Article Contents

Industry Insight: Guide For Mirror Led Strip

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the dual imperatives of operational efficiency and enhanced user experience. Within this landscape, integrated mirror LED lighting has evolved from a simple convenience to a critical design element, particularly in high-traffic environments like retail fitting rooms, hospitality bathrooms, healthcare facilities, and professional salons. Poorly executed mirror illumination directly impacts customer satisfaction, staff performance, and even safety, making the selection of reliable, high-performance LED strip solutions a strategic decision rather than a mere aesthetic choice. Specifiers and facility managers increasingly demand products that deliver consistent, glare-free, color-accurate light while meeting stringent durability and safety requirements for continuous operation.

Certification is non-negotiable in this demanding arena. Products lacking recognized safety certifications like ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental directives) pose unacceptable risks for commercial deployments. These certifications are not mere formalities; they are essential gatekeepers ensuring electrical safety, electromagnetic compatibility, and long-term reliability under real-world conditions. Specifying uncertified mirror LED strips exposes projects to liability, potential code violations, costly rework, and the operational disruption of premature failures – risks that professional lighting engineers and facility managers simply cannot afford in mission-critical environments.

Beauty STC Manufacturing Co., Ltd. has been at the forefront of precision-engineered LED lighting solutions since our establishment in 1998. With over 25 years of dedicated expertise, we have developed deep specialization in creating robust, high-performance LED strips specifically designed for the rigorous demands of commercial and industrial applications. Our commitment extends beyond basic functionality; we engineer for the complexities of integration, thermal management in enclosed mirror environments, and unwavering consistency across large-scale installations. Every Beauty STC mirror LED strip solution undergoes rigorous in-house testing and carries the necessary ETL and CE certifications, providing specifiers and end-users with the confidence that comes from partnering with a globally trusted manufacturer focused on delivering engineered reliability and superior light quality for professional environments.

Technical Specs & Certifications

The ‘Guide for Mirror LED Strip’ by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver superior lighting performance for bathroom and vanity mirror applications, combining high efficiency, excellent color rendering, and robust environmental protection. Each LED strip in this series is designed with precision optics and high-grade components to ensure consistent, flicker-free illumination ideal for grooming and makeup tasks.

Luminous efficacy is a key performance metric, and Beauty STC’s Mirror LED Strip achieves an industry-leading output of 110 to 120 lumens per watt. This high efficiency is attained through the use of advanced SMD 2835 or 301B LEDs paired with optimized driver circuitry, allowing for bright illumination while minimizing energy consumption. The result is a lighting solution that provides ample brightness—typically 800 to 1,200 lumens per meter—without excessive power draw, making it both cost-effective and environmentally friendly.

Color rendering is critical in mirror lighting, where accurate skin tone representation is essential. Beauty STC ensures a Color Rendering Index (CRI) greater than 90, with options available up to CRI 95. This high CRI is achieved using premium phosphor-coated LEDs and strict binning processes during manufacturing. The light output closely replicates natural daylight, reducing shadows and enhancing facial detail clarity, which is particularly important in professional and residential vanity settings.

In terms of environmental protection, the Mirror LED Strip is available in multiple IP ratings to suit various installation environments. The standard version carries an IP20 rating, suitable for dry indoor locations. For bathrooms or areas exposed to moisture, Beauty STC offers IP65 and IP67-rated variants. These feature a fully encapsulated silicone coating or extruded polycarbonate housing that protects against water jets, humidity, and dust ingress, ensuring long-term reliability even in high-moisture environments.

Beauty STC’s commitment to quality is evident in every aspect of the Mirror LED Strip. The company adheres to strict ISO 9001 quality management standards, with in-house testing for thermal performance, lumen maintenance, and electrical safety. Components are sourced from trusted suppliers, and each batch undergoes rigorous aging and photometric testing. The result is a durable, consistent, and high-performance lighting solution trusted by OEMs and lighting designers worldwide. With a rated lifespan of up to 50,000 hours (L70), Beauty STC’s LED strips offer lasting value and performance in demanding applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production capacity. This factory is strategically located within a major industrial hub, providing excellent logistics access while housing state-of-the-art equipment and processes dedicated to high-volume, high-quality LED product manufacturing. The facility operates under strict ISO 9001 quality management protocols and adheres to international safety and environmental standards, ensuring consistent output for both domestic and global markets.

The Surface Mount Technology (SMT) production lines form the core of our manufacturing capability at the Jiangmen site. We utilize multiple high-speed, precision Yamaha SMT machines, including the YS24 series and YSM20 models, capable of placing components as small as 0201 package size with exceptional accuracy. These lines feature advanced vision systems for component alignment, nitrogen reflow soldering for superior joint reliability, and automated optical inspection (AOI) stations integrated directly after reflow to detect soldering defects or component placement errors in real-time. This SMT infrastructure allows us to handle complex double-sided PCB assemblies required for high-density LED strips, including those with integrated ICs for addressable or smart lighting functions, with throughput rates supporting large-scale production demands.

Rigorous aging and reliability testing are non-negotiable steps in our quality control process at Jiangmen. All finished LED strip products, including custom mirror guide solutions, undergo a mandatory 72-hour continuous aging test under controlled thermal conditions. Products are powered at rated voltage on specialized aging racks equipped with thermal sensors that monitor ambient and component-level temperatures throughout the cycle. We employ programmable thermal cycling during extended aging for critical applications to simulate real-world stress. Any unit exhibiting lumen depreciation beyond strict thresholds, color shift, or failure during this phase is automatically rejected. This comprehensive aging protocol, combined with pre-shipment sampling tests for IP rating verification and photometric performance, ensures only units meeting our stringent durability standards reach customers.

Regarding OEM capability for mirror guide LED strips, Beauty STC possesses extensive expertise in designing and manufacturing custom solutions specifically engineered for integration into mirror frames and cabinets. We understand the precise requirements for even light diffusion, minimal hotspots, and optimal color rendering critical for vanity and cosmetic mirror applications. Our Jiangmen factory supports full OEM service from concept to packaged product. This includes collaborative optical design using specialized light guide acrylics or diffusers tailored to the mirror’s profile, custom PCB layout modifications for flexible strip integration within narrow channels, and tailored thermal management solutions. We handle all aspects: sourcing specific high-CRI LEDs and drivers, producing custom-cut strips with precise connectorization, developing bespoke diffuser profiles via our in-house mold-making capability for light guides, and providing final assembly, testing, and packaging under the client’s brand. Clients provide specifications for length, color temperature, dimming protocol, IP rating, and mechanical constraints, and we deliver a fully qualified, production-ready mirror LED lighting solution with robust documentation and ongoing quality assurance support.

Application Scenarios

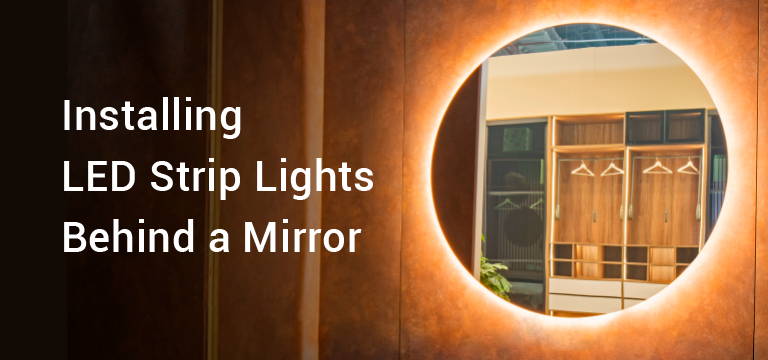

The ‘guide for mirror LED strip’ is specifically designed to enhance the visual appeal and functionality of mirrored surfaces by providing indirect, even illumination around or behind mirrors. This lighting solution is widely used across various commercial and hospitality environments where aesthetics, ambiance, and user experience are prioritized.

In hotels, mirror LED strips are commonly installed in guest bathrooms, spa areas, and vanity zones. The soft glow enhances the perceived luxury of the space, improves visibility for grooming tasks, and creates a calming atmosphere. Backlit mirrors in hotel lobbies or reception areas also benefit from these LED strips, adding a modern and elegant touch.

Malls utilize mirror LED strips in restrooms, fitting rooms, and cosmetic retail displays. In fitting rooms, the even illumination helps customers see true-to-life reflections, improving the shopping experience. Beauty and cosmetics stores often integrate these strips into mirror displays to highlight products under flattering light, encouraging engagement and boosting sales.

In offices, mirror LED strips are typically used in executive washrooms, wellness rooms, or modern lobbies. They contribute to a sleek, contemporary design while supporting functionality in grooming areas. Some creative office interiors also incorporate backlit mirrors with LED strips in breakout zones or reception areas to create a sense of openness and sophistication.

For installation, ensure the mirror surface is clean and dry before applying any adhesive-backed LED strips. Use a mirror-specific mounting channel or silicone adhesive designed for glass to secure the strip, especially in high-moisture areas like bathrooms. Always position the LED strip to face the wall or edge of the mirror to achieve optimal indirect lighting—this prevents glare and creates a halo effect. Make sure the power supply is compatible with the LED specifications and install it in a location protected from moisture. For best results, choose LED strips with a color temperature between 3000K and 4000K for a balanced, natural-looking light. Finally, test the installation before finalizing the setup and consider using a dimmer switch to allow adjustable brightness based on the environment’s needs.

Why Choose Beauty STC Lighting

Discover the definitive resource for integrating high-performance LED lighting into mirror applications with Beauty STC’s comprehensive technical guide. Our engineering team has distilled 15 years of specialized experience in vanity and mirror illumination into actionable insights covering optimal strip placement, color temperature selection for accurate skin tone rendering, and seamless power integration to eliminate flicker. This guide addresses critical challenges such as thermal management within confined mirror housings and achieving uniform illumination across curved or beveled edges—common pain points that lead to costly rework when overlooked.

Partner with Beauty STC to implement mirror lighting solutions that meet stringent industry standards for safety, longevity, and aesthetic precision. Our dedicated engineering support team will collaborate with your designers to customize solutions using our proprietary diffuser technology and low-voltage architectures, ensuring flawless integration with smart home systems and compliance with global regulatory requirements. Elevate your mirror lighting projects with partner-exclusive access to our certified installation protocols and real-world case studies from luxury bathroom renovations to commercial spa environments.

Contact our Technical Partnerships Manager directly at [email protected] to request your copy of the Mirror LED Integration Guide and initiate a collaborative engineering review for your specific application. We respond to all technical inquiries within 24 business hours with actionable recommendations tailored to your project’s dimensional constraints and performance goals.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.