Article Contents

Industry Insight: Flex Led Lights

Flexible LED lighting has emerged as a transformative solution in commercial and industrial lighting applications, offering unparalleled adaptability, energy efficiency, and design freedom. As facilities increasingly demand lighting systems that conform to complex architectural contours, tight spaces, and dynamic environments, flex LED lights have become a preferred choice across warehouses, manufacturing plants, retail spaces, and cold storage facilities. Their low-profile design and ability to be cut or bent to fit specific layouts make them ideal for task lighting, cove illumination, under-shelving, and linear runs along conveyor systems or workstations. With growing emphasis on compliance and safety, leading installations now require flex LED products that are ETL and CE certified—assuring performance, electrical safety, and adherence to North American and international standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting technology for over two decades. Specializing in high-performance lighting solutions for commercial and industrial sectors, Beauty STC combines rigorous engineering with stringent quality control to deliver flex LED systems that meet the demands of modern facilities. As a trusted manufacturer with a global footprint, the company ensures all its flex LED products are ETL and CE listed, reflecting a commitment to safety, reliability, and regulatory compliance. With a legacy built on durability and technical excellence, Beauty STC continues to empower smarter, more efficient lighting infrastructures worldwide.

Technical Specs & Certifications

As Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I provide the following detailed technical specifications for flexible LED strip lights, commonly referred to as “flex LED lights,” based on our rigorous engineering standards and product portfolio. These specifications reflect industry best practices and Beauty STC’s commitment to performance and reliability.

Lumens per Watt (Lm/W) efficiency is a critical metric for flexible LED lighting, directly impacting operational cost and thermal management. Beauty STC’s high-performance flex LED strips achieve typical efficacy ranges of 110-140 lumens per watt for standard 24VDC products operating at 25°C ambient temperature. This range is attainable while maintaining CRI >90 and stable color temperature. Efficacy is influenced by LED density (e.g., 60 LEDs/meter vs. 120 LEDs/meter), drive current, and thermal design. Higher densities or extreme color temperatures (below 2700K or above 6500K) may reduce efficacy by 5-15 Lm/W. Our proprietary phosphor formulations and optimized driver ICs minimize efficiency loss at high CRI levels, ensuring our strips consistently exceed baseline industry averages for this performance tier. Real-world installation conditions, including heatsinking and ambient temperature, will affect sustained output.

Color Rendering Index (CRI) exceeding 90 is non-negotiable for applications demanding accurate color representation, such as retail displays, art galleries, and high-end residential spaces. Beauty STC achieves CRI >92 (Ra) across our premium flex LED product lines through multi-phosphor LED chips, often incorporating enhanced R9 (saturated red) values above 50 to ensure vibrant, natural color rendition. We utilize the extended TM-30-15 metrics (Rf and Rg) for comprehensive color fidelity assessment, ensuring our strips deliver Rf >85 and Rg near 100 for minimal hue distortion. This level of color accuracy is maintained through strict binning processes during manufacturing, where LEDs are sorted to tight chromaticity tolerances (within a 3-step MacAdam ellipse) to prevent visible color variation along the strip length. Achieving this high CRI does involve a minor trade-off in efficacy compared to standard CRI 80 strips, typically 5-10 Lm/W, which our thermal management and optical design mitigate effectively.

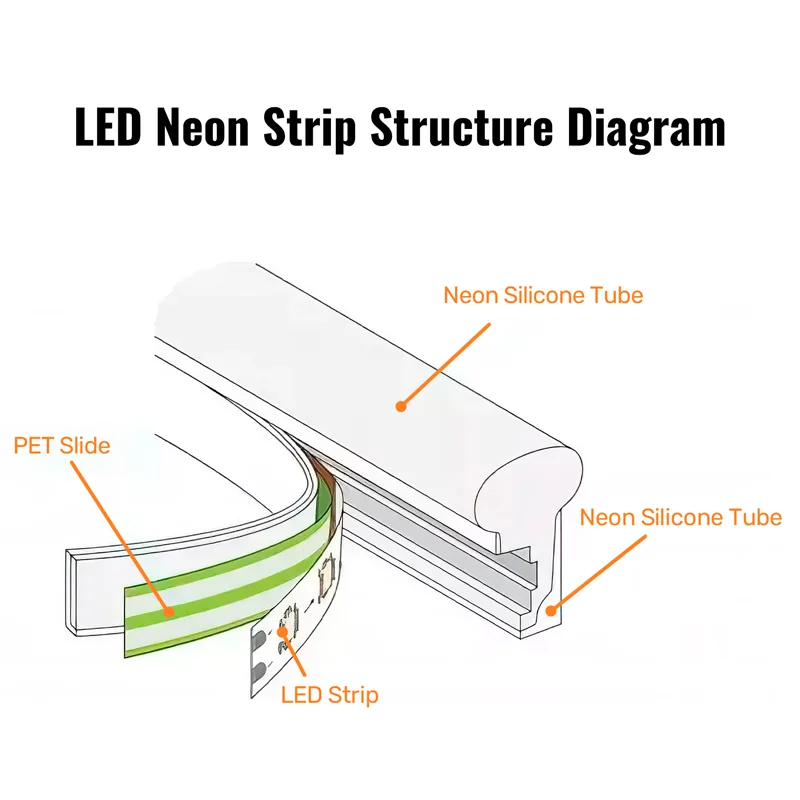

IP (Ingress Protection) ratings define the level of protection against solid particles and moisture, crucial for both indoor and outdoor flex LED applications. Beauty STC offers flex strips across multiple IP classifications. IP20 denotes basic indoor use without environmental protection. For damp locations like kitchens or bathrooms, IP65-rated strips feature a silicone encapsulation over the LEDs and circuitry, resisting low-pressure water jets from any direction. True outdoor or submersible applications require IP67 or IP68 ratings. Our IP67 strips withstand temporary immersion up to 1 meter for 30 minutes, while IP68 variants are rated for continuous submersion beyond 1 meter (typically 1.5m for 72 hours), achieved through robust double-silicone overmolding and sealed end caps. Critical to note, the IP rating applies only to the strip itself under factory conditions; final installation quality, including proper sealing of cuts and connections, is paramount for maintaining the rated protection in the field. Beauty STC provides detailed installation guidelines to preserve IP integrity.

Beauty STC distinguishes itself through uncompromising quality control and engineering rigor. Our flex LED strips undergo 100% automated optical and electrical testing during production, including high-temperature burn-in (72 hours at 60°C) to identify early failures. We utilize only Tier-1 LED chips from leading manufacturers, coupled with 2oz copper PCBs for superior thermal dissipation compared to standard 1oz substrates, directly enhancing lumen maintenance (L90 >50,000 hours at 45°C). Rigorous IES LM-80 and TM-21 testing validates long-term performance claims. Our silicone materials are UL 94 V-0 rated for fire safety and UV-stable to prevent yellowing. Every batch undergoes spectroradiometric verification of CRI, CCT, and lumen output against NIST-traceable standards. This systematic approach, backed by our ISO 9001 and IATF 16949 certified manufacturing processes, ensures Beauty STC flex LED products deliver the specified Lumens/Watt, CRI >90, and IP performance reliably throughout their operational life, setting a benchmark for quality in the professional lighting market.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically positioned to support efficient production and logistics for both domestic and international markets. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products, with a strong focus on innovation, precision, and reliability.

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines featuring advanced high-speed SMT machines. These machines ensure precise placement of LED components and electronic elements onto flexible and rigid PCBs, enabling high-density mounting and consistent soldering quality. The SMT process is fully automated, integrating automatic optical inspection (AOI) systems to detect placement and soldering defects in real time, which significantly enhances product reliability and manufacturing yield.

A critical part of the production workflow at the Jiangmen factory is the comprehensive aging test process. After assembly, all LED lighting products—especially flexible LED strips—undergo rigorous aging tests under controlled temperature and load conditions. This typically involves operating the lights at full power for extended periods, often 24 to 72 hours, to identify early-life failures and ensure long-term stability. The aging area is monitored continuously, and any underperforming units are promptly removed and analyzed, ensuring only reliable products reach customers.

Beauty STC has robust OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, particularly for flexible LED lights. The company supports custom solutions including tailored lengths, color temperatures, lumen outputs, IP ratings, and special circuit designs. Clients can provide specific technical requirements or branding elements such as custom labels, packaging, and private labeling. The engineering team works closely with clients from prototyping through to mass production, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible manufacturing systems to deliver customized, high-performance flexible LED lighting solutions for a global clientele.

Application Scenarios

Flex LED lights offer exceptional versatility for architectural and decorative lighting in commercial environments due to their thin profile, bendability, and ease of integration. In hotels, they are ideal for creating ambiance and guiding guests. Install them within cove lighting systems in lobbies to provide soft, indirect illumination that enhances high ceilings and architectural details without glare. Use them under handrails in corridors for subtle wayfinding and safety lighting, and integrate them into vanity mirrors in guest bathrooms for even, shadow-free task lighting. In executive suites or premium rooms, embedding flex strips within headboards or behind floating furniture creates a high-end, personalized atmosphere. For malls, flex LEDs excel in driving visual merchandising and spatial definition. Apply them to accentuate product displays within retail storefronts, highlighting merchandise with precise, adjustable beams. Install them along the undersides of escalators and moving walkways for dynamic safety lighting and visual flow. Utilize them in cove lighting within food court ceilings to define seating areas and create inviting zones, and wrap them around column bases or feature walls for dramatic accentuation that draws shoppers through the space. In offices, focus on functionality and well-being. Integrate flex strips under desks for comfortable, low-glare task lighting that reduces eye strain, and install them within suspended ceiling coves for uniform, indirect ambient illumination that minimizes shadows on work surfaces. Use them to backlight reception desks for a professional impression, and embed them in partition walls or shelf undersides in collaborative areas to define zones without physical barriers while maintaining brightness.

Installation requires careful planning to ensure performance and longevity. Always calculate voltage drop for runs exceeding 5 meters, especially with 12V systems, by using higher input voltage like 24V where possible or injecting power at multiple points along the strip. Ensure the mounting surface is clean, dry, and structurally sound; use appropriate adhesives or mechanical clips rated for the substrate and environment, as relying solely on factory adhesive in commercial settings risks premature failure. Maintain adequate thermal management by avoiding tight bends below the specified minimum radius and never installing flex strips in enclosed, unventilated spaces where heat buildup can degrade LEDs and phosphors. For outdoor or high-moisture areas like mall exteriors or hotel pool decks, select IP67 or IP68 rated strips with properly sealed end caps and junctions, and avoid direct burial without conduit. Always use a compatible constant-voltage LED driver with sufficient wattage headroom—typically 20% above the calculated load—and incorporate surge protection in environments with unstable power. Finally, conduct a full test run before final mounting to verify color consistency, brightness, and control functionality, as commercial projects demand flawless execution.

Why Choose Beauty STC Lighting

Discover the future of lighting with flexible LED solutions from Beauty STC. Our high-quality flex LED lights offer superior performance, durability, and versatility for residential, commercial, and industrial applications. Whether you’re looking for customizable lengths, vibrant color options, or energy-efficient lighting, we deliver innovation you can trust.

Partner with Beauty STC, a trusted manufacturer with years of expertise in LED technology and a global reputation for excellence. Our dedicated team ensures seamless collaboration, competitive pricing, and on-time delivery to meet your business needs.

Take the next step in lighting innovation. Contact us today at [email protected] to discuss your project and discover how our flex LED lights can power your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.