Article Contents

Industry Insight: Flexible Trim Strips

The commercial and industrial lighting sector continues to evolve rapidly, driven by demands for versatile, energy-efficient solutions that meet stringent performance and safety standards. Flexible trim strips have emerged as a transformative technology within this landscape, offering unprecedented design freedom for architectural cove lighting, signage, task illumination, and accent features in demanding environments like retail spaces, warehouses, offices, and manufacturing facilities. Their ability to conform to complex curves, integrate seamlessly into tight spaces, and provide uniform, high-quality light output makes them a superior alternative to traditional rigid fixtures, particularly in retrofit projects where adaptability is paramount. Crucially, specifying such products requires absolute confidence in regulatory compliance; ETL certification for North American safety standards and CE marking for the European market are not optional extras but fundamental requirements for project approval, liability mitigation, and ensuring long-term operational safety in commercial installations.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution for over 25 years. As a dedicated LED lighting engineering and manufacturing leader, we understand the critical intersection of innovative design, rigorous performance, and uncompromising adherence to global safety protocols like ETL and CE. Our deep expertise in flexible trim strip technology stems from decades of collaborating with architects, engineers, and contractors to solve real-world lighting challenges across diverse commercial and industrial applications. We engineer our products not just to meet the baseline requirements of these certifications, but to exceed expectations for durability, thermal management, and optical consistency in the demanding environments where our clients operate. This commitment to engineering excellence and regulatory certainty is woven into the foundation of every flexible trim strip solution Beauty STC delivers.

Technical Specs & Certifications

Flexible trim strips from Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high performance and reliability for architectural and decorative lighting applications. These LED flexible trim strips are designed with precision to ensure consistent light output, excellent color rendering, and long-term durability.

In terms of efficiency, Beauty STC’s flexible trim strips achieve a luminous efficacy ranging from 90 to 110 lumens per watt, depending on the specific configuration and color temperature. This high efficiency ensures optimal energy savings without compromising brightness, making them ideal for both residential and commercial installations where lighting performance and operational cost are critical.

A key feature of these trim strips is their high Color Rendering Index (CRI), consistently exceeding 90, with select models reaching CRI values of 95 or higher. This superior color fidelity ensures that illuminated surfaces appear natural and vibrant, which is especially important in retail, hospitality, and high-end interior environments where accurate color representation enhances visual appeal.

Regarding environmental protection, Beauty STC offers flexible trim strips in multiple Ingress Protection (IP) rated variants to suit diverse installation conditions. Standard versions are available with IP20 rating for indoor dry locations, while fully potted and silicone-coated options provide IP65 and IP67 ratings, offering robust protection against dust, moisture, and temporary immersion. This makes them suitable for damp locations, outdoor cove lighting, and challenging environments where resistance to humidity and particulates is essential.

Beauty STC maintains stringent quality control throughout the manufacturing process, utilizing premium-grade LEDs, stable PCB substrates, and high-quality diffusers to ensure uniform light distribution and minimal lumen depreciation over time. The company adheres to international standards and conducts rigorous testing for thermal management, electrical safety, and long-term reliability. With over two decades of expertise in LED lighting solutions, Beauty STC has built a reputation for delivering flexible trim strips that combine advanced technical performance with exceptional build quality, ensuring customer satisfaction across global markets.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, ISO-certified manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta for efficient logistics and access to a robust supply chain. This facility serves as a core production hub for our LED lighting solutions, integrating advanced automation with stringent quality control processes throughout the manufacturing flow. Our Jiangmen factory is specifically engineered to handle high-volume precision assembly while maintaining the flexibility required for diverse customer specifications, particularly for complex products like flexible LED trim strips.

The Surface Mount Technology (SMT) production lines form the backbone of our electronics assembly capability. We utilize multiple high-speed, high-precision SMT machines from leading manufacturers, capable of placing components down to the 0201 package size with exceptional accuracy. These lines feature automated optical inspection (AOI) systems integrated directly after the reflow soldering ovens, ensuring immediate detection of soldering defects, component misalignment, or missing parts. This automated inspection is critical for the reliability of densely packed LED driver circuits and control modules used in our flexible trim strips, where even minor assembly flaws can lead to premature failure. The SMT process is tightly controlled with environmental monitoring for temperature and humidity to maintain optimal solder paste performance and component integrity.

Rigorous aging and reliability testing are non-negotiable steps in our production protocol, especially for LED products where long-term performance is paramount. The Jiangmen factory houses extensive dedicated aging test chambers capable of simultaneously operating thousands of units under controlled thermal and electrical stress. Flexible trim strips undergo extended burn-in cycles, typically at elevated temperatures (65°C to 85°C) and full operational current, for durations ranging from 24 to 72 hours. During this period, luminance output, chromaticity coordinates, and forward voltage are continuously or periodically monitored to identify and eliminate any units exhibiting early-life failures, significant lumen depreciation, or color shift. This proactive stress testing significantly enhances field reliability and ensures the product meets our stringent lifetime specifications before shipment.

Our OEM capability for flexible trim strips is a significant strength developed and refined at the Jiangmen facility. We possess comprehensive in-house engineering support to translate client concepts into manufacturable products. This includes expertise in designing and producing custom flexible printed circuits (FPCs) with varying copper weights, layer counts, and bend radii to suit specific application demands. We offer extensive customization options including precise LED density and spacing, multiple color temperatures and CCT tuning, various silicone encapsulation profiles and durometers for different IP ratings (up to IP67/IP68), specialized diffusers, connector types, and reel lengths. The factory supports low to high-volume production runs with dedicated changeover procedures on our SMT and assembly lines, ensuring efficient transition between different customer specifications while maintaining consistent quality. Our engineering team collaborates closely with clients from the initial design phase through prototyping and into full production, providing DFM feedback and validation testing to ensure the final product meets all functional, aesthetic, and reliability requirements. This end-to-end OEM service, backed by the advanced manufacturing and testing infrastructure in Jiangmen, allows us to deliver truly tailored flexible lighting solutions.

Application Scenarios

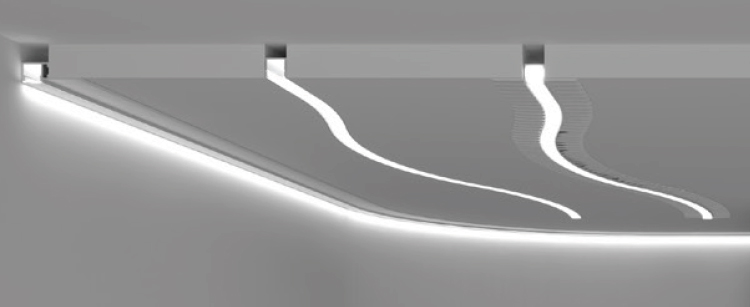

Flexible trim strips are versatile LED lighting solutions ideal for architectural accentuation and ambient illumination. They are commonly used across various commercial and hospitality environments including hotels, malls, and offices due to their adaptability, sleek appearance, and ability to follow curved or linear architectural features.

In hotels, flexible trim strips are often installed in reception areas, lobbies, corridors, and guest rooms to create a warm and inviting atmosphere. They are particularly effective when integrated into cove lighting, under wall-mounted features, or along stair edges for both aesthetic appeal and safety. In guest bathrooms and wardrobe areas, they provide subtle task lighting with a high-end finish.

In malls and retail environments, flexible trim strips are used to highlight displays, signage, and architectural contours. Their flexibility allows them to be installed along curved ceilings, columns, or shelving units, enhancing product visibility and guiding customer flow through dynamic lighting schemes. They are also used in ceiling coves and soffits to provide indirect illumination that reduces glare while maintaining brightness.

In office spaces, these trim strips are typically applied in drop ceilings, under cabinets, along walkways, and in reception areas. They contribute to a modern, professional look while improving visual comfort. When used in conjunction with daylight sensors or dimming systems, they support energy efficiency and employee well-being by providing adjustable ambient lighting.

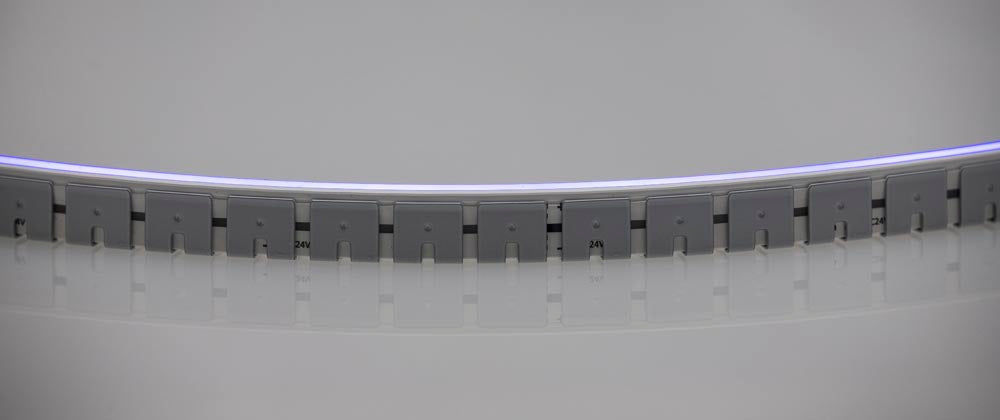

For successful installation, ensure the surface is clean, dry, and free of dust or grease to promote strong adhesion of the strip’s backing. Always measure and plan the layout before installation to avoid unnecessary cuts or gaps. Use compatible connectors and power supplies, and make sure the total wattage of the strip does not exceed the driver’s capacity. Avoid sharp bends—respect the minimum bending radius specified by the manufacturer to prevent damage to the LEDs or circuitry. For curved installations, consider using flexible aluminum channels that can be bent to match the contour while providing heat dissipation and protection. Finally, secure the strips using additional mechanical fasteners if installing on vertical or overhead surfaces to prevent sagging over time.

Why Choose Beauty STC Lighting

Transform your lighting vision with Beauty STC’s precision-engineered flexible trim strips designed for seamless integration and exceptional performance in demanding architectural applications. Our advanced manufacturing capabilities ensure consistent quality, superior flexibility, and reliable longevity whether you’re creating curved coves, intricate facades, or dynamic interior features. Partner with Beauty STC to leverage our engineering expertise and scalable production for custom solutions that meet your exact project specifications and timelines. Elevate your next project with lighting components built to exceed industry standards. Contact our dedicated team today at [email protected] to discuss how our flexible trim strips can bring your design concepts to life.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.