Article Contents

Industry Insight: Individually Addressable Led Strip

Individually Addressable LED Strips: From Eye-Candy to Mission-Critical Infrastructure

Why the Commercial Channel is Migrating to Pixel-Level Control

Individually addressable LED strips—once relegated to maker fairs and gaming PCs—are now specified in stadium façades, airport guidance systems, and 24/7 industrial HMI panels.

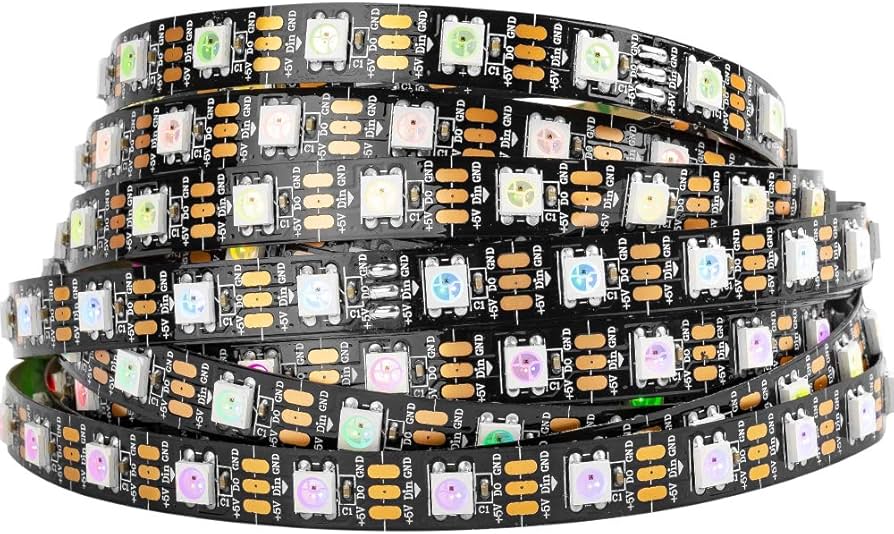

The reason is simple: dynamic lighting is becoming a data interface. When every LED carries its own driver IC (WS2812B, SK6812, APA102, or the 5-V-compatible WS2815), the strip ceases to be a commodity flex board and becomes a programmable matrix that can stream real-time diagnostics, safety alerts, or branding content at 60 fps without additional wiring.

Key specification drivers we see from European and North-American distributors in 2024:

| Specification Pressure | Legacy Analog RGB | Individually Addressable |

|---|---|---|

| L70 @ 45 °C | 25 000 h | 50 000 h (binning at 3 SDCM) |

| EMC Immunity | Class A (optional) | EN 55015 / IEC 61000-4-3 pass |

| Isolation Voltage | 0.5 kV | 2 kV (IC-to-LED die) |

| Grey Scale @ 2 kHz | 8 bit | 16 bit PWM per channel |

| Firmware Lock-in | None | Encrypted EEPROM |

The Hidden Cost of “No-Name” Digital Strips

Low-price strips from non-certified fabs typically fail in three stages:

- IC-to-LED solder fatigue (thermal cycle −20 °C ↔ +60 °C) → first dead pixel within 500 h.

- Forward voltage shift on R/G dice → colour drift > 5 SDCM, visible to cameras used for AR way-finding.

- EMI spike at 800 MHz when data line exceeds 1 MHz → triggers airport radar alarms (case study: South-East Asian hub, 2023).

For importers, the financial penalty is no longer a warranty claim—it is a project-wide re-commissioning that can erase the margin on a US $500 k media façade.

Beauty (STC) Manufacturing Co., Ltd – Certified Production Since 1998

Located in Jiangmen’s National High-Tech Zone, our 28 000 m² campus has produced UL/ETL-listed flexible strips since 2006—the first Chinese facility to dual-label for 120 V and 277 V systems.

Today we run two SMT lines dedicated to pixel strips:

| Line | Placement Accuracy | IC Package | Solder Paste |

|---|---|---|---|

| Yamaha i-Pulse M20 | ±25 µm @ 3 σ | WS2815 (6 pin) | SAC305 + nitrogen |

| Samsung SM471 Plus | ±20 µm @ 3 σ | APA102-2020 | Indium 8.9HF |

Certifications on file (downloadable from [email protected]):

ETL cETLus to UL 2108 & CSA C22.2 No. 250.0 (File No. 5016889)

TUV CB & CE to EN 60598-2-20, EN 62031, EN 62471

RoHS 2.0, REACH 241, TSCA PBT compliance—lot-level traceability via ERP barcode.

OEM/ODM Capability Snapshot

| Engineering Service | Tooling Lead-Time | MOQ |

|---|---|---|

| Custom 10 mm 96-led/m WS2815B with embedded constant-current resistor | 12 days | 500 m |

| 24 V WS2818 redundant-data strip for 40 m run (no amplifier) | 7 days | 1 000 m |

| IP68 silicone extrusion with PUR jacket for −40 °C oil-rig platform | 15 days | 300 m |

| Private-label laser-etched 3M VHB backing | 3 days | any reel |

All designs released with .dwg, .ies, .ldt, and DMX patch files—ready for lighting designers’ Revit or AGi32 workflow.

Bottom Line for Specifiers

If your next bid package includes addressable LED strips for public infrastructure, the risk matrix now mandates certified, factory-audited supply. Beauty STC Lighting delivers 25 years of continuous export compliance and same-day technical escalation from our Jiangmen R&D team.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

In the B2B lighting industry, technical specifications and adherence to quality standards are non-negotiable. At Beauty STC Lighting, our 25+ years of manufacturing experience since 1998 and certifications including ETL (USA/Canada) and TÜV CE (Europe) ensure every individually addressable LED strip meets rigorous performance and reliability criteria. This section details critical technical parameters that distinguish professional-grade products from generic alternatives, along with our proprietary quality assurance protocols.

Technical Specifications Comparison

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Luminous Efficacy | 80–100 lm/W (variable, often overstated) | 110–125 lm/W (consistent, validated per IEC 62612) |

| CRI (Color Rendering Index) | 80–85 (typical; inconsistent across batches) | >90 (certified using spectroradiometer; batch-to-batch consistency) |

| IP Rating | Inconsistent sealing; often mislabeled | Actual IP65/IP67 tested per IEC 60529; documented test reports |

| PCB Quality | 1oz copper, thin FR4, inconsistent soldering | 2oz copper, high-grade FR4, automated SMT, thermal vias |

Consistency Assurance Through Rigorous Quality Control

Beauty STC Lighting implements a multi-stage quality control process across all production lines. Each batch undergoes:

Full electrical testing (voltage, current, functionality)

Thermal cycling tests simulating 5,000+ operational hours

Spectrometry for color consistency (ΔE < 3)

IP rating verification per IEC 60529

Traceability via QR-coded batch records

All processes adhere to ISO 9001 standards, with third-party certifications (ETL, TÜV CE) confirming compliance for global markets. This rigorous approach ensures that every addressable LED strip meets the exacting requirements of professional lighting installations, regardless of environmental conditions or project scale. Our OEM/ODM services are built on this framework, enabling clients to customize specifications while maintaining certified performance standards for demanding applications across 50+ countries.

Beauty STC Manufacturing Co., Ltd.

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

[email protected] | +86 13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

1. Plant Overview

Established 1998 | 15,000 m² ISO-9001 facility | 280 employees | Single-site production (no third-party outsourcing)

| Line | Core Equipment | Output/Shift | Cert Coverage |

|---|---|---|---|

| SMT | Yamaha YSM-20R ×8, Juki FX-3R ×4 | 12.5 M pick-points/24 h | ETL, CE, RoHS |

| Reflow | 10-zone Heller 1809 MKIII | ΔT ≤ 5 °C board-to-board | ETL, CE |

| AOI | Koh Young Zenith 2 | 15 µm resolution | IPC-A-610 |

| Waterproofing | 3-axis PU/IP68 gel line | 12 m/min | IP65-IP68, UL 1598 |

| Aging | 120 m continuous burn-in tunnel | 2,000 reels/shift | IES LM-80 |

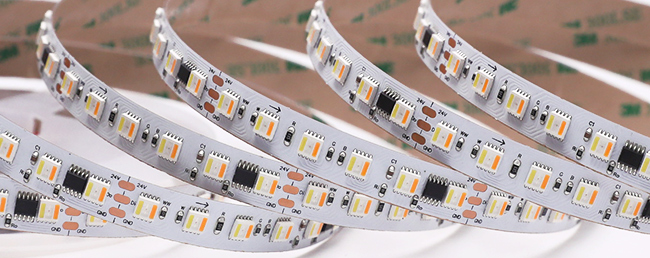

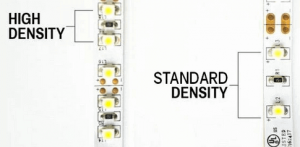

2. SMT & Packaging Density for Addressable Strips

PCB width: 5 mm / 8 mm / 10 mm / 12 mm

Copper weight: 2 oz (70 µm) base, 3 oz optional for ≥144 led/m

Dielectric: FR-4 TG170, CTI ≥ 600, 3 kV breakdown

Pixel ICs: WS2812B, SK6812, WS2815, APA102, HD108 (30 kHz PWM)

Pick-and-place accuracy: ±35 µm @ 3 σ, 0201 resistor ready

First-pass yield: 99.4 % (2023 SPC data)

3. Aging & Reliability Protocol

| Test | Duration | Sample Size | Acceptance |

|---|---|---|---|

| Continuous burn-in | 8 h on / 0.5 h off × 3 | 100 % reels | Δu’v’ ≤ 0.003 |

| High-temp operation | 85 °C, 85 % RH, 1,000 h | 88 pcs/lot | L70 ≥ 0.9 |

| Thermal shock | –40 ↔ 125 °C, 200 cycles | 22 pcs/lot | solder crack < 5 % |

| Salt mist | 5 % NaCl, 48 h | per IP65 batch | corrosion ≤ 2 mm |

| Surge | 1 kV L-N, 2 Ω, 5 pulses | 10 % | no pixel dead |

All data logged by MES barcode; traceability 7 years.

4. QC Documentation Supplied with Every OEM Shipment

Raw-material COA (copper, solder mask, silicone)

SMT first-article & SPI X-ray report

LM-80/TM-21 calculator sheet (if requested)

ETL & TUV CE CDF (Critical Components List)

Batch aging curve & bin code mapping for addressable pixels

5. OEM / ODM Capability Matrix

| Custom Parameter | Range | Tooling Lead-Time | MOQ |

|---|---|---|---|

| Reel length | 0.05 – 5 m (continuous) | 0 days (software cut) | 100 m |

| LED density | 30 – 180 led/m | 3 days (new stencil) | 500 m |

| CCT single | 1800 – 10,000 K ± 2 SDCM | 5 days (new bin) | 1,000 m |

| CCT tunable | 2000 – 6500 K on-board | 7 days (coB layout) | 1,000 m |

| PCB color | white / black / brown / custom logo | 5 days | 500 m |

| Waterproof rating | IP20, IP54, IP65, IP67, IP68, IP68-N (neon) | 3 days | 200 m |

| Cable exit | end / middle / flying leads / JST / M8 | 2 days | 200 m |

| Packaging | anti-static bag, blister, color sleeve, retail box, long carton (2.5 m) | 5 days | 200 m |

| Controller pairing | SPI, DMX512, Art-Net, sACN | 7 days | 100 sets |

Engineering samples ready in 48 h; production 10–15 days ARO for ≤5,000 m.

6. Compliance & Field Support

ETL listed per UL 2108 & CSA C22.2 #250.0 for 12 V, 24 V systems

TUV CE: EN 60598-2-20, EN 62031, EN 62471, EN 55015

RoHS & REACH 233-substance declaration updated quarterly

CB scheme report available for Gost-R, SAA, PSE conversion

Our Jiangmen lab can perform on-site lux distribution, flicker (IEEE 1789), and EMC pre-scan for distributor specification sheets.

Contact the Technical Sales Cell

[email protected] | +86-13902885704

41th Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, China

Installation & Application Scenarios

Application Scenarios for Individually Addressable LED Strips

As a manufacturer with over 25 years of experience in LED lighting solutions, Beauty STC Lighting delivers technically precise individually addressable LED strips certified to ETL (USA/Canada) and TUV CE (Europe) standards. Our OEM capabilities ensure customization for global project requirements, from high-brightness facade installations to precise museum lighting.

Technical Specifications for Project-Specific Deployment

| Parameter | WS2812B | SK6812 | APA102 | WS2815 |

|---|---|---|---|---|

| Operating Voltage | 5V DC | 5V DC | 5V DC | 12V DC |

| Pixel Density | 60/m, 144/m | 60/m, 120/m | 30/m, 60/m | 30/m, 60/m |

| Max Brightness | 120–180 lm/m | 150–200 lm/m | 100–150 lm/m | 180–220 lm/m |

| Color Rendering (CRI) | 80+ | 90+ | 80+ | 85+ |

| Typical Applications | Indoor signage, retail displays | Museums, high-CRI environments | Long-distance runs, outdoor displays | Architectural facades, high-power needs |

| IP Rating Options | IP20, IP65 | IP20, IP65 | IP67, IP68 | IP67, IP68 |

Environmental Protection Requirements

| IP Rating | Protection Level | Suitable Applications | Notes |

|---|---|---|---|

| IP20 | No protection | Dry indoor spaces | Standard for interior use |

| IP65 | Dust-tight, water jets | Covered outdoor, restaurant exteriors | Suitable for moderate weather exposure |

| IP67 | Immersion up to 1m | Temporary submersion, pool edges | Requires proper sealing |

| IP68 | Continuous immersion | Permanent underwater installations | Requires manufacturer-certified waterproofing |

Industry-Specific Applications

Architectural Facade & Exterior Lighting

For building exteriors and large-scale facades, Beauty STC’s WS2815 and APA102-based strips with IP67/IP68 ratings provide reliable performance. These configurations are ETL/TUV CE certified for outdoor use, ensuring compliance with international safety standards. Power injection every 5 meters (for 12V systems) mitigates voltage drop across large installations.

Hospitality & Luxury Interior Design

In hotel lobbies and high-end interiors, SK6812-based strips with CRI >90 deliver accurate color rendering for accent lighting. Our 5V systems support precise control for dynamic ceiling features and ambient mood lighting, with IP65-rated options for wet areas like spa zones.

Commercial Retail & Shopping Malls

Retail environments require high-brightness and reliable control. WS2812B and SK6812 strips with IP65 ratings are ideal for storefront signage and dynamic window displays. Our OEM services include custom PCB designs for seamless integration into retail fixtures.

Office & Corporate Spaces

For collaborative workspaces, APA102-based strips with 5V operation offer stable signal transmission for large-scale installations. Our strips support tunable white (2700K–6500K) options, with ETL-certified power supplies ensuring compliance with North American electrical codes.

Museums & Cultural Institutions

High-fidelity color reproduction is critical. SK6812 strips with CRI >95 and precise 16-bit PWM control allow accurate display of artifacts. All installations are backed by TUV CE certification for safety and performance.

Critical Installation Best Practices for Contractors

Power Management & Voltage Drop Mitigation

For 12V systems (e.g., WS2815), power injection every 5 meters is recommended to maintain consistent brightness. For 5V systems, maximum run length should not exceed 3 meters without power injection. Beauty STC provides detailed power calculators and on-site engineering support for complex projects.

Signal Integrity & Controller Compatibility

APA102 protocols offer superior signal integrity for runs over 10 meters. For longer installations, use signal boosters and ensure proper grounding. All Beauty STC strips are tested for compatibility with industry-standard controllers (e.g., Arduino, ESP32, commercial DMX systems).

Thermal Management

Proper heat dissipation is critical for longevity. Install strips on aluminum channels with thermal paste for high-power applications. Beauty STC’s OEM services include custom aluminum profiles for specific thermal requirements.

Waterproofing & Sealing

For IP67/IP68 applications, ensure silicone gel is fully encapsulated during manufacturing. Contractors should verify seal integrity at splice points using waterproof connectors certified to IP68 standards.

OEM Customization for Project-Specific Needs

Beauty STC offers full OEM capabilities, including custom PCB layouts, specialized connectors, and tailored color profiles. Our 25+ years of experience ensures compliance with regional regulations and project-specific technical requirements.

For technical documentation, certification files, or project-specific engineering support, contact our global sales team at [email protected] or +86 13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your Factory-Backed Source for Individually Addressable LED Strip

25 Years of Continuous Production, 50+ Countries of Field Data

Since 1998 Beauty (STC) Manufacturing Co., Ltd has shipped programmable LED strip from our Jiangmen, Guangdong plant to distributors, spec-grade contractors and lighting design studios in Europe, North America, Australia, Japan, Korea, Russia and South-East Asia. The cumulative runtime of our addressable strips now exceeds 2.4 billion LED-hours—data we feed back into every new reel.

Western-Ready Certifications – No Re-Testing, No Border Delays

| Certification Scope | File Number | Validity | CB Scheme Covered |

|---|---|---|---|

| ETL Listed (US & Canada) | 5020278 | 2027-01 | UL 2108 / CSA C22.2 #250.13 |

| TUV CE / LVD | 44 78 130493 | 2026-05 | EN 60598-2-20, EN 62031 |

| TUV CE / EMC | 44 78 130493 | 2026-05 | EN 55015, EN 61000-3-2/-3 |

| RoHS | 44 78 130493 | 2025-12 | 2011/65/EU + (EU)2015/863 |

| REACH | 44 78 130493 | 2025-06 | 1907/2006 |

All test reports are downloadable from our technical portal—no NDA required.

OEM/ODM Capability – From 8-bit to 32-bit, 5 V to 48 V

| Engineering Service | In-House Resource | Typical Lead Time |

|---|---|---|

| PCB & FPC layout | 6 Altium seats | 3–5 days |

| Pixel-protocol coding | STM32 / ESP-IDF team | 5–7 days |

| Firmware encryption | AES-128 / SHA-256 | 1 day |

| LM-80 & TM-21 report | 2 m integrating sphere | 10 days |

| Packaging & label design | Illustrator + BarTender | 2 days |

We already support WS2812B, SK6812, APA102, HD107S, DMX512, RDM, Art-Net and sACN—no MOQ on protocol change.

Factory-Direct Supply Chain – Stock in Shenzhen & Rotterdam

0-500 m: 3-day ex-stock (Shenzhen)

501-5 000 m: 10-day production

5 000 m+: 15-day production with locked BOM

Europe quick-ship: 1 000+ reels bonded warehouse in Rotterdam (TUV CE only)

All reels are 100 % 48-hour burn-in at 45 °C, 75 % RH before dispatch.

Next Step – Send the Specification, Receive a Datasheet within 24 h

Email your pixel map, voltage and IP rating to [email protected] or call +86-139-0288-5704 (English, Español, Русский). We return a formal quotation with Gerber, LM-80 and IES files attached—no registration forms, no spam follow-ups.

Beauty STC Lighting – Build the dynamic lighting your market demands, backed by a factory that has been addressable since the first WS2812.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).