Article Contents

Industry Insight: Ic Led Controller

In the rapidly evolving landscape of commercial and industrial lighting, intelligent control systems have become essential for optimizing energy efficiency, enhancing operational flexibility, and ensuring compliance with rigorous safety standards. At the heart of this transformation lies the IC LED controller—precision-engineered driver technology that enables seamless integration, dimming capabilities, and reliable performance across demanding environments. As facilities increasingly adopt smart lighting solutions, the demand for controllers that meet both ETL and CE certifications has surged, underscoring the importance of regulatory compliance in North American and European markets. These certifications are not just marks of quality—they are critical indicators of electrical safety, electromagnetic compatibility, and long-term reliability in large-scale installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED driver innovation for over two decades. Specializing in high-performance IC LED controllers for commercial and industrial applications, Beauty STC combines advanced circuit design with robust manufacturing practices to deliver solutions trusted by lighting professionals worldwide. With a proven track record in developing ETL- and CE-certified products, the company continues to set benchmarks in reliability, efficiency, and technological sophistication across warehouses, manufacturing plants, office complexes, and public infrastructure.

Technical Specs & Certifications

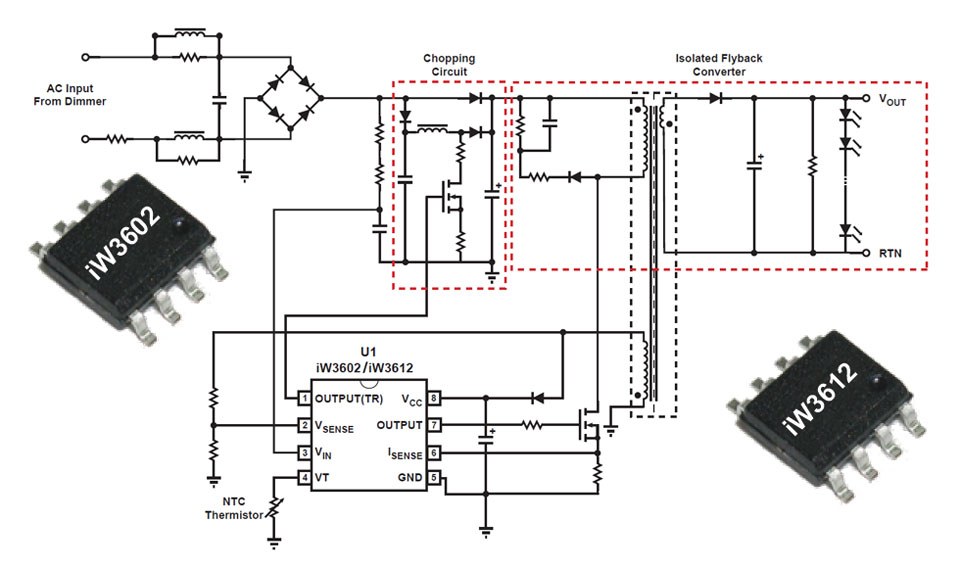

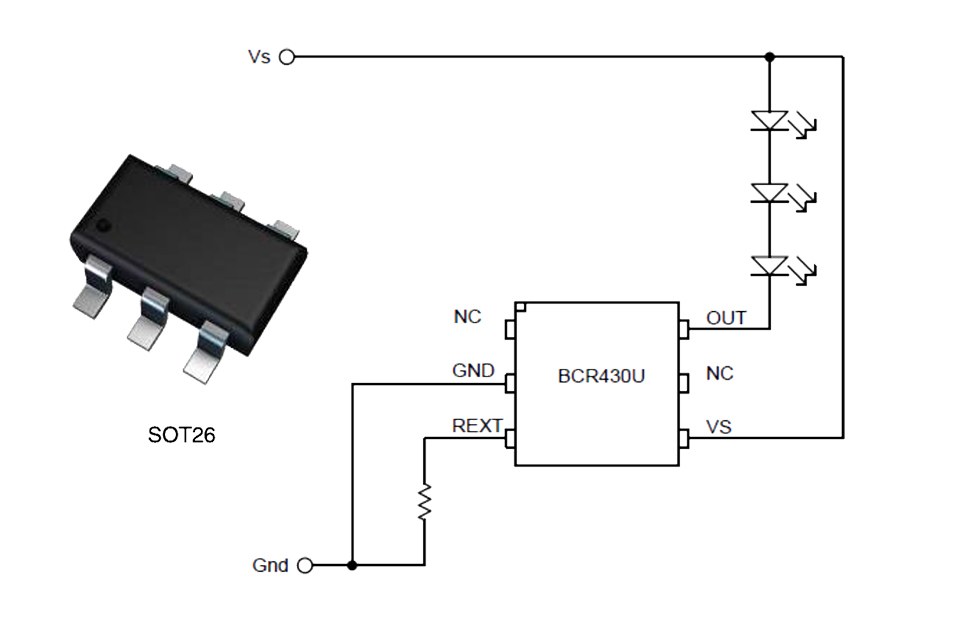

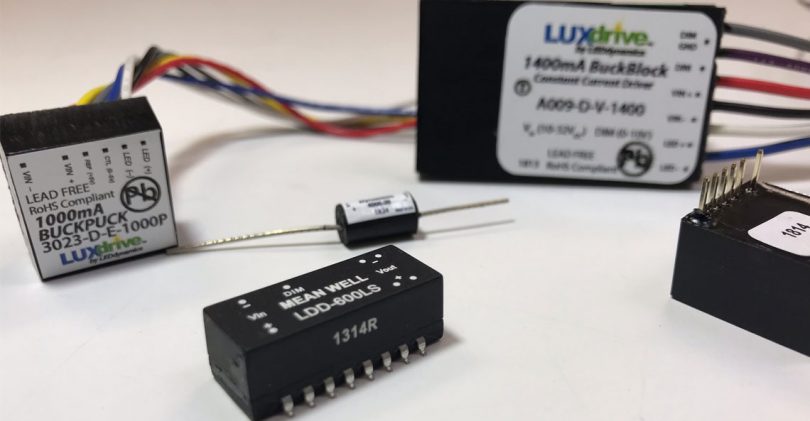

Beauty STC Manufacturing Co., Ltd. designs and manufactures high-performance IC-based LED drivers and controllers that serve as the critical power and control interface for our professional lighting systems. It is essential to clarify that the term “IC LED controller” typically refers to the integrated circuit chip itself, which is a core component within the complete LED driver or controller unit. Beauty STC focuses on the engineering and production of these complete, certified driver/controller units, where the IC is a vital element enabling precise functionality. Our technical specifications for these finished products, particularly for high-end applications demanding exceptional efficiency and color quality, are rigorously defined.

Regarding lumens per watt (lm/W), this metric is primarily a characteristic of the complete LED luminaire system, not solely the driver/controller. However, the driver’s efficiency directly impacts the overall system lm/W. Beauty STC drivers achieve industry-leading efficiencies, typically ranging from 92% to 96% across our constant current and constant voltage product lines for architectural and commercial applications. This high driver efficiency minimizes power loss as heat, directly contributing to the luminaire achieving system efficacies often exceeding 140 lm/W for standard white points and reaching 180-200 lm/W in high-efficacy configurations. Our proprietary thermal management design within the driver housing ensures this high efficiency is maintained consistently over the product’s lifespan, even under demanding ambient conditions, maximizing the usable light output per watt consumed by the system.

For Color Rendering Index (CRI), Beauty STC drivers are engineered to power LEDs capable of delivering CRI values consistently above 90, with many solutions exceeding 95. We achieve this through stringent binning requirements for the LEDs we integrate and precise current regulation from our drivers, ensuring stable color point and minimal flicker. Beyond CRI Ra, we prioritize high R9 (saturated red) values, typically >90, and often provide TM-30-15 metrics (Rf and Rg) upon request for critical color applications such as retail, museums, and high-end hospitality. The driver’s stable constant current output, free from ripple and noise, is fundamental to maintaining this high color fidelity over time and under varying load conditions, preventing color shift that can occur with inferior power supplies.

IP ratings are critical for product suitability in diverse environments. Beauty STC manufactures LED drivers and controllers across a comprehensive range of ingress protection ratings. For indoor dry locations, standard units carry IP20. For damp locations like covered outdoor areas, bathrooms, or retail environments, IP65-rated drivers are standard, providing full dust protection and resistance to low-pressure water jets from any direction. For fully outdoor applications, submerged景观 lighting, or harsh industrial settings, we offer robust IP67 and IP68 rated solutions, with IP68 units capable of continuous submersion beyond 1 meter as per specific product specifications. All IP-rated enclosures utilize high-purity silicone seals, corrosion-resistant aluminum or polycarbonate housings, and undergo rigorous third-party testing to ensure long-term environmental sealing integrity.

Beauty STC’s commitment to quality is embedded in every driver and controller. We utilize only A-tier components, including the critical ICs sourced from leading global semiconductor manufacturers, ensuring reliability and performance consistency. Our manufacturing adheres strictly to ISO 9001 standards within our state-of-the-art facility, featuring automated SMT lines and comprehensive in-circuit testing. Each unit undergoes 100% functional testing, including extended burn-in periods simulating 50,000+ hours of operation, and rigorous safety certification to UL, cUL, CE, and TÜV standards. This meticulous attention to detail, from component selection through final assembly and testing, guarantees the high efficiency, color stability, environmental resilience, and exceptional longevity that define Beauty STC products in the professional lighting market. Our drivers are not just components; they are engineered systems ensuring the optimal performance and lifespan of the entire luminaires they power.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility located in Jiangmen, Guangdong Province, China. The factory is strategically situated within the Pearl River Delta region, known for its robust electronics supply chain and logistics infrastructure, enabling efficient production and global distribution.

The Jiangmen facility is equipped with advanced SMT (Surface Mount Technology) production lines that support high-precision assembly of LED lighting components and control systems. These SMT machines, including high-speed pick-and-place units, automated solder paste printers, and reflow ovens, ensure consistent quality and high throughput. The use of automated optical inspection (AOI) systems further enhances quality control by detecting placement and soldering defects in real time, minimizing rework and ensuring product reliability.

A critical part of the manufacturing process at the Jiangmen factory is the comprehensive aging and burn-in testing. Completed LED controllers and lighting modules undergo extended operational testing under controlled thermal and electrical conditions. This aging process typically lasts from 4 to 12 hours, during which units are monitored for performance stability, thermal behavior, and electrical integrity. This rigorous testing protocol ensures that only units meeting strict reliability standards are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly for intelligent LED control solutions such as IC-based LED controllers. The company supports full customization, from circuit design and firmware development to PCB layout and final assembly. Clients can provide specifications for dimming protocols (e.g., PWM, 0-10V, DALI), communication interfaces (e.g., DMX, Zigbee, Wi-Fi), or form factors, and Beauty STC will engineer and manufacture the solution accordingly. The factory’s flexible production lines allow for both low-volume prototyping and high-volume manufacturing, making it well-suited for global lighting brands seeking tailored, high-quality controller solutions.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, product reliability, and customer-focused innovation in the LED lighting industry.

Application Scenarios

The term “IC LED controller” is not standard industry terminology and likely represents a misunderstanding or miscommunication. Within professional LED lighting control for commercial applications like hotels, malls, and offices, the relevant technologies are specific control protocols and systems such as DALI (Digital Addressable Lighting Interface), 0-10V, DMX512, wireless protocols (like Bluetooth Mesh or Zigbee), or proprietary building management system (BMS) interfaces. There is no distinct product category universally known as an “IC LED controller.” It’s probable the query refers to integrated circuit-based controllers inherent within standard dimming drivers or centralized control systems. Assuming the intent is to understand where standard LED control systems are applied and how to install them correctly in these venues, here is the guidance.

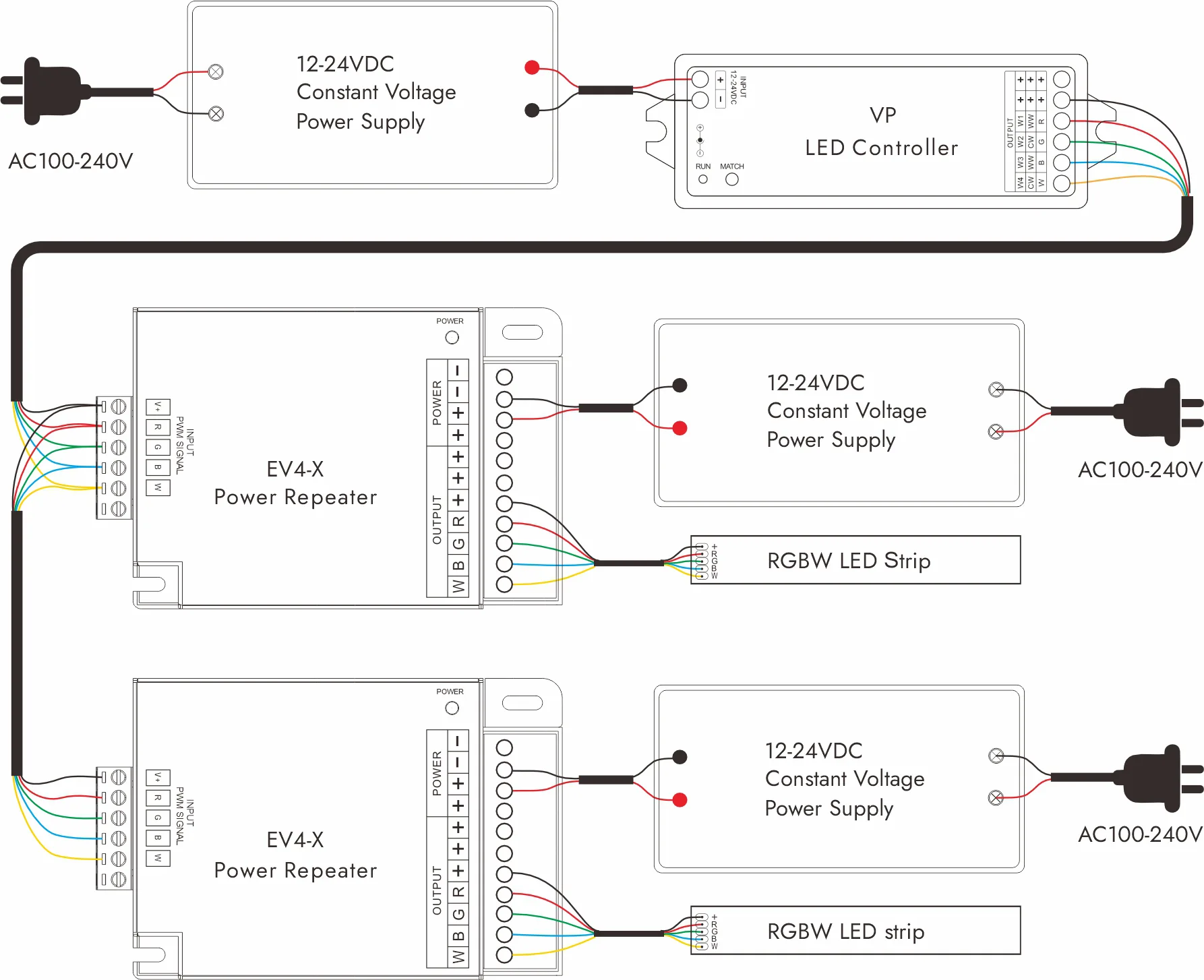

In hotels, sophisticated LED control systems are essential for creating ambiance and operational efficiency. Lobbies and reception areas utilize DALI or DMX512 systems to enable dynamic scene setting, transitioning from bright morning welcome lighting to warm, relaxing evening moods. Guest room lighting typically employs 0-10V or wireless controls integrated with in-room automation systems, allowing guests to adjust brightness and scenes via wall panels or apps while enabling housekeeping mode for energy savings. Restaurants and bars rely heavily on DMX512 for precise color tuning and dimming of RGBW fixtures to enhance the dining experience, while ballrooms and conference spaces use DALI for flexible zoning, allowing partitioned areas to have independent lighting levels for simultaneous events. Corridors and back-of-house areas often use simpler 0-10V or DALI with occupancy sensors for basic energy management.

Malls demand robust and flexible control systems due to their scale and diverse tenant requirements. Common areas and atriums implement DALI systems with daylight harvesting sensors to reduce energy use by dimming perimeter lighting when natural light is sufficient, while maintaining consistent illumination levels throughout the day. Retail storefronts within the mall frequently use 0-10V or proprietary systems controlled by individual tenants for their signage and interior lighting, requiring careful coordination with the mall’s master system for facade lighting. Feature lighting such as dynamic cove lighting in walkways or decorative elements often employs DMX512 for synchronized color-changing effects during events or holidays. Parking garages utilize DALI or 0-10V with occupancy sensors and scheduling to provide safety lighting at reduced levels during off-peak hours, ramping up when movement is detected.

Offices prioritize productivity, comfort, and energy compliance through precise lighting control. Open-plan workspaces almost exclusively use DALI systems for granular individual or small-group desk control, enabling personal task lighting adjustment while integrating seamlessly with ceiling occupancy sensors and daylight harvesting to minimize energy waste. Private offices and meeting rooms typically employ 0-10V or DALI with wall-mounted controls offering preset scenes for presentations, video conferencing, and focused work. Conference rooms with advanced AV setups often require DMX512 for synchronized control of architectural lighting alongside projection environments. Reception and break areas may use simpler DALI or wireless systems for basic scene setting and scheduling.

Critical installation practices apply universally across these venues to ensure reliability and performance. Always separate low-voltage control wiring from mains power cables by a minimum of 200mm and cross them at 90-degree angles to prevent electromagnetic interference causing flicker or signal loss. For DALI systems, strictly adhere to the 300m maximum cable run length and 64-device limit per loop, using certified DALI cable with a characteristic impedance of 120 ohms and terminating both ends of the bus with 100-ohm resistors to prevent signal reflections. When installing 0-10V systems, ensure the control wires are twisted pair and verify the controller’s polarity matches the driver’s requirements, as reversing polarity can damage equipment. For all systems, provide dedicated, clean power supplies for controllers and signal boosters, avoiding shared circuits with heavy machinery like HVAC compressors. Rigorously label every device, circuit, and control wire at both ends during installation; this is non-negotiable for troubleshooting in complex commercial environments. Conduct comprehensive system testing under full load conditions before client handover, verifying every zone, scene, and sensor function. Maintain detailed as-built documentation including network topology, device addresses, and configuration files, as this is essential for future maintenance and expansion. Finally, consult the specific manufacturer’s specifications for the chosen control protocol and drivers, as requirements can vary significantly between brands and product generations. Assuming “IC LED controller” refers to a specific proprietary product, always obtain and follow its exact technical documentation.

Why Choose Beauty STC Lighting

Discover the future of lighting control with Beauty STC’s advanced IC LED controllers. Engineered for precision, reliability, and seamless integration, our IC solutions empower smarter, more efficient lighting systems across residential, commercial, and industrial applications.

Partner with Beauty STC, a trusted leader in innovative LED technology, and gain access to cutting-edge products, dedicated technical support, and customized solutions tailored to your market needs.

Take the next step in intelligent lighting. Contact our sales manager today at [email protected] to discuss how our IC LED controllers can elevate your product offerings and drive your business forward.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.