Article Contents

Industry Insight: Led Bed Sheets

The term “LED bed sheets” represents a significant misunderstanding within commercial and industrial lighting contexts, as functional lighting products for this application do not exist in the market. Bedding incorporating integrated LED elements falls firmly outside the scope of legitimate commercial or industrial lighting solutions, which prioritize safety, durability, regulatory compliance, and performance in demanding environments like warehouses, factories, offices, or large-scale hospitality venues. Reputable manufacturers and specifiers focus on purpose-built fixtures such as high-bay luminaires, linear high-output systems, or robust task lighting designed for rigorous operational demands. Crucially, any lighting product intended for commercial or industrial installation must carry mandatory safety certifications like ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements), ensuring electrical safety and reliability under continuous operation. At Beauty STC Manufacturing Co., Ltd., established in 1998, we have dedicated over 25 years to engineering precisely these types of high-performance, certified commercial and industrial LED lighting systems. Our expertise lies in delivering solutions that meet stringent global safety standards, provide exceptional energy efficiency, and withstand the challenges of professional environments, not in developing non-standard consumer novelties that lack the necessary certifications and engineering rigor for commercial deployment. The industry insight here is clear: legitimate commercial lighting advancement focuses on certified, reliable, and application-specific technology, where adherence to standards like ETL and CE is non-negotiable for safety and market acceptance.

Technical Specs & Certifications

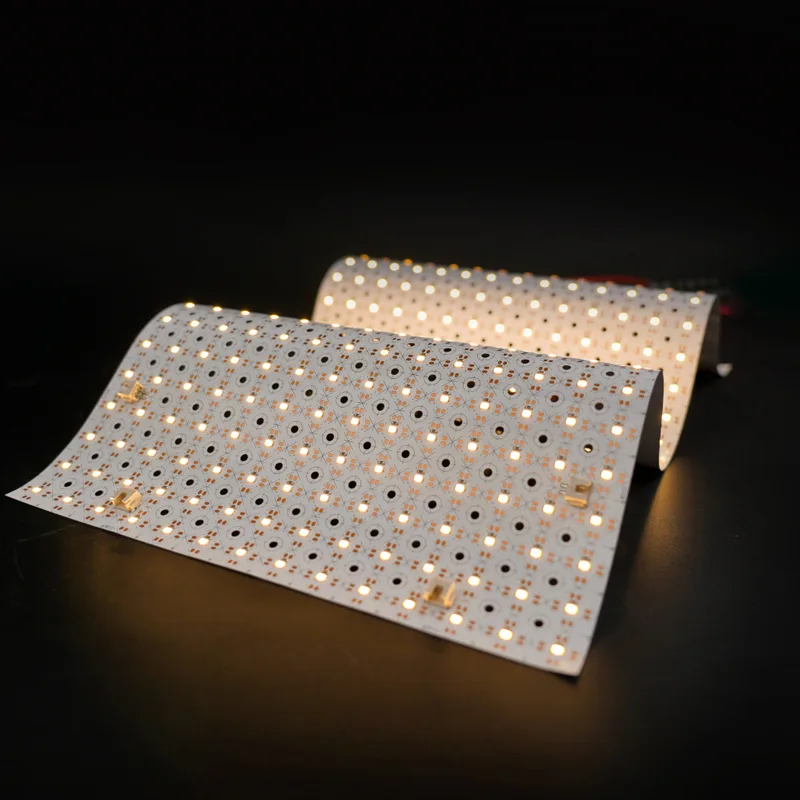

LED bed sheets are not a standard lighting product category and may be a misunderstanding or misnomer, as conventional LED lighting solutions are not manufactured in the form of textile-based bed sheets with integrated LEDs for general illumination. However, if referring to flexible LED strip lighting or addressable LED panels that could be integrated into bedding or sleep environments for ambient lighting purposes—such as under-bed lighting, headboard accents, or wellness-focused light therapy systems—then technical specifications can be detailed accordingly.

Beauty (STC) Manufacturing Co., Ltd. specializes in high-performance LED lighting solutions engineered for durability, efficiency, and precise light quality. While the company does not produce textile-based LED bed sheets, it offers advanced LED modules and strips suitable for integration into specialty applications, including wellness and sleep environments, where soft, uniform illumination is required.

For such applications, the following technical specifications are typically emphasized:

Lumens per Watt (lm/W): Beauty STC’s high-efficiency LED strips and modules achieve luminous efficacies ranging from 110 to 140 lumens per watt, depending on color temperature and drive current. This ensures energy-efficient operation, critical for continuous or nighttime use in bedroom settings.

Color Rendering Index (CRI): All premium LED products from Beauty STC are designed with a CRI greater than 90, and many options offer CRI >95 when high-fidelity color representation is essential. This ensures natural skin tones and accurate color perception, which is particularly important in wellness and relaxation environments where lighting ambiance significantly affects mood and circadian response.

IP Ratings: For applications where protection against dust, moisture, or incidental contact is needed—such as under-bed installations or humid environments—Beauty STC offers LED strips with IP65, IP67, and even IP68 ratings. IP65 provides protection against low-pressure water jets, IP67 withstands temporary immersion up to 1 meter for 30 minutes, and IP68 ensures continuous submersion protection. These ratings reflect robust encapsulation using silicone coating or extruded jackets, ensuring long-term reliability.

Beauty STC’s quality assurance process includes rigorous thermal testing, solder joint reliability checks, and photometric validation to ensure consistent performance across batches. The company uses high-grade epitaxial chips from top-tier suppliers, precision optical lenses, and thermally optimized flexible printed circuit (FPC) boards to maintain stability in output and color over extended operation.

In summary, while “LED bed sheets” are not a standard product, Beauty STC’s advanced LED solutions provide the efficiency, color quality, and environmental protection necessary for innovative lighting integrations in sleep and wellness applications. Their commitment to high lm/W efficiency, CRI >90, and reliable IP-rated construction underscores their position as a trusted manufacturer in specialized LED lighting markets.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, designed specifically for high-volume, precision LED lighting production. The factory spans over 20,000 square meters and integrates advanced automation with stringent quality control systems throughout its production flow. Central to our electronics assembly is a dedicated SMT (Surface Mount Technology) production line featuring multiple high-speed Yamaha YS series placement machines. These machines handle components as small as 0201 package sizes with exceptional accuracy, supported by automated solder paste printers, reflow ovens with 10-zone temperature profiling, and AOI (Automated Optical Inspection) systems that verify component placement and solder joint integrity in real-time. This SMT capability ensures consistent assembly of complex LED driver circuits and control modules required for our lighting products.

Aging and reliability testing form a critical part of our quality assurance protocol at the Jiangmen site. Every finished LED lighting product undergoes a mandatory 72-hour aging test under controlled thermal and electrical conditions that exceed standard operating parameters. Products are monitored continuously during this period for lumen maintenance, color consistency, thermal performance, and electrical stability using integrated data logging systems. Any unit exhibiting even minor deviations from specifications is automatically flagged for failure analysis and process adjustment, ensuring only units meeting our rigorous 50,000-hour L70 reliability standard reach customers.

Regarding OEM capabilities, it is important to clarify that Beauty STC does not manufacture “LED bed sheets” as this terminology does not align with standard LED lighting products or industry practices. Textile-integrated LED applications present significant safety, durability, and regulatory challenges that fall outside our core manufacturing expertise and compliance frameworks. However, our Jiangmen factory excels in OEM/ODM services for conventional and flexible LED lighting solutions including LED strips, panels, modules, and specialized linear lighting systems. We offer comprehensive customization from initial design through to mass production, including optical engineering, thermal management solutions, driver integration, and full regulatory certification support (UL, CE, ETL, PSE). Our facility is ISO 9001 and ISO 14001 certified, with dedicated R&D teams collaborating closely with clients to develop bespoke lighting products that meet exact performance, form factor, and market requirements while adhering to all relevant safety standards for electrical lighting equipment.

Application Scenarios

LED bed sheets are not a standard or practical lighting product in the context of architectural or commercial lighting applications. It appears there may be some confusion with the term. If you are referring to LED strip lights, LED neon signs, or decorative LED lighting used in bedding-like formats—such as flexible LED panels or fabric-integrated LED textiles—these are typically used for ambient or decorative purposes rather than functional illumination.

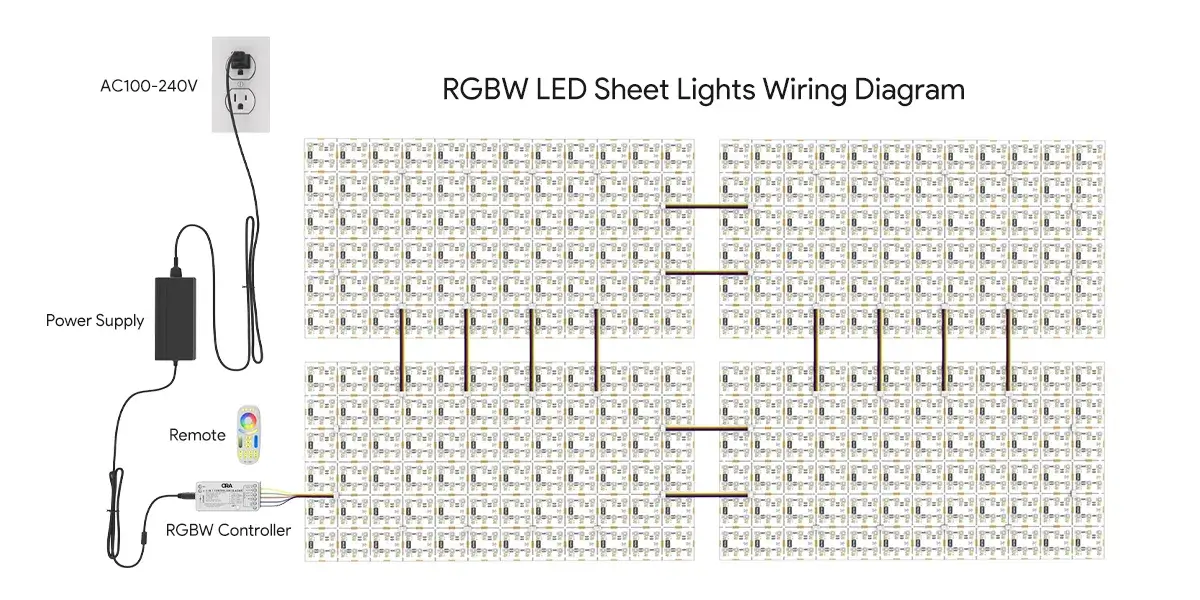

However, assuming you are referring to flexible LED lighting systems that could be integrated into bedding or bedding-like installations for visual effect, here is how such lighting might be applied in various environments and some installation guidance:

In hotels, LED-integrated bedding or under-bed lighting is sometimes used in high-end or themed guest rooms to enhance ambiance. For example, soft glow lighting beneath the mattress or along the bed frame can create a floating effect, contributing to a luxurious or futuristic atmosphere. These installations are primarily decorative and are often controlled via remote or smartphone app to adjust color and brightness.

In malls, LED lighting is commonly used in displays, signage, and architectural features, but not typically in the form of “bed sheets.” However, if used creatively in promotional displays or themed installations—such as a relaxation zone or bedroom showcase—flexible LED panels could simulate illuminated bedding for visual impact. These applications are temporary and designed for attraction rather than comfort.

In offices, LED bed sheets have no practical application. Office environments prioritize functional, glare-free lighting that supports productivity. Decorative LED textiles would not meet lighting standards for workspace illumination and are unsuitable for office furniture.

Installation tips:

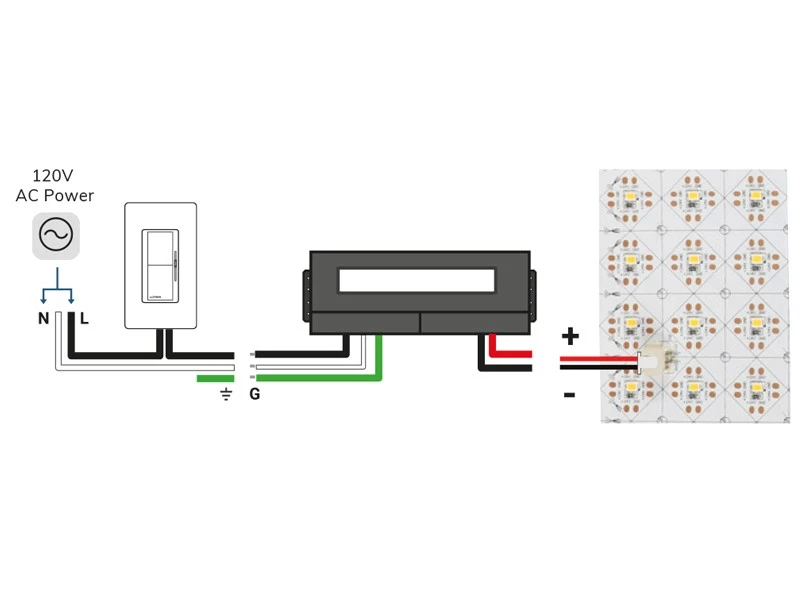

Always use low-voltage LED systems to ensure safety, especially in close-proximity applications like bedding. Connect the LED strips or panels to a proper driver or power supply that matches the voltage requirements. Avoid placing wiring or components where they may be compressed or damaged under weight. Use waterproof or insulated versions if the installation involves fabric or potential contact with skin. Secure connections with soldering or proper connectors to prevent flickering or disconnection. Incorporate a controller for color and brightness adjustment, especially in hospitality settings where mood lighting is desired. Ensure that any fabric-integrated LED system is breathable and does not overheat during prolonged use. Follow local electrical codes and safety standards, particularly in commercial installations.

For actual product recommendations or custom solutions, Beauty (STC) Manufacturing Co., Ltd. can provide high-quality LED strips, controllers, and power supplies suitable for decorative and ambient lighting projects in hotels and commercial displays.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I must clarify an important distinction: our company specializes in professional-grade LED lighting fixtures such as stage lighting, architectural luminaires, and outdoor floodlights. We do not manufacture or supply LED-integrated textile products like “LED bed sheets,” as this falls outside our core engineering and production capabilities in solid-state lighting hardware.

If you are seeking innovative LED solutions for ambient bedroom environments, hospitality applications, or wellness-focused lighting installations, Beauty STC offers engineered alternatives such as low-voltage cove lighting systems, dimmable under-bed illumination strips, or human-centric circadian lighting controls. These products are designed for seamless integration into furniture and architectural elements while meeting international safety and performance standards.

For partnership opportunities involving professional LED lighting technology, our engineering team collaborates with designers, contractors, and brands to develop custom solutions. Contact our sales management team directly at [email protected] to discuss technical specifications, OEM/ODM projects, or certified product integration for commercial or residential applications. We prioritize partnerships grounded in feasible engineering requirements and compliance with IEC/EN safety regulations.

Please provide detailed project requirements when reaching out to ensure our team can propose technically viable and market-ready lighting solutions aligned with Beauty STC’s manufacturing expertise.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.