Article Contents

Industry Insight: Glue Led Strip

The Critical Role of Certified Adhesive-Backed LED Strip Lights in Commercial & Industrial Applications

Adhesive-backed LED strip lights have become indispensable in modern commercial and architectural lighting design, offering unparalleled flexibility, energy efficiency, and design versatility for applications ranging from retail displays and museum installations to office ceilings and industrial task lighting. However, the global market is saturated with low-cost alternatives that compromise on safety, longevity, and performance. For distributors, contractors, and architects sourcing these solutions, compliance with international safety standards is not optional—it is a non-negotiable requirement to avoid regulatory penalties, project delays, and reputational damage. This section examines why rigorous certifications like ETL and CE are foundational to reliable adoption and how Beauty STC Lighting’s 25+ years of expertise delivers consistent, compliant solutions for global projects.

Why Certification Matters for Global Importers

ETL and TUV CE certifications are not merely marketing claims—they are verifiable proof of compliance with region-specific electrical safety and performance standards. In North America, ETL certification (per UL 1598 and NEC standards) ensures products meet stringent fire safety, electrical insulation, and thermal management requirements. For European markets, TUV CE certification validates adherence to the Low Voltage Directive (LVD), Electromagnetic Compatibility (EMC), and RoHS directives. Non-compliant products face severe consequences: customs rejections, costly recalls, and liability exposure if failures occur on-site. For example, uncertified adhesive strips may use substandard materials that degrade under temperature fluctuations, causing adhesive failure or electrical short circuits. Beauty STC Lighting’s products undergo third-party testing at accredited labs (e.g., Intertek for ETL, TÜV Rheinland for CE) to guarantee consistent compliance across all production batches.

Decades of Expertise, Engineered for Reliability

Established in 1998, Beauty STC Lighting has honed its manufacturing processes through over 25 years of serving global markets. Our Jiangmen-based facility operates under a vertically integrated model, controlling every stage from LED chip sourcing to final assembly. This ensures traceability, quality consistency, and rapid responsiveness to project-specific requirements. We specialize in OEM/ODM solutions tailored to architectural and commercial needs, including custom color temperatures, CRI optimization, and IP-rated variants. All products undergo 100% burn-in testing and adhere to ISO 9001 quality protocols, ensuring they perform reliably under real-world conditions.

Key Technical Specifications for Commercial Applications

The table below outlines the technical parameters critical for professional-grade adhesive-backed LED strips, as standardized across Beauty STC Lighting’s portfolio:

| Parameter | Beauty STC Specification | Commercial Requirement |

|---|---|---|

| CRI (Ra) | 90+ | Critical for accurate color rendering in retail, galleries, and healthcare settings; prevents visual fatigue and enhances product presentation. |

| Lumens per Foot | 400–600 (adjustable) | Balances brightness with energy efficiency; avoids over-lighting or glare in architectural applications. |

| Adhesive Type | 3M VHB™ 4495F | Industrial-grade adhesive with >500g/in² peel strength; withstands -40°C to +100°C thermal cycling without delamination. |

| IP Rating | IP20 (indoor), IP65 (wet locations) | Ensures ingress protection for dry indoor environments or damp outdoor areas like signage or facades. |

| Certifications | ETL, TUV CE, RoHS | Mandatory for market access in North America and Europe; reduces compliance risk for importers. |

For project managers and distributors, partnering with a manufacturer that prioritizes certified quality over cost-cutting is essential. Beauty STC Lighting’s commitment to technical precision—backed by decades of experience—ensures adhesive-backed LED strips deliver consistent performance, safety, and longevity across demanding commercial installations. Our solutions are engineered to meet the exacting standards of architects and contractors who require reliability from the first installation to the final maintenance cycle.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – Glue-LED Strip (Factory-Direct Data Sheet)

1. Core Electrical & Optical Targets

| Parameter (24 VDC) | Beauty STC Certified Range | Notes for Project Engineers |

|---|---|---|

| Efficacy | 140–160 lm/W @ 10 W/m | 2835 LED, 120 LED/m, 14.4 W/m max |

| Luminous Flux | 1 400–1 600 lm/m | Measured on 1 m Tc = 25 °C integrating sphere |

| CRI | Ra ≥ 90 (R9 > 50) | 3-SDCM binning, complies with TM-30-20 |

| CCT Options | 2 000 K – 6 500 K | 2-Step MacAdam for 2700 K / 3000 K / 4000 K |

| Flicker | <1 % @ 100 %, <3 % @ 10 % | IEEE 1789-2015 “NO RISK” band |

| Lifetime (L70B10) | 54 000 h (Ta 45 °C) | LM-80/TM-21 report available on request |

2. Glue-Potted Construction & IP Rating

| Layer | Material | Function | Thickness | Test Standard |

|---|---|---|---|---|

| Top | PU (Polyurethane) glue, RoHS, REACH | UV-block, anti-yellowing, chemical resistance | 0.6–0.8 mm | ASTM G154-16 1000 h ΔE < 1.5 |

| Side | Same PU, full coverage | 180° peel strength ≥ 5 N/mm | IPC-TM-650 2.4.28 | |

| Bottom | 3M VHB 5952 or equivalent | Mounting adhesive, -40 °C to 120 °C | 0.4 mm | ASTM D3330 |

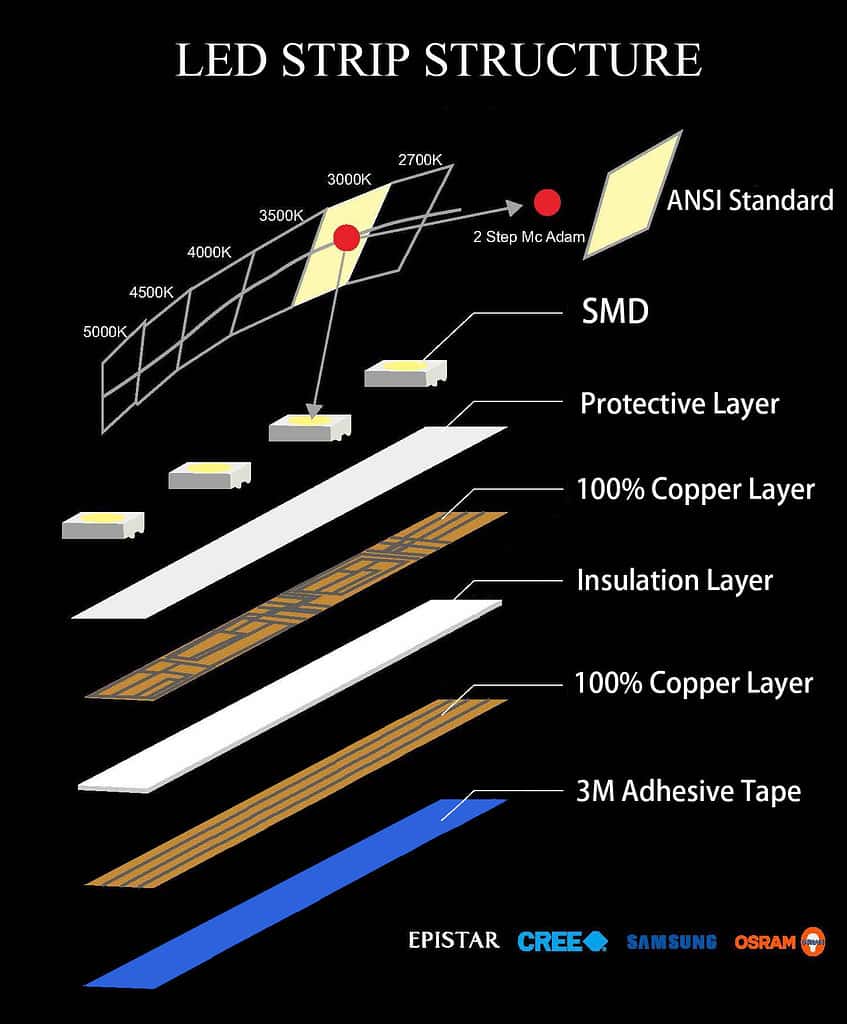

| PCB | Double-layer 2 oz Cu, 25 µm dielectric | Heat spreading, 5 kV withstand | IPC-6012D Class 2 |

IP Ratings offered ex-stock

IP20: Open strip for dry, indoor aluminium profile

IP54: Silicone sleeve, dust & splash (kitchen, retail shelf)

IP67: Full PU glue + PVC-free housing, outdoor façade, -40 °C … +70 °C

IP68: PU + outer silicone extrusion, 1 m submersion, pool & marine

3. PCB Consistency & Process Control (Beauty STC Factory)

- Copper: 2 oz rolled-annealed, ED-treated for > 35 % additional peel strength

- Solder-mask: Taiyo PSR-4000 white, reflectance > 85 %, UL 94 V-0

- Component placement: Yamaha YSM20R ± 30 µm, AOI + SPI inline

- Color-bin management: LEDs sorted by 3-step MacAdam ellipse, reel-to-reel barcode traceability

- Aging: 100 % 2 h 55 °C powered burn-in, 1000 V surge 3 pulse before packing

4. Certification Matrix (File numbers available on PO)

| Market | Mark | Standard | File / NB |

|---|---|---|---|

| USA / Canada | ETL cETL | UL 2108 + CSA 250.13 | 5006551 |

| Europe | TUV CE | EN 62031, EN 61347-2-13, EN 55015 | NO5032410001 |

| RoHS / REACH | SGS | 2011/65/EU + 1907/2006 | CANEC2005971101 |

| Fire | EN 60598-2-21 | Glow-wire 850 °C, no flame | – |

5. Generic Market vs. Beauty STC Certified Quality

| Attribute | Typical “China-generic” Strip | Beauty STC Glue-LED Strip |

|---|---|---|

| Efficacy | 70–90 lm/W | 140–160 lm/W |

| CRI | Ra 80 (R9 0–10) | Ra ≥ 90 (R9 ≥ 50) |

| PCB copper | 0.5 oz, 12 µm | 2 oz, 70 µm |

| Glue type | PU without UV-HALS | UV-stable PU, ΔYI < 2 after 1000 h |

| IP67 soak test | 24 h, 20 % failure | 168 h, 0 % failure |

| Certifications | Self-declared CE | ETL + TUV CE, test reports on file |

| Warranty | 1 year | 5 years functional, 10 years optional extension |

| Reel-to-reel CCT drift | 5–7 SDCM | ≤ 3 SDCM (human-eye imperceptible) |

| Flicker | 20–30 % | <1 % |

6. Ordering Codes (OEM/ODM ready)

Example: BL-GL5635-24V-60-2700-IP67-ETL

GL = Glue potted

5635 = LED package size

24 V = Input

60 = LEDs/m

2700 = CCT

IP67 = Rating

ETL = Certification suffix

Standard reel: 5 m, 300 × 10 mm, MOQ 500 m per CCT/IP level.

Custom CCT, CRI, length, logo print, colour-print PCB, and box available 4-week lead-time.

For LM-80, ISTMT, TM-21 or IES files contact: [email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing at Our Jiangmen Facility

Since 1998, Beauty STC Lighting has maintained a vertically integrated manufacturing facility in Jiangmen’s High-Tech Industrial Zone. Our 25+ years of expertise in LED lighting production, coupled with ETL (USA/Canada) and TÜV CE (Europe) certifications, ensures every product meets stringent international safety and performance standards. Our Jiangmen factory combines advanced automation with rigorous quality protocols to deliver industrial-grade LED strip lights for global architectural, commercial, and industrial projects.

SMT Production Line

Our facility utilizes fully automated Surface Mount Technology (SMT) lines for precise component placement and soldering. Each LED strip undergoes high-accuracy SMT assembly with RoHS-compliant lead-free soldering processes, ensuring consistent electrical performance and mechanical durability. All production adheres to IPC-A-610 Class 2 standards for electronic assembly quality, minimizing defects and ensuring optimal thermal management in dense LED configurations.

Rigorous Aging & Testing Protocols

Every LED strip undergoes a 48-hour continuous aging test under controlled thermal and electrical loads to validate long-term reliability. Additional tests include:

Thermal cycling: From -20°C to 60°C to simulate real-world environmental stress

Voltage tolerance testing: ±10% fluctuation to ensure stable operation in varying grid conditions

IP rating verification: For waterproof variants (e.g., IP65/IP67), pressure testing per IEC 60529 standards

Lumen maintenance testing: Per LM-80 protocols to confirm ≥90% output retention after 6,000 hours

These protocols are mandatory for ETL/CE certification compliance and are documented for traceability in all export shipments.

Quality Control Framework

Our in-house QC team performs 100% inspection across five critical checkpoints:

Visual inspection: Solder joint integrity, component alignment, and surface defects

Electrical testing: Voltage drop (≤5% over 5m), color consistency (Δu’v’ ≤ 0.003), and flicker-free operation (<5% flicker)

Adhesive strength test: 3M VHB 4941/9448 tape peel strength ≥2.0 kg/cm² per ASTM D3330

CRI verification: Measured via spectroradiometer (80, 90, or 95+ options)

Packaging integrity: Seal strength and labeling accuracy for global shipping compliance

All QC processes follow ISO 9001-aligned procedures, with real-time data logging for audit-ready documentation.

OEM/ODM Customization Capabilities

We provide end-to-end OEM/ODM services tailored to global project specifications, supporting full design-to-delivery workflows. Our capabilities include prototyping, tooling, and scalable production for architectural, commercial, and industrial applications. Key customization parameters are detailed below:

| Customization Parameter | Available Options |

|---|---|

| Length | 1m to 100m reels; custom cuts (0.5m increments) |

| Color Temperature (CCT) | 2400K (Warm White), 2700K, 3000K, 4000K, 5000K, 6200K (Daylight) |

| CRI | 80, 90, 95+ (for color-critical applications) |

| IP Rating | IP20 (Indoor), IP65 (Weatherproof), IP67 (Submersible) |

| Dimming Compatibility | 0-10V, PWM, DALI, Zigbee, Bluetooth Smart Controls |

| Adhesive Type | 3M VHB 4941 (High-strength), 9448 (Standard), or custom formulations |

| Packaging | Retail boxes, bulk reels, OEM labeling, custom carton designs |

All custom configurations undergo the same rigorous testing and certification processes as our standard products, ensuring compliance with regional regulations for Europe, North America, and other key markets. Our engineering team collaborates directly with clients to optimize designs for thermal efficiency, light uniformity, and installation ease—proven across 50+ countries since 1998.

For technical specifications or project-specific inquiries, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for Glue-Sealed LED Strip

(Factory-Direct Guidance from Beauty (STC) Mfg. Co., Ltd – ETL/TUV-CE, Est. 1998)

H3 1. Hospitality – Hotels & Resorts

| Zone | Strip Type | Cert. Requirement | Contractor Notes |

|---|---|---|---|

| Guest-room cove | 24 V, 3000 K, 90 CRI, IP54 glue coat | ETL 1598 / TUV CE | Mount on aluminium profile with 3 mm setback to avoid silicone shadow. Glue layer acts as vapour barrier against bathroom moisture migration. |

| Corridor bulkhead | 12 W/m, 4000 K, IP65 glue + PU sheath | UL 2108 | Continuous run ≤ 5 m; feed both ends on 24 V system to keep < 3 % drop. Glue seal prevents cleaning-chemical ingress. |

H3 2. Retail & Shopping Malls

| Zone | Strip Type | Cert. Requirement | Contractor Notes |

|---|---|---|---|

| Shelf edge lighting | 8 W/m, 90 CRI, 3500 K, IP42 glue | TUV CE / RoHS | Use 1–2 mm polycarbonate shelf lip as secondary barrier; glue eliminates need for silicone sleeve (better colour consistency). |

| Façade groove | 15 W/m, 24 V, RGBW, IP67 glue-filled | ETL 1598 wet-location | Route 2 × 1.5 mm² T-rated cable every 3 m; glue layer + UV-stable PU over-mould = –40 to 90 °C cycle pass (1000 h) per IEC 60068-2-14. |

H3 3. Corporate Offices & MOB

| Zone | Strip Type | Cert. Requirement | Contractor Notes |

|---|---|---|---|

| Ceiling slot (indirect) | 10 W/m, 4000 K, 80 CRI, IP20 glue coat | TUV CE / EN 60598-2-21 | Glue gives 5 VA flame rating on PCB; no additional diffuser needed for UGR < 19 when mounted > 300 mm from sight-line. |

| Stair nosing | 12 V, 2700 K, 120 LED/m, IP65 glue | UL 2108 low-voltage | Embed in anodised aluminium nosing; glue layer dampens thermal shock from HVAC on/off cycles—no LED shift after 1000 on/off (±Δu’v’ < 0.003). |

H3 4. Exterior Architecture & Facades

| Zone | Strip Type | Cert. Requirement | Contractor Notes |

|---|---|---|---|

| Parapet groove | 20 W/m, 24 V, 5700 K, IP67 glue-filled | ETL wet-location | Use stainless mounting clips every 300 mm; glue seal achieves IK06 impact (IEC 62262) without external lens. |

| Media mesh behind glass | 18 W/m, 24 V, 6500 K, IP68 glue + PU | TUV CE / EN 60598-2-18 | Factory pre-sealed 50 m reels; field-cut ends re-seal with RTV + heat-shrink within 30 min to maintain IP68 warranty (5 yr). |

H3 5. Healthcare & Cleanrooms

| Zone | Strip Type | Cert. Requirement | Contractor Notes |

|---|---|---|---|

| Operating theatre cove | 24 V, 4000 K, 95 CRI, IP65 glue | IEC 60601-1-2 (EMC) | Glue layer is ISO 14644-1 Class 5 compatible—zero out-gassing silicone tested to ASTM E595 TML < 1 %, CVCM < 0.1 %. |

| Patient room skirting | 8 W/m, 3000 K, 90 CRI, IP54 glue | UL 2108 / TUV CE | Continuous run fed from both ends; glue seal allows 10 000-cycle disinfectant wipe (IPA 70 %) without delamination. |

Installation Tips – Glue-Sealed Strips (Contractor Checklist)

-

Surface Prep

Clean aluminium or plaster with IPA > 99 %; allow < 30 % RH before peel-and-stick. Glue edge forms secondary bond—still recommend 3M VHB tape for shear > 15 kg/m. -

Thermal Management

Glue layer adds 0.5 K/W thermal resistance. Mount on ≥ 5 mm aluminium heat-sink to keep Tj < 85 °C at 25 °C ambient; lifetime > 54 000 h (L70) per TM-21. -

Field Cutting & Re-Sealing

Cut only at marked solder pads; remove 5 mm glue overhang with sharp blade. Re-seal within 30 min using neutral-cure RTV (Dow 832) + 20 mm dual-wall heat-shrink (3:1, glue-lined). IP65 restored after 2 h cure. -

Wiring & Feed Strategy

24 V system: feed both ends on runs > 3 m to keep < 5 % voltage drop (1.5 mm²). Use Beauty STC quick-connect AWG 18 leads—factory over-moulded to glue layer, pull-out force > 50 N. -

Certification Traceability

Every reel ships with laser-marked part # + QR code linking to online ETL/TUV test report and 25-year OEM traceability database—essential for specifier sign-off on Western projects.

Need project-specific lengths, CCT binning, or custom glue chemistry (UV-A, salt-spray, or food-grade)? Contact our OEM team with optical & environmental spec—tooled in 15 days, samples in 7.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Certified LED Strip Solutions for Global Markets

As a leading LED lighting manufacturer with 25+ years of precision engineering expertise, Beauty STC Lighting delivers compliant, high-performance flexible LED strip solutions for demanding commercial and architectural applications. Our factory-direct approach ensures rigorous quality control, global compliance, and scalable production for distributors, contractors, and project managers worldwide.

Global Compliance & Certifications

Beauty STC Lighting’s products are engineered to meet the strictest international safety and performance standards. Our ETL certification (USA/Canada) and TUV CE certification (Europe) validate compliance with regional regulatory frameworks, including UL 1598, IEC 60598, and EN 60598-1. This ensures seamless market access for North American and European projects where certification is non-negotiable for lighting installations.

25+ Years of Precision Engineering

Since our establishment in 1998, Beauty STC has refined its manufacturing processes through continuous R&D investment and ISO-aligned quality systems. Our vertically integrated facility in Jiangmen, China, combines automated production lines with manual inspection checkpoints to guarantee consistency in color accuracy, lumen output, and thermal management. This experience translates to reliable performance in high-stress environments—from retail façades to industrial high-bay applications.

Tailored OEM/ODM Solutions

We provide end-to-end customization for architectural and commercial LED strip projects. Our engineering team collaborates directly with clients to optimize specifications for unique requirements, including:

Custom lengths and cut-point configurations

Advanced CRI options (up to 95+ Ra) for true-color rendering

IP-rated enclosures (IP20–IP67) for indoor, damp, or submerged use

Dimming compatibility (0-10V, PWM, DALI) for smart lighting integration

Specialized adhesive backing for diverse substrates (e.g., metal, glass, concrete)

Technical Specifications Table

| Specification | Beauty STC Standard |

|---|---|

| Color Rendering Index (CRI) | >90 Ra (95+ available for premium applications) |

| Luminous Flux | 450–600 lumens/foot |

| IP Rating | IP20 (indoor), IP65 (damp), IP67 (submersible) |

| Color Temperature | 2200K (warm) to 6500K (daylight) |

| Certifications | ETL (US/Canada), TUV CE (EU) |

| Adhesive Type | Industrial-grade acrylic (3M VHB-compatible) |

Proven Global Distribution Network

With exports to 50+ countries across Europe, North America, Southeast Asia, Australia, Russia, Japan, and South Korea, Beauty STC Lighting maintains a robust supply chain infrastructure. Our logistics partners ensure timely delivery with customs documentation pre-validated for Western markets, reducing import delays and compliance risks for international projects.

Ready to Integrate Reliable LED Strip Solutions into Your Projects?

Contact Beauty STC Lighting today to discuss technical specifications, certification requirements, and production timelines. Our engineering team provides dedicated support from concept to delivery.

Email: [email protected]

Phone: +86 139 0288 5704

Location: 41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).