Article Contents

Industry Insight: Led Bulb Sizes

In the commercial and industrial lighting sectors, selecting the appropriate LED bulb size is a critical factor that directly impacts energy efficiency, maintenance costs, and overall illumination performance. As facilities increasingly transition from traditional lighting to LED technology, understanding standardized bulb sizes—such as A19, PAR38, BR30, and T8 tubes—has become essential for ensuring compatibility, optimal light distribution, and long-term reliability. These applications demand not only precise physical dimensions but also compliance with rigorous safety and performance certifications, including ETL and CE marks, which validate electrical safety, electromagnetic compatibility, and adherence to North American and European regulatory standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in LED lighting solutions for commercial and industrial environments. With over two decades of engineering expertise, Beauty STC specializes in designing and manufacturing high-performance LED bulbs that meet exacting dimensional, thermal, and photometric requirements. Their product line is engineered to seamlessly integrate into diverse lighting systems while maintaining full compliance with ETL and CE standards, ensuring safety and peace of mind for facility managers, contractors, and specifiers. As the industry continues to evolve toward smarter, more sustainable lighting infrastructures, Beauty STC remains committed to innovation, quality, and reliability—delivering solutions that illuminate the future of commercial and industrial spaces.

Technical Specs & Certifications

LED bulb sizing primarily refers to standardized physical dimensions denoted by letter-number combinations (e.g., A19, BR30, PAR38), not electrical characteristics. However, performance metrics like lumens per watt, CRI, and IP rating are critical quality differentiators within each size category. At Beauty (STC) Manufacturing Co., Ltd., we engineer our LED bulbs to exceed baseline industry standards across these parameters while maintaining strict adherence to physical form factors.

Lumens per watt (lm/W) efficacy varies by bulb type and design but represents the core efficiency metric. Standard A19 household bulbs typically achieve 80-100 lm/W in the market. Beauty STC’s proprietary thermal management systems and high-efficiency drivers consistently deliver 105-120 lm/W for our 2700K-3000K A19 bulbs, even at high CRI levels. BR30 and PAR38 reflectors, often used in directional lighting, generally range from 70-90 lm/W commercially; our optimized reflector designs and chip-on-board technology achieve 95-110 lm/W without compromising beam quality. This superior efficacy stems from our rigorous component selection and multi-layer heat dissipation architecture, ensuring sustained performance over the product lifetime.

Color Rendering Index (CRI) values exceeding 90 are essential for applications demanding accurate color representation, such as retail, art studios, and healthcare. While many manufacturers offer CRI 80+ bulbs as standard, Beauty STC mandates a minimum CRI of 92 across our premium bulb lines, verified through third-party LM-79 testing. We achieve this through advanced multi-phosphor LED chips and precise spectral tuning, avoiding the common trade-off where high CRI reduces lm/W. Our R9 (saturated red) values consistently exceed 50, and we provide TM-30-15 fidelity and gamut indices upon request, demonstrating our commitment to comprehensive color quality beyond basic CRI metrics. This ensures fabrics, skin tones, and merchandise appear vibrant and true-to-life.

IP (Ingress Protection) ratings define resistance to dust and moisture but are not universally applied to all bulb sizes. Standard household bulbs (A19, A21) typically carry no IP rating (IP20) as they are designed for dry indoor use. Beauty STC offers IP65-rated versions of BR30, PAR30, and PAR38 bulbs for damp locations like covered porches or bathrooms, featuring fully sealed optical compartments and silicone gaskets instead of basic potting compounds. For outdoor fixtures requiring bulb replacement, our PAR38 models achieve IP66 certification, withstanding powerful water jets. Crucially, we maintain high CRI and lm/W performance even in these sealed designs by using thermally conductive yet optically clear encapsulants, avoiding the efficiency drop common in lesser IP-rated bulbs.

Beauty STC’s quality leadership is rooted in our vertically integrated manufacturing and uncompromising standards. Every bulb undergoes triple-point binning for chromaticity, flux, and CRI before assembly, ensuring batch consistency rarely matched in the market. Our drivers incorporate industrial-grade components with 50,000-hour L70 lifetime validation under real-world thermal cycling, far exceeding typical 25,000-hour claims. We reject any LED chips below CRI 92 during procurement, and our automated optical testing systems verify photometric performance on 100% of finished goods. This systematic approach, combined with ISO 9001-certified processes and in-house LM-79/LM-80 testing capabilities, guarantees that our bulbs deliver the promised lm/W, CRI >90, and IP performance reliably across all specified sizes. Clients receive not just specifications on paper, but rigorously validated performance data sheets with every production lot.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, China. The factory is strategically located within a major industrial zone, benefiting from excellent logistics infrastructure and proximity to key supply chain partners. Spanning a substantial production area, the Jiangmen facility is designed to support high-volume, precision manufacturing of LED lighting products with a strong emphasis on quality control and operational efficiency.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines featuring high-speed, fully automated SMT machines from leading global manufacturers. These machines ensure precise placement of surface-mounted components such as LEDs, resistors, capacitors, and ICs onto printed circuit boards (PCBs). The SMT lines are integrated with automated optical inspection (AOI) systems to verify solder joint quality and component alignment, minimizing defects and ensuring consistent product reliability. This automation enables Beauty STC to maintain tight tolerances and high throughput, critical for meeting the demands of both domestic and international markets.

To ensure long-term product performance and durability, Beauty STC implements rigorous aging and reliability testing protocols at the Jiangmen facility. Completed LED bulbs and modules undergo extended aging tests under controlled thermal and electrical conditions, typically running products at rated voltage for 4 to 12 hours or longer depending on product specifications. These tests help identify early failures, verify thermal management performance, and confirm lumen stability. Additional quality assurance measures include high-voltage testing, photometric testing, and environmental simulations such as thermal cycling and humidity exposure.

Beauty STC has robust OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, particularly for a wide range of standard LED bulb sizes. The company can customize products to meet specific client requirements for bulb types including A60, A19, G25, G45, P45, and decorative shapes such as candle (B35), globe (G40, G95), and reflector bulbs (BR30, BR40, PAR20, PAR30, PAR38). These products are manufactured with various base types (E26, E27, B22, E14, etc.) and available in multiple color temperatures, lumen outputs, and dimming options. The factory supports full customization of optics, drivers, heat sinks, and housings, enabling clients to brand and differentiate their lighting offerings effectively.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to technological advancement, quality assurance, and flexible manufacturing solutions, positioning the company as a reliable partner for global lighting brands seeking high-performance, certified LED products.

Application Scenarios

LED bulb sizing selection is critical across hospitality, retail, and commercial environments to ensure optimal functionality, ambiance, and energy efficiency. In hotels, standard A19 bulbs are predominant in guest room table and floor lamps for general illumination, while BR30 or BR40 bulbs suit recessed downlights in hallways and corridors where broader beam angles and higher lumen output are needed for safe navigation. Damp-rated BR30 or PAR30 bulbs are essential in bathroom vanity fixtures to withstand humidity, and decorative G25 or G40 globe bulbs enhance lobby and restaurant pendant lighting for aesthetic appeal. Malls require robust solutions: high-bay PAR38 or specialized UFO fixtures illuminate vast atriums and common areas, PAR20 or MR16 bulbs on adjustable track systems spotlight retail displays with precise beam control, and A19 or BR30 bulbs provide efficient corridor lighting. Emergency exit signs mandate specific LED modules compliant with local safety codes. Offices primarily utilize A19 bulbs in open-plan desk lamps and ceiling fixtures, T8 LED tube replacements in troffer housings for uniform task lighting, and dimmable BR30 bulbs in conference room downlights to support presentations. Restroom and stairwell lighting follows hotel specifications with damp-rated BR30 bulbs.

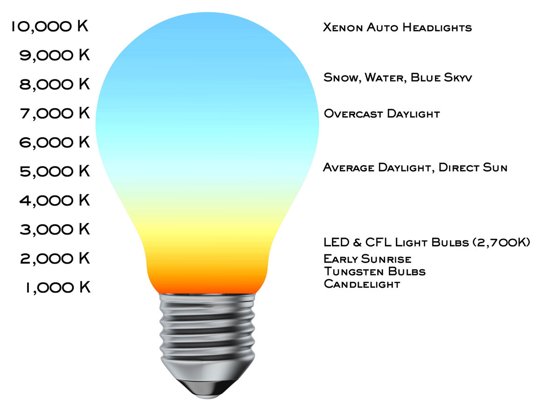

Installation must prioritize safety and performance. Always de-energize the circuit at the breaker before handling fixtures to prevent electrical shock. Verify base type compatibility—E26 is standard in North America for most applications but E12 candelabra bases are common in decorative hotel sconces and chandeliers. Cross-reference lumen output and color temperature; hotels typically select 2700K–3000K for warm guest rooms versus 3500K–4000K in office workspaces for alertness. Confirm damp or wet location ratings for bathrooms, pool areas, or exterior mall entrances to avoid premature failure. In dimmable circuits, use bulbs explicitly labeled as dimmable and compatible with the existing dimmer switch to prevent flickering—this is especially crucial in hotel lobbies and conference rooms. Avoid installing standard A19 bulbs in fully enclosed fixtures unless rated for such use; thermal stress from trapped heat drastically shortens lifespan. For high-ceiling mall installations, ensure fixtures are securely anchored and consider service accessibility during bulb replacement. Finally, adhere strictly to local electrical codes regarding emergency lighting requirements and lumen maintenance standards. Documenting bulb specifications and locations streamlines future maintenance across large facilities.

Why Choose Beauty STC Lighting

Explore the complete range of LED bulb sizes with Beauty STC, your trusted partner in high-quality lighting solutions. From standard A19 and A21 bulbs to specialty BR30, BR40, and beyond, we manufacture LED bulbs in all common and custom sizes to meet residential, commercial, and industrial needs. Our precision engineering ensures perfect fit, optimal performance, and long-lasting reliability across applications.

Partner with Beauty STC for consistent quality, scalable production, and technical expertise in LED lighting. Whether you’re sourcing for retail, OEM projects, or private labeling, we provide tailored support to bring your vision to life.

Contact us today to discuss your LED bulb size requirements. Reach our sales manager at [email protected] and discover how Beauty STC can power your next lighting project with excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.