Article Contents

Industry Insight: Individual Led

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and regulatory compliance. As facility managers and project specifiers prioritize long-term performance and safety, individual LED components have become foundational in designing tailored, high-performance lighting systems. These discrete LED solutions offer flexibility in thermal management, optical control, and system integration—critical factors in demanding environments such as warehouses, manufacturing plants, and commercial buildings. Compliance with international standards like ETL and CE is no longer optional; it is a prerequisite for market access, ensuring products meet rigorous safety, electromagnetic compatibility, and performance benchmarks.

At the forefront of this transformation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting technology since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading manufacturer of high-quality individual LED components and complete lighting solutions designed specifically for commercial and industrial applications. Backed by stringent quality control and a deep understanding of global certification requirements, including ETL and CE, Beauty STC delivers reliable, code-compliant products that empower lighting designers and OEMs to build smarter, safer, and more sustainable systems.

Technical Specs & Certifications

When discussing “individual LED” specifications, it is critical to clarify a common industry misconception: the term typically refers to the complete LED luminaire (fixture), not the bare semiconductor chip. The bare LED chip itself does not possess metrics like lumens per watt, CRI, or IP ratings. These parameters are defined at the luminaire level, where the LED chip is integrated with drivers, optics, thermal management, and housing. Beauty STC designs and manufactures high-performance LED luminaires where these specifications are rigorously engineered and validated.

Lumens per watt (lm/W) efficiency for Beauty STC luminaires ranges from 150 to 200 lm/W in standard commercial and industrial product lines. This efficiency is achieved through proprietary multi-die LED packages, optimized driver electronics with >92% efficiency, and advanced thermal management using extruded aluminum heat sinks with thermal interface materials rated for 100,000+ hours of operation. Our high-bay and linear fixture series consistently exceed 180 lm/W at 5000K CCT while maintaining lumen maintenance of L90 > 100,000 hours per IES LM-80 and TM-21 standards.

Color Rendering Index (CRI) values exceeding 90 are standard across Beauty STC’s architectural and retail lighting portfolios. We achieve Ra > 90 with R9 > 50 using tri-phosphor and quad-phosphor LED packages tuned to deliver full-spectrum light. This requires precise binning of LED chips at 3-step MacAdam ellipse tolerance and spectral power distribution engineering to ensure vibrant, accurate color rendering critical for applications like art galleries and retail displays. Independent third-party testing reports (IES LM-79) verify CRI performance, and we provide TM-30-15 fidelity index data upon request to address limitations of basic CRI metrics.

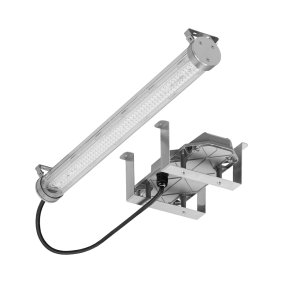

IP ratings apply exclusively to the completed luminaire, not individual components. Beauty STC fixtures achieve IP65, IP66, and IP67 ratings through fully sealed polycarbonate or tempered glass optics with silicone gaskets, marine-grade aluminum housings, and potted driver compartments. For example, our outdoor floodlight series features IP67 certification verified through 30-minute submersion testing at 1m depth per IEC 60529, while industrial high-bays maintain IP66 with 100 kPa water jet resistance. All ingress protection claims are validated through UL 1598 and IEC 60598 certified laboratory testing.

Beauty STC’s quality commitment is embedded in every luminaire through ISO 9001-certified manufacturing processes, 100% in-line photometric testing, and accelerated life testing exceeding IES LM-84 requirements. We utilize only Epistar and Samsung LED chips with wafer-level traceability, coupled with Mean Well or Inventek drivers featuring 5-year warranties. Our thermal design ensures junction temperatures remain below 85°C under full load, preventing lumen depreciation and color shift. This systems-level engineering approach—integrating high-efficacy LEDs, precision optics, and robust mechanical design—delivers luminaires that consistently outperform industry benchmarks for efficiency, color quality, and environmental resilience.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is equipped with advanced surface mount technology (SMT) production lines that ensure high-precision assembly of LED lighting components. These SMT machines are fully automated and capable of handling a wide range of LED packaging types, including 2835, 5050, and COB configurations, allowing for efficient and consistent mounting of LED chips onto printed circuit boards (PCBs). The integration of automated optical inspection (AOI) systems within the SMT process ensures strict quality control by detecting placement errors and solder defects in real time.

The Jiangmen facility includes comprehensive aging and reliability testing capabilities to ensure product longevity and performance. Completed LED modules and finished luminaires undergo rigorous aging tests, typically conducted over 48 to 72 hours under elevated temperature and full-load conditions. These tests simulate extended operation to identify early failure modes and verify thermal management, driver stability, and optical consistency. Additional environmental testing such as humidity exposure, thermal cycling, and ESD protection checks are also performed to meet international safety and performance standards including CE, RoHS, and UL.

Beauty STC has strong OEM capabilities tailored to customized LED solutions, including the production of individual LED components based on client specifications. This includes custom binning of LED chips for precise color temperature and lumen output, tailored PCB layouts, and specialized phosphor coatings for unique spectral outputs. The company supports low to high-volume OEM orders with flexible manufacturing setups, enabling clients to brand and design LED products for niche markets such as architectural lighting, commercial downlights, or specialty horticultural fixtures. With in-house R&D support and engineering collaboration, Beauty STC provides end-to-end OEM services from prototype development to mass production, ensuring scalability and compliance with global market requirements.

Application Scenarios

The term “individual LED” typically refers to discrete, self-contained LED luminaires such as downlights, spotlights, or small recessed/applied fixtures, as opposed to linear LED strips or large integrated panels. These are widely used across hospitality, retail, and commercial sectors for precise illumination control. Below is guidance on application and installation for each environment.

In hotels, individual LED downlights or adjustable spotlights are essential in guest room bathrooms for focused task lighting around vanities, ensuring even illumination without shadows. They are equally critical in lobbies for accenting artwork or architectural features, where narrow-beam spotlights (15°-25°) highlight textures while wider floods (35°-60°) provide ambient washes. Corridors benefit from uniformly spaced downlights with 4000K CCT for safety and wayfinding, avoiding glare through careful placement away from reflective surfaces. Always verify beam angles match the ceiling height to prevent hotspots or inadequate coverage.

Malls deploy individual LEDs strategically in retail storefronts where high-CRI (≥90) track spotlights draw attention to merchandise, particularly in luxury boutiques requiring precise beam control. Food court seating areas use recessed downlights with diffusers to minimize glare over tables, while directional pendants illuminate directory signage without spilling light onto adjacent stores. Critical considerations include matching color temperature across adjacent stores to avoid visual dissonance and ensuring sufficient lumen output for merchandise vibrancy without creating uncomfortable brightness contrasts in circulation zones.

Offices rely on individual LED downlights in open-plan areas with careful spacing (typically 1.8-2.4m on center) to eliminate dark spots between workstations. Meeting rooms require dimmable, high-CRI fixtures for video conferencing clarity, while private offices benefit from adjustable wall-washer spotlights to reduce screen glare. Avoid installing fixtures directly above desks; offset them 30-60cm from the workstation’s long edge to prevent reflections. Use 3500K-4000K CCT for balanced alertness and comfort, ensuring all fixtures within a visual field share identical chromaticity to prevent eye strain.

Installation requires strict adherence to thermal management protocols. Always maintain minimum clearance above recessed fixtures as specified by the manufacturer—typically 50mm from insulation—to prevent lumen depreciation. Verify compatible dimmers during electrical rough-in, especially for phase-cut or 0-10V systems, and conduct voltage drop calculations for long mall corridor runs to avoid inconsistent output. Test all fixtures for CCT and output uniformity before final mounting; batch variations become glaringly obvious in large installations. Crucially, coordinate cutout sizes precisely with ceiling grid tolerances—mismeasured apertures in office drop ceilings cause uneven trim alignment that compromises aesthetics. Always use manufacturer-provided mounting hardware to avoid stress cracks in optical components during installation.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality individual LED solutions from Beauty STC. As a trusted manufacturer in the LED industry, we specialize in delivering durable, energy-efficient, and innovative LED components tailored to meet diverse project needs. Partner with Beauty STC to access reliable products, expert technical support, and customized service that drives success.

For collaboration opportunities or product inquiries, contact our team at [email protected]. Let’s illuminate the future together—reach out today and take the first step toward a brighter, more efficient solution.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.