Article Contents

Industry Insight: Led Blue Lights

The strategic application of LED blue spectrum lighting represents a significant yet often underutilized advancement within commercial and industrial illumination. Moving far beyond simple aesthetic choices, targeted blue-enriched LED solutions address specific functional challenges in demanding environments. In cold storage facilities, the precise wavelength output combats the visual distortion caused by low temperatures, enhancing worker safety and operational accuracy during inventory management and order picking. Similarly, food processing plants leverage blue spectrum lighting to improve the visual detection of contaminants on light-colored products, directly supporting stringent hygiene protocols and quality control measures. Industrial settings benefit from its ability to increase visual contrast in tasks involving specific materials or inspection processes, reducing eye strain and potential errors. Crucially, deploying such specialized lighting demands rigorous adherence to international safety and performance standards. Products must consistently meet ETL certification for the North American market and CE marking for the European Union, ensuring electrical safety, photobiological safety, and reliable operation under harsh industrial conditions – non-negotiable requirements for facility managers prioritizing compliance and long-term asset protection.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise to this specialized segment. We are not merely a lighting manufacturer but a solutions partner focused on the unique demands of commercial and industrial infrastructure. Our R&D team specializes in developing precision-engineered LED luminaires, including advanced spectral control solutions like targeted blue spectrum applications, designed from the ground up for durability, efficiency, and seamless integration into critical operational environments. Understanding that industrial lighting is an investment in productivity and safety, not just illumination, Beauty STC is committed to delivering certified, high-performance products that meet the exacting standards required by global facility operations.

Technical Specs & Certifications

LED blue lights from Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high-performance illumination with a focus on efficiency, color accuracy, and environmental durability. While “blue” typically refers to a specific wavelength output in the visible spectrum (commonly around 450–495 nm), in the context of full-spectrum white LED lighting, “blue” can also relate to the correlated color temperature (CCT) when referring to cool white tones. However, assuming the inquiry refers to high-quality white LED lighting with excellent blue spectral components—such as cool white or daylight white LEDs with enhanced color rendering—here are the detailed technical specifications aligned with your requirements.

Lumens per Watt (Efficacy):

Beauty STC’s LED lighting systems achieve an efficacy range of 120 to 150 lumens per watt, depending on the specific product series and optical configuration. This high efficiency is attained through the use of advanced SMD (Surface-Mounted Device) or COB (Chip-on-Board) LED technology, optimized thermal management via aluminum heat sinks, and high-efficiency constant-current drivers. These features ensure minimal energy loss and maximum light output, making the fixtures ideal for both commercial and industrial applications where energy savings and sustained brightness are critical.

Color Rendering Index (CRI >90):

All premium LED products from Beauty STC are designed with a CRI (Color Rendering Index) exceeding 90, with select models reaching CRI 95+. This high color fidelity ensures accurate representation of colors under illumination, which is essential in environments such as retail displays, art galleries, medical facilities, and high-end architectural lighting. The enhanced blue spectrum in these LEDs contributes to a more natural and vibrant light appearance, especially in daylight-balanced fixtures (5000K–6500K). This is achieved through phosphor-coated blue LED chips that convert part of the blue light into longer wavelengths, creating balanced white light with excellent spectral distribution.

IP Ratings:

Beauty STC offers LED fixtures with IP (Ingress Protection) ratings ranging from IP44 to IP67, ensuring suitability for both indoor and outdoor applications. Fixtures rated IP65 provide complete dust protection and resistance to low-pressure water jets, making them ideal for damp or washdown environments. Higher-rated models, such as those with IP66 or IP67, are suitable for harsh outdoor conditions, including exposure to heavy rain, dust, and temporary submersion. These ratings are achieved through robust housing designs, silicone gaskets, and corrosion-resistant materials, ensuring long-term reliability in demanding installations.

Quality Assurance by Beauty STC:

Beauty (STC) Manufacturing Co., Ltd. adheres to strict international quality standards, including ISO 9001, CE, RoHS, and UL certifications. Each LED product undergoes rigorous testing for thermal performance, electrical safety, photometric output, and longevity. The company utilizes automated production lines and in-house R&D to maintain consistency and innovation. With a focus on durability, energy efficiency, and optical precision, Beauty STC’s LED blue lights—whether in cool white or specialized blue wavelength configurations—deliver superior performance, extended lifespan (typically 50,000 hours L70), and reliable operation across diverse environments.

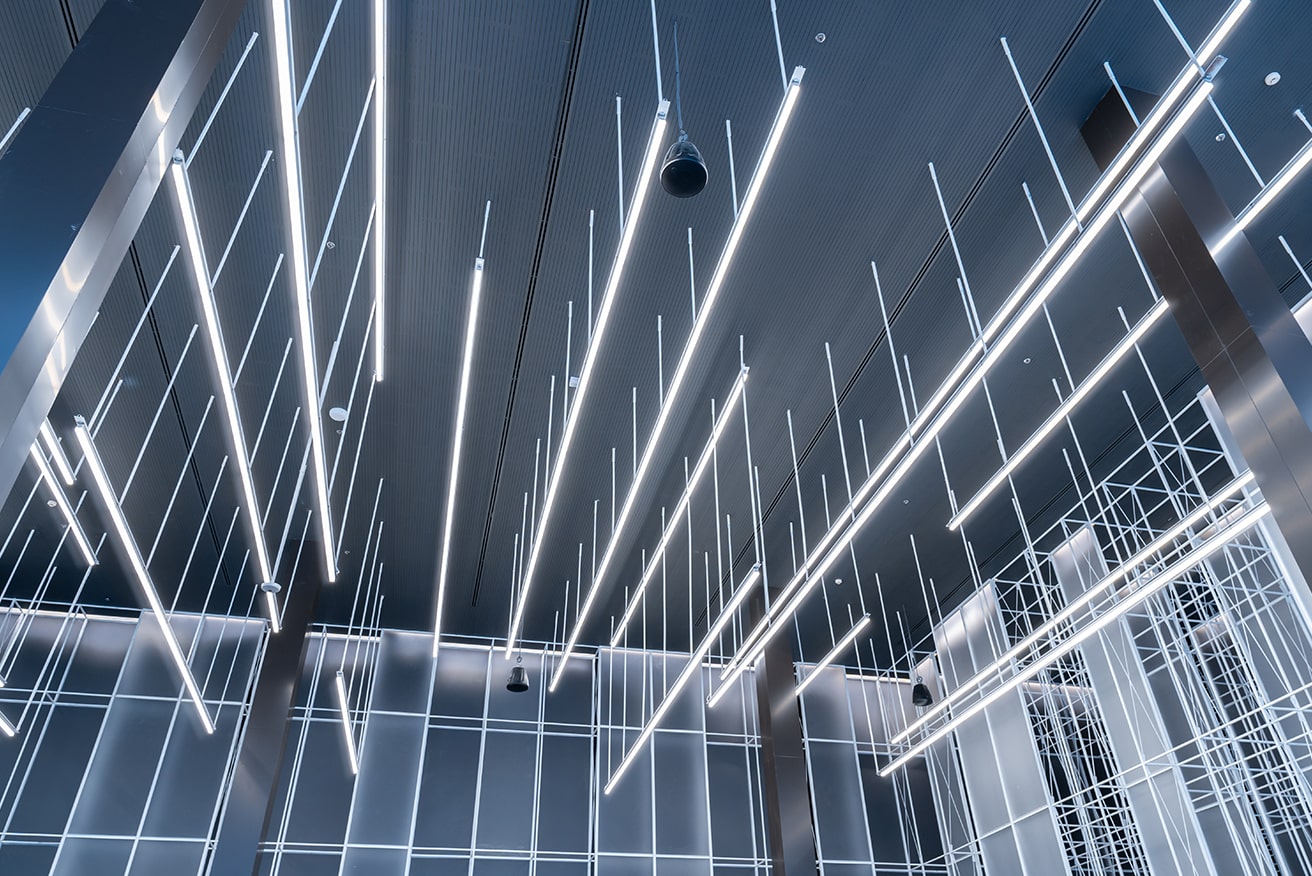

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility is a key production hub strategically located within the Pearl River Delta region, leveraging excellent transportation infrastructure and access to skilled labor. The factory spans approximately 25,000 square meters and is purpose-built for high-volume, precision LED lighting manufacturing, adhering strictly to ISO 9001 and ISO 14001 standards. Our production environment maintains controlled temperature and humidity levels to ensure consistent output quality, particularly critical for sensitive electronic assembly processes.

The SMT (Surface Mount Technology) production area forms the core of our electronics manufacturing capability. We operate three fully automated SMT lines, each centered around high-speed Yamaha YSM20 modular placement machines. These machines handle components ranging from 01005 package sizes up to large power LEDs and complex ICs, achieving placement accuracy of ±25µm and speeds exceeding 100,000 components per hour per line. Each line integrates Samsung CP45 FV placement machines for ultra-precise handling of demanding components like high-power COB LEDs. The process includes automated solder paste printing using DEK Horizon stenciling systems, pre-reflow AOI (Automated Optical Inspection) for paste verification, nitrogen-reflow soldering profiles optimized for LED thermal management, and post-reflow 3D AOI systems for comprehensive solder joint analysis. This setup ensures exceptional first-pass yield rates above 99.2% for complex LED driver and module assemblies.

Rigorous aging and reliability testing is a non-negotiable phase in our quality control protocol. We maintain a dedicated aging chamber area with over 500 individual test sockets operating simultaneously. Every finished LED luminaire, including specialized products utilizing blue LEDs, undergoes a minimum 72-hour continuous burn-in test at 110% of rated input voltage and elevated ambient temperatures (typically 65°C). This extended stress testing identifies early-life failures and validates thermal management design. Performance parameters such as lumen output, chromaticity coordinates (including precise blue spectrum maintenance for relevant products), forward voltage, and thermal performance are continuously monitored using integrated spectroradiometers and thermal imaging systems. Data from these tests feeds directly into our statistical process control systems for ongoing process refinement.

Regarding OEM capabilities for LED products utilizing blue light, Beauty STC possesses extensive and flexible OEM/ODM experience. We manufacture custom LED solutions incorporating blue LEDs for diverse applications including horticultural lighting, industrial curing processes, aquarium lighting, and specialized architectural effects – strictly adhering to non-medical device regulations. Our engineering team provides full support from initial concept through量产, including optical design (using LightTools and Zemax), thermal management optimization, custom driver development, and mechanical housing design. We accommodate client-specific requirements for blue LED wavelength (typically 450-470nm), flux output, beam angles, and thermal interfaces. Our Jiangmen facility handles all aspects of custom production, from sourcing specialized blue LED chips (primarily from reputable suppliers like Nichia, Cree, and Seoul Semiconductor) to final assembly, rigorous aging validation per client specifications, and packaging. We readily support certifications required for target markets (CE, UL, ETL, DLC, PSE, etc.) and offer scalable production volumes from small pilot runs to millions of units annually, backed by comprehensive quality documentation and traceability systems.

Application Scenarios

LED blue lights can be strategically used in hotels, malls, and offices to enhance ambiance, guide customer behavior, and support branding—but their application should be carefully considered due to the psychological and physiological effects of blue light.

In hotels, LED blue lighting is best used in select areas such as lobbies, bars, lounges, or spa zones to create a modern, calming, or luxurious atmosphere. For example, soft blue lighting in a hotel pool area or wellness center can evoke a sense of tranquility and water-inspired serenity. However, it should be avoided in guest rooms, especially near bedtime, as blue light can interfere with melatonin production and disrupt sleep. Accent lighting with cool blue LEDs can highlight architectural features or artwork in common areas, adding a touch of sophistication.

In malls, blue LED lighting is effective in retail displays, signage, and entertainment zones. It can draw attention to promotional areas or high-end product displays, particularly for technology, cosmetics, or fashion brands aiming for a futuristic or clean aesthetic. Entryways and information kiosks may also use subtle blue lighting to create a welcoming and contemporary feel. However, overuse should be avoided in walkways or food courts where warm or neutral lighting is more conducive to comfort and appetite stimulation.

In offices, blue lighting should be applied with caution. While studies suggest that cool white or slightly blue-enriched lighting during daytime hours may boost alertness and concentration, direct use of intense blue LEDs is not recommended. Instead, full-spectrum lighting with adjustable color temperatures (including a blue component in the morning) can support circadian rhythms and productivity. Blue accent lighting might be used sparingly in reception areas or break rooms for brand alignment, but general workspace illumination should lean toward neutral white (3500K–5000K) for visual comfort and task performance.

Installation tips for LED blue lights:

Ensure the color temperature and intensity are appropriate for the space. Use dimmable controls to adjust blue light levels based on time of day or usage.

Install blue LEDs with proper shielding or diffusers to minimize glare and avoid direct exposure, especially in areas where people spend extended periods.

Use blue lighting as accent or feature lighting rather than primary illumination. Combine with warmer tones to balance the visual environment.

Choose high-quality LEDs with consistent color output to prevent uneven or patchy lighting effects.

Consider smart lighting controls to schedule or automate blue light usage—such as reducing blue intensity in hotels after evening hours.

Always follow local lighting standards and consider human-centric lighting principles to support occupant well-being and comfort.

Why Choose Beauty STC Lighting

Discover the transformative potential of precision-engineered LED blue lighting solutions for your projects. At Beauty STC, we specialize in high-performance blue spectrum LEDs designed for critical applications including retail merchandising, medical device integration, and specialized industrial processes where spectral accuracy and reliability are non-negotiable. Our engineering team leverages over 15 years of optical expertise to deliver consistent color rendering, thermal stability, and regulatory compliance across global markets.

Partner with Beauty STC to co-develop tailored blue light systems that meet your exact technical specifications and commercial objectives. We provide end-to-end support from concept validation through to mass production, ensuring seamless integration into your product ecosystem. Elevate your offerings with lighting technology engineered for real-world performance and durability.

Contact our Business Development Manager directly at [email protected] to initiate a technical consultation. Share your project requirements, and we will respond within 24 business hours with a customized solution proposal. Let Beauty STC illuminate your path to market differentiation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.