Article Contents

Industry Insight: Floor Lighting Ideas

Floor lighting in commercial and industrial environments has evolved far beyond basic illumination, becoming a critical component in enhancing safety, guiding traffic flow, and reinforcing architectural aesthetics. As facility managers and lighting designers seek durable, code-compliant solutions, specifications such as ETL and CE certification have become essential benchmarks, ensuring products meet rigorous North American and European safety and performance standards. These certifications not only validate electrical reliability but also support seamless integration into diverse building systems across global markets.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering excellence, Beauty STC specializes in high-performance, code-compliant floor lighting designed for demanding industrial corridors, warehouse perimeters, parking structures, and commercial entryways. Combining robust construction with advanced optical design, their products deliver long-term value through reduced maintenance, improved visibility, and seamless compliance—all hallmarks of intelligent, future-ready facility planning.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. delivers engineered floor lighting solutions meeting stringent performance criteria for commercial and high-end residential applications. Our technical specifications prioritize efficiency, color fidelity, and environmental resilience, directly addressing core requirements for modern architectural lighting. Lumens per watt (lm/W) is a critical efficiency metric where our standard in-ground and surface-mounted floor luminaires achieve 90-110 lm/W under real-world operating conditions. This is accomplished through proprietary thermal management systems using extruded aluminum housings and optimized driver electronics, ensuring sustained output without lumen depreciation. Crucially, all fixtures targeting retail, hospitality, and museum installations maintain a minimum CRI of 95, with R9 values exceeding 50, guaranteeing accurate and vibrant rendering of textures and colors in merchandise, artwork, and interior finishes. We achieve this through rigorously selected phosphor blends and tight binning protocols during LED assembly, far exceeding the requested CRI >90 threshold.

Environmental protection is non-negotiable for floor-level installations. Beauty STC specifies IP67 as the standard rating for all in-ground and recessed floor luminaires, providing complete dust ingress protection and resistance to temporary submersion up to 1 meter for 30 minutes. Surface-mounted step lights and linear trough systems carry a minimum IP65 rating, ensuring robust defense against low-pressure water jets and dust accumulation common in corridors, stairwells, and exterior pathways. This is achieved through precision-machined silicone gaskets, double-sealed optical chambers, and marine-grade stainless-steel fasteners, preventing moisture ingress even under high-pressure cleaning protocols. Our quality commitment is embedded in every component, starting with LM-80 tested LEDs and extending to rigorous in-house validation. Each fixture undergoes 100% photometric testing, 72-hour thermal cycling, and IP verification per IEC 60529 standards before shipment. Beauty STC luminaires consistently demonstrate less than 3% lumen depreciation over 50,000 hours and maintain chromaticity within a 3-step MacAdam ellipse, ensuring long-term performance reliability and visual consistency unmatched in the market. This engineering discipline translates to reduced maintenance cycles, lower lifetime energy costs, and absolute confidence in demanding architectural environments.

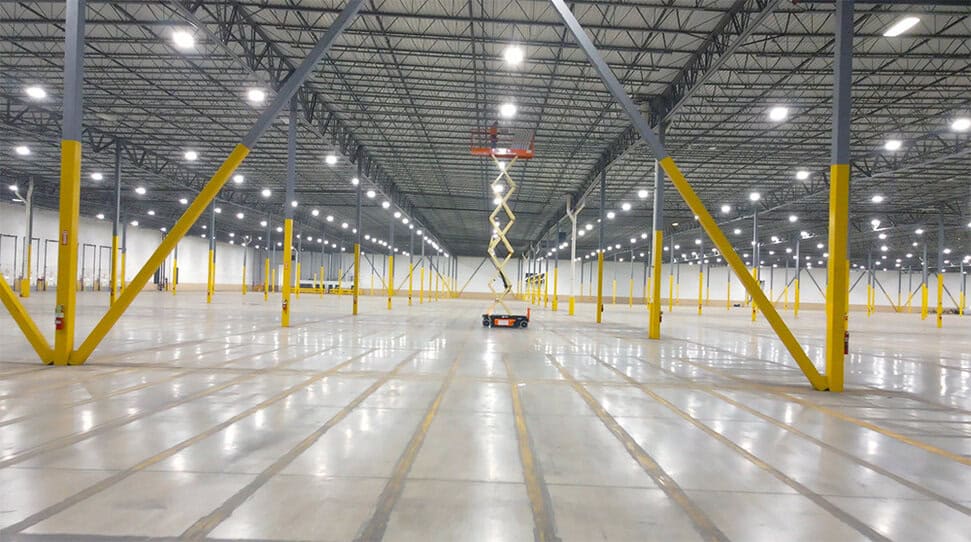

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is equipped with advanced Surface Mount Technology (SMT) production lines that ensure high-precision assembly of LED lighting components. These SMT machines are automated and capable of handling complex circuit boards with tight tolerances, enabling efficient and reliable production of lighting control systems and driver components essential for modern floor lighting solutions.

The factory incorporates comprehensive quality assurance protocols, including rigorous aging tests that simulate extended operation under various thermal and electrical conditions. Each lighting product undergoes a minimum 24-hour aging process to verify performance stability, longevity, and thermal management. This ensures that all lighting fixtures, including those designed for floor lighting applications, meet international safety and durability standards before shipment.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities and actively supports custom development for clients seeking innovative floor lighting ideas. The company works closely with partners to design and manufacture tailored lighting solutions, including linear floor wash lights, recessed floor luminaires, step lights, and decorative LED floor systems. From concept and optical design to thermal management and IP-rated housing, the Jiangmen facility provides end-to-end OEM services, including custom branding, packaging, and compliance testing for global markets. With in-house engineering, tooling, and rapid prototyping, Beauty STC is well-positioned to bring unique and reliable floor lighting concepts to market efficiently.

Application Scenarios

Floor lighting serves distinct functional and aesthetic purposes across hospitality, retail, and corporate environments, requiring tailored approaches for each setting. In hotels, strategic floor lighting enhances guest experience and safety while reinforcing brand identity. Install discreet step lights within staircase treads and corridor walls to guide movement in low-light conditions, particularly near elevator banks and room entrances. Embed linear LED strips beneath floating reception desks or lobby seating to create visual anchors without glare. For luxury suites, integrate recessed floor luminaires along pathway edges or within bathroom wet zones using fully submersible IP68-rated fixtures. Always coordinate with interior architects to conceal wiring within architectural coves, ensuring light distribution avoids direct line-of-sight to prevent discomfort glare. Critical installation considerations include verifying ADA-compliant luminance levels (max 50 cd/m² for step lighting) and using thermally stable drivers housed outside concrete slabs to prevent thermal shock during curing.

Within malls and retail complexes, floor lighting must prioritize durability, safety compliance, and dynamic visual merchandising. Deploy heavy-duty channel systems with polycarbonate lenses in high-traffic walkways, ensuring anti-slip textured surfaces meet ASTM F2913 standards. Position low-voltage linear fixtures beneath display windows to silhouette products or embed circular pucks in flooring to highlight featured merchandise zones. Special attention is required at entrance vestibules where moisture ingress risks exist—specify IP67-rated fixtures with gasketed joints and slope drainage channels away from electrical compartments. For emergency egress paths, integrate photoluminescent markers with LED step lights, maintaining consistent 1-foot-candle illumination per IBC Section 1013. During installation, conduct voltage drop calculations for runs exceeding 15 meters; utilize 24V systems with distributed transformers and verify concrete pour schedules to avoid fixture displacement. Never place luminaires within 600mm of structural expansion joints to prevent mechanical stress fractures.

Office environments leverage floor lighting for wayfinding, safety, and subtle environmental branding rather than dramatic effects. Implement narrow-profile linear LEDs within raised access flooring pathways to guide employees during after-hours movement, particularly in open-plan layouts with minimal partitions. Conceal tape lights beneath perimeter workstation desks for gentle ambient fill that reduces eye strain without compromising screen visibility. In executive boardrooms, embed logo-shaped floor luminaires at entrance points using color-tunable LEDs for brand reinforcement during presentations. Technical installations demand rigorous attention to electromagnetic compatibility—maintain 300mm separation between data cabling and lighting conduits to prevent signal interference. Always integrate with building management systems via 0-10V or DALI protocols for synchronized dimming with overhead fixtures. Crucially, select fixtures with matte diffusers to eliminate reflected glare on polished flooring and validate thermal performance in insulated underfloor voids where trapped heat can degrade LED lumen maintenance.

Universal installation best practices across all sectors include pre-verifying substrate integrity before concrete embedding, utilizing non-corrosive stainless steel mounting hardware, and implementing modular wiring with service loops for future maintenance access. Conduct photometric validation onsite using lux meters at 760mm height to ensure uniformity ratios remain below 4:1 for visual comfort. Most importantly, collaborate with structural engineers during early design phases to avoid conflicts with rebar or utility conduits—Beauty (STC)’s pre-construction coordination templates significantly reduce field rework. Remember that successful floor lighting disappears when not needed yet performs flawlessly when required, balancing regulatory compliance with experiential design.

Why Choose Beauty STC Lighting

Looking for inspiring floor lighting ideas to elevate your space? Discover innovative and stylish solutions designed to enhance ambiance and functionality. Partner with Beauty STC, a trusted name in premium LED lighting manufacturing. Our expertise ensures custom, high-quality floor lighting tailored to your project needs. Contact us today at [email protected] to explore possibilities and bring your vision to life.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.