Article Contents

Industry Insight: Flood Vs Spot Light

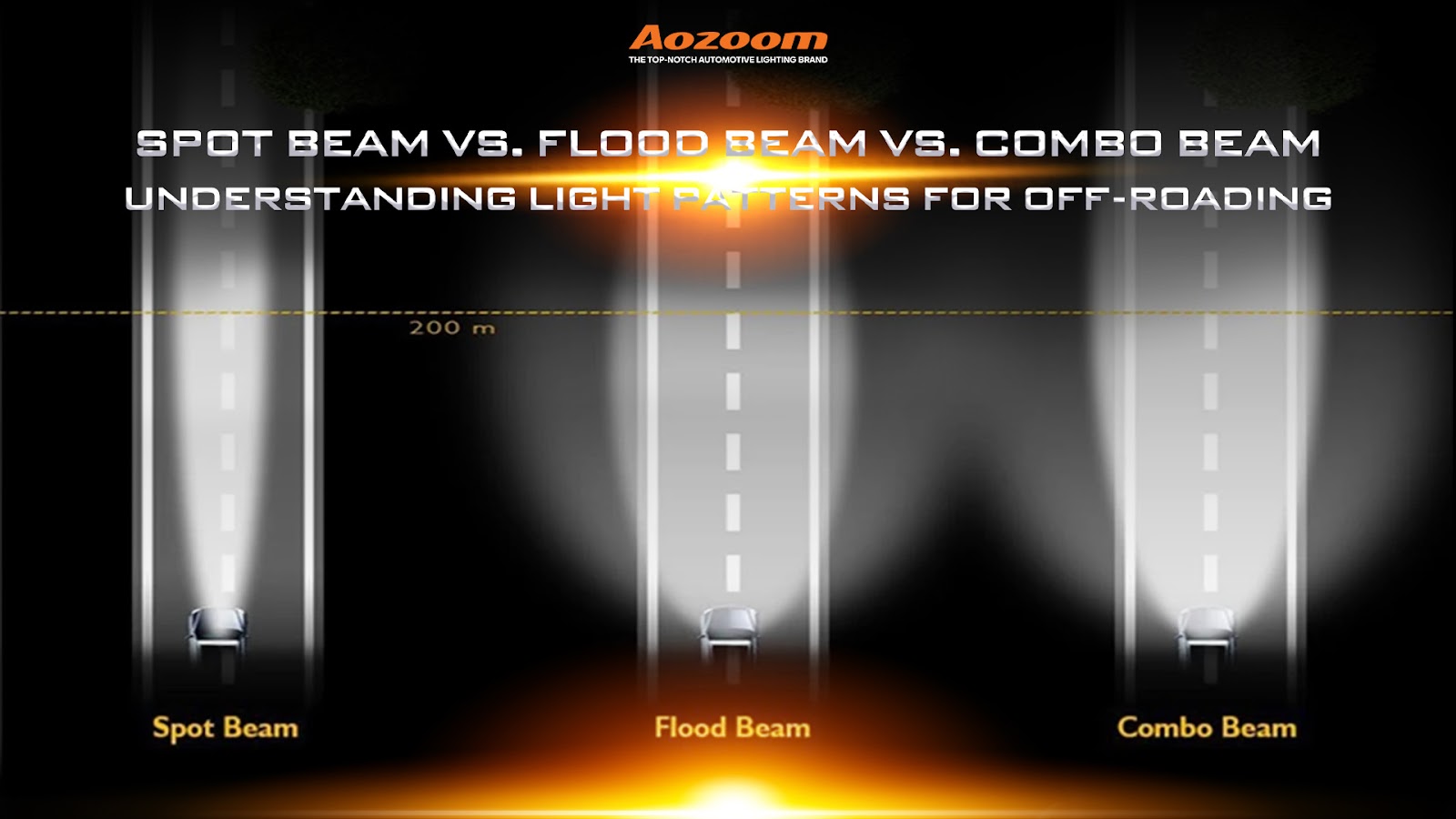

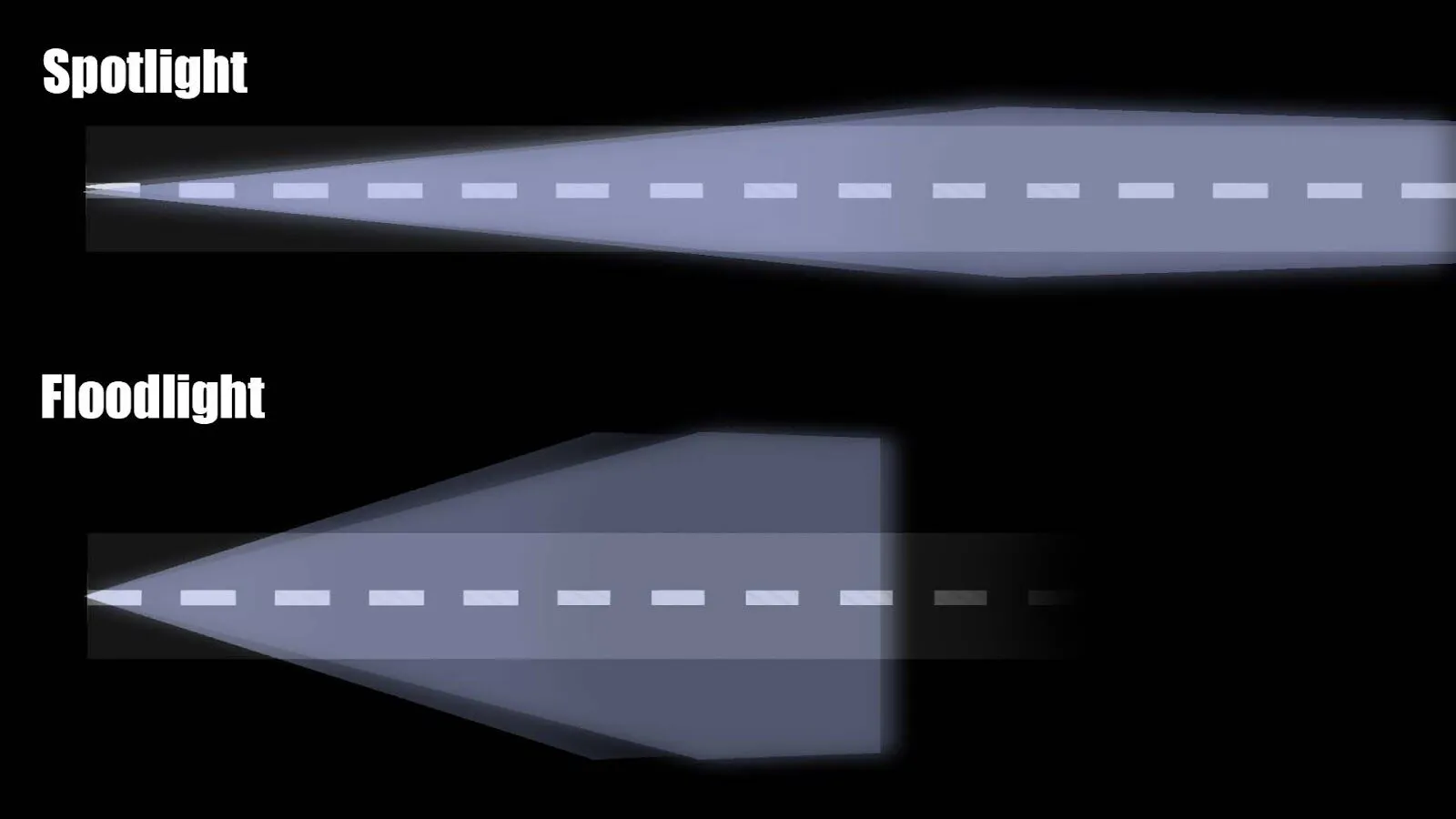

In the commercial and industrial lighting sector, selecting the right beam pattern—flood versus spot—is a critical decision that directly impacts visibility, safety, and operational efficiency. Flood lights provide wide, even illumination ideal for large open areas such as warehouses, parking lots, and construction sites, while spot lights deliver concentrated beams suited for targeted lighting in high-bay applications, security perimeters, or architectural highlighting. As energy efficiency and regulatory compliance become increasingly vital, lighting solutions must meet rigorous standards such as ETL and CE certifications, ensuring electrical safety, performance reliability, and global market readiness.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-performance commercial and industrial lighting, Beauty STC combines advanced optical engineering with stringent quality control to deliver lighting systems that exceed industry benchmarks. With a comprehensive portfolio that includes both flood and spot light configurations, all designed and tested to meet ETL and CE requirements, Beauty STC empowers businesses worldwide with durable, energy-efficient, and code-compliant lighting solutions tailored to the demands of modern industrial environments.

Technical Specs & Certifications

Flood lights and spot lights serve distinct illumination purposes primarily defined by their beam angles, which subsequently influence key performance metrics like lumens per watt, color rendering capabilities, and environmental protection requirements. Flood lights typically feature wide beam angles exceeding 100 degrees, designed to uniformly illuminate large surface areas such as building facades, parking lots, or sports fields. Spot lights, conversely, produce narrow, concentrated beams usually between 15 and 45 degrees, intended for accent lighting, highlighting architectural details, or long-throw applications like stadium lighting or perimeter security. This fundamental optical difference impacts efficiency considerations. Both types can achieve high efficacy, commonly ranging from 130 to 150 lumens per watt in modern commercial-grade LED fixtures when utilizing efficient COB or SMD LED arrays coupled with well-designed thermal management. However, spot lights often exhibit a slight efficacy reduction of 5-10% compared to equivalently powered flood lights due to the optical losses inherent in precise beam control elements like reflectors or total internal reflection (TIR) lenses, which are less necessary in the diffused output of flood lights. Achieving a Color Rendering Index (CRI) greater than 90, essential for applications demanding accurate color representation like retail display, art galleries, or high-end architectural lighting, is attainable in both flood and spot configurations through the use of high-quality phosphor-converted LEDs with tightly binned chromaticity. Beauty STC rigorously selects LED packages from premium suppliers such as Samsung and Nichia, implementing a strict 3-step binning process for both color temperature and CRI to ensure consistent Ra values exceeding 90 and R9 values above 50 across all production batches, verified through integrated spectroradiometer testing during manufacturing.

Environmental protection, denoted by Ingress Protection (IP) ratings, is critical for outdoor and demanding indoor applications but varies based on fixture placement. Flood lights deployed for exterior area lighting universally require a minimum IP65 rating, protecting against dust ingress and low-pressure water jets from any direction, suitable for most outdoor environments. Beauty STC’s premium flood light series, however, consistently achieves IP66 or IP67 ratings, with specific marine-grade models rated IP68 for continuous submersion, utilizing triple-sealed optical compartments and corrosion-resistant housings. Spot lights used outdoors for architectural highlighting or security similarly necessitate IP65 as a baseline, though fixtures mounted under eaves or in sheltered locations might utilize IP54-rated models where direct weather exposure is minimal. Beauty STC emphasizes robust environmental sealing across its entire outdoor portfolio; even compact spot fixtures undergo rigorous 500-hour salt spray testing per ASTM B117 and feature gasketed driver compartments to maintain IP66 integrity over extended service life. This commitment to quality extends beyond specifications. Beauty STC integrates advanced thermal management systems utilizing extruded aluminum heatsinks with optimized fin structures, ensuring junction temperatures remain within strict limits to prevent lumen depreciation and maintain both high efficacy and consistent CRI performance throughout the rated 50,000+ hour L70 lifespan. Every fixture undergoes 100% photometric validation and harmonic distortion testing, guaranteeing that the published lumens per watt, beam angle, and CRI values are not theoretical maximums but reliably delivered performance characteristics meeting or exceeding IEC 62717 and LM-79 standards. This systematic approach to engineering and quality control ensures Beauty STC luminaires provide dependable, high-fidelity illumination tailored precisely to the demands of either flood or spot lighting applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern, well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the facility benefits from strong logistical access and a skilled manufacturing workforce, supporting both domestic and international markets.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines, which enable precise and efficient mounting of electronic components onto LED circuit boards. These SMT machines are automated and calibrated for high-speed placement, ensuring consistent quality and reliability in every lighting unit produced. The integration of automated optical inspection (AOI) systems further guarantees that soldering and component placement meet strict quality standards before products move to the next stage of assembly.

A critical part of the manufacturing process at the Jiangmen facility is the comprehensive aging test procedure. All LED products undergo rigorous burn-in testing, typically lasting 12 to 24 hours under elevated temperatures and full operational load. This process helps identify early-life failures, ensuring that only durable and stable products reach customers. Environmental simulation chambers are also used to test performance under various conditions, including humidity and thermal cycling, enhancing product reliability for diverse end-use applications.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, allowing for customized design, engineering, and production tailored to client specifications. This includes the development of specialized LED lighting solutions such as flood lights and spot lights. For flood lights, the factory can produce wide-beam-angle fixtures designed for broad area illumination, commonly used in outdoor security, parking lots, and industrial yards. For spot lights, the focus is on narrow, concentrated beams ideal for accent lighting, architectural highlighting, or targeted task lighting.

The OEM process begins with client consultation, followed by optical, thermal, and electrical design using advanced simulation tools. Prototypes are built and tested in-house before mass production. Beauty STC can customize optics, housings, color temperatures, lumen outputs, and driver configurations to meet exact requirements for both flood and spot light applications. This flexibility, combined with strict quality control and scalable production capacity, makes the Jiangmen factory a reliable partner for global lighting brands seeking high-performance, custom LED solutions.

Application Scenarios

The fundamental distinction between flood and spot lighting lies in beam spread and intensity. Flood lights deliver wide, even illumination across broad areas with beam angles typically exceeding 120 degrees, ideal for general ambient lighting. Spot lights produce a concentrated, intense beam with angles usually under 45 degrees, designed for highlighting specific objects or tasks. Selecting the correct type is critical for achieving both functional illumination and desired aesthetic effects in commercial environments.

In hotel applications, flood lighting is essential for creating welcoming ambient conditions. Install flood fixtures with 100-120 degree beams in lobbies, corridors, and guest room ceilings to provide uniform, glare-free illumination across large surfaces. For guest room bathrooms, use flood lights above mirrors to eliminate harsh shadows. Conversely, deploy spot lights with 25-40 degree beams for accentuation; highlight artwork in corridors, feature walls in lobbies, or architectural details in ballrooms. In guest rooms, use adjustable spotlights above bedside tables for focused reading light while maintaining lower ambient flood lighting. Spa areas benefit from soft flood lighting for relaxation zones but require precise spot lighting to accentuate water features or treatment stations without causing glare.

Mall environments demand strategic layering. Utilize high-output flood lights with 90-110 degree beams mounted on high ceilings (8-12 meters) to establish baseline ambient illumination across concourses and common areas, ensuring safe navigation. However, install narrow spot lights with 15-30 degree beams directly above storefronts to intensely highlight merchandise displays and create visual magnetism. Position spots above escalators and staircases for vertical surface illumination enhancing safety. Crucially, in malls with polished flooring, ensure spot lights are precisely aimed to avoid uncomfortable reflections; use baffles or louvers to control spill light. Food court seating areas require wide flood lighting for table surfaces while spotlights should accentuate signage or feature elements without dazzling diners.

Office lighting prioritizes visual comfort and task performance. Implement flood lights with 90-110 degree beams in suspended ceiling grids for open-plan offices to deliver uniform horizontal illuminance across workstations, minimizing shadows on documents. Conference rooms need broad flood coverage for table surfaces but benefit from narrow spotlights (25-35 degrees) aimed precisely at presentation screens or video conferencing cameras to avoid screen glare. Executive offices often combine ambient flood lighting with adjustable spotlights on desks for focused task lighting. Avoid using spot lights for general office illumination as they create uneven pools of light causing eye strain; reserve them strictly for highlighting whiteboards, reception logos, or specific display areas.

Installation requires meticulous attention to detail regardless of fixture type. Always verify the fixture’s thermal management capabilities, especially in enclosed or high-ambient-temperature locations like mall ceilings, as inadequate heat dissipation drastically shortens LED lifespan. Precisely calculate mounting height versus beam spread using manufacturer photometric data; a spot light intended for a 4-meter-high retail display requires different optics than one for a 10-meter mall ceiling. Ensure all adjustable spot lights have secure locking mechanisms to prevent beam drift over time. Integrate dimming systems compatible with the LED drivers, particularly in hotels where scene-setting is essential, and always use high-CRI (90+) LEDs in retail and hospitality to render colors accurately. Finally, provide adequate service access; recessed fixtures in high-ceiling malls must be maintainable via lift equipment without disrupting operations. Voltage drop calculations are non-negotiable for long circuit runs in expansive malls to prevent lumen depreciation at fixture ends.

Why Choose Beauty STC Lighting

Discover the key differences between flood and spot lights to elevate your lighting projects with precision and performance. Whether you need wide-area illumination or focused beam control, Beauty STC delivers high-quality LED solutions tailored to your needs. Partner with Beauty STC today and experience reliable, energy-efficient lighting engineered for excellence. For expert guidance and product support, contact our lighting specialist at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.