Article Contents

Industry Insight: Led Colored Strip Lights

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the demand for dynamic, energy-efficient, and highly functional illumination solutions. Within this evolution, LED colored strip lights have rapidly moved beyond their initial novelty applications to become indispensable tools for enhancing safety, wayfinding, brand identity, and operational efficiency across diverse professional environments. From guiding personnel in complex warehouse logistics and highlighting critical machinery in manufacturing plants to creating immersive retail experiences and defining architectural features in hospitality venues, the strategic application of controllable color is proving its operational and economic value. However, deploying these systems in demanding commercial and industrial settings necessitates far more than basic color output; it requires robust engineering, stringent reliability, and unwavering adherence to global safety standards. Compliance with certifications such as ETL for the North American market and CE marking for Europe is not merely a regulatory formality but a fundamental requirement, ensuring electrical safety, electromagnetic compatibility, and long-term performance under continuous operation – factors that directly impact facility uptime, insurance compliance, and user safety.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this professional LED lighting evolution. With over 25 years of specialized expertise, we understand the unique challenges and critical performance demands of commercial and industrial applications. We engineer our LED colored strip light systems specifically for these rigorous environments, prioritizing industrial-grade components, advanced thermal management, and rigorous in-house testing protocols that consistently exceed ETL and CE requirements. Our commitment goes beyond supplying products; we provide engineered lighting solutions designed for seamless integration, exceptional durability, and predictable performance, empowering businesses to leverage the power of color with confidence and reliability.

Technical Specs & Certifications

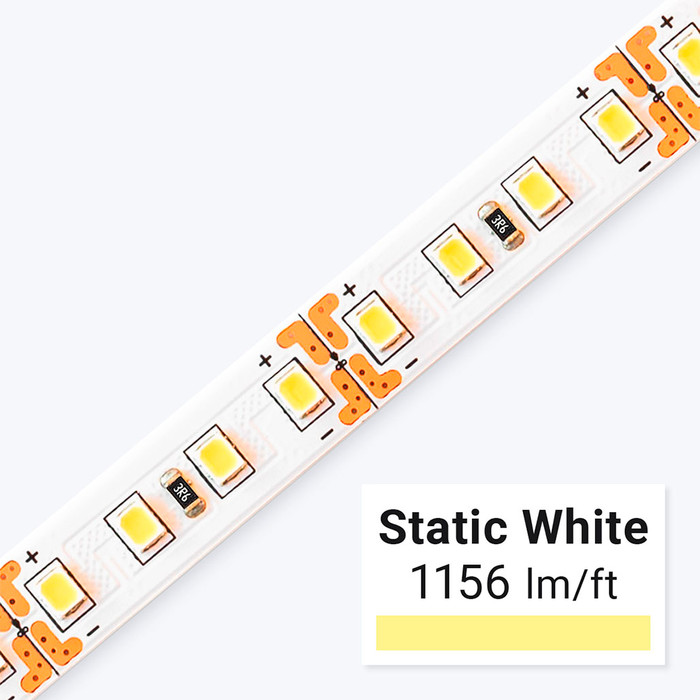

LED colored strip lights from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance, color accuracy, and environmental resilience, making them ideal for both decorative and functional lighting applications. These strips deliver excellent lumens per watt efficiency, ensuring energy savings without compromising brightness. Typical output ranges from 18 to 22 lumens per watt for standard RGB and RGBW configurations, with high-density variants reaching up to 25 lumens per watt depending on the LED chip configuration and drive current. This efficiency is achieved through the use of premium 5050 or 3535 SMD LEDs and optimized PCB thermal management, ensuring sustained performance over extended operation.

A key hallmark of Beauty STC’s colored strip lights is the availability of high CRI (Color Rendering Index) options exceeding 90. While standard RGB strips inherently have lower spectral continuity due to discrete color diodes, Beauty STC offers RGBW and tunable white variants with integrated high-CRI white channels (CRI >90, typically Ra 92–95) to deliver natural, vibrant color blending and accurate white light reproduction. These high-CRI white segments use phosphor-coated diodes with tightly binned color temperatures, ensuring consistency across installations. This makes the strips suitable for retail, hospitality, and architectural applications where color fidelity is critical.

In terms of environmental protection, Beauty STC provides LED colored strip lights in multiple IP ratings to suit diverse installation environments. IP20 versions are available for indoor, dry locations where protection is minimal. For damp or outdoor use, IP65-rated strips are standard—these feature a silicone encapsulation that protects against dust and low-pressure water jets, allowing safe use in kitchens, bathrooms, or covered outdoor areas. For fully outdoor or submerged applications, such as landscape lighting or pool perimeters, IP67 and IP68-rated strips are offered. These are fully potted with waterproof silicone, enabling temporary or continuous submersion up to 1 meter for IP68, depending on length and connector integrity.

Beauty STC’s commitment to quality is evident in every stage of production. The company adheres to strict manufacturing standards, utilizing automated SMT lines for precise component placement and conducting rigorous aging and electrical testing. All strip lights undergo 100% functional checks, including color consistency, voltage drop evaluation, and waterproof performance validation. Components are sourced from trusted suppliers to ensure long life—typically rated at 50,000 hours—and stable chromatic performance. With UL, CE, and RoHS certifications, Beauty STC’s LED colored strip lights combine reliability, efficiency, and superior optical quality, setting a benchmark in the professional lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting solutions, including specialized LED colored strip lights. Spanning over 50,000 square meters, this state-of-the-art factory integrates rigorous quality control with high-volume production capacity, operating under ISO 9001 and IECQ-certified processes to ensure global compliance. The facility is strategically equipped to handle complex manufacturing demands while maintaining strict adherence to international safety and performance standards.

Our SMT production lines feature high-precision JUKI and Fuji NXT III placement machines, capable of handling components as small as 0201 metric packages with ±25μm placement accuracy. These systems are optimized for LED strip assembly, supporting multi-layer PCBs with tight pitch LEDs up to 600 units per meter. Each line incorporates triple-stage AOI verification—pre-reflow, post-reflow, and 3D solder paste inspection—to eliminate defects in solder joints and component alignment, critical for maintaining color consistency in RGB/RGBIC strips. The reflow ovens utilize nitrogen-assisted profiles to prevent oxidation, ensuring reliable thermal management for high-density color-mixing applications.

Aging testing is conducted in dedicated environmental chambers where 100% of finished LED colored strip lights undergo 24-hour continuous operation at 50°C ambient temperature. This accelerated life testing validates thermal stability of IC controllers and color uniformity across segments, with real-time spectral analysis verifying Δu’v’ color shift remains below 0.003. Strips are monitored for flicker, voltage drop, and silicone coating integrity, with any unit exhibiting >0.5% lumen depreciation or color deviation automatically quarantined. We maintain a dedicated failure analysis lab to investigate root causes, ensuring corrective actions are implemented within 72 hours of anomaly detection.

For OEM partnerships focused on LED colored strip lights, we offer end-to-end customization from prototyping to mass production. Our engineering team collaborates with clients on optical design—adjusting LED density, diffuser profiles, and color calibration for specific CCT ranges or saturated hues—and can integrate proprietary ICs for addressable protocols like DMX512 or Art-Net. We support reel labeling, custom packaging, and multi-voltage configurations (12V/24V/48V) while maintaining strict IP65/IP67 ingress protection standards. With NPI cycles as short as 15 days and MOQs starting at 500 meters per configuration, we provide full documentation including IES files, spectral reports, and UL/CE certification support tailored to regional market requirements. This comprehensive OEM framework has enabled us to deliver over 200 unique colored strip variants annually for global lighting brands.

Application Scenarios

LED colored strip lights are versatile lighting solutions that can enhance aesthetics, create ambiance, and improve functionality across various commercial environments. Their flexibility and customizable color options make them ideal for specific applications in hotels, malls, and offices.

In hotels, LED colored strip lights are commonly used in guest rooms to highlight architectural features such as cove ceilings, headboards, or under-bed installations to create a luxurious and relaxing atmosphere. They are also effective in lobbies, lounges, and bars to accentuate design elements like reception counters, columns, or water features. In hospitality settings, tunable white and RGB options allow for mood-based lighting that can shift from vibrant and energetic during the day to soft and warm in the evening.

Malls utilize LED colored strip lights to enhance visual merchandising and guide foot traffic. They are often installed in signage, display windows, and ceiling coves to draw attention to promotions or specific retail areas. Colored lighting can also be synchronized with seasonal themes or events, adding a dynamic and engaging experience for shoppers. Corridors, escalator surrounds, and food courts benefit from accent lighting that improves spatial perception and creates a vibrant environment.

In offices, while neutral lighting is typically preferred for productivity, LED colored strip lights can be used strategically in common areas, reception zones, or breakout spaces to reflect brand identity or encourage creativity. They may also be installed under cabinets, shelves, or in stairwells for both decorative and functional low-level lighting. However, in workspaces, it’s important to avoid overly saturated colors that can cause distraction or eye strain.

For successful installation, consider the following tips. Always ensure the surface is clean, dry, and smooth before applying the strip lights to maximize adhesive performance. For long-term durability, especially in high-traffic or high-humidity areas, use mounting clips or aluminum channels which also help dissipate heat and protect the strips. Plan the power supply carefully—calculate the total wattage required and avoid overloading drivers. Use compatible controllers and ensure connections are secure, preferably soldered or using proper connectors, to prevent flickering or failure. When installing in coves or indirect lighting setups, position the strip facing the wall or ceiling to create a soft, diffused glow rather than direct glare. Finally, test the lighting setup before finalizing the installation to confirm color consistency, brightness, and control functionality.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium LED colored strip lights, engineered for exceptional color accuracy, durability, and seamless integration. As a global leader in innovative LED solutions, we deliver customizable, high-performance strips trusted by designers and manufacturers worldwide for dynamic ambient, architectural, and specialty applications. Partner with Beauty STC to access cutting-edge technology, rigorous quality control, and dedicated engineering support tailored to your specific requirements. Elevate your product offerings with reliable, vibrant lighting that meets international standards and exceeds market expectations. Contact our partnership manager today at [email protected] to discuss how our LED colored strip lights can enhance your portfolio and drive mutual growth.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.