Article Contents

Industry Insight: Green Led Tape Lights

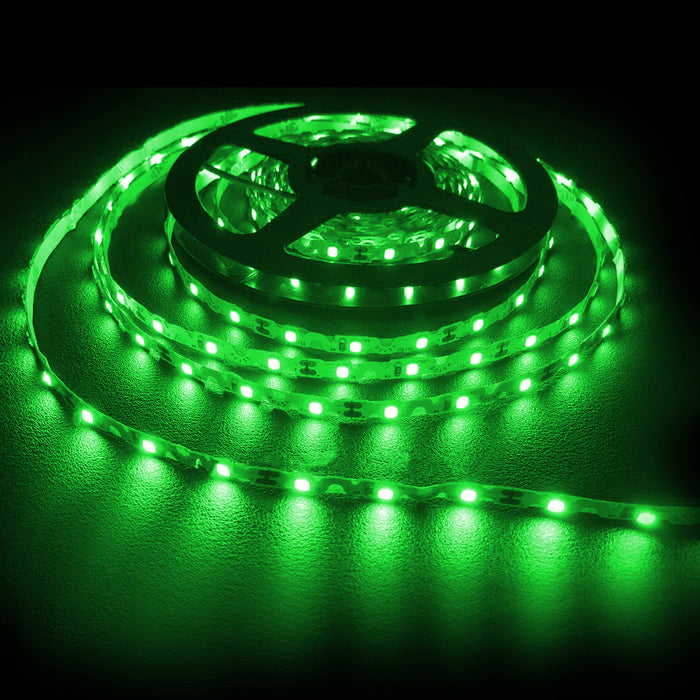

The commercial and industrial lighting sector is undergoing a transformative shift toward energy efficiency, durability, and sustainability—driving widespread adoption of advanced LED solutions. Among these innovations, green LED tape lights have emerged as a strategic lighting choice for applications ranging from architectural accenting and safety signage to machinery highlighting and cold storage illumination. Their compact form factor, low heat emission, and long operational life make them particularly well-suited for demanding environments where reliability and compliance are paramount.

As regulatory standards tighten globally, certifications such as ETL and CE have become essential benchmarks for product safety, electromagnetic compatibility, and environmental conformity. These certifications ensure that LED tape lights meet rigorous North American and European standards, giving facility managers, engineers, and contractors confidence in their performance and reliability under continuous operation.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, delivering high-performance LED lighting solutions tailored for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC combines cutting-edge technology with stringent quality control to produce green LED tape lights that are not only energy-efficient and durable but also fully compliant with ETL and CE requirements. As industries prioritize smarter, greener lighting infrastructure, Beauty STC continues to set the standard for innovation and trust in the LED lighting marketplace.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance green LED tape lights designed for professional applications where color accuracy, efficiency, and durability are critical. The term “green” in this context refers to the daylight color temperature range (typically 5700K to 6500K), not the physical color of the tape, ensuring a crisp, natural white light ideal for task lighting and modern aesthetics. Our tapes consistently achieve a minimum Color Rendering Index (CRI) of 90+, with many variants exceeding Ra 92. This high CRI is accomplished through stringent phosphor formulation control and binning processes during LED chip manufacturing, ensuring faithful color representation essential for retail, healthcare, and architectural settings where visual clarity is non-negotiable.

Luminous efficacy for our green LED tape lights typically ranges from 120 to 140 lumens per watt at 25°C ambient temperature, measured under standard drive currents (e.g., 180mA for 24VDC tapes). This efficiency is realized through the use of premium-bin SMD 2835 or 5050 LEDs with optimized thermal management in the flexible PCB design. It is important to note that achieving CRI >90 inherently involves a slight trade-off against maximum theoretical efficacy; however, our engineering team balances this by selecting LEDs with the highest efficacy within the high-CRI binning tier, ensuring minimal compromise. Performance data is validated using integrating sphere measurements per IES LM-79 standards, with results documented in full photometric reports available upon request.

Regarding environmental protection, Beauty STC offers multiple IP-rated variants to suit diverse installation environments. Our standard non-waterproof tapes carry an IP20 rating for dry indoor use. For damp or outdoor applications, we provide rigorously tested IP65-rated tapes featuring a continuous silicone encapsulation over the LED array and circuitry, protecting against low-pressure water jets and dust ingress. For submerged or high-moisture environments such as cove lighting in pools or marine settings, our premium IP67 and IP68 tapes utilize a dual-layer silicone coating process with reinforced end caps, validated through 30-minute submersion testing at 1 meter depth (IP67) and extended 1-meter submersion per manufacturer specifications (IP68). All waterproofing processes are integrated into our automated production line to ensure consistent coverage without voids.

Beauty STC’s commitment to quality is embedded in every tape light. We utilize only Tier-1 LED chips from recognized global suppliers, subjected to our internal 72-hour burn-in and binning protocol before assembly. Our flexible PCBs employ 2oz copper for superior heat dissipation, directly contributing to sustained lumen maintenance and longevity. Each production batch undergoes rigorous electrical safety testing (including HIPOT) and photometric verification, with full traceability from raw materials to finished goods. Our tapes are UL/cUL listed, CE marked, and RoHS compliant, with a standard 5-year warranty reflecting confidence in performance stability. This systematic approach to quality control and component selection ensures our green LED tape lights deliver not only the specified lumens per watt and CRI >90 but also exceptional reliability in demanding real-world installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated LED lighting production facility strategically located in the Guangdong province, a hub for electronics and lighting manufacturing. The Jiangmen facility is equipped with advanced surface mount technology (SMT) production lines that ensure high-precision assembly of LED components onto flexible printed circuits used in LED tape lights. These SMT machines are capable of handling a wide range of LED chip sizes, including 2835, 3528, 5050, and 5730, supporting both high-density and high-lumen output tape light designs. Automated optical inspection (AOI) systems are integrated into the SMT process to guarantee solder joint integrity and component placement accuracy, minimizing defects and ensuring consistent product quality.

After SMT assembly, all LED tape light products undergo rigorous aging tests as part of the factory’s quality assurance protocol. The aging process typically involves operating the tape lights continuously at full power for 24 to 72 hours under controlled temperature and humidity conditions. This stress testing helps identify early failures, ensures thermal stability, and verifies long-term performance. The factory also conducts photometric testing, electrical safety checks, and waterproof testing (for IP-rated products) to meet international standards such as CE, RoHS, UL, and CCC.

Beauty STC has strong OEM and ODM capabilities, particularly in the development and production of eco-friendly “green” LED tape lights. The term “green” refers not only to environmentally friendly materials and low energy consumption but also to compliance with RoHS and REACH regulations, lead-free soldering processes, and the use of recyclable packaging. The company supports custom solutions including tailored color temperatures (ranging from 2200K to 6500K), RGB and RGBW color options, custom lengths, dimming protocols (such as PWM, 0-10V, DALI), and specialized diffusers or silicone coatings. Clients can also request private labeling, custom branding, and unique packaging designs.

The Jiangmen factory’s combination of automated SMT lines, comprehensive aging and testing procedures, and flexible OEM services positions Beauty STC as a reliable manufacturing partner for high-quality, sustainable LED tape lighting solutions serving global markets.

Application Scenarios

Green LED tape lights serve specific aesthetic and functional purposes in commercial environments but require careful application due to their strong color saturation. Pure green is rarely suitable for general illumination as it distorts skin tones and natural colors, creating an unnatural or clinical atmosphere. Instead, it is best reserved for targeted accent lighting, thematic installations, or signaling purposes where the green hue aligns with the design intent. Below are context-specific applications for hotels, malls, and offices, followed by critical installation considerations.

In hotels, green LED tape lights should be used sparingly and strategically. They work effectively in spa treatment rooms to reinforce a natural, calming ambiance when combined with other earthy tones, though tunable white systems are generally preferable for flexibility. Pool and wellness areas may incorporate subtle green under-lighting in water features or along submerged steps for safety and visual interest, provided it meets IP68 ratings and local aquatic lighting codes. Avoid using green in guest room cove lighting, lobbies, or corridors where accurate color rendering is essential for guest comfort and perception of quality. Green can also highlight specific architectural elements in eco-themed boutiques or event spaces during temporary installations, such as sustainability-focused exhibitions, but should never replace primary warm white lighting in guest-facing areas.

For malls and retail environments, green LED tape lights are primarily valuable for seasonal or promotional displays. They excel during Halloween events for eerie effects in haunted house installations or themed kiosks, and can emphasize eco-friendly product sections in stores—such as organic grocery aisles or sustainable fashion pop-ups—when integrated into shelving or signage. Permanent installations should be limited to non-customer zones; for example, green tape can delineate emergency exit paths in back-of-house corridors where high visibility is critical, though building codes often mandate specific green exit signage instead of decorative tape. Never install green tape in general shopping corridors, fitting rooms, or food courts, as it negatively impacts merchandise appearance and patron experience by washing out colors and creating unflattering lighting.

Offices present the least appropriate setting for green LED tape lights in functional workspaces. Task lighting must prioritize high-CRI (90+) neutral or warm white LEDs to reduce eye strain and support productivity. Green light severely compromises color accuracy, making documents, screens, and even colleagues appear unnatural. Limited exceptions exist in creative agency break rooms or gaming lounge areas where brand identity calls for bold colors, or as a subtle under-desk accent in non-work zones if the company culture embraces it. However, such uses remain niche and should never interfere with primary workspace illumination. Green tape might also serve as a low-level pathway marker in server rooms during maintenance hours, but standard white or blue is typically preferred for safety.

Installation demands rigorous attention to technical details. Always use constant-voltage power supplies matched precisely to the tape’s voltage (12V or 24V) and calculate total load at 20% below capacity to prevent overheating. For green LEDs—which often have lower lumen output per watt than white—ensure adequate tape density; 16.4ft (5m) reels may require double runs in coves to avoid visible dots. Aluminum mounting channels are non-negotiable for thermal management; adhesive-backed tape alone will overheat, causing color shift and premature failure. Maintain strict voltage drop control by keeping runs under 32.8ft (10m) for 12V systems or using parallel wiring for longer installations. In humid areas like hotel spas, select tape with silicone encapsulation (IP67 minimum) and avoid solderless connectors, which are prone to corrosion. Finally, always test green tape against the actual surface material first—certain finishes may reflect an unintended turquoise or yellow-green hue due to pigment interactions. For any application where human appearance matters, prioritize high-quality tunable white or warm white tape with CRI >90 and R9 >50 over colored alternatives.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality green LED tape lights designed for durability, energy efficiency, and vibrant color consistency. At Beauty (STC) Manufacturing Co., Ltd., we specialize in premium LED solutions tailored to meet the demands of residential, commercial, and industrial applications.

Partner with Beauty STC to benefit from OEM/ODM capabilities, competitive pricing, and reliable production capacity. Our green LED tape lights are RoHS compliant, low-voltage safe, and built to last in diverse environments.

For inquiries, wholesale orders, or technical support, contact our sales manager at [email protected]. Let’s illuminate your next project together—reach out today and experience superior quality from a trusted industry leader.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.