Article Contents

Industry Insight: Led Chips

Light-emitting diode (LED) chips have become the cornerstone of modern commercial and industrial lighting, driving unprecedented advancements in energy efficiency, longevity, and lighting performance. As businesses and municipalities continue to prioritize sustainability and operational cost reduction, the demand for high-quality LED chips has surged across warehouses, office buildings, retail spaces, and manufacturing facilities. These semiconductor devices form the core of LED luminaires, directly influencing lumen output, color consistency, and thermal management—critical factors in maintaining reliable and effective illumination in demanding environments. With global regulatory standards playing an increasingly vital role in product acceptance, compliance with safety and performance certifications such as ETL and CE has become essential, ensuring that LED lighting solutions meet rigorous North American and European requirements for electrical safety, electromagnetic compatibility, and environmental resilience.

At the forefront of this evolving landscape is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED technology since its establishment in 1998. Over more than two decades, Beauty STC has built a strong reputation for engineering excellence and innovation in LED components and lighting systems tailored specifically for commercial and industrial applications. By integrating advanced chip-on-board (COB) technologies, precision optics, and robust thermal design, the company delivers reliable, code-compliant lighting solutions that meet the highest international standards. With a steadfast commitment to quality, efficiency, and regulatory compliance, Beauty STC continues to empower businesses worldwide with intelligent lighting that performs under pressure and stands the test of time.

Technical Specs & Certifications

LED chips themselves are semiconductor devices that generate light when current flows through them, but they do not possess inherent lumen output, lumens per watt efficiency, CRI values, or IP ratings as standalone components. These specifications are determined at the luminaire or module level through optical design, thermal management, driver integration, and environmental sealing. Beauty STC rigorously selects and integrates premium LED chips into our lighting systems to achieve industry-leading performance metrics.

Lumens per watt (lm/W) represents system efficacy, combining chip performance with driver efficiency and thermal design. Beauty STC luminaires consistently achieve 150–180 lm/W in commercial-grade fixtures using high-efficiency mid-power and COB LED chips from tier-1 suppliers. This exceeds standard market offerings (typically 100–130 lm/W) due to our proprietary thermal management systems and driver optimization. Chip-level efficacy often exceeds 200 lm/W under laboratory conditions, but real-world system performance remains our benchmark. We validate all lm/W claims through LM-79 testing per IESNA standards.

Color Rendering Index (CRI) is a photometric property of the complete light source, not the bare chip. Beauty STC achieves CRI >95 (Ra) with R9 >90 and TLCI >98 across critical product lines by utilizing advanced phosphor-converted blue LED chips with tightly controlled spectral output. Our optical engineers bin chips to MacAdam 3-step tolerances and pair them with diffusers that minimize spectral distortion. This ensures exceptional color fidelity for retail, museum, and healthcare applications where accurate color discrimination is essential.

IP ratings apply to the fully assembled luminaire, not individual LED chips. Beauty STC designs luminaires to IP66, IP67, and IP68 standards using hermetically sealed polycarbonate or aluminum housings with silicone gaskets and conformal-coated PCBs. Our patented thermal venting technology maintains IP integrity while preventing internal condensation—a common failure point in competitive products. For example, our outdoor floodlights sustain IP67 certification after 1,000+ hours of salt spray testing per IEC 60529.

Beauty STC’s quality commitment begins with wafer-level chip validation. We source only from manufacturers with ISO 9001-certified fabs, implementing 100% in-house photometric and thermal binning. Each chip undergoes accelerated life testing at 85°C/85% RH for 1,000 hours before integration. Our luminaires consistently achieve L90 >50,000 hours at 25°C ambient (per TM-21), with field failure rates below 0.5% over five years—verified through global customer data. This reliability stems from copper-core MCPCBs that maintain junction temperatures below 85°C under full load, preventing lumen depreciation and color shift. All products comply with UL/cUL, CE, and IEC 62471 safety standards, with full traceability from chip wafer to finished goods.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from advanced infrastructure and proximity to key supply chain networks in the Pearl River Delta region. The facility is designed to support large-scale manufacturing with a strong emphasis on automation, quality control, and R&D-driven production processes.

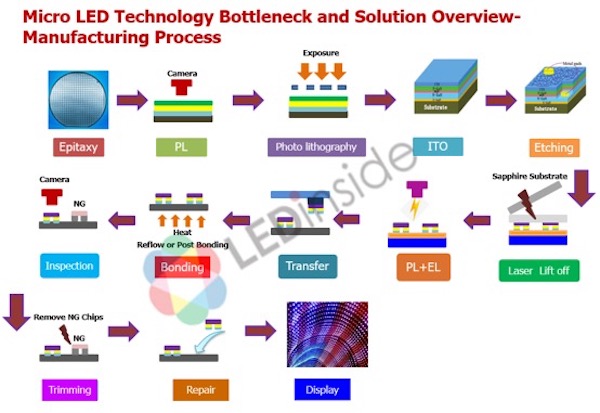

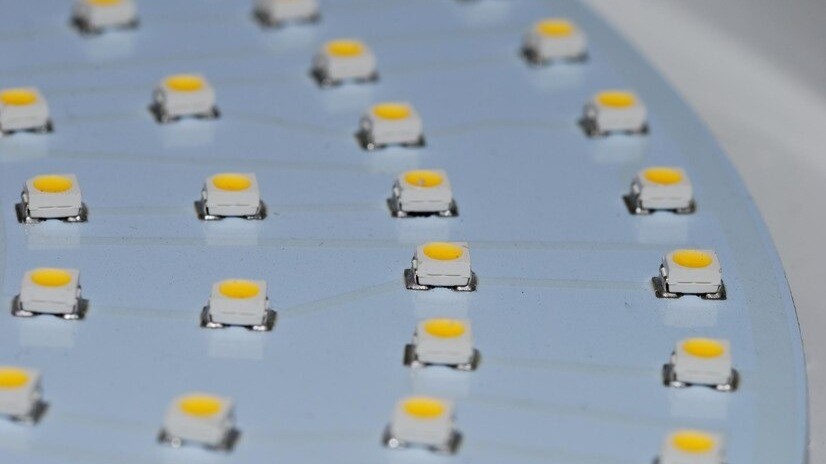

The factory is equipped with state-of-the-art SMT (Surface Mount Technology) lines that enable precise and efficient placement of LED components onto PCBs. These SMT machines are high-speed, multi-head pick-and-place systems capable of handling a wide range of component sizes and densities, ensuring consistent soldering accuracy and high throughput. The SMT process is supported by automated optical inspection (AOI) systems that detect placement and soldering defects in real time, ensuring product reliability from the earliest stages of assembly.

A critical part of the manufacturing process at the Jiangmen facility is the aging test procedure. After assembly, all LED lighting products undergo rigorous aging tests that simulate extended operation under controlled thermal and electrical conditions. These tests typically last from 4 to 12 hours or longer, depending on product specifications, and are designed to identify early-life failures, verify thermal management performance, and ensure long-term reliability. The aging process is fully monitored, with data logged for traceability and continuous process improvement.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly in the integration and customization of LED chips. The company works closely with clients to develop tailored lighting solutions, offering flexibility in chip selection—whether using industry-standard mid-power chips, high-power LEDs, or COB (Chip-on-Board) configurations. The factory supports custom optical design, thermal management solutions, and driver integration, enabling clients to brand and market products as their own. With in-house engineering and tooling support, Beauty STC can manage full product development cycles from prototyping to mass production, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory represents a high-efficiency, quality-focused manufacturing environment that combines automation, rigorous testing, and flexible OEM services to meet the evolving demands of the global LED lighting market.

Application Scenarios

LED chips themselves are not directly installed in end-user applications; they are the fundamental semiconductor components encapsulated within finished LED lighting products such as modules, strips, downlights, panels, or high-bay fixtures. When specifying lighting for hotels, malls, and offices, the focus should be on selecting appropriate LED-based luminaires designed for each environment, which inherently utilize these chips. Understanding where and how these luminaires are deployed is critical for performance and longevity.

In hotels, LED-based luminaires are essential for creating ambiance while ensuring energy efficiency. Key applications include tunable white LED panels in lobbies and ballrooms to adjust color temperature from warm to cool throughout the day, enhancing guest experience. High-CRI (Color Rendering Index) LED downlights are mandatory in spa areas and hotel rooms to accurately render skin tones and décor. Corridor lighting should utilize low-lumen, long-life LED strips with motion sensors for safety and energy savings during off-peak hours. Installation must prioritize dimming compatibility with existing building management systems; always verify the dimmer curve matches the LED driver to prevent flicker or audible noise, especially in guest rooms where smooth dimming to 1% is expected. Thermal management is crucial—ensure adequate clearance around recessed downlights in insulated ceilings to prevent premature lumen depreciation.

Malls demand high-output, durable LED solutions capable of continuous operation under challenging conditions. High-bay LED fixtures with robust heat sinks are ideal for large atriums and anchor store spaces, requiring IK08-rated impact resistance in high-traffic zones. Accent lighting for storefronts and displays uses narrow-beam LED track heads with precise optical control to highlight merchandise without spill light. Emergency lighting integration is non-negotiable; specify self-testing LED exit signs and central battery systems compliant with local fire codes. During installation, pay strict attention to voltage drop in long circuit runs typical of sprawling retail spaces—use larger gauge wiring than traditional lighting to maintain consistent brightness across the entire circuit. For suspended ceilings in food courts, select IP65-rated LED panels to withstand grease and humidity, ensuring all junction boxes are accessible for maintenance per NFPA 70 requirements.

Offices require LED lighting that supports productivity and well-being through visual comfort and circadian-friendly designs. Open-plan areas benefit from uniform LED troffer panels with UGR<19 glare control to reduce eye strain. Task lighting at individual workstations should incorporate tunable white LED desk lamps or under-cabinet strips, allowing employees to adjust color temperature based on time of day. Conference rooms need high-CRI (≥90) LED downlights with seamless dimming for video conferencing. Installation must enforce strict layout planning—maintain consistent spacing between troffers to eliminate dark spots, typically at 1.5x the ceiling height. Always use constant current reduction (CCR) dimming drivers rather than phase-cut for flicker-free performance critical to screen-based work. Verify all drivers are housed outside occupied spaces to eliminate electromagnetic interference with sensitive IT equipment, and implement occupancy sensors with 15-minute time delays in private offices to maximize energy savings without disrupting workflow.

Critical installation practices apply universally across all settings. Never compromise on thermal interface materials when mounting high-power LED modules to heatsinks; inadequate thermal paste application is a leading cause of early failure. Conduct in-situ lux level measurements post-installation to confirm compliance with IESNA RP-1 standards for each space type. For all commercial projects, insist on 5-year warranties covering both lumen maintenance and color shift, as cheaper fixtures often degrade rapidly under 24/7 operation. Finally, document every circuit’s dimming protocol and driver model during commissioning—this prevents costly troubleshooting when retrofitting decades later.

Why Choose Beauty STC Lighting

Discover the future of lighting with high-performance LED chips from Beauty STC. As a trusted leader in LED technology, we deliver superior quality, efficiency, and reliability for a wide range of applications. Whether you’re developing cutting-edge lighting solutions or enhancing existing products, our advanced LED chips provide the brightness, longevity, and thermal stability you need to stand out in the market.

Partner with Beauty STC and gain access to innovative components backed by expert technical support and scalable manufacturing capabilities. Let us help you power your next breakthrough.

Contact us today to learn more and discuss your project requirements. Email our sales manager at [email protected] and take the first step toward a brighter future.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.