Article Contents

Industry Insight: Hardwire Led Strip

In the evolving landscape of commercial and industrial lighting, hardwire LED strips have emerged as a cornerstone solution for energy-efficient, durable, and high-performance illumination. Designed to directly connect to building electrical systems without the need for plug-in power supplies, hardwire LED strips offer seamless integration into architectural coves, high-bay fixtures, under-canopy installations, and large-scale facility retrofits. Their low-profile design and continuous light output make them ideal for applications demanding both aesthetic precision and operational reliability. With growing emphasis on safety and compliance, leading installations now require hardwire LED strips to meet rigorous certification standards such as ETL and CE, ensuring electrical safety, electromagnetic compatibility, and adherence to North American and international regulations.

As a trusted innovator in the LED lighting industry since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of developing hardwire LED strip solutions engineered specifically for commercial and industrial environments. With over two decades of expertise, Beauty STC combines robust thermal management, precision optics, and certified components to deliver products that meet the demanding needs of modern facilities—from warehouses and manufacturing plants to retail spaces and office complexes. Backed by a commitment to quality and regulatory compliance, Beauty STC continues to set benchmarks in performance-driven LED technology, providing integrators and contractors with reliable, code-compliant lighting systems that enhance both functionality and sustainability.

Technical Specs & Certifications

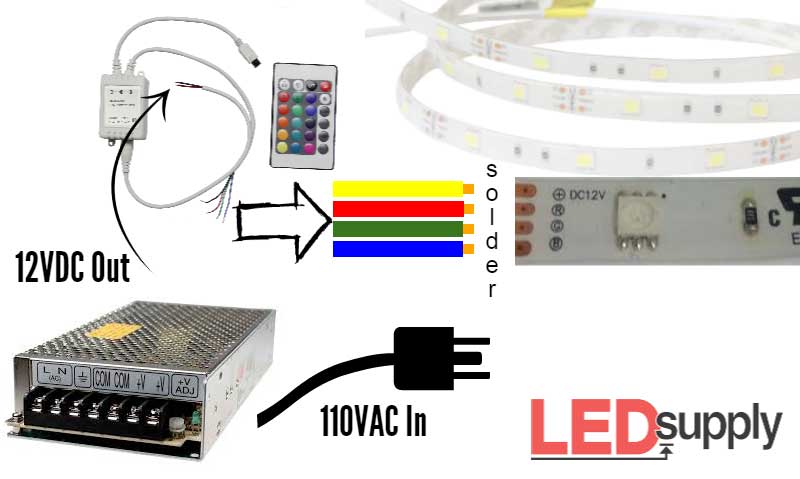

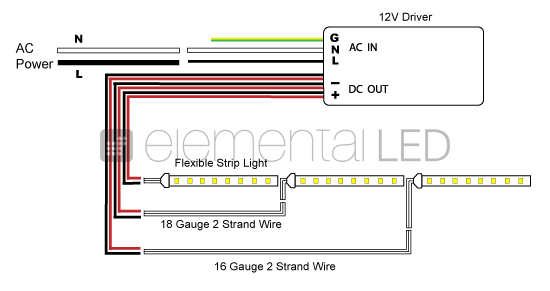

Beauty STC Manufacturing Co., Ltd. designs and produces hardwire LED strips engineered for superior performance in commercial and high-end residential applications. It is critical to clarify that “hardwire” refers to the direct connection of the LED strip system to mains voltage AC power via an integrated or remote constant-voltage LED driver, not an inherent property of the strip itself. The strip remains a low-voltage DC component; the hardwiring aspect pertains to the power delivery method. Our technical specifications for such systems prioritize efficiency, color fidelity, and environmental resilience.

Lumens per Watt (lm/W) efficiency is a core focus. Beauty STC’s hardwire LED strip systems, utilizing premium SMD LEDs such as 301B or 3528 packages on high-thermal-conductivity PCBs, consistently achieve 120-150 lm/W at 25°C ambient temperature under standard operating conditions. This high efficacy is maintained through optimized drive currents, advanced phosphor conversion, and minimal optical losses in our diffusers. System-level efficiency includes the driver contribution, with our UL-listed constant-voltage drivers operating at 90-94% efficiency. Real-world output depends on installation factors like ambient temperature and mounting surface thermal management, but our thermal design ensures stable lumen maintenance well beyond standard benchmarks.

Color Rendering Index (CRI) performance exceeds the >90 requirement with significant rigor. Beauty STC specifies a minimum CRI Ra >95 across our premium hardwire strip lines, verified by third-party LM-79 testing. Crucially, we emphasize high fidelity in critical red (R9 >50) and saturated cyan (R12 >50) rendering, which many competitors neglect despite meeting basic Ra thresholds. This is achieved through proprietary multi-phosphor blends and tight binning of high-CRI LED chips from tier-1 suppliers like Nichia and Seoul Semiconductor. Our production process includes spectroradiometric sorting to ensure every reel meets the stated CRI specifications, guaranteeing accurate color representation essential for retail, hospitality, and art lighting applications.

IP ratings define environmental protection for the LED strip assembly. Beauty STC offers hardwire systems in multiple configurations. Bare strips (no coating) are rated IP20, suitable for dry indoor use only. For damp or outdoor applications, our standard offering features a flexible silicone overmolding process, achieving IP65 protection against dust and low-pressure water jets from any direction. For demanding environments like cove lighting exposed to weather or marine settings, we provide IP67-rated strips, fully sealed to withstand temporary immersion up to 1 meter. All encapsulated strips use UV-stabilized, halogen-free silicone resistant to yellowing and thermal cycling, maintaining integrity across -40°C to +70°C operational ranges. IP ratings apply to the complete strip assembly post-manufacturing; proper end-cap sealing during installation is required to maintain the rating.

Beauty STC’s quality commitment is embedded in every hardwire LED strip system. We enforce rigorous in-process controls including 100% automated optical inspection (AOI) for solder joints and component placement, followed by burn-in testing at elevated temperatures. Our silicone encapsulation uses medical-grade materials applied via precision metering systems to eliminate voids and ensure uniform thickness. Unlike competitors, we provide full LM-79/LM-80 test reports for lumen maintenance (L70/B50 exceeding 50,000 hours) and chromaticity stability. Every batch undergoes CRI verification using calibrated spectroradiometers, not just initial samples. This systematic approach, combined with UL/cUL safety certification for drivers and adherence to IEC 60598 standards, delivers exceptional longevity and consistent photometric performance, making Beauty STC strips the reliable choice for specifiers demanding uncompromised quality in critical lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility strategically located within one of China’s key manufacturing hubs. The Jiangmen site is fully equipped to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and customization for global markets.

The factory features advanced surface mount technology (SMT) production lines that enable precise and automated assembly of LED components onto flexible and rigid circuit boards. These SMT machines are capable of handling high-density placements with tight tolerances, ensuring consistent performance and reliability across batches. The use of automated optical inspection (AOI) systems further enhances quality assurance by detecting defects in real time during the soldering and mounting processes.

A critical part of the manufacturing process at the Jiangmen facility is the comprehensive aging and reliability testing. Completed LED strips undergo extended burn-in tests under controlled thermal and electrical conditions, typically lasting 24 to 72 hours. This aging process helps identify early-life failures, ensuring that only stable and durable products reach customers. Additional testing includes waterproof verification for IP-rated strips, color consistency checks using spectrometers, and mechanical stress tests for flexible and hardwired variants.

Beauty STC has robust OEM capabilities, particularly for hardwired LED strip lighting solutions. The company supports full customization including length, color temperature, lumen output, PCB design, input voltage, and connector types. Clients can provide technical specifications or work with Beauty STC’s engineering team to develop tailored solutions for commercial, industrial, or residential applications. The factory also offers custom labeling, packaging, and private branding services, making it a preferred partner for distributors and lighting brands seeking differentiated products.

Overall, the Jiangmen factory combines automation, rigorous quality testing, and flexible manufacturing to deliver high-performance, hardwired LED strip lighting solutions under OEM arrangements, meeting international standards and customer-specific requirements.

Application Scenarios

Hardwired LED strip installations are essential in commercial environments like hotels, malls, and offices where permanent, reliable, and code-compliant lighting solutions are required. Unlike plug-in strips, hardwired systems connect directly to the building’s electrical circuit via junction boxes, eliminating exposed plugs and ensuring safety for continuous operation under strict commercial electrical codes. In hotels, hardwired LED strips are ideal for cove lighting in lobbies and ballrooms to create ambient warmth, under-bar counter accents in restaurants for task lighting, headboard niches in guest rooms for subtle night lighting, and stair tread illumination in corridors for safety. Their seamless integration supports the high-end aesthetic while meeting fire safety regulations for concealed wiring.

Malls extensively utilize hardwired LED strips for storefront signage backlighting to ensure vibrant brand visibility, display case lighting within retail tenants for product highlighting, and architectural coving in common areas to guide foot traffic. Directory boards and information kiosks also require hardwired strips for reliable 12–16 hour daily operation without plug failures. The permanent connection is critical here due to high foot traffic, security concerns with exposed cords, and the need for uniform lighting across large spaces.

Offices deploy hardwired LED strips beneath suspended ceiling grids for indirect ambient lighting that reduces glare, under workstation cabinets for functional task illumination, and within reception desk perimeters to convey professionalism. Conference rooms benefit from cove lighting that sets presentation moods, while server rooms use them for low-heat aisle marking. Hardwiring is non-negotiable in these settings due to strict corporate facility standards, the necessity for 24/7 operational readiness in critical areas, and avoidance of tripping hazards from cords in open-plan layouts.

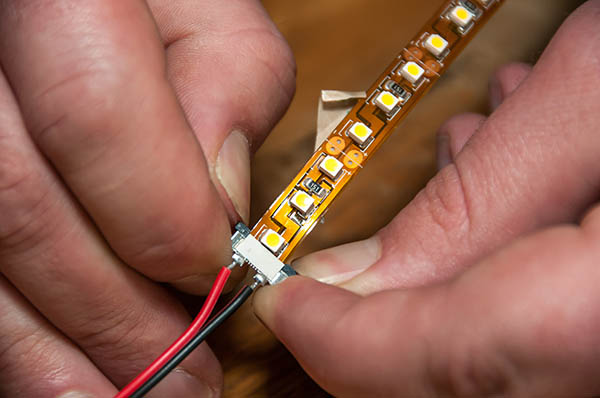

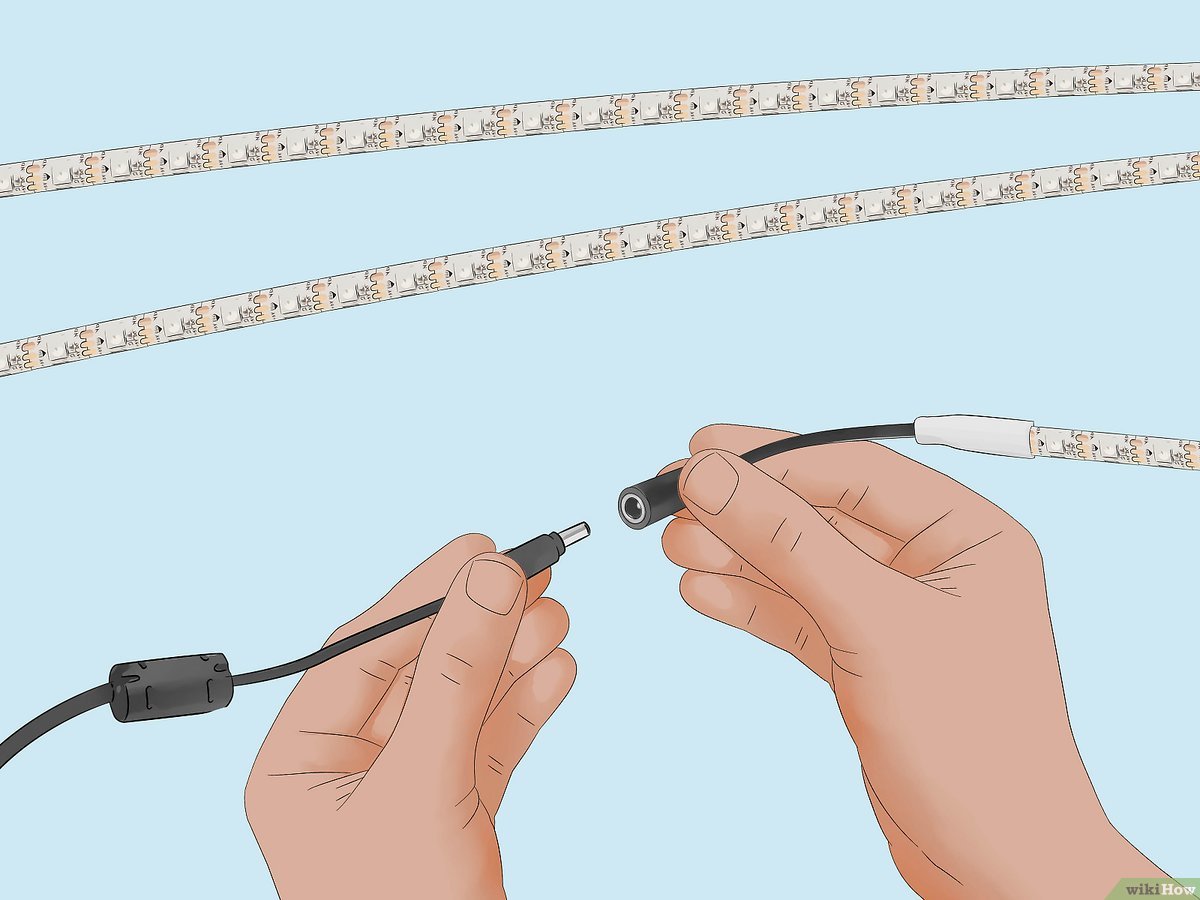

Installation begins with meticulous voltage drop calculations during design—use 24V strips for runs exceeding 5 meters and calculate wire gauge (typically 18–14 AWG) based on total load and distance to prevent dimming. Always terminate strips at junction boxes compliant with local codes (NEC Article 410 in the US); never splice directly into building wiring. Prepare surfaces by cleaning with isopropyl alcohol to ensure optimal thermal contact for adhesive-backed strips, and install aluminum mounting channels for heat dissipation in enclosed coves. For multi-zone control, group strips by circuit amperage (stay below 80% of breaker capacity) and use low-voltage transformers or drivers rated for continuous commercial use, secured within accessible junction boxes. Test all connections with a multimeter before final mounting, verify grounding continuity, and document circuit layouts for facility maintenance teams. Crucially, collaborate with licensed electricians for final circuit integration to ensure compliance with jurisdictional inspections.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality hardwire LED strips designed for seamless integration and long-lasting performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our hardwire LED strips offer reliable, energy-efficient lighting perfect for architectural, commercial, and residential applications.

To learn more or to discuss custom solutions for your needs, contact our sales manager at [email protected]. Let Beauty STC be your trusted lighting partner—delivering excellence, one strip at a time.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.