Article Contents

Industry Insight: Led Control Rgb

The evolution of commercial and industrial lighting has been significantly shaped by advancements in LED control technologies, particularly in the realm of RGB lighting systems. As facilities increasingly demand greater flexibility, energy efficiency, and dynamic ambience control, LED control RGB solutions have emerged as a cornerstone in modern architectural, hospitality, manufacturing, and retail environments. These systems enable precise management of color, intensity, and lighting effects, allowing businesses to enhance aesthetics, support productivity, and reduce operational costs. With growing regulatory emphasis on safety and performance, compliance with international standards such as ETL and CE has become essential, ensuring that LED control systems meet rigorous requirements for electrical safety, electromagnetic compatibility, and environmental resilience.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance, code-compliant RGB control systems tailored for demanding commercial and industrial applications. By integrating robust driver technologies, seamless control protocols, and rigorous certification standards, Beauty STC continues to empower lighting designers and facility managers with intelligent, reliable, and scalable lighting ecosystems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. approaches RGB and RGBW LED lighting systems with a focus on high performance, color fidelity, and robust construction, particularly for demanding applications like retail beauty environments where accurate color rendering is critical. The term ‘LED control RGB’ typically refers to tunable RGB or RGBW (Red, Green, Blue, White) systems controlled via dedicated drivers and protocols. For such systems, achieving high lumens per watt while maintaining CRI >90 requires specific design choices, as pure RGB systems inherently struggle with high CRI due to spectral gaps. Beauty STC primarily utilizes high-CRI RGBW architectures where the dedicated warm white or neutral white channel (typically 2700K-4000K) ensures excellent color rendering, while the RGB channels enable dynamic color tuning and saturation.

Lumens per watt for these integrated RGBW systems vary significantly based on the selected output. The white channel alone, using high-efficiency 90+ CRI LEDs, typically delivers 85-95 lumens per watt at 2700K-3000K under standard operating conditions. When operating in full RGB color mixing mode, especially at highly saturated colors, system efficacy drops considerably—often to 40-60 lumens per watt—due to the lower inherent efficiency of monochromatic LEDs and optical losses in the mixing process. Beauty STC optimizes driver efficiency (typically >92% for constant current drivers) and thermal management using aluminum MCPCBs to minimize lumen depreciation and maintain stable output over time. System-level efficacy must be evaluated per application, as control method and dimming profile also impact real-world efficiency.

Critical to Beauty STC’s design philosophy is ensuring a minimum CRI of 90 (Ra) across all white points and blended colors, with Ra9 (saturated red) consistently exceeding 50. This is achieved not by using standard RGB diodes alone but by integrating a high-CRI, spectrally optimized white LED channel alongside carefully selected narrow-band RGB emitters. Our proprietary color mixing algorithms and optical diffusers prevent color separation and maintain Rf and Rg metrics suitable for critical tasks like skin tone evaluation. Every white LED bin is rigorously tested to exceed CRI 90 and TM-30-15 standards, with spectral power distribution tuned to eliminate cyan deficiencies common in lower-quality LEDs.

IP ratings for Beauty STC RGBW systems are application-dependent and clearly defined per product line. Standard indoor fixtures (e.g., cove lighting, display integrations) carry IP20 certification, ensuring basic protection against touch and dust ingress. For damp locations like bathrooms or semi-outdoor retail canopies, we implement IP65-rated luminaires with conformal-coated PCBs, silicone-sealed optical chambers, and integrated gaskets at all junctions. Full outdoor or wash-down zone applications utilize IP67-rated solutions featuring hermetically sealed driver compartments, marine-grade aluminum housings, and potted cable entries to withstand temporary submersion and high-pressure cleaning. All ingress protection claims are validated through third-party testing per IEC 60529 standards.

Beauty STC’s quality commitment is embedded in every RGBW system. We enforce triple-stage binning for chromaticity (within a 3-step MacAdam ellipse for white channels) and flux, ensuring visual consistency across installations. Thermal management exceeds industry norms with die-cast aluminum heat sinks maintaining junction temperatures below 85°C under maximum load, directly contributing to L70 lifetimes of 50,000 hours. Our drivers feature active power factor correction (PFC >0.95), 0-10V/DALI-2/DMX compatibility, and surge protection up to 10kV. Rigorous in-house testing includes 100% burn-in verification, accelerated lifetime testing per IES LM-84, and color stability validation over 6,000 hours. This disciplined approach results in field failure rates below 0.5% at 3 years, backed by a comprehensive 5-year warranty covering LEDs, drivers, and structural integrity. Beauty STC luminaires consistently achieve UL/cETL, ENEC, and SAA certifications, reflecting our adherence to global safety and performance benchmarks.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co. Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province, China. The factory is strategically situated within the Pearl River Delta region, known for its robust electronics and lighting supply chain, enabling efficient material sourcing and logistics.

The production floor is centered around advanced Surface Mount Technology (SMT) lines, which are critical for high-precision assembly of LED lighting components. These SMT machines are fully automated and include high-speed pick-and-place units, reflow soldering ovens, and automated optical inspection (AOI) systems. This ensures consistent quality, tight tolerances, and high throughput when mounting LED chips, resistors, capacitors, and control ICs onto printed circuit boards. The SMT process supports both small-batch prototyping and large-scale mass production.

A key strength of the Jiangmen factory is its comprehensive aging and reliability testing procedures. Completed LED products undergo rigorous aging tests under controlled thermal and electrical conditions, typically running at elevated temperatures for durations ranging from 4 to 24 hours. This process helps identify early-life failures, ensuring only durable and stable products reach customers. Additional testing includes waterproofing verification, thermal performance analysis, color consistency checks, and electrical safety testing, all conducted in dedicated quality assurance labs.

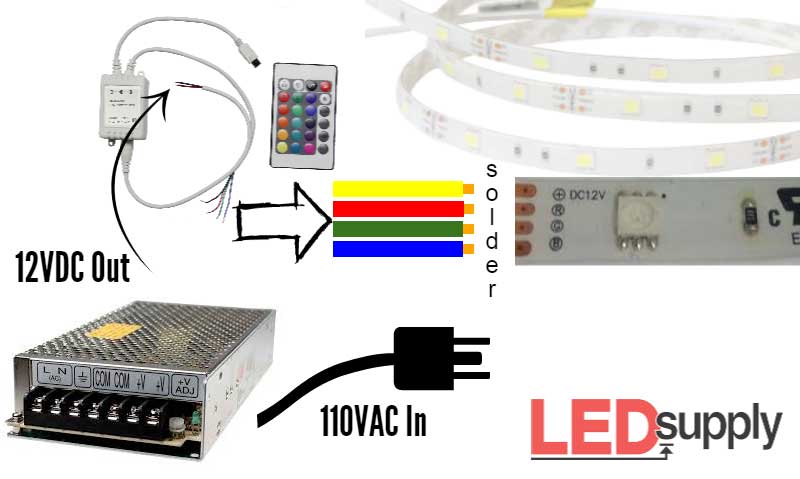

Beauty STC has strong OEM and ODM capabilities, particularly in the area of RGB LED controls. The company supports custom development of RGB LED strips, controllers, power supplies, and integrated smart lighting systems tailored to client specifications. This includes custom PCB designs, firmware programming for RGB color mixing and effects, branding, packaging, and compatibility with various control protocols such as PWM, DMX, DALI, or wireless systems like Zigbee, Bluetooth, and Wi-Fi. Customers can provide technical requirements or product concepts, and Beauty STC handles the full development cycle from design and prototyping to certification and volume production.

Overall, the Jiangmen factory combines automation, stringent quality control, and flexible manufacturing to deliver reliable, high-performance RGB LED lighting solutions under customer brands, making it a trusted partner for global lighting brands and distributors.

Application Scenarios

RGB LED control systems offer dynamic lighting solutions that enhance ambiance, functionality, and branding across commercial spaces. Their strategic implementation requires careful consideration of both application context and technical execution. In hotels, RGB systems excel in lobbies for creating adaptable atmospheres that transition from bright, welcoming daylight settings to warm, sophisticated evening moods without physical fixture changes. They are equally valuable in banquet halls where customizable color schemes support diverse event themes, from corporate conferences to weddings, and in premium bars or lounges to establish immersive, mood-driven environments. Hotel spas and wellness areas also benefit through color therapy applications, while exterior facade lighting with RGB can highlight architectural features or promote seasonal campaigns. Crucially, guest room RGB should be limited to accent features like cove lighting or footlights, avoiding direct task lighting to ensure guest comfort and restful sleep.

For shopping malls, RGB control shines in large-scale feature installations such as central atrium columns or suspended art pieces that serve as visual anchors and social media attractions. Retail storefronts leverage RGB for dynamic window displays that capture attention during promotions or holidays, while directional signage integrated with color-coded pathways guides shoppers intuitively during events. Mall facades become digital canvases for community engagement, displaying local pride colors or charity campaigns. Temporary event zones—like holiday markets or product launches—rely on RGB’s flexibility for rapid environment transformation. However, RGB is unsuitable for general retail sales floors where accurate color rendering (CRI >90) is critical for merchandise presentation, nor in corridors where consistent, neutral lighting supports safe navigation.

In office environments, RGB must be applied judiciously. Primary workspaces require stable, high-CRI white light to reduce eye strain and maintain productivity; RGB here is counterproductive. Instead, focus on high-impact communal areas: reception zones can reflect corporate branding through subtle accent lighting, while collaborative lounges or break rooms use energizing colors to stimulate creativity during downtime. Conference rooms benefit from programmable scenes—cool white for focus during presentations, warmer tones for relaxed brainstorming. RGB is also effective in executive suites for ambiance during client meetings and in wellness rooms for circadian rhythm support. Never install RGB in open-plan workstations, laboratories, or server rooms where visual clarity and operational safety are paramount.

Installation demands meticulous planning to ensure reliability and longevity. Always begin by verifying compatibility between RGB strips/drivers, controllers (DMX, DALI, or wireless protocols like Bluetooth Mesh), and building management systems (BMS) to avoid integration failures. Prioritize thermal management: install LED strips with adequate spacing in aluminum channels to dissipate heat, especially in enclosed mall ceilings or hotel wall cavities where overheating causes premature lumen depreciation. Use shielded cables for data lines in offices near IT infrastructure to prevent electromagnetic interference, and strictly separate low-voltage control wiring from mains power. Conduct comprehensive pre-installation testing of all components on a bench—never after drywall or ceiling closure—to catch faulty pixels or communication errors. For large-scale deployments like mall facades, implement segmented power injection every 5 meters to prevent color shift at strip ends, and document all channel mappings and IP assignments meticulously for future maintenance. Crucially, calibrate white point consistency across all fixtures using spectroradiometers; mismatched whites undermine the professionalism of hotel lobbies or office receptions. Finally, provide end-users with intuitive control interfaces—dedicated touch panels for staff in hotel backrooms, but simplified mobile apps for mall event coordinators—to ensure adoption without technical overhead.

Why Choose Beauty STC Lighting

Discover the full potential of customizable lighting with Beauty STC’s advanced LED control RGB solutions. As a trusted leader in innovative lighting technology, we offer high-performance, energy-efficient RGB systems designed for seamless integration and vibrant color accuracy. Partner with Beauty STC to access reliable, scalable, and cutting-edge LED control solutions tailored to your project needs. For collaboration opportunities and expert support, contact us at [email protected] and take the next step in transforming your lighting applications.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.