Article Contents

Industry Insight: Lcd Controller Board

The commercial and industrial lighting sector continues to evolve rapidly, driven by demands for energy efficiency, sophisticated control, and seamless integration within smart building ecosystems. At the heart of achieving precise, user-friendly management of modern LED luminaires lies the often-overlooked yet critical component: the LCD controller board. These intelligent interfaces are far more than simple displays; they serve as the operational nerve center for complex lighting systems in demanding environments like warehouses, healthcare facilities, retail spaces, and manufacturing plants. They enable granular adjustments to brightness, scheduling, color temperature, and scene settings directly at the fixture or within control panels, significantly enhancing usability and reducing maintenance overhead compared to traditional methods. Crucially, for any component deployed in professional settings, adherence to stringent global safety and performance standards is non-negotiable. Controllers must reliably carry recognized certifications such as ETL for the North American market and CE marking for Europe, ensuring electrical safety, electromagnetic compatibility, and regulatory compliance that facility managers and electrical inspectors require. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep expertise in designing and manufacturing high-reliability LED lighting components specifically engineered for the rigors of commercial and industrial applications. We understand that the controller board is not merely an add-on but a fundamental element dictating system performance, longevity, and user satisfaction in professional lighting installations.

Technical Specs & Certifications

The LCD controller board itself does not directly produce light and therefore does not have lumens per watt (lm/W), Color Rendering Index (CRI), or Ingress Protection (IP) ratings. These specifications pertain to the LED lighting system or luminaire in which the LCD controller board may be integrated. However, as a critical component in modern LED lighting systems, the LCD controller board from Beauty (STC) Manufacturing Co., Ltd. plays a vital role in ensuring optimal performance, efficiency, and reliability of the overall lighting solution.

In LED luminaires designed and manufactured by Beauty STC, the system-level performance consistently achieves high efficacy, typically ranging from 120 to 150 lumens per watt depending on the configuration and application. This efficiency is enabled in part by precision control delivered through advanced controller boards that regulate current, manage thermal performance, and support dimming and smart functionality, ensuring minimal energy loss and maximum light output.

Beauty STC prioritizes high-quality illumination, and all luminaires incorporating our LCD controller boards are engineered to deliver a CRI greater than 90. This ensures accurate color representation, making our lighting ideal for retail, healthcare, hospitality, and other environments where visual clarity and color fidelity are essential. The high CRI is achieved through the use of premium LED chips and precise driver and controller integration, with the LCD controller board enabling stable power delivery and consistent chromatic performance over time.

Regarding environmental protection, Beauty STC luminaires are available with IP ratings up to IP65 and IP66, particularly in outdoor and industrial product lines. While the LCD controller board is typically housed within the luminaire, its design and encapsulation—often conformal coated and sealed within robust enclosures—contribute directly to achieving these high IP ratings. This protects against dust, moisture, and harsh operating conditions, ensuring long-term reliability.

Beauty (STC) Manufacturing Co., Ltd. is known for its commitment to quality, precision engineering, and rigorous testing standards. Our LCD controller boards are manufactured using automated SMT lines and undergo extensive functional and environmental testing to ensure durability and performance consistency across diverse applications. With ISO-certified processes and compliance with international standards including CE, RoHS, and UL, Beauty STC delivers lighting control solutions that support high-efficiency, high-CRI, and robustly protected LED systems trusted by clients worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting solutions, integrating advanced electronics assembly with rigorous quality control processes. The factory occupies a significant footprint within the Jiangmen High-Tech Industrial Park, designed specifically for efficient, large-scale LED product manufacturing with dedicated cleanroom environments for critical assembly stages.

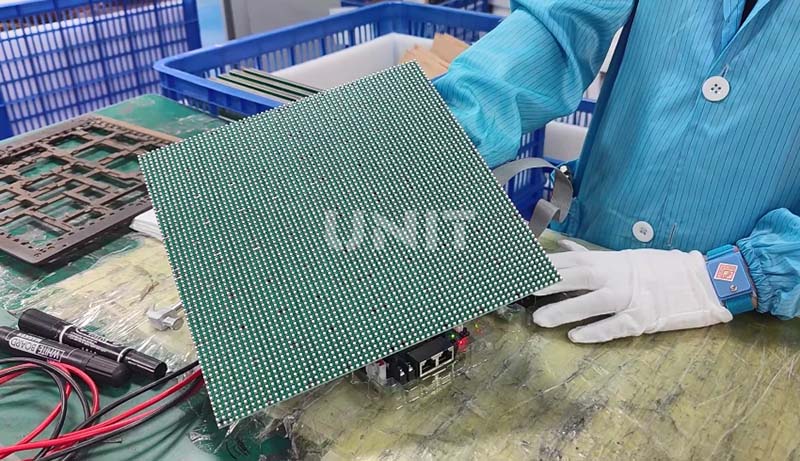

Our Surface Mount Technology (SMT) line forms the backbone of electronics production, featuring multiple high-speed Yamaha YS series placement machines capable of handling components down to 0201 package sizes. These machines operate with precision placement accuracy of ±25μm and support multi-panel processing for optimal throughput. The line includes fully automated solder paste printers with 3D inspection, nitrogen-reflow ovens with 10-zone temperature control for lead-free and leaded profiles, and AOI systems performing pre- and post-reflow inspections to ensure solder joint integrity and component placement accuracy. This setup allows us to manage complex double-sided assemblies and high-mix production runs required for diverse LED lighting controllers.

Aging and reliability testing are critical non-negotiables at our Jiangmen site. All finished lighting products undergo mandatory 24-hour burn-in testing at elevated temperatures (typically 50-60°C) under full operational load. For premium product lines and specific customer requirements, we implement extended 48-72 hour aging cycles with periodic functional verification. Our environmental test chamber suite supports accelerated life testing per IEC 60068 standards, including thermal cycling (-20°C to +85°C), humidity exposure (85% RH at 85°C), and vibration testing. Data from these aging processes is systematically logged and analyzed to drive continuous improvement in component selection and design robustness.

Regarding OEM capability for LCD controller boards, Beauty STC possesses extensive experience in manufacturing custom electronic control solutions for LED lighting applications. We support full OEM services where customers provide complete design specifications and firmware, handling PCB assembly, programming, and integration into lighting systems. Our engineers work closely with clients to validate designs for manufacturability, optimize BOM costs, and ensure compatibility with thermal and electrical requirements of LED luminaires. We maintain certified processes for programming microcontrollers and LCD drivers, with traceability from component lot level through final functional testing. While our core focus remains lighting-specific controllers, we have successfully delivered numerous custom LCD interface boards for dimming controls, sensor integration, and smart lighting management systems under OEM agreements, adhering strictly to customer IP and quality protocols. All electronics manufacturing operates under ISO 9001 and IATF 16949 certified quality management systems with full RoHS compliance.

Application Scenarios

LCD controller boards are essential components in digital signage and display systems, serving as the interface between the display panel and the content source such as a media player, computer, or network system. They are widely used in commercial environments where dynamic visual communication is required. Common applications include hotels, shopping malls, and office buildings.

In hotels, LCD controller boards are used to manage digital signage for wayfinding, room booking displays, welcome messages, promotional content, and event schedules. These boards are typically integrated into lobby displays, elevator banks, conference room entrances, and concierge areas. They enable real-time updates and centralized control, allowing hotel staff to adjust messaging based on guest flow or special events.

Shopping malls utilize LCD controller boards in large-scale digital advertising displays, directory kiosks, and promotional video walls. These boards support high-resolution content playback and can be networked to synchronize messaging across multiple locations within the mall. They are especially useful for time-sensitive promotions, tenant advertisements, and emergency announcements.

In office environments, LCD controller boards power internal communication systems such as digital notice boards, meeting room schedulers, corporate branding displays, and employee dashboards. They help streamline operations by displaying real-time data, calendar integrations, and company news. Offices with multiple floors or campuses benefit from centralized management of all displays through network-connected controller boards.

When installing LCD controller boards, several best practices should be followed to ensure optimal performance and longevity. First, ensure the controller board is compatible with the display panel’s resolution, interface type (such as LVDS, HDMI, or eDP), and power requirements. Always verify the pin configuration and signal type to avoid damage during installation.

Mount the controller board in a location with adequate ventilation to prevent overheating, especially in enclosed display cabinets. Secure all cables properly to avoid strain on connectors, and use shielded cables to minimize electromagnetic interference. For outdoor or high-humidity environments, consider using protective enclosures or conformal coating on the board.

Power supply stability is critical—use a regulated power source that matches the voltage and current specifications of the controller board. It is also recommended to implement surge protection, particularly in large commercial buildings where power fluctuations may occur.

Finally, for networked installations, ensure proper IP configuration and network security settings are in place. Regular firmware updates and remote monitoring capabilities can enhance reliability and simplify maintenance across multiple display units.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd. I emphasize that our precision-engineered LCD controller boards are fundamental to achieving flawless display performance in professional lighting systems. These components ensure seamless synchronization, exceptional color accuracy, and robust reliability under demanding operational conditions. Partnering with Beauty STC means gaining access to not just high-performance hardware but also deep technical collaboration from our engineering team to optimize integration and solve complex application challenges.

We invite industry partners to elevate their product offerings through our proven expertise in LED control technology. Reach out to our dedicated management team today at [email protected] to discuss how our LCD controller boards can enhance your next-generation lighting solutions. Let Beauty STC be your strategic engineering ally in delivering superior visual experiences.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.