorously tests efficiency across the full load and temperature range, adhering to strict internal benchmarks exceeding global standards like DOE Level VI and EU CoC Tier 2.

Regarding CRI >90, this specification is determined solely by the LED package and phosphor formulation used in the light engine, not by the driver. However, the driver plays a vital supporting role. A high-quality driver from Beauty STC provides exceptionally stable, low-ripple constant current output. This stability prevents LED current fluctuations that could cause minor color shifts or flicker, which might otherwise compromise the perceived color quality or consistency over time, especially in high-CRI applications demanding precise color rendition. Our drivers incorporate advanced circuit topologies and filtering to maintain ripple currents typically below 5%, ensuring the LEDs operate under ideal electrical conditions to consistently deliver the intended CRI performance specified by the luminaire manufacturer.

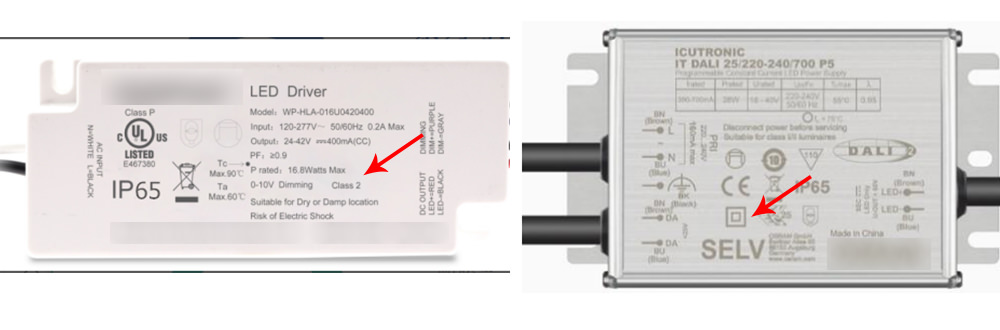

IP (Ingress Protection) ratings define a driver’s resistance to dust and moisture ingress. Beauty STC offers a comprehensive range of drivers tailored to diverse environmental demands. For indoor dry locations, standard IP20 drivers are common. For demanding environments like outdoor fixtures, industrial settings, or damp indoor areas (e.g., bathrooms), Beauty STC excels in producing robust IP65, IP66, and IP67 rated drivers. These feature fully potted construction using high-thermal-conductivity, moisture-resistant silicones or polyurethanes within rugged aluminum or high-grade polycarbonate housings. The potting compound completely encapsulates the electronics, providing superior protection against dust, humidity, rain, and temporary submersion, while also improving thermal management and vibration resistance. All encapsulated drivers undergo stringent validation testing, including prolonged exposure to high humidity, thermal cycling, and water immersion tests per IEC 60529 standards.

Beauty STC’s commitment to quality is foundational to every driver we produce. Our manufacturing process integrates rigorous quality control at every stage, from component selection (using only A-grade, automotive or industrial-rated parts from trusted suppliers) through automated optical inspection (AOI) and in-circuit testing (ICT) on the production line. Each driver batch undergoes 100% functional testing for output parameters, efficiency, and safety, followed by extended burn-in testing at elevated temperatures to identify early-life failures. We implement a five-stage reliability testing protocol including HALT (Highly Accelerated Life Testing) to validate performance under extreme stress conditions far beyond normal operation. This unwavering focus on precision engineering, material integrity, and exhaustive validation ensures Beauty STC drivers deliver exceptional reliability, long service life exceeding 50,000 hours at full load, and consistent performance, forming a trustworthy foundation for high-efficacy, high-CRI luminaires in even the most challenging installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated production facility specializing in the design and manufacturing of LED lighting components, with a strong focus on LED drivers. The Jiangmen factory is strategically located in the Guangdong province, an industrial hub known for electronics and lighting manufacturing, providing access to a robust supply chain and skilled technical workforce.

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, featuring high-precision automated pick-and-place machines from leading global brands. These SMT lines enable the accurate and efficient assembly of surface-mount components onto printed circuit boards (PCBs) used in LED drivers. With multiple SMT lines operating in parallel, the factory achieves high throughput and consistent quality, supporting both small-batch prototyping and large-scale mass production. The SMT process is complemented by automated optical inspection (AOI) systems to ensure soldering and component placement accuracy, minimizing defects and enhancing product reliability.

A critical part of the manufacturing process at the Jiangmen factory is the comprehensive aging and reliability testing for LED drivers. Every batch of drivers undergoes rigorous aging tests under elevated temperatures and full-load conditions, typically lasting 4 to 8 hours or longer depending on customer specifications. This process helps identify early-life failures and ensures long-term stability. In addition to aging, the factory conducts a full suite of electrical, thermal, and environmental tests, including surge protection, power efficiency, harmonic distortion, and damp heat testing, in compliance with international standards such as IEC, UL, and CCC.

Beauty STC has strong OEM and ODM capabilities for LED drivers used in LED lighting systems. The company supports custom design and manufacturing based on client requirements, including input/output specifications, dimming functions (such as 0-10V, DALI, or TRIAC), IP ratings, and mechanical form factors. With an in-house engineering team experienced in power electronics and thermal management, the factory can deliver tailored driver solutions for commercial, industrial, and residential lighting applications. Clients benefit from flexible MOQs, fast prototyping, full documentation support (including schematics, test reports, and certifications), and strict IP protection.

Overall, the Jiangmen factory represents a high-capability manufacturing platform that combines advanced automation, rigorous quality control, and deep technical expertise to serve global lighting brands and system integrators requiring reliable, high-performance LED drivers.

Application Scenarios

LED drivers are indispensable components for virtually all LED lighting systems across commercial applications including hotels, malls, and offices. They are not optional accessories but fundamental to converting incoming mains voltage to the precise low-voltage direct current required by LED modules while regulating current to prevent damage from voltage fluctuations. Their use is mandatory wherever LED luminaires or strips operate on standard AC power supplies, which encompasses nearly all installations in these settings.

In hotels, LED drivers are critical for guest room lighting where dimmable ambiance is essential, requiring constant current drivers compatible with leading-edge or trailing-edge dimmers. Lobby and corridor lighting demands drivers with high surge immunity to handle voltage spikes from HVAC systems cycling, while bathroom vanity lights necessitate drivers with robust IP67 ratings for damp location safety. High-end suites often utilize programmable constant voltage drivers for architectural LED tape installations under cabinets or cove details, where precise color consistency across multiple zones is non-negotiable for luxury aesthetics.

Malls deploy high-wattage constant current drivers for suspended retail display lighting, particularly in jewelry or high-end fashion zones where color rendering index stability above 90 CRI is mandatory. These drivers must support 0-10V or DALI protocols for daylight harvesting integration with skylights. Parking garage high-bay fixtures require industrial-grade drivers with extended operating temperature ranges down to -40°C and exceptional vibration resistance. Wayfinding signage throughout malls relies on compact constant voltage drivers powering flexible LED strips, where overcurrent protection prevents cascading failures in long continuous runs.

Office environments depend heavily on flicker-free constant current drivers for open-plan workspaces to eliminate visual fatigue, with strict compliance to IEEE PAR1789 standards for low ripple current. Conference rooms integrate multi-channel programmable drivers enabling dynamic white tuning for video conferencing optimization. Under-cabinet task lighting in kitchens or break rooms uses low-profile constant voltage drivers with short-circuit protection. Server rooms and data centers specify drivers with ultra-low harmonic distortion to prevent interference with sensitive equipment, often requiring medical-grade isolation certifications.

Installation requires meticulous attention to thermal management as driver lifespan halves for every 10°C above rated temperature. Always mount drivers in well-ventilated areas away from heat-generating fixtures, never embedding them in fully enclosed ceiling voids without thermal validation. Verify exact compatibility between driver output specifications and LED load requirements – mismatched forward voltage or current ratings cause catastrophic failure. For constant voltage systems powering LED strips, calculate total load at 120% of strip requirements and never exceed 80% of the driver’s rated capacity to accommodate inrush currents. In multi-zone installations, avoid daisy-chaining drivers; each zone requires its own dedicated driver output. Always install drivers upstream of any dimming controls and confirm dimmer compatibility with the specific driver model to prevent audible buzzing or limited dimming range. Crucially, never connect mains voltage directly to LED modules assuming “built-in driver” claims without verifying the luminaire’s internal construction – many cheap fixtures omit adequate driver protection leading to premature field failures. Adhering to these practices ensures the reliability and performance expected in professional commercial lighting environments.

Why Choose Beauty STC Lighting

Looking for a reliable LED driver for your LED lighting projects? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED drivers and lighting solutions. Our products are engineered for performance, durability, and energy efficiency, meeting international standards for safety and reliability. Whether you’re a distributor, contractor, or OEM, we offer customized solutions to meet your specific needs. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your business with premium LED drivers and exceptional service.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.