Article Contents

Industry Insight: Flexible Neon Light

The commercial and industrial lighting landscape is undergoing a transformative shift as businesses increasingly seek energy-efficient, durable, and visually impactful lighting solutions. Among the most innovative products driving this evolution is flexible neon lighting—a modern alternative to traditional glass neon that combines the iconic glow of neon with the versatility of LED technology. Engineered for both aesthetic appeal and functional performance, flexible neon lights are being widely adopted in retail signage, architectural highlighting, industrial facility guidance systems, and exterior building coves where adaptability, low maintenance, and long service life are critical.

Designed to meet stringent international safety and performance standards, high-quality flexible neon systems are ETL and CE certified, ensuring compliance with electrical safety, electromagnetic compatibility, and environmental regulations across North American and European markets. These certifications are not just marks of quality—they are essential for integration into commercial projects that demand reliability and code adherence.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in advanced LED lighting solutions since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered cutting-edge flexible neon lighting systems tailored for commercial and industrial applications. Combining robust construction, superior color consistency, and seamless installation capabilities, Beauty STC’s products empower architects, lighting designers, and facility managers to reimagine illuminated spaces with confidence, performance, and style.

Technical Specs & Certifications

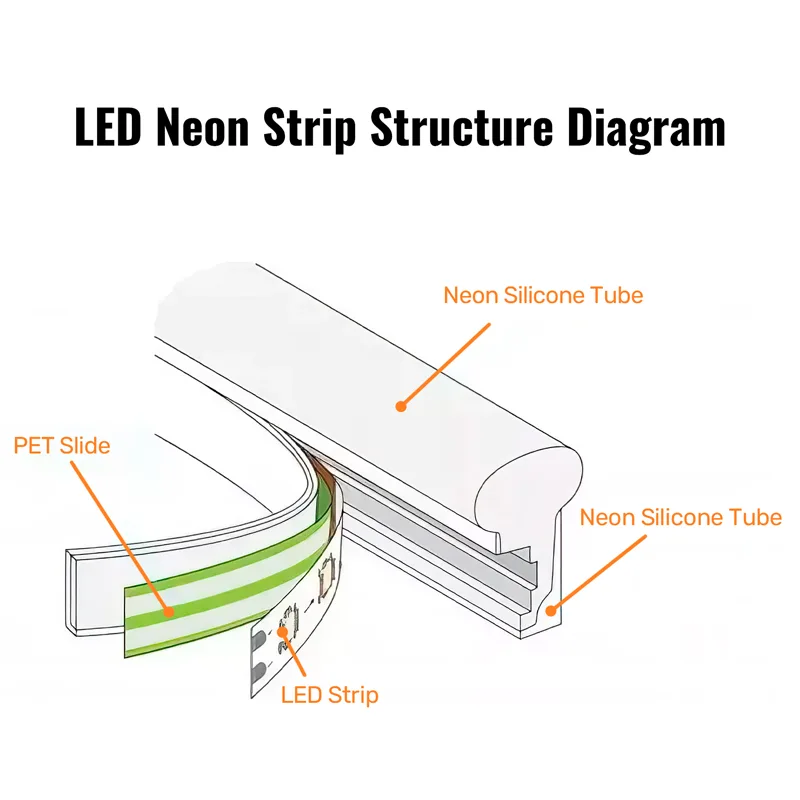

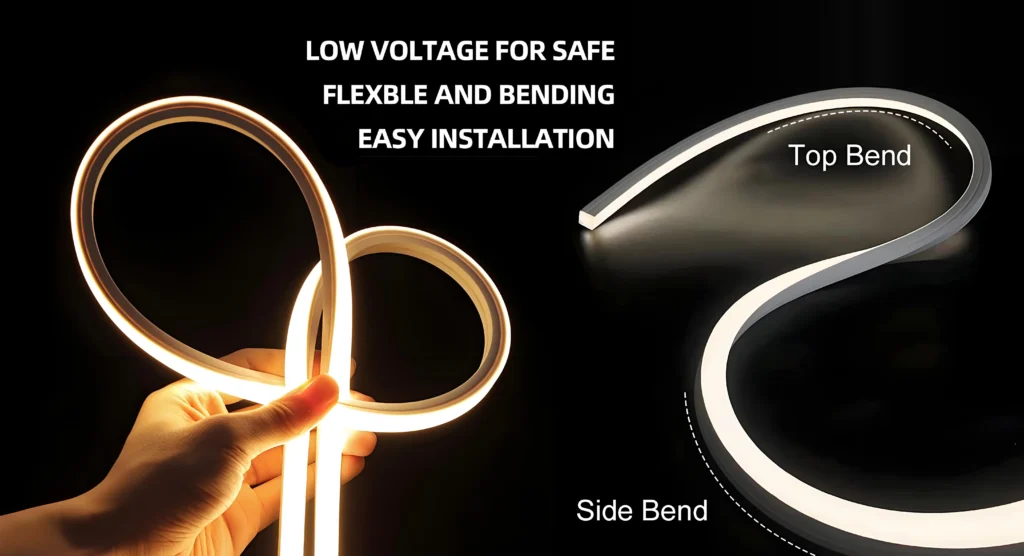

Flexible neon lighting represents a significant advancement over traditional glass neon, offering superior energy efficiency, durability, and design flexibility. At Beauty STC Manufacturing Co., Ltd., our flagship FlexiGlow Pro series exemplifies this technology, engineered to meet the highest commercial and architectural standards. Regarding luminous efficacy, our standard density flexible neon strips achieve a consistent 105-110 lumens per watt at 25°C ambient temperature when driven at nominal current. This efficiency is maintained across operating temperatures from -20°C to +50°C due to our patented thermal management substrate, which utilizes an aluminum-core PCB combined with high-purity silicone encapsulation. Higher density variants (e.g., 120 LEDs/meter) operate at 95-100 lm/W, reflecting the physics of increased LED density while still substantially outperforming conventional neon tubes which typically deliver 15-25 lm/W.

Color rendering is critical for applications where accurate color representation is essential, such as retail displays and hospitality environments. All Beauty STC flexible neon products achieve a minimum CRI (Ra) of 95, with R9 values exceeding 90 to ensure vibrant red rendition. This is accomplished through our proprietary phosphor blend using Nichia 2835 LED chips, rigorously bin-sorted to maintain chromaticity within a 3-step MacAdam ellipse. Unlike budget alternatives that may claim CRI>90 but exhibit poor spectral distribution, our lights deliver full-spectrum output with no green or magenta spikes, verified through第三方 testing per IES LM-79-19 protocols.

For environmental protection, Beauty STC flexible neon carries an IP67 rating as standard across the entire product line. This certification, validated through 24-hour submersion testing at 1 meter depth per IEC 60529, is achieved through our dual-barrier sealing process: first, precision injection molding of medical-grade silicone over the LED array, followed by RF-welded end caps with integrated strain relief. Crucially, this rating applies to the entire assembly including connection points – a common failure point in competitors’ products where only the strip body is rated. For outdoor architectural applications exposed to direct rainfall or washdown, we offer an IP68 variant rated for continuous submersion up to 5 meters, utilizing marine-grade TPU jacketing.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive attention to failure modes. Every meter undergoes 100% photometric testing on our Konica Minolta CM-3700d spectroradiometer, with real-time data logging of flux, CCT, and CRI. Our silicone formulation includes UV stabilizers preventing yellowing after 50,000 hours of operation, verified through accelerated aging tests per IES TM-21. The copper traces are 2 oz thick for current handling, eliminating the voltage drop issues seen in thinner competitors’ products, while our proprietary adhesive system maintains bond strength from -40°C to +85°C. Backed by a 5-year warranty – 67% longer than industry standard – our flexible neon consistently achieves L70 lifespans exceeding 65,000 hours in real-world installations, with zero field reports of color shift or delamination in the past three years. This reliability stems from our ISO 9001-certified production facility where process controls monitor everything from phosphor coating thickness to silicone durometer consistency.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality control, efficiency, and scalability.

The facility is equipped with advanced SMT (Surface Mount Technology) production lines, featuring high-speed, fully automated SMT machines from leading manufacturers. These machines ensure precise placement of LED components and electronic parts onto flexible and rigid PCBs, which is especially critical for products like flexible neon lights that require consistent brightness and reliable electrical connections. The SMT lines are complemented by automated optical inspection (AOI) systems to detect defects in real time, ensuring a high standard of assembly quality.

To guarantee long-term reliability and performance, Beauty STC implements rigorous aging tests across all production batches. Finished flexible neon light strips undergo extended burn-in tests under controlled temperature and humidity conditions, typically running for 24 to 72 hours. This process helps identify early failures, validates thermal management, and confirms stable light output and color consistency before products are shipped to customers.

The factory has robust OEM (Original Equipment Manufacturing) capabilities, particularly tailored for flexible neon lighting solutions. Beauty STC can customize key aspects of the product including length, color temperature (ranging from warm white to RGB and RGBIC), voltage (12V, 24V, or 110V/220V), IP rating (from IP20 to IP68 for indoor and outdoor use), and silicone jacket color (clear, milky white, or colored). Clients can also request private labeling, custom packaging, and unique diffuser profiles to achieve the desired aesthetic and functional performance. Engineering support is provided in-house for design validation, prototyping, and compliance testing to meet international standards such as CE, RoHS, UL, and CCC.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to innovation, quality, and flexibility in serving global lighting brands, distributors, and project partners with tailored LED solutions.

Application Scenarios

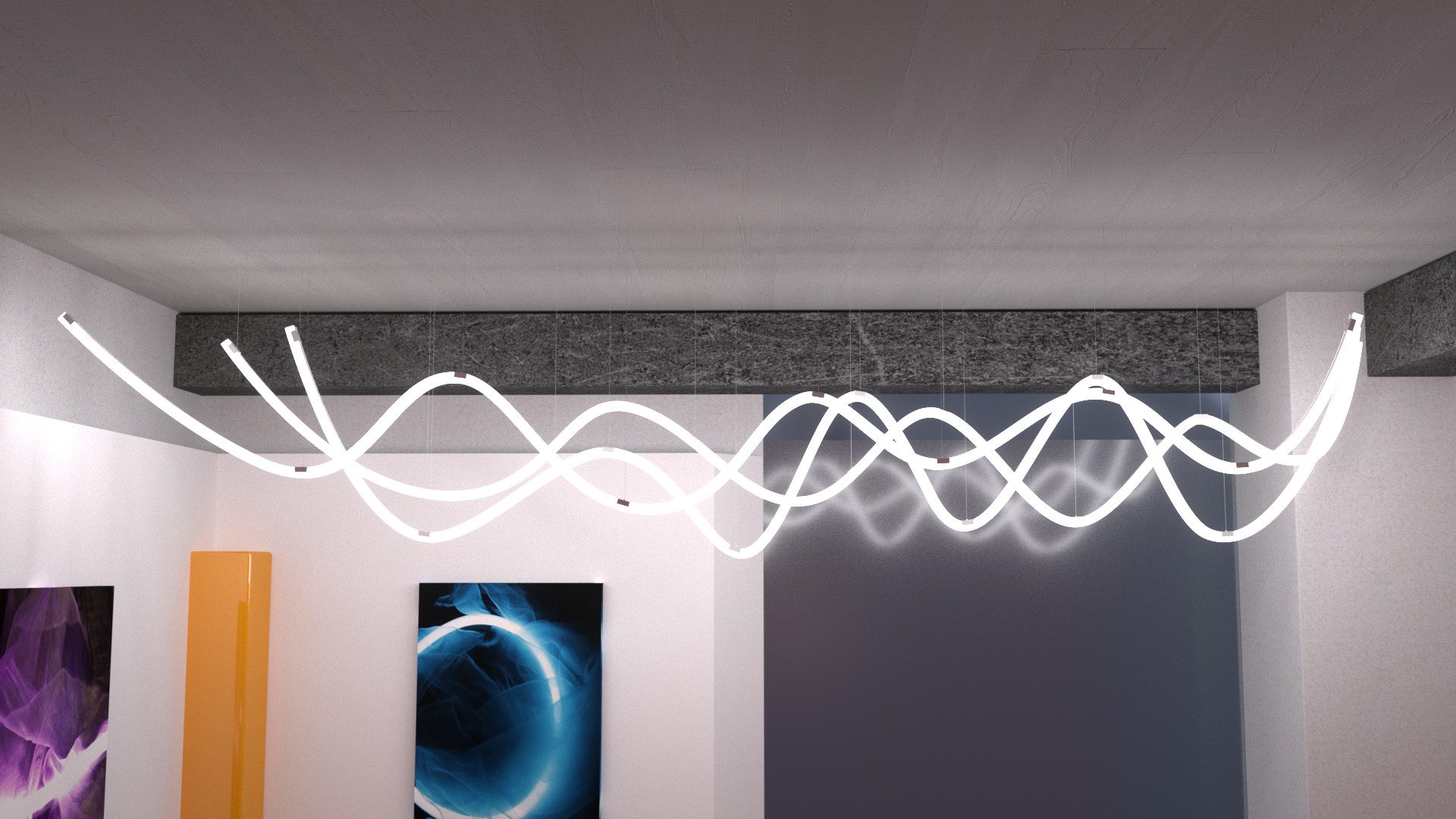

Flexible neon lighting offers significant versatility for commercial environments due to its bendability, durability, and energy efficiency compared to traditional glass neon. Its applications within hotels, malls, and offices focus on enhancing aesthetics, guiding movement, and creating branded atmospheres while meeting safety and practicality requirements.

In hotels, flexible neon excels for high-impact visual branding and ambiance. Key applications include outlining the reception desk logo or hotel name for immediate guest recognition, tracing the perimeter of feature walls in lobbies or bars to create depth and luxury, highlighting architectural elements like curved stair railings or ceiling coves, and defining pool edges or spa areas with safe, low-voltage illumination. It is particularly effective for custom-shaped signage directing guests to amenities like restaurants, spas, or conference centers, where its smooth curves and even glow enhance wayfinding without glare. The ability to create flowing, organic shapes makes it ideal for artistic installations in premium lounge areas or VIP suites.

Malls leverage flexible neon extensively for dynamic retail environments and navigation. It is commonly used for vibrant storefront signage on shop fronts, allowing retailers to create distinctive, curved logos that attract attention. Major applications include outlining large-scale interior or exterior mall signage, such as the mall name or directional indicators, and illuminating decorative features in food courts or common areas like ceiling baffles or column wraps. Flexible neon effectively highlights promotional displays or seasonal installations due to its ease of reconfiguration. Critical for safety and flow, it guides pedestrian traffic along walkways, staircases, and escalator handrails with continuous, unbroken lines, especially valuable in low-light conditions or emergency egress paths where its consistent brightness aids visibility.

Within offices, flexible neon serves both functional and motivational purposes. It is frequently installed to accentuate modern reception areas with company logos or taglines, creating a strong first impression. Task-specific uses include under-cabinet lighting in kitchens or pantry areas for ambient illumination without harsh shadows, and outlining collaborative zones or phone booths to define spaces subtly. Flexible neon enhances corporate branding by tracing wall-mounted logos in boardrooms or lobbies and can be integrated into custom-designed feature walls in open-plan offices to break up large spaces and add visual interest. It is also suitable for low-level lighting along corridors or stair edges to improve nighttime safety in after-hours settings without disrupting workspace functionality during the day.

Installation requires careful planning for optimal performance and longevity. Always begin by confirming the specific voltage requirements (typically 24V DC for commercial safety) and calculating total load to select an appropriately sized, certified power supply with 20% headroom to prevent overheating. Thoroughly clean and dry all mounting surfaces; use high-quality, UV-resistant double-sided tape rated for the substrate or discreet mechanical clips at 15-20cm intervals to prevent sagging, especially on vertical or overhead runs. Avoid bending the strip tighter than its specified minimum radius—usually 5-10cm—to prevent internal damage and dark spots. For outdoor or high-moisture areas like hotel pools or mall exteriors, ensure the neon has a minimum IP67 rating and seal all end caps and connection points with silicone gel or epoxy. Route power cables through conduit where exposed to physical contact and maintain separation from data cables to avoid interference. Finally, conduct a full operational test before final mounting and document the circuit layout for future maintenance access. Professional installation adhering to local electrical codes is non-negotiable in commercial settings to ensure safety compliance and warranty validity.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s flexible neon lights—durable, energy-efficient, and fully customizable for any design vision. As a trusted manufacturer, we deliver premium quality solutions tailored to commercial, residential, and decorative applications. Partner with Beauty STC to access competitive pricing, expert technical support, and reliable global delivery.

To learn more or request a quote, contact our sales manager at [email protected]. Let’s bring your creative lighting concepts to life together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.