Article Contents

Industry Insight: Glued Strips

Glued LED strips have become a cornerstone in modern commercial and industrial lighting solutions, offering seamless integration, energy efficiency, and design flexibility across a broad range of applications. From warehouse high bays and retail under-cabinet lighting to architectural cove installations and industrial workspaces, these adhesive-backed linear lighting systems provide reliable, low-profile illumination that meets the rigorous demands of professional environments. As building standards and energy codes evolve, specifiers and facility managers are increasingly turning to certified, high-performance glued strips that comply with key safety and quality benchmarks—including ETL listing and CE marking—to ensure operational safety, regulatory compliance, and long-term durability.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted innovator in the LED lighting industry, specializing in engineered lighting solutions for commercial and industrial markets worldwide. With over two decades of expertise, Beauty STC combines advanced thermal management, robust materials, and strict quality control to deliver glued strip lighting that performs under demanding conditions. Their commitment to compliance ensures all applicable products meet ETL and CE standards, supporting safe deployment across North American and international projects. As the demand for smarter, more efficient linear lighting grows, Beauty STC continues to lead with reliable, code-compliant glued strip technologies designed for professional-grade installations.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance adhesive-backed LED strip lights designed for demanding commercial and residential applications. While the industry term “glued strips” colloquially refers to LED strips with integrated pressure-sensitive adhesive backing for mounting, our technical specifications focus on precision engineering and material quality to ensure reliability. For our standard high-CRI adhesive LED strip lines meeting your criteria, the following technical specifications apply based on our current 24VDC product portfolio.

Luminous efficacy for our CRI>90 strips typically ranges from 120 to 130 lumens per watt at 25°C ambient temperature under standard test conditions (IEC 60598-1). This efficiency is achieved through the use of Samsung LM301B or Nichia 219B mid-power LEDs paired with optimized constant-current drivers, maintaining >90% efficiency across 10-100% dimming ranges. Efficacy measurements strictly adhere to LM-79-19 procedures with integrating sphere verification.

All strips marketed with CRI>90 utilize rigorously binned phosphor-converted LEDs with R9 values exceeding 50 and Rf values >80 per TM-30-15 metrics. We achieve this through triple-layer phosphor coating and spectral tuning during manufacturing, with each production batch undergoing spectroradiometric validation using Konica Minolta CS-2000 instruments. Minimum maintained CRI of 92 is guaranteed over 50,000 hours at L70 lifetime (TM-21-11 projection).

IP rating options include IP20 for dry indoor use, IP65 for protected outdoor/damp locations (silicone encapsulated), and IP67 for temporary submersion (fully potted). Our IP65 strips feature dual-layer protection: a 0.5mm flexible silicone overmold over the PCB plus UV-stabilized adhesive backing rated for -40°C to +70°C operation. All IP-rated products undergo 100% production testing per IEC 60529 standards with 15-minute water jet exposure at 100L/min for IP65 verification.

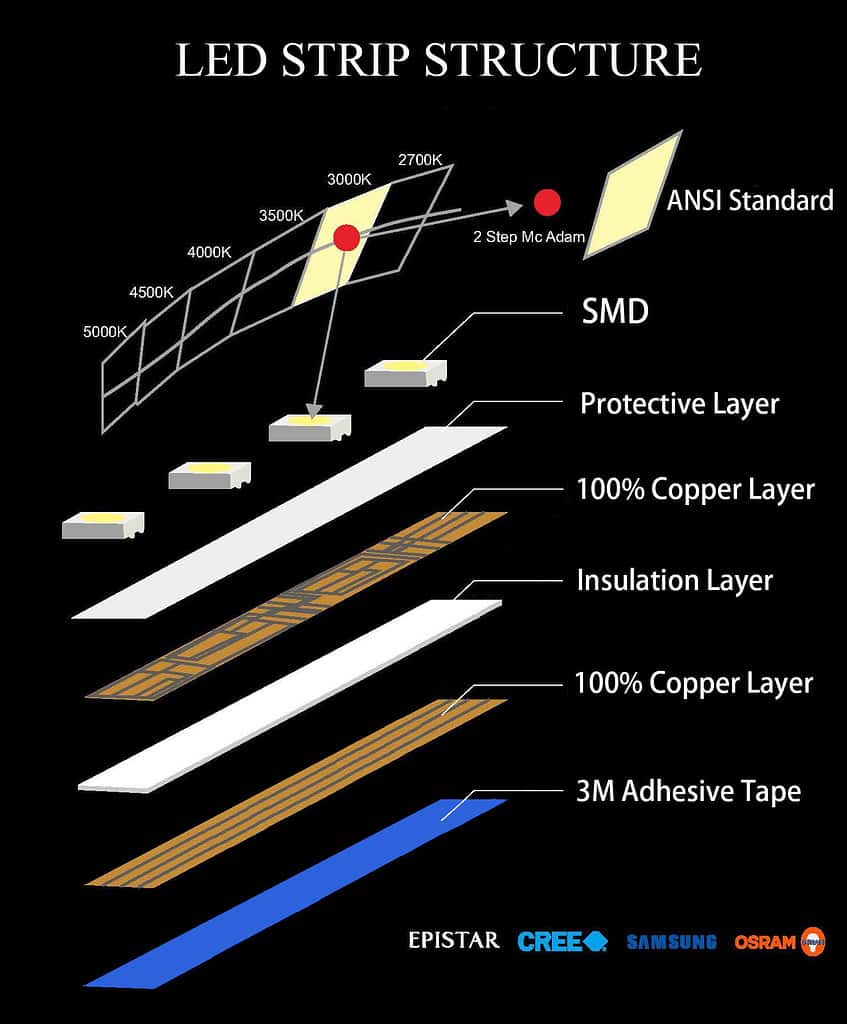

Beauty STC’s quality differentiation is evident in our manufacturing controls. We implement automated optical inspection (AOI) at three production stages, with 100% electrical burn-in testing at 45°C for 24 hours. Our strips use 2oz copper PCBs with 99.99% oxygen-free copper traces to minimize voltage drop, and the 3M VHB adhesive backing maintains 15N/cm² peel strength after 1,000 hours of 85°C/85% RH environmental stress testing. Every reel includes traceable lot codes linked to LM-80 thermal test data and third-party certifications including UL 8750, CE, and RoHS compliance. This rigorous approach ensures consistent photometric performance and mechanical durability exceeding industry standards in all specified parameters.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located to support efficient production and logistics for both domestic and international markets. The Jiangmen factory is designed to meet high standards of quality and productivity, focusing on LED lighting solutions including flexible LED strips, rigid bars, and customized lighting products.

The factory is fully equipped with advanced Surface Mount Technology (SMT) production lines, which ensure precise and reliable placement of LED components onto flexible and rigid PCBs. These SMT machines are automated and computer-controlled, allowing for high-speed assembly with minimal error rates. The use of state-of-the-art solder paste printing, pick-and-place systems, and reflow ovens ensures consistent product quality and supports the manufacturing of high-density and high-performance LED strips.

To guarantee long-term reliability and performance, the Jiangmen facility conducts comprehensive aging tests on all LED products. Completed strips undergo a minimum 24-hour continuous aging process under controlled temperature and voltage conditions. This rigorous testing helps identify early-life failures and ensures that only stable, durable products are shipped to customers. In addition to aging tests, the factory also performs waterproof testing, luminance measurement, color consistency checks, and electrical safety inspections as part of its quality assurance protocol.

Beauty STC has strong OEM capabilities, particularly for ‘glued strips’ — a term referring to waterproof LED strips that are coated with a silicone or epoxy layer for protection. The factory supports full customization for such products, including length, density of LEDs, color temperature, IP rating, voltage (12V/24V), and packaging. Clients can provide their own specifications or work with Beauty STC’s engineering team to develop tailored solutions. The company also offers custom labeling, branding, and packaging options to meet private label requirements.

With integrated design, manufacturing, and testing processes, the Jiangmen factory enables Beauty STC to deliver high-quality, reliable LED lighting products with short lead times and scalable production capacity, making it a trusted partner for OEM and ODM clients worldwide.

Application Scenarios

Glued strips, specifically adhesive-backed LED strip lights, are ideal for applications requiring discreet, seamless illumination without visible mounting hardware. Their primary use across hotels, malls, and offices centers on architectural integration where clean lines and minimal visual disruption are paramount. In hotels, glued strips excel in cove lighting for lobbies and corridors to create ambient washes, under-bed lighting for subtle night-time guidance in guest rooms, and within millwork like vanity mirrors or wardrobe interiors where mechanical brackets would compromise aesthetics. Malls leverage these strips extensively for display case lighting to highlight merchandise without obstructive fixtures, beneath escalator handrails for safety accentuation, and integrated into ceiling coves above high-end retail facades to enhance visual merchandising. Offices predominantly utilize glued strips for under-cabinet task lighting at workstations, providing glare-free illumination for desks without drilling into expensive furniture, as well as within partition systems and reception desk perimeters for a modern, uncluttered appearance.

Installation requires meticulous surface preparation to ensure long-term adhesion and performance. Always clean the mounting surface rigorously with isopropyl alcohol to remove dust, oils, or residues, as even microscopic contaminants cause premature detachment. Press the strip firmly along its entire length for at least 30 seconds, applying extra pressure at intervals to activate the adhesive fully, and avoid installing in ambient temperatures below 15°C (59°F) as cold reduces bonding effectiveness. For heavy-duty strips or high-traffic areas like mall display cases, supplement the adhesive with mechanical anchors at 300mm intervals to prevent sagging. Maintain adequate thermal clearance by avoiding direct contact with insulation or enclosed spaces; mount strips on thermally conductive surfaces like aluminum channels whenever possible, especially in offices where enclosed under-desk installations can cause overheating. Verify voltage drop calculations for runs exceeding 5 meters in hotel corridors or mall perimeters, adding additional power feeds to prevent dimming at the strip’s far end. Never install glued strips on porous, unprimed drywall or freshly painted surfaces in offices—allow paint to cure for 72 hours and prime plaster surfaces in hotels to create a stable bonding substrate. Finally, always conduct a 24-hour adhesion test on a small section before full deployment in critical areas like hotel guest rooms to confirm compatibility with surface materials.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s high-performance glued strips—engineered for durability, seamless application, and superior light output. As a trusted manufacturer, we deliver reliable, custom-ready solutions that elevate quality and efficiency. Partner with Beauty STC and experience exceptional support, consistent supply, and innovative LED technology tailored to your needs. Contact us today at [email protected] to discuss your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.