Article Contents

Industry Insight: Hardwired Led Strip Lights

The commercial and industrial lighting sector is undergoing a significant transformation, with hardwired LED strip light systems rapidly displacing temporary plug-and-play solutions for permanent installations. Driven by the demand for seamless integration, superior reliability, and long-term operational cost savings in demanding environments like warehouses, retail spaces, offices, and manufacturing facilities, these systems offer a clean, professional aesthetic and eliminate the visual clutter and potential failure points of visible cords and adapters. Critical to their adoption in professional settings is adherence to rigorous safety and performance standards; ETL listing for the North American market and CE marking for Europe are non-negotiable requirements, ensuring electrical safety, electromagnetic compatibility, and compliance with regional regulations. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. Leveraging over 25 years of specialized engineering expertise in LED technology, we design and manufacture hardwired strip lighting solutions built specifically for the demanding requirements of commercial and industrial applications, prioritizing robust construction, certified performance, and simplified installation to reduce costly maintenance cycles and deliver lasting value.

Technical Specs & Certifications

Hardwired LED strip lights are a permanent lighting solution designed for direct electrical connection to a building’s low-voltage or line-voltage circuit, eliminating the need for plug-in power supplies in many installations. At Beauty (STC) Manufacturing Co., Ltd., our hardwired LED strip lights are engineered for high performance, reliability, and superior light quality, meeting the demands of both residential and commercial applications.

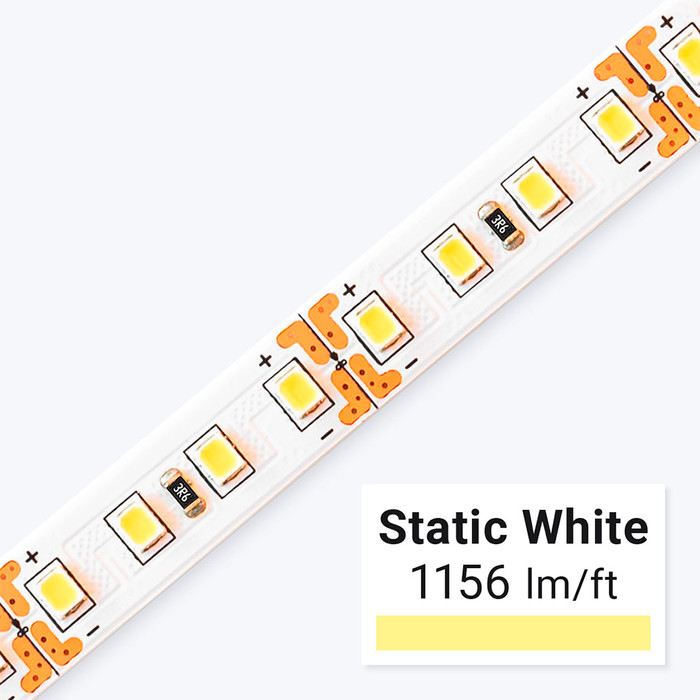

One of the key performance metrics for LED lighting is lumens per watt (lm/W), which measures luminous efficacy—how efficiently a light source produces visible light. Beauty STC’s hardwired LED strip lights achieve an industry-leading efficacy range of 110 to 130 lumens per watt, depending on color temperature and density configuration. This high efficiency ensures reduced energy consumption and lower operational costs over time, making our strips ideal for long-duration lighting applications such as under-cabinet lighting, cove lighting, and architectural accenting.

Color Rendering Index (CRI) is another critical specification, especially in environments where accurate color representation is essential—such as retail displays, art galleries, and high-end residential interiors. All Beauty STC hardwired LED strip lights are designed with a CRI greater than 90, with select models reaching CRI 95+. This ensures that illuminated objects appear vibrant and true to life, with excellent differentiation between shades and tones. Our use of high-grade phosphor-coated LEDs and precise binning processes guarantees consistent color quality across production batches.

Ingress Protection (IP) ratings define a product’s resistance to dust and moisture, a vital consideration for durability in various environments. Beauty STC offers hardwired LED strip lights in multiple IP ratings to suit diverse installation conditions. Our standard non-encapsulated strips are rated IP20, suitable for dry indoor environments. For damp or outdoor applications, we provide fully encapsulated versions with IP65, IP67, and even IP68 ratings. These are achieved through silicone encapsulation or extruded aluminum profiles with sealed diffusers, ensuring protection against water jets, temporary submersion, and dust ingress.

Beauty STC’s commitment to quality is evident in every stage of production. Our LED strips are manufactured using high-purity copper PCBs for optimal thermal management and longevity, with rigorously tested SMD LEDs from trusted suppliers. Each batch undergoes photometric testing, thermal stress screening, and aging verification to ensure consistent performance over a rated lifespan of up to 50,000 hours. With UL/CUL, CE, and RoHS certifications, our hardwired LED strip lights meet international safety and environmental standards, reinforcing Beauty STC’s reputation for durable, high-fidelity lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in Jiangmen, Guangdong Province, China. This state-of-the-art factory serves as the company’s main production hub for LED lighting products, including our specialized hardwired LED strip lights. The facility operates under strict ISO 9001 quality management standards and maintains comprehensive certifications including UL, cUL, CE, and RoHS compliance, ensuring all processes meet rigorous international safety and environmental requirements. The Jiangmen plant integrates advanced automation with skilled craftsmanship to deliver high-volume production while maintaining exceptional quality control.

Our Surface Mount Technology (SMT) production lines are a cornerstone of the Jiangmen factory’s capabilities. We utilize multiple high-speed Yamaha YS24 series SMT placement machines, renowned for their precision and reliability in handling miniature LED components. These machines achieve placement accuracy within ±0.025mm, critical for mounting demanding chip sizes like 2835 and 5050 LEDs onto flexible printed circuit boards. The SMT process includes automated solder paste application via high-precision stencil printers, component placement at rates exceeding 80,000 components per hour per line, and controlled nitrogen-reflow soldering profiles optimized for thermal management. This advanced setup ensures consistent solder joint integrity and minimizes defects across every LED strip produced, forming the essential foundation for product longevity and performance.

Rigorous aging and burn-in testing is systematically integrated into our quality assurance protocols at the Jiangmen facility. Every batch of hardwired LED strip lights undergoes a mandatory 24-hour aging test under continuous operational conditions. Strips are powered at 1.2 times their rated voltage within temperature-controlled environmental chambers to accelerate potential early-life failures. During this process, automated monitoring systems track luminous output, color consistency, and thermal performance. Crucially, we employ thermal imaging cameras to identify any localized overheating points indicative of solder defects or component inconsistencies. Only strips passing this stringent endurance test, alongside final visual inspection and photometric verification, are cleared for shipment, guaranteeing field reliability and adherence to our 50,000-hour lifespan specifications.

Beauty STC possesses extensive OEM capabilities specifically tailored for hardwired LED strip light solutions. Our Jiangmen factory supports fully customized hardwired configurations from initial design through to final packaging. We handle all aspects including custom PCB layout for integrated copper busbars, specification of LED density and binning, selection of specialized phosphor coatings for precise CCT and CRI requirements, and implementation of proprietary thermal management features like enhanced copper thickness (1.0oz standard). Clients can specify unique input voltages, connector types, IP-rated overmolding materials (including IP67 silicone encapsulation), and custom reel lengths. Our engineering team collaborates directly with OEM partners to develop solutions meeting exact electrical, thermal, and mechanical specifications, supported by in-house tooling for custom extrusions and molding. This comprehensive OEM service extends to private labeling, custom packaging, and dedicated production scheduling for volume orders, all executed within our vertically integrated Jiangmen manufacturing ecosystem.

Application Scenarios

Hardwired LED strip lights are ideal for commercial and high-traffic environments where permanent, reliable, and energy-efficient lighting is required. They are commonly used in hotels, malls, and offices due to their sleek appearance, long lifespan, and ability to provide consistent ambient or task lighting.

In hotels, hardwired LED strip lights are often installed in guest rooms to highlight architectural features such as coves, headboards, and under cabinets. They are also used in lobbies, corridors, and restrooms to create a welcoming atmosphere while maintaining energy efficiency. Their low heat output and long operational life make them suitable for areas where lights may remain on for extended periods.

In malls, these lights are frequently used for accent lighting in display areas, signage backlighting, and architectural detailing such as stairwells, columns, and ceilings. The continuous illumination capability and uniform light distribution enhance the visual appeal of retail spaces, drawing attention to products and guiding foot traffic.

In offices, hardwired LED strips are commonly integrated into ceiling coves, under desks, in meeting rooms, and along corridors to provide indirect lighting that reduces glare and eye strain. Their flexibility allows for creative lighting designs that support both functionality and aesthetics in modern workspaces.

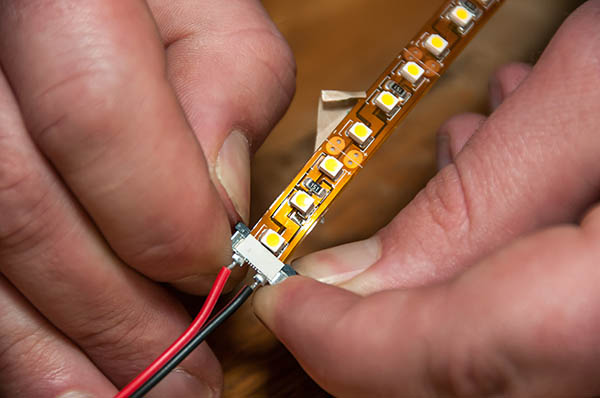

When installing hardwired LED strip lights, ensure that the power supply matches the voltage and current requirements of the strip. Always use a compatible constant-voltage LED driver, and verify local electrical codes to confirm compliance with safety standards. It is recommended to use aluminum channels to improve heat dissipation, extend LED life, and provide a clean, professional look. Make sure connections are secure and properly insulated, and use junction boxes where necessary. For long runs, consider injecting power at multiple points to avoid voltage drop and maintain consistent brightness. Finally, test the system before finalizing the installation and always de-energize the circuit during installation to ensure safety.

Why Choose Beauty STC Lighting

Elevate your lighting projects with professionally installed hardwired LED strip lights engineered for superior performance and reliability. Beauty STC delivers commercial-grade solutions designed for seamless integration into architectural cove lighting, under-cabinet installations, and custom applications where permanent, maintenance-free illumination is essential. Our hardwired systems feature robust construction, precise color consistency, and advanced thermal management to ensure longevity in demanding environments.

Partner with Beauty STC to access customizable lengths, multiple color temperatures, and high CRI options backed by rigorous safety certifications and a 5-year warranty. We provide dedicated engineering support and flexible manufacturing to meet your project specifications without compromising on quality.

Contact our lighting solutions manager today at [email protected] to discuss how our hardwired LED strip lights can enhance your next project with professional-grade results. Let us help you deliver exceptional value to your clients through innovation you can trust.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.