Article Contents

Industry Insight: Led Channels And Diffusers

In the rapidly evolving landscape of commercial and industrial lighting, LED channels and diffusers have become foundational components in achieving both functional performance and aesthetic precision. As businesses increasingly prioritize energy efficiency, durability, and seamless light distribution, the demand for high-quality aluminum profiles and optical-grade diffusers has surged. These elements not only protect and organize LED strips but also play a critical role in minimizing glare, ensuring uniform illumination, and enhancing the overall visual comfort within environments such as warehouses, office buildings, retail spaces, and manufacturing facilities.

Compliance with international safety and performance standards is paramount in these demanding applications. Products that carry ETL and CE certifications meet rigorous North American and European regulatory requirements, providing assurance of electrical safety, thermal management, and long-term reliability under continuous operation. As such, specifying certified LED channels and diffusers is no longer optional—it’s a necessity for architects, engineers, and facility managers committed to code-compliant, future-ready lighting solutions.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation in LED structural components. With over two decades of expertise, Beauty STC delivers precision-engineered aluminum channels, polycarbonate and acrylic diffusers, and complete linear lighting systems designed specifically for the demands of commercial and industrial environments. Backed by a commitment to quality, sustainability, and global compliance, Beauty STC continues to set the standard for performance-driven lighting infrastructure trusted by professionals worldwide.

Technical Specs & Certifications

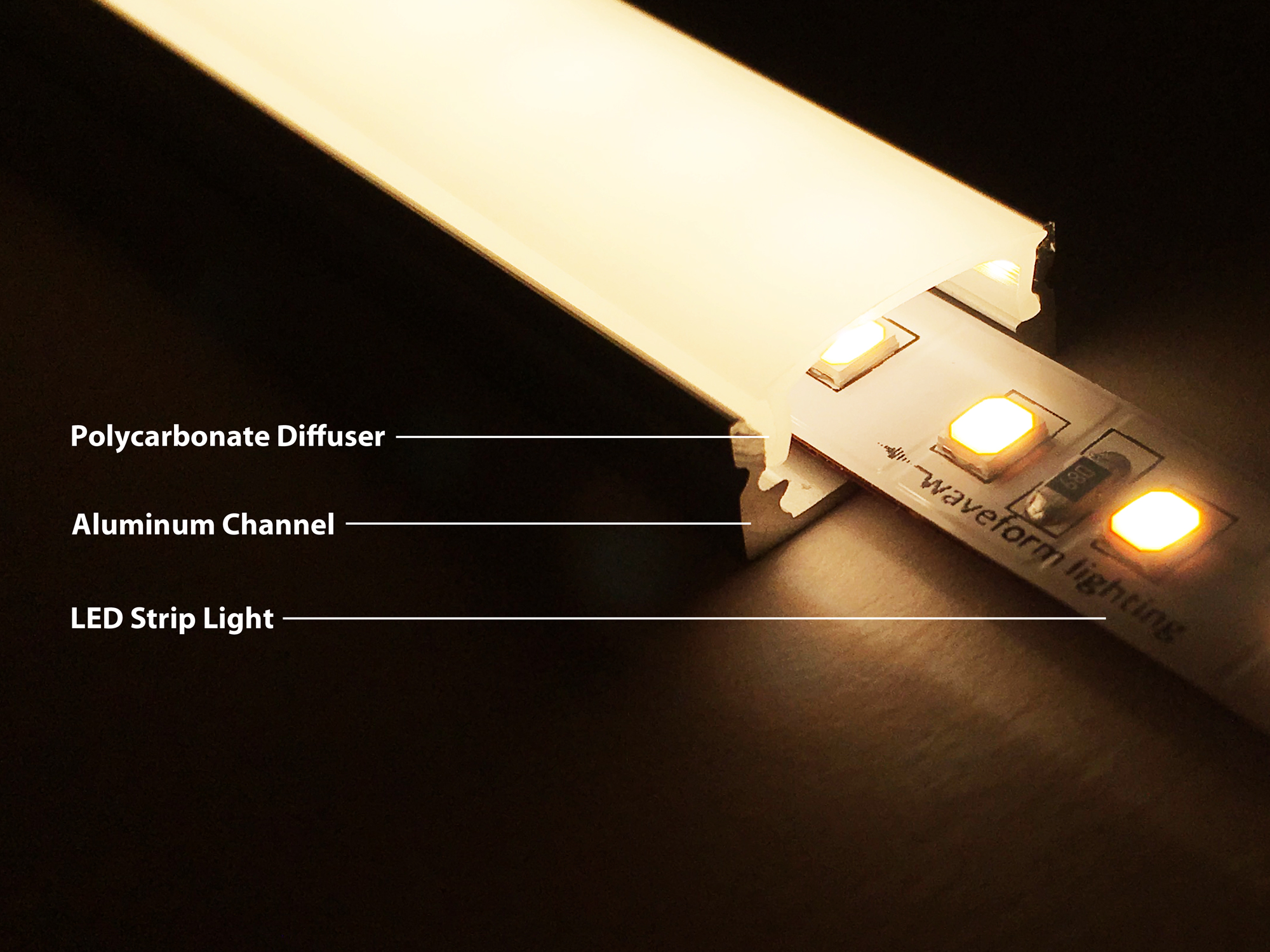

LED channels and diffusers are passive components within an integrated lighting system; they do not generate lumens or consume watts themselves. Their technical specifications directly influence the performance, efficiency, and optical quality of the LED light engine they house. At Beauty STC Manufacturing Co., Ltd., we engineer these components to maximize system-level performance, ensuring compatibility with high-efficiency LED modules while meeting stringent optical and environmental requirements.

Lumens per Watt (lm/W) is a metric for the LED light source, not the channel or diffuser. However, our extruded aluminum LED channels are designed with thermal management as a core principle. Precision-engineered heat sink profiles and thermally conductive anodized finishes ensure optimal heat dissipation from the LED strip, preventing lumen depreciation and maintaining the rated lm/W output over the product’s lifespan. Poor thermal design in channels can reduce system efficacy by 15-20%; Beauty STC channels consistently support maintaining >95% of initial lm/W output under continuous operation. Our diffusers utilize proprietary high-transmission optical-grade PMMA or PC materials, achieving light transmission rates of 92-95%. This minimizes optical loss compared to standard diffusers (typically 85-90%), effectively preserving the luminaire’s overall system efficiency without compromising glare control.

Color Rendering Index (CRI) is determined by the LED chip and phosphor formulation, but diffuser quality critically impacts perceived color fidelity. Beauty STC diffusers are manufactured using ultra-clear, UV-stabilized materials with nanoscale surface texturing. This technology prevents yellowing, spectral filtering, or color shift over time, ensuring the maintained CRI consistently exceeds 90 (Ra) and reaches 95+ for R9 (saturated red) in compatible LED systems. Unlike lower-quality diffusers that absorb specific wavelengths, our materials are spectrally neutral, preserving the LED’s original color accuracy and preventing CRI degradation even after 50,000 hours of use. This is rigorously validated through third-party LM-79 testing of complete luminaires using our components.

IP Ratings define ingress protection for the entire luminaire assembly. Beauty STC channels and diffusers are engineered as system solutions to achieve specific IP classifications. Our IP20 indoor channels feature seamless snap-fit joints and precision-tolerance diffuser slots that prevent dust ingress at critical seams. For wet-location applications, IP65 and IP67-rated channels incorporate dual silicone gasket systems: one between the channel body and mounting surface, and another between the diffuser and channel lip. Diffusers for these ratings use impact-resistant polycarbonate with integrated sealing ribs, ensuring no water penetration during heavy spray or temporary submersion testing. All IP-rated assemblies undergo 100% post-production pressure testing per IEC 60529 standards, not just sample validation.

Beauty STC’s quality commitment is embedded in material science and process control. Our aluminum channels use 6063-T5 alloy with aerospace-grade anodization (15-25μm thickness), resisting corrosion in saline environments. Diffusers are produced via injection molding with <0.05mm dimensional tolerance, eliminating light leaks or uneven illumination. Every batch undergoes spectrophotometric validation for clarity and UV resistance, plus thermal cycling tests from -40°C to +85°C. This results in diffusers retaining >98% light transmission after 1,000 hours of UV exposure—exceeding ISO 4892-2 standards. Unlike generic suppliers, Beauty STC provides full traceability from raw material certificates to final assembly test reports, ensuring every component meets our zero-defect manufacturing philosophy for critical architectural and retail lighting applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility dedicated to the production of high-quality LED lighting components and systems. Strategically located in the Guangdong province, the Jiangmen factory benefits from strong regional manufacturing infrastructure and proximity to key supply chains, enabling efficient operations and timely delivery.

The factory is outfitted with advanced surface mount technology (SMT) production lines that ensure precision and consistency in assembling LED components. These SMT machines are capable of handling high-volume production with tight tolerances, supporting the placement of small and complex LED chips onto PCBs efficiently and reliably. The automated SMT process enhances product quality, reduces human error, and increases throughput, making it ideal for both standard and custom LED lighting solutions.

To ensure long-term performance and reliability, the factory conducts comprehensive aging tests on finished products. These tests simulate extended operational conditions by subjecting LED channels, diffusers, and assembled lighting units to prolonged operation under controlled thermal and electrical stresses. This rigorous quality control step allows Beauty STC to identify early failures, verify thermal management performance, and guarantee that products meet or exceed industry standards before they reach customers.

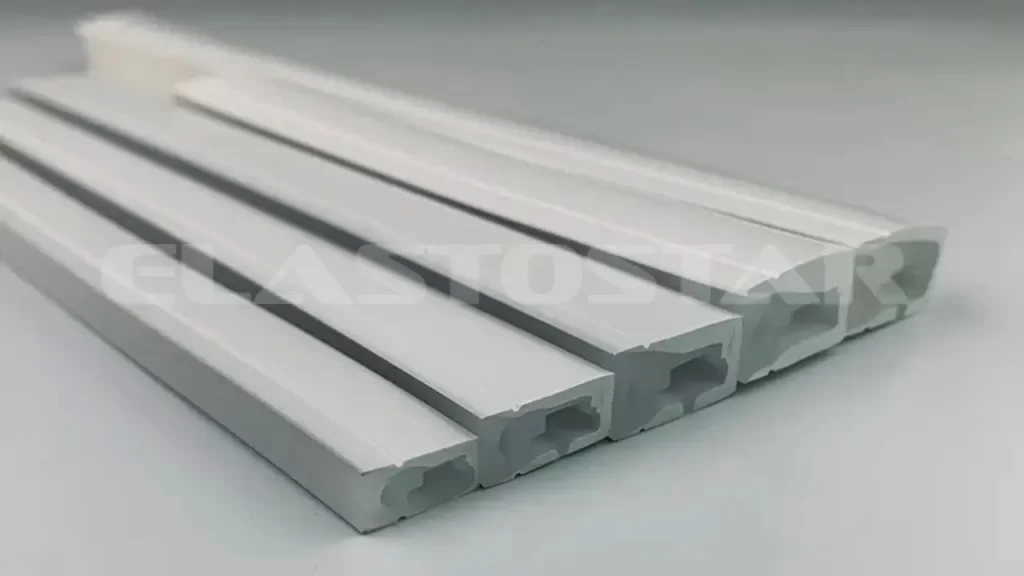

Beauty STC also offers strong OEM (Original Equipment Manufacturer) capabilities, particularly for LED channels and diffusers. The company works closely with clients to customize profiles, dimensions, materials, and finishes according to specific project requirements. Whether it’s aluminum extrusion for LED channels or polycarbonate or PMMA diffusers with varying light transmission and diffusion properties, the factory supports end-to-end development—from design and prototyping to mass production. This flexibility, combined with in-house tooling and molding capabilities, enables Beauty STC to deliver tailored solutions efficiently and cost-effectively for global partners in architectural, commercial, and residential lighting markets.

Application Scenarios

LED channels and diffusers are essential components in professional lighting installations across commercial environments, providing both functional and aesthetic benefits. Their primary purpose is to house LED strips securely, manage heat dissipation, and most critically, transform the inherently point-source nature of individual LEDs into a smooth, uniform, continuous line of light by eliminating visible hotspots and dark spots between diodes. This creates a high-quality, visually comfortable illumination that is crucial for premium commercial spaces.

In hotel environments, LED channels with diffusers are indispensable for creating the desired ambiance and functionality. They are extensively used in architectural cove lighting within lobbies and corridors to provide soft, indirect illumination that guides guests while establishing a welcoming atmosphere. Guest room headboards often feature integrated channels with diffusers for gentle, glare-free task lighting. Bathroom mirrors benefit significantly from perimeter or back-of-mirror channel installations with high-clarity diffusers, ensuring even, shadow-free illumination for grooming. High-end suites and spa areas utilize them for step lighting, under-counter lighting, and within custom millwork to enhance luxury without visual distraction. The diffuser choice here is typically opal or prismatic, balancing diffusion with light output to maintain a warm, inviting feel without compromising on light quality.

For shopping malls and retail environments, the application focuses on visual merchandising and navigational clarity. LED channels and diffusers are fundamental in creating seamless, high-impact cove lighting throughout main concourses and atriums, providing uniform ambient light that enhances the space’s grandeur and directs customer flow. Display windows and storefronts rely heavily on channels with diffusers for top or back lighting of products, ensuring merchandise is showcased evenly without distracting glare or hotspots. Within individual retail stores, they are used for shelf lighting, signage backlighting, and feature walls where consistent light distribution is critical for product presentation. Checkout counters and service desks also employ them to provide functional task lighting that appears integrated and professional. Retail settings often demand diffusers with higher clarity, such as prismatic or micro-prismatic types, to maximize light output onto merchandise while still maintaining uniformity.

Office buildings utilize LED channels and diffusers to promote productivity and visual comfort in workspaces. They are commonly installed in suspended ceiling coves for indirect ambient lighting, reducing glare on computer screens and creating a more spacious feel in open-plan offices. Perimeter cove lighting in boardrooms and executive offices provides sophisticated, shadow-free illumination ideal for presentations and video conferencing. Under-cabinet task lighting in kitchenettes and reception desks uses channels with diffusers to deliver functional light without harsh reflections. Feature walls, stairwells, and elevator lobbies also benefit from the clean, uniform lines achievable with properly diffused channel lighting. Offices typically prioritize diffusers that offer excellent uniformity and minimal glare, such as opal or satin finishes, to support prolonged visual tasks and reduce eye strain.

Installation requires careful attention to detail for optimal performance. Always select a channel profile and diffuser material specifically matched to the LED strip’s lumen output, color temperature, and beam angle; mismatched components lead to visible dots or excessive light loss. Ensure the channel is securely mounted to a stable surface using appropriate fasteners spaced no more than 500mm apart to prevent sagging, especially in longer runs. Allow for thermal expansion by incorporating small gaps between channel sections or using expansion joints in runs exceeding 3 meters, as aluminum channels expand significantly when heated. Maintain perfect alignment between channel sections using splicing connectors to avoid light leakage or visual breaks. When installing diffusers, ensure they are fully seated and snapped into the channel groove along their entire length; partial seating causes uneven diffusion and visible gaps. For critical applications, conduct an on-site mock-up with the actual LED strip and diffuser to verify the light quality meets expectations before full-scale installation. Finally, always follow the LED strip manufacturer’s guidelines regarding maximum run lengths and power injection points to prevent voltage drop, which manifests as dimming at the end of the run and cannot be corrected by the diffuser. Proper installation ensures the lighting system delivers the intended aesthetic quality, longevity, and performance across these demanding commercial settings.

Why Choose Beauty STC Lighting

Discover premium LED channels and diffusers designed for seamless integration and superior light performance. At Beauty STC, we specialize in high-quality aluminum profiles and optical-grade diffusers that enhance the aesthetics and efficiency of any lighting application. Partner with Beauty STC to access custom solutions, reliable manufacturing, and expert technical support. For inquiries and collaboration opportunities, contact us at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.