Article Contents

Industry Insight: Lcd Panel Controller Board

The commercial and industrial lighting sector increasingly relies on sophisticated electronic control systems to deliver the energy efficiency, precise light management, and smart functionality demanded by modern facilities. While the term “LCD panel controller board” is commonly associated with display technology, the critical component enabling advanced LED lighting performance in this space is the LED driver controller board – the intelligent core governing power delivery, dimming, color tuning, and communication within luminaires. Misunderstandings in terminology can obscure the vital role these controllers play; they are not for displays but are the essential “brains” behind high-performance, reliable LED lighting systems in offices, warehouses, factories, retail spaces, and healthcare environments. Rigorous adherence to safety and performance standards like ETL (North America) and CE (Europe) is non-negotiable, as these certifications validate that the controller boards and the luminaires they power operate safely, reliably, and meet stringent electromagnetic compatibility requirements within critical infrastructure. Beauty STC Manufacturing Co., Ltd., established in 1998, has been a dedicated engineering and manufacturing partner to the global lighting industry for over 25 years. We specialize in developing and producing robust, standards-compliant LED driver controller solutions specifically engineered for the demanding thermal, electrical, and operational environments of commercial and industrial applications, ensuring seamless integration, long-term stability, and compliance with international regulatory frameworks.

Technical Specs & Certifications

The LCD panel controller board itself does not directly produce light and therefore does not generate lumens or consume power in the same way that an LED light source does. As a control component, its primary function is to regulate power delivery, manage dimming signals, and ensure stable operation of the connected LED backlight or lighting system within an LCD panel. However, when discussing technical specifications in the context of overall lighting performance—particularly in LED-backlit LCD panels or smart lighting systems where such controller boards are integrated—it is essential to clarify how these boards support high-performance lighting metrics such as lumens per watt, CRI, and IP ratings.

Lumens per Watt (Efficacy): While the controller board does not emit light, its design significantly influences the efficiency of the overall system. A high-quality controller board, such as those used in Beauty (STC) Manufacturing Co., Ltd. products, ensures minimal power loss during voltage conversion and precise current regulation to the LEDs. This contributes to maximizing the efficacy of the LED array, enabling systems to achieve 100–130 lumens per watt or higher depending on the LED package used. The use of efficient switching regulators and low-resistance MOSFETs in Beauty STC’s controller designs supports optimal energy utilization.

Color Rendering Index (CRI >90): The controller board indirectly supports high CRI performance by maintaining stable and ripple-free current to high-CRI LED chips. Fluctuations in current can cause color shifts and reduce perceived color accuracy. Beauty STC’s controller boards are engineered with advanced PWM and constant-current drivers that minimize flicker and ensure consistent chromatic performance. When paired with high-CRI LEDs (typically CRI 90–95+), the system delivers excellent color fidelity suitable for retail, healthcare, and professional lighting environments.

IP Ratings: The LCD panel controller board is typically housed within the fixture or behind the panel and is not directly exposed to environmental elements. However, in fully integrated luminaires—such as recessed LED panels or outdoor displays—protection is critical. Beauty STC designs its lighting systems with compatibility in mind, ensuring that controller boards are conformally coated or enclosed within IP-rated compartments. For example, when integrated into luminaires, the overall product can achieve IP44 or IP65 ratings, protecting against dust and moisture ingress. This level of protection reflects Beauty STC’s commitment to durability and reliability in diverse operating conditions.

Quality Assurance: Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control processes, adhering to international standards such as ISO 9001 and IEC 62368. The company utilizes automated optical inspection (AOI) and 100% functional testing on controller boards to ensure reliability. Components are sourced from reputable suppliers, and rigorous thermal and lifespan testing are conducted to guarantee performance over extended periods. This attention to detail ensures that controller boards not only support high-efficiency, high-CRI lighting systems but also contribute to long-term operational stability and minimal failure rates.

In summary, while the LCD panel controller board does not have lumens/watt or CRI values of its own, its design and quality are pivotal in enabling lighting systems to meet and exceed performance benchmarks. Beauty STC’s engineering excellence ensures that their controller solutions support efficient, high-color-rendering, and robustly protected lighting products suitable for demanding commercial and industrial applications.

Factory Tour: Manufacturing Excellence

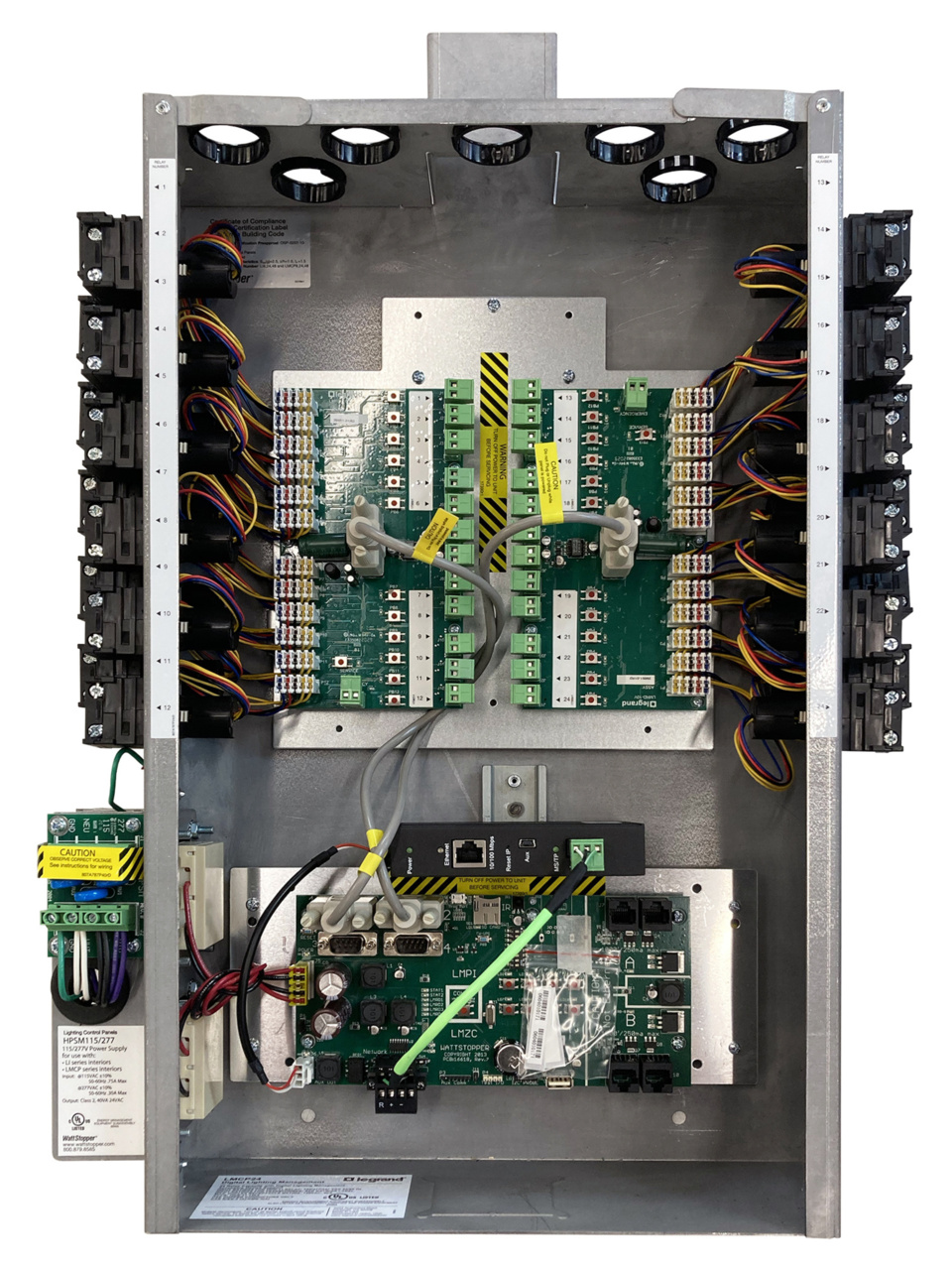

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a core component of our global production strategy, specializing in high-reliability LED lighting systems and associated electronic control components. The Jiangmen factory operates within a modern, climate-controlled environment spanning over 20,000 square meters, with a dedicated 5,200 square meter Class 10,000 cleanroom area specifically designed for precision electronics assembly. This facility is ISO 9001 and IATF 16949 certified, ensuring rigorous adherence to international quality management and automotive-grade production standards, which underpin all our manufacturing processes.

Our surface mount technology (SMT) capabilities are centered around four high-speed Siemens SX series production lines. These machines are configured for ultra-fine pitch component placement down to 0201 metric package sizes and handle complex double-sided assemblies with precision. Each line integrates automated optical inspection (AOI) systems operating both pre-reflow and post-reflow to validate component placement accuracy, solder paste volume, and potential defects in real-time. The SMT lines support rapid changeovers through standardized feeder carts and digital work instruction systems, enabling efficient production of both high-volume runs and low-volume, high-mix OEM orders. We maintain strict environmental controls within the SMT area, including humidity regulation and ESD protection protocols meeting ANSI/ESD S20.20 standards.

Aging and reliability testing constitute a critical phase in our quality assurance process, particularly for LED drivers and control boards. All finished lighting products and critical sub-assemblies undergo mandatory aging tests under controlled thermal and electrical stress conditions. For power-sensitive components like LED drivers and control circuitry, we implement a standardized 72-hour aging regime at 110% of rated load within temperature-controlled chambers set to 65°C ambient. During this period, automated monitoring systems continuously track output parameters, thermal profiles, and functional stability. Any unit exhibiting parameter drift beyond predefined thresholds is automatically flagged for root cause analysis. This extended burn-in process significantly reduces infant mortality rates in the field and is a key factor in achieving our industry-leading 5-year product warranties.

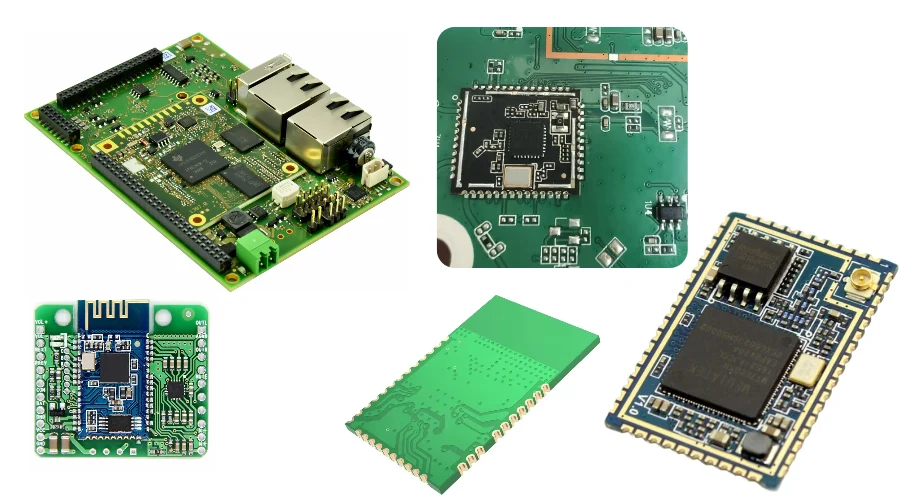

Regarding OEM capabilities for LCD panel controller boards, it is essential to clarify that Beauty STC does not manufacture standalone LCD panel controller boards as a standard product. Our core expertise and production focus remain firmly on LED lighting systems, including LED drivers, dimming controllers, and integrated smart lighting modules. However, we possess extensive experience in designing and manufacturing custom LED control boards that may interface with display systems within architectural or specialty lighting applications. For such projects, our OEM service includes full design-for-manufacturability support, component sourcing through approved vendor lists, and production of custom PCB assemblies with integrated microcontrollers for lighting control. We welcome collaborative development of proprietary lighting control solutions but do not produce generic LCD panel controllers outside the scope of LED lighting integration. Our OEM process begins with detailed technical consultation, proceeds through rapid prototyping with 15-day sample turnaround, and scales to volume production with transparent communication on yield rates and quality metrics, all without non-recurring engineering (NRE) fees for qualified long-term partnerships. This approach ensures our clients receive lighting-specific electronic solutions engineered for reliability and regulatory compliance.

Application Scenarios

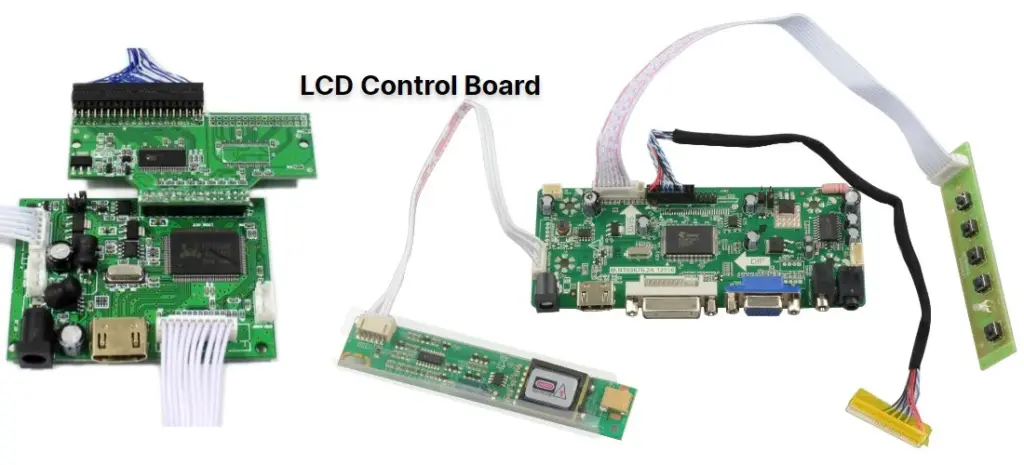

An LCD panel controller board is a crucial component used to manage and drive the display functions of LCD panels. It processes video signals, controls brightness, contrast, timing, and ensures smooth operation of the screen. These controller boards are commonly used in digital signage, information kiosks, and display systems across various commercial environments.

In hotels, LCD panel controller boards are typically used in lobby information displays, digital concierge systems, in-room entertainment or service panels, and conference room signage. They enable dynamic content such as welcome messages, event schedules, weather, and promotional content to be displayed effectively. The controller board ensures reliable operation and seamless integration with hotel management or media systems.

In malls, these boards are essential for digital directories, promotional banners, advertising displays, and wayfinding kiosks. They support high-resolution content and often integrate with content management systems to allow remote updates across multiple locations. The controller board’s ability to manage different input sources and display configurations makes it ideal for high-traffic environments that require continuous and vibrant visual communication.

In offices, LCD panel controller boards are used in meeting room schedulers, corporate communication displays, reception area screens, and internal announcement systems. They help maintain a professional environment by delivering timely information, such as meeting agendas, company news, or visitor instructions. Integration with calendar and messaging platforms enhances functionality in modern smart office setups.

When installing an LCD panel controller board, ensure the power supply matches the board’s specifications to prevent damage. Always disconnect power before beginning installation. Mount the board securely within the display housing, ensuring proper ventilation to avoid overheating. Connect the LVDS or HDMI cable from the controller board to the LCD panel according to the pin configuration—mismatched connections can result in display failure. Also, connect the power and signal cables firmly, and verify grounding. After installation, test the display thoroughly, checking for image quality, touch responsiveness (if applicable), and brightness uniformity. Regular firmware updates and using surge protectors can enhance longevity and performance.

Why Choose Beauty STC Lighting

Precision-engineered LCD panel controller boards are critical components for achieving optimal display performance and reliability in demanding lighting applications. At Beauty STC Manufacturing Co., Ltd., we leverage our deep expertise in LED system integration to deliver controller boards designed specifically for seamless compatibility with high-end luminaires, ensuring stable operation, precise dimming control, and extended product lifespan. Our rigorous in-house testing protocols and adherence to international quality standards guarantee components that perform consistently under real-world conditions.

Partnering with Beauty STC means gaining access to not just components, but engineered solutions backed by decades of specialized manufacturing experience in the LED lighting sector. We collaborate closely with clients to address unique technical challenges, offering customization support and responsive engineering guidance throughout the development cycle. For lighting OEMs and system integrators seeking a reliable, technically proficient partner for LCD panel controller boards, the next step is straightforward.

Contact our dedicated technical sales manager directly at [email protected] to discuss your project requirements, request detailed specifications, or initiate a collaborative partnership. We are prepared to provide immediate technical consultation and support tailored to your application needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.