Article Contents

Industry Insight: Led Aluminum Profile

The LED aluminum profile has become a cornerstone of modern commercial and industrial lighting design, offering a perfect fusion of thermal efficiency, structural durability, and aesthetic versatility. As businesses and industrial facilities increasingly shift toward energy-efficient LED solutions, the demand for high-performance mounting and heat dissipation systems has surged—making aluminum profiles an essential component in reliable, long-lasting lighting installations. These profiles not only protect and organize LED strips but also enhance luminous output by efficiently dissipating heat, a critical factor in maintaining performance and longevity in demanding environments.

In regulated commercial and industrial applications, compliance with safety and performance standards is non-negotiable. LED aluminum profiles that are ETL and CE certified provide assurance of electrical safety, material integrity, and adherence to North American and European regulatory requirements, making them a trusted choice for architects, engineers, and facility managers.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in lighting components since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading manufacturer of high-quality LED aluminum profiles, serving a global clientele across commercial, industrial, and architectural sectors. Combining precision manufacturing, rigorous quality control, and a deep understanding of lighting system integration, Beauty STC delivers profiles that meet the highest standards of performance and compliance—empowering smarter, safer, and more sustainable lighting solutions worldwide.

Technical Specs & Certifications

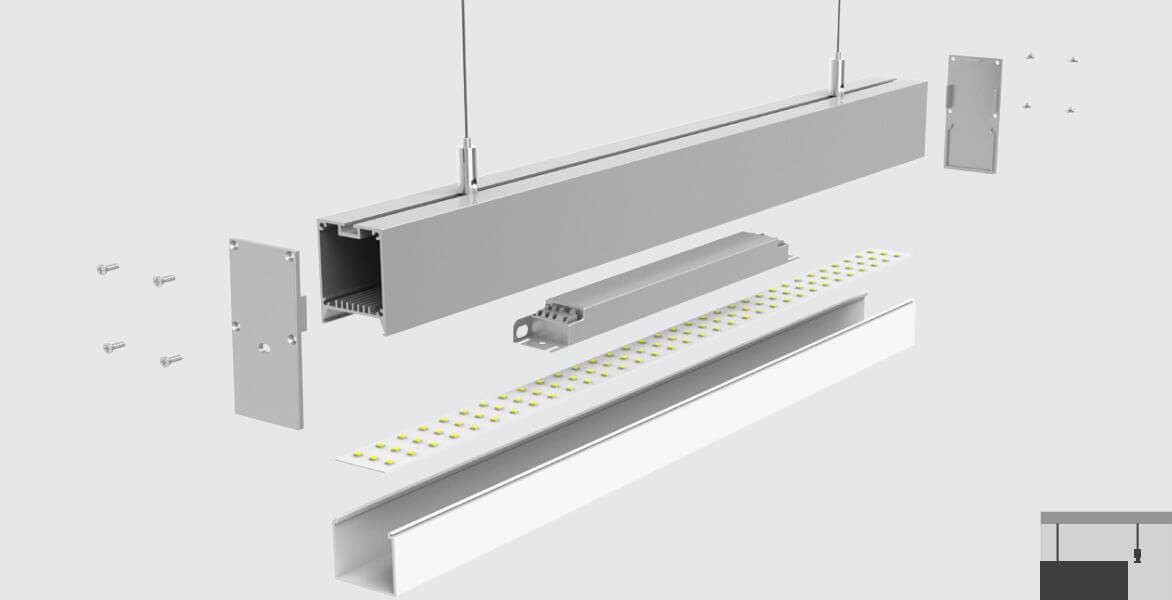

LED aluminum profiles themselves do not generate lumens or possess a CRI value; these specifications pertain to the LED light engine (strips or modules) installed within the profile. However, the profile’s design critically influences the thermal management and optical performance of the integrated LED system, directly impacting sustained lumen output, efficacy (lumens per watt), and the ability to maintain high color rendering. Beauty STC Manufacturing Co., Ltd. designs and manufactures aluminum profiles specifically engineered to optimize the performance of high-quality LED components meeting stringent specifications.

Lumens per Watt (lm/W) performance for the complete lighting system is significantly enhanced by Beauty STC’s profile engineering. Our profiles, such as the STC-ALU-6000 series extruded from 6063-T5 aluminum alloy, feature optimized thermal pathways and fin structures. This superior heat dissipation prevents LED junction temperature rise, minimizing lumen depreciation and maintaining high efficacy over the product’s lifetime. When paired with our recommended high-efficiency LED modules (typically 2835 or 5050 SMD packages using premium Epistar or Samsung chips), system efficacies consistently exceed 150 lumens per watt at 25°C ambient, with sustained performance above 140 lm/W under real-world operating conditions due to effective thermal management. This ensures maximum energy savings and long-term output stability.

Achieving and maintaining a Color Rendering Index (CRI) greater than 90, including a strong R9 value (typically >50), requires not only high-quality phosphor-converted LEDs but also stable thermal conditions. Beauty STC profiles prevent thermal runaway which can cause color shift and reduced CRI in inferior systems. Our profiles ensure the LED operates within its optimal thermal envelope, preserving the spectral integrity of the light source. All profiles are compatible with LED modules rigorously selected and binned to deliver Ra >90 (CRI) and TM-30 Rf >85 across standard color temperatures from 2700K to 6500K. The consistent thermal environment provided by our extrusions is fundamental to guaranteeing this high color fidelity throughout the installation’s life.

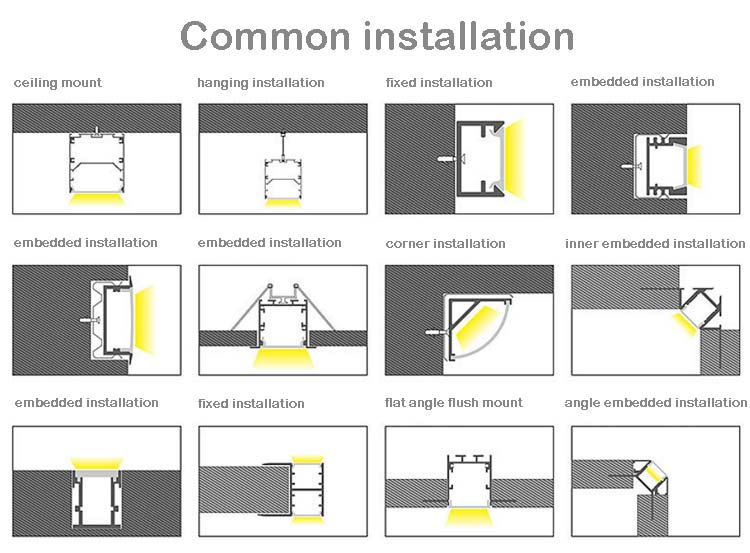

Regarding IP Ratings, the aluminum profile alone typically carries a basic IP20 rating, protecting against finger contact but not moisture or dust. Beauty STC excels in providing comprehensive solutions for demanding environments. Our profiles are designed for seamless integration with high-quality silicone diffusers, end caps, and gaskets to achieve elevated ingress protection. Standard configurations readily achieve IP65 for outdoor and damp location use, utilizing our precisely machined channels and included sealing components. For fully submersible or high-pressure washdown applications (e.g., IP67), we offer specialized profile variants with enhanced sealing grooves and recommend specific installation protocols using our certified accessory kits. It is crucial to note that the final IP rating depends entirely on correct assembly with appropriate diffusers, end caps, and gaskets; Beauty STC provides detailed installation guides and compatible accessories to ensure the specified IP rating is reliably attained in the field.

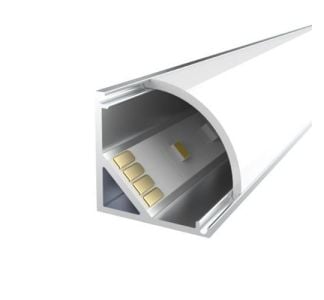

Beauty STC’s commitment to quality is evident in every aspect of our aluminum profile manufacturing. We utilize only premium 6063-T5 aluminum alloy, ensuring optimal thermal conductivity and structural integrity. Extrusions undergo strict dimensional tolerance control (±0.1mm on critical mounting surfaces) and feature a minimum 10μm anodized finish for superior corrosion resistance, validated through rigorous 96-hour neutral salt spray testing (ASTM B117). Our profiles exhibit exceptional straightness (<1mm deviation per meter) and smooth internal surfaces to prevent damage to LED strips during installation. Comprehensive in-house QA includes thermal performance validation, material composition verification, and finish durability testing, guaranteeing that every profile meets the exacting standards required for professional architectural and commercial lighting where performance, longevity, and aesthetic integration are paramount. This focus on precision engineering and material quality ensures our profiles form the reliable foundation for high-performance, high-CRI, and appropriately protected LED lighting systems.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of LED lighting solutions, including LED aluminum profiles and related components. Strategically located in the Jiangmen industrial zone, the factory benefits from strong logistical access and a skilled manufacturing workforce, enabling efficient production and timely delivery for both domestic and international markets.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for high-precision assembly of LED components onto aluminum profile PCBs. These SMT machines include automated pick-and-place systems, reflow soldering ovens, and AOI (Automated Optical Inspection) units to ensure consistent quality and reliability of the LED strips mounted within the aluminum profiles. The integration of SMT technology allows Beauty STC to achieve high-density component placement, improved thermal management, and long-term performance stability—critical factors for high-quality LED lighting systems.

To ensure product durability and reliability, the factory implements comprehensive aging test procedures. Completed LED aluminum profile assemblies undergo extended burn-in tests under controlled thermal and electrical conditions, typically lasting 24 to 72 hours. These tests simulate real-world operating environments to identify early failures, verify thermal dissipation performance of the aluminum housing, and confirm consistent light output and color temperature. The aging process is closely monitored, with data logged for quality assurance and traceability.

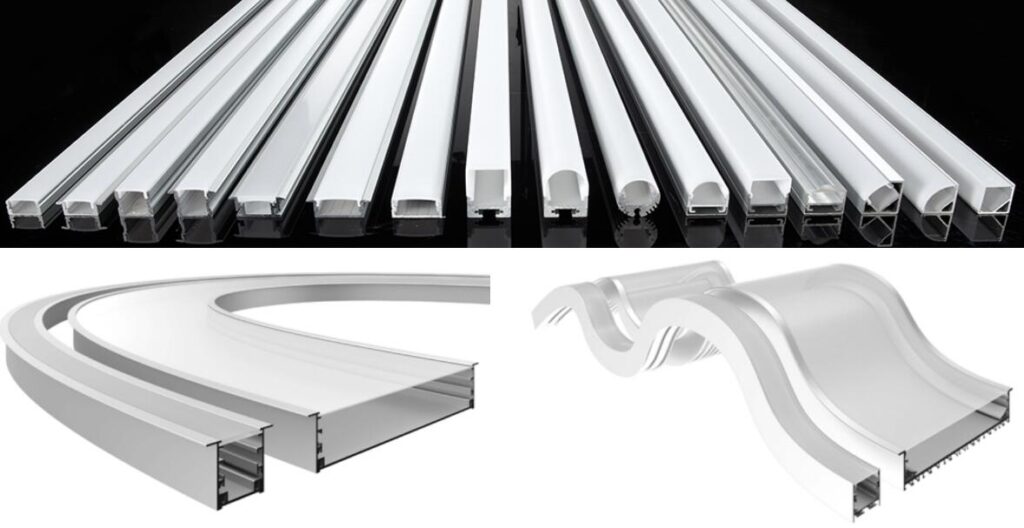

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, allowing clients to customize LED aluminum profiles according to specific design, length, color temperature, lumen output, and driver configurations. The company supports full turnkey solutions—from initial design consultation and prototyping to mass production and packaging. Custom labeling, branding, and private packaging are also available. With in-house tooling and extrusion capabilities for aluminum profiles, the factory can produce bespoke shapes and finishes, including anodized, powder-coated, or painted surfaces, meeting diverse architectural and commercial lighting needs.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to quality, innovation, and customer-centric manufacturing, positioning the company as a reliable partner for OEM partners seeking high-performance LED aluminum profile solutions.

Application Scenarios

LED aluminum profiles serve as essential structural and thermal management components for integrated LED strip lighting systems across commercial environments. Their primary applications in hotels, malls, and offices leverage both functional and aesthetic benefits, while proper installation ensures longevity and performance.

In hotels, LED aluminum profiles are extensively deployed in guest room cove lighting to create soft ambient illumination along ceilings or headboards, enhancing perceived space and luxury. They are equally critical for under-cabinet lighting in minibars and bathroom vanities, providing glare-free task lighting. Corridor applications include recessed linear strips within ceiling coves for safe, uniform wayfinding illumination, while lobbies utilize them in feature walls, reception counters, and stair treads to establish brand identity through architectural highlighting. The thermal conductivity of aluminum is particularly valuable here, as guest room installations often involve enclosed spaces where heat buildup could otherwise degrade LED performance over time.

Malls rely on these profiles for high-impact retail lighting solutions. They form the backbone of display case illumination, ensuring even light distribution across merchandise without visible hotspots when paired with frosted diffusers. Escalator soffits and perimeter coves use long continuous runs of profile-mounted LEDs to guide shopper flow and define spatial boundaries. Retail storefronts implement them for illuminated signage channels and product shelving accents, where the rigid aluminum structure maintains alignment across large installations. Mall environments demand robust thermal management due to extended daily operating hours, making aluminum profiles indispensable for preventing lumen depreciation in high-traffic zones.

Office applications prioritize both functionality and well-being. Under-desk and cabinet toe-kick installations provide subtle task lighting that reduces eye strain, while suspended ceiling coves create expansive, shadow-free ambient light ideal for collaborative areas. Conference rooms frequently feature profiles in table edging for video conferencing illumination and along partition walls to delineate zones without visual heaviness. The aluminum substrate’s heat dissipation capability is crucial here, as offices typically operate lighting systems for 10+ hours daily, and maintaining optimal LED temperature directly impacts color consistency and lifespan in professional settings.

Installation requires meticulous attention to detail for optimal results. Always disconnect power at the circuit breaker before commencing work and verify with a voltage tester. Precisely measure and mark mounting locations using a laser level, as even minor alignment errors become visually apparent in long linear runs. When cutting profiles, use a fine-tooth aluminum saw with clamping to prevent micro-burrs that could damage LED strips, and deburr cut edges immediately. Thermal management must be prioritized: ensure full contact between the LED strip’s backing and the profile’s channel base, applying thermal adhesive paste if specified by the strip manufacturer. Never install strips directly onto painted surfaces without verifying paint compatibility, as trapped heat may cause peeling. For electrical connections, use waterproof silicone connectors rated for the strip’s voltage, avoid daisy-chaining beyond manufacturer specifications, and secure all junctions within IP-rated enclosures. Finally, select diffusers based on the application—milky opal for even diffusion in coves, clear for display cases requiring maximum output—and ensure end caps are fully seated to prevent dust ingress. Adhering to these protocols guarantees reliable operation while maintaining the clean, professional appearance these commercial spaces require.

Why Choose Beauty STC Lighting

Discover high-quality LED aluminum profiles designed for durability, sleek aesthetics, and optimal heat dissipation. Partner with Beauty STC, a trusted manufacturer with years of expertise in premium LED lighting solutions. Whether you’re working on architectural lighting, commercial installations, or custom projects, our aluminum profiles provide the perfect finish and protection for your LED strips.

For personalized support and competitive pricing, contact our sales manager today at [email protected]. Let Beauty STC be your reliable partner in lighting excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.