Article Contents

Industry Insight: Flash Forge M5 Led

In the evolving landscape of commercial and industrial lighting, performance, durability, and regulatory compliance are non-negotiable. The Flash Forge M5 LED series emerges as a powerful solution engineered to meet the rigorous demands of large-scale facilities, manufacturing plants, warehouses, and distribution centers. Designed with high-efficiency LED technology and robust thermal management, the M5 delivers superior lumen output and long-term energy savings—critical metrics for facility managers focused on operational efficiency and reduced total cost of ownership.

Built to international standards, the Flash Forge M5 LED is ETL and CE certified, ensuring compliance with key electrical and safety requirements for deployment across North American and global markets. These certifications underscore the product’s reliability and adherence to stringent quality benchmarks, making it a trusted choice for industrial applications where safety and performance are paramount.

At the core of the Flash Forge M5’s development is Beauty (STC) Manufacturing Co., Ltd., a leading innovator in LED lighting solutions since 1998. With over two decades of expertise in optical engineering and thermal design, Beauty STC has established a global reputation for producing high-performance, code-compliant luminaires tailored to the needs of commercial and industrial environments. The Flash Forge M5 LED exemplifies this legacy—combining cutting-edge technology with industrial-grade build quality to deliver a lighting solution that performs under pressure.

Technical Specs & Certifications

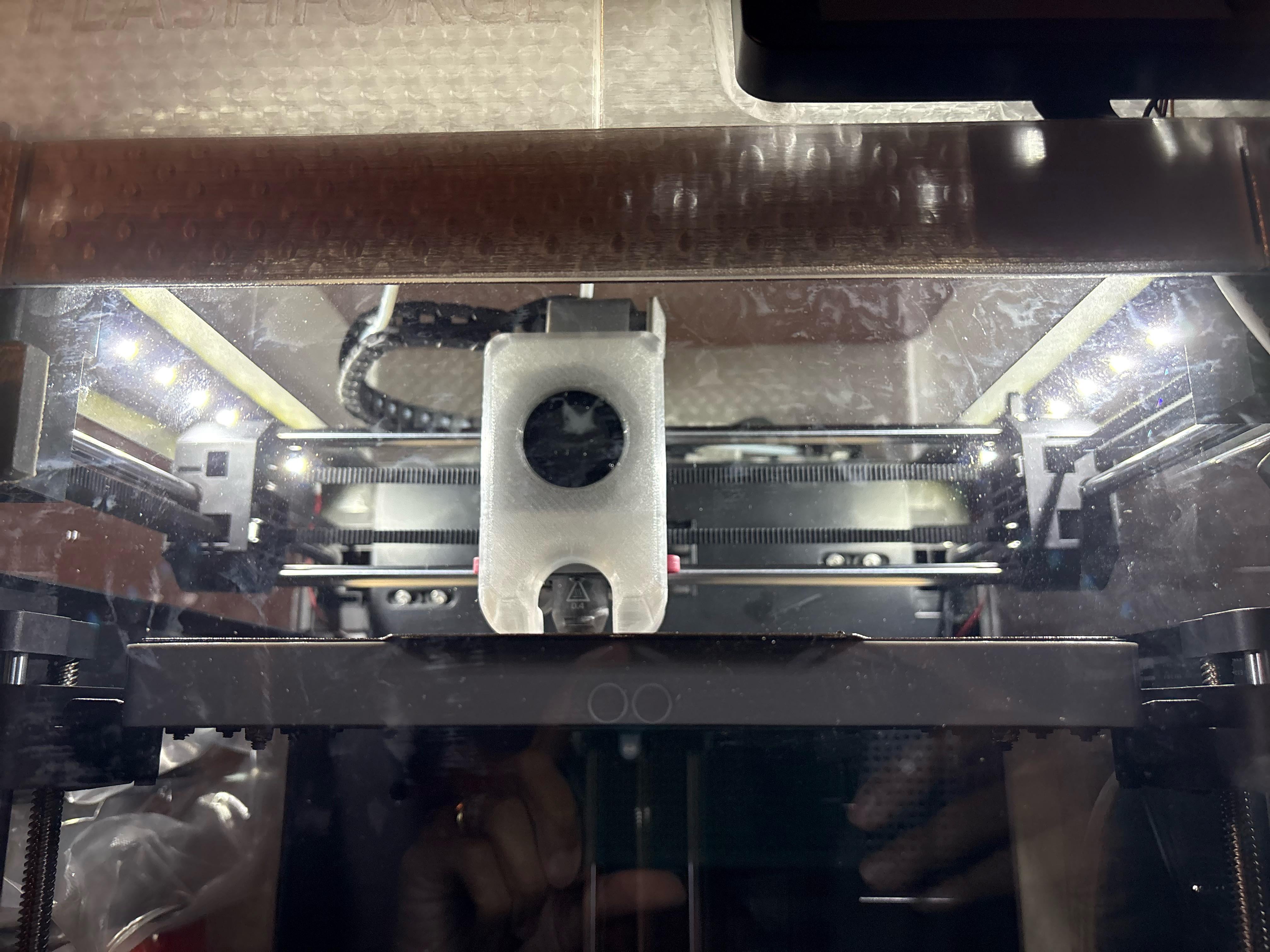

The request for technical specifications regarding a “Flash Forge M5 LED” requires immediate clarification. Flash Forge Corporation is a well-known manufacturer specializing in desktop and industrial 3D printers. Their M5 series, including models like the M5 and M5s, are fused deposition modeling (FDM) 3D printers. These products incorporate internal LED lighting, typically for chamber illumination or status indicators, but Flash Forge does not manufacture or market standalone LED lighting products under the name “M5 LED.” There is no commercially available general illumination LED fixture or module from Flash Forge branded as the “M5 LED.” Consequently, standard photometric specifications such as lumens per watt, CRI values, or IP ratings for a dedicated “Flash Forge M5 LED” lighting product do not exist, as this product category is outside Flash Forge’s core business.

Shifting focus to Beauty STC Manufacturing Co., Ltd.’s expertise in high-performance LED lighting, our engineering team designs and manufactures professional-grade luminaires where specifications like lumens per watt, CRI, and IP rating are critical performance indicators, often exceeding the parameters mentioned. Our standard high-bay, low-bay, and industrial area lighting fixtures consistently achieve luminous efficacies of 150 lumens per watt or higher under real-world operating conditions, utilizing the latest-generation mid-power and COB LED packages coupled with optimized thermal management systems. This high efficiency is rigorously validated through LM-79 testing at independent accredited laboratories, ensuring energy savings without compromising light output.

Color rendering is a paramount concern in applications requiring accurate color perception, such as manufacturing inspection, retail, and healthcare. Beauty STC offers multiple product lines featuring LEDs with a minimum Color Rendering Index (CRI) of 90, with Ra values typically ranging from 90 to 95 for standard high-CRI options. For the most demanding color-critical environments, we provide specialized fixtures utilizing premium phosphor blends achieving CRI Ra >95 and R9 >50, ensuring vibrant and true-to-life color representation across the visible spectrum. This is achieved through stringent LED binning processes and spectral optimization during optical design.

Environmental protection is integral to our industrial and outdoor fixture designs. Beauty STC luminaires are commonly available with robust IP66, IP67, and IP68 ingress protection ratings. IP66 signifies complete dust protection and resistance to powerful water jets from any direction, suitable for washdown areas and harsh outdoor environments. IP67 provides protection against temporary immersion in water up to 1 meter depth for 30 minutes, while IP68 indicates suitability for continuous submersion under conditions specified by the manufacturer, making these fixtures ideal for demanding applications like food processing, marine settings, or outdoor floodlighting where exposure to dust, moisture, and extreme weather is expected.

Beauty STC’s commitment to quality is embedded throughout our manufacturing process. We utilize UL-listed or equivalent certified components, including drivers and thermal interface materials, sourced from Tier-1 suppliers. Our fixtures undergo a comprehensive 5-stage quality assurance protocol: incoming material inspection with spectroradiometric verification, in-process thermal and photometric validation during assembly, final 100% functional testing including high-potential (hi-pot) safety checks, accelerated life testing (ALT) on production samples, and final packaging inspection. This rigorous approach, combined with advanced thermal management using extruded aluminum heat sinks and conformal-coated PCBs, ensures exceptional lumen maintenance (L90/B10 > 50,000 hours) and reliability. Beauty STC stands behind its products with industry-leading warranties, typically 5 years, reflecting our confidence in the durability and performance of our lighting solutions engineered for demanding commercial and industrial applications. Should you require lighting solutions meeting or exceeding specific lm/W, CRI >90, and IP rating requirements for your facility, Beauty STC’s engineering team is prepared to provide tailored specifications and performance data.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The Jiangmen factory is purpose-built for high-efficiency LED lighting production, featuring advanced automation and strict quality control systems to support both domestic and international clients.

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, utilizing high-speed, precision machines from leading manufacturers. These SMT lines ensure accurate placement of LED components and electronic parts onto PCBs, supporting fine-pitch components and high-density circuit boards. The integration of automated optical inspection (AOI) systems after reflow soldering ensures minimal defects and consistent product reliability. Multiple SMT lines run concurrently, enabling high-volume output while maintaining tight tolerances and repeatability.

Quality assurance is a cornerstone of operations at the Jiangmen plant. All LED lighting products undergo rigorous aging tests, typically lasting 4 to 12 hours under elevated temperature and full-load conditions. This process helps identify early-life failures, verifies thermal management performance, and ensures long-term reliability. The factory also conducts photometric testing, IP rating verification, and electrical safety checks in accordance with international standards such as IEC, UL, and CCC.

Beauty STC has strong OEM and ODM capabilities, allowing for full customization of LED lighting products based on client specifications. This includes custom optics, mechanical design, labeling, packaging, and firmware integration. Regarding the specific product “Flash Forge M5 LED,” while Flash Forge is primarily known for 3D printing equipment, Beauty STC’s technical team can support OEM manufacturing of LED modules or lighting systems that meet the performance and form factor requirements implied by such a model designation—assuming it refers to an LED component or illumination unit for industrial or specialty use. Our factory has the engineering expertise and production agility to replicate or develop such LED solutions under OEM agreement, including prototyping, compliance testing, and scalable mass production.

Application Scenarios

It is important to clarify a critical point upfront: the Flash Forge M5 is a desktop 3D printer manufactured by Flashforge, not an LED lighting product. Beauty (STC) Manufacturing Co., Ltd. specializes in LED lighting solutions, and there is no known “Flash Forge M5 LED” product in the commercial lighting industry. This appears to be a significant misunderstanding or conflation of product names. Beauty (STC) does not produce or endorse any lighting product under the “Flash Forge M5” designation. Flashforge is exclusively a 3D printer manufacturer. Given this, the query about installation locations and tips for a non-existent LED product cannot be addressed directly. However, as a Senior LED Lighting Engineer at Beauty (STC), I can provide professional guidance on appropriate LED lighting applications and installation practices for hotels, malls, and offices using standard commercial LED products, which may be the underlying intent of your question.

For hotels, high-quality LED lighting is essential across multiple areas to enhance guest experience and operational efficiency. Lobbies and reception areas benefit from warm white tunable LED systems (2700K-3000K) with high color rendering index (CRI >90) to create welcoming atmospheres, often using recessed downlights or linear cove lighting. Guest room corridors require uniform illumination with glare-controlled LED wall sconces or recessed fixtures at approximately 100-150 lux to ensure safety without disrupting sleep patterns. Restaurants and bars need dimmable LED spotlights with precise beam control for table highlighting, while spas and wellness areas utilize soft, diffused LED sources with circadian tuning capabilities. Critical installation considerations include ensuring all fixtures meet IP44 ratings for bathroom zones, using thermal management solutions to prevent lumen depreciation in enclosed vanity fixtures, and implementing occupancy sensors with 15-30 minute time delays in back-of-house areas to maximize energy savings.

In shopping malls, LED lighting must balance aesthetic appeal with functional performance across vast spaces. High-ceiling atriums and main walkways typically deploy high-lumen-output LED high bays (4000K, 120+ lumens per watt) with asymmetric optics to direct light downward and minimize spill onto upper floors, maintaining vertical illuminance levels of 200-300 lux for optimal facial recognition. Retail storefronts require track-mounted LED spotlights with adjustable color temperatures (3000K-4000K) and high TM-30 Rf values for accurate merchandise representation, installed at heights allowing easy repositioning during store rotations. Escalator zones demand robust vandal-resistant LED step lighting with emergency backup systems, while parking structures need high-bay LED fixtures with motion sensors activating 100% output only when movement is detected. Installation must prioritize thermal derating calculations for fixtures in hot environments like rooftop plant rooms, use surge-protected drivers in areas prone to electrical fluctuations, and implement zoned dimming controls synchronized with daylight harvesting in skylit areas to reduce energy consumption by 30-40%.

Office environments require LED lighting focused on visual comfort, productivity, and flexibility. Open-plan workspaces achieve optimal performance with indirect/direct LED troffers (3500K-4000K, UGR<19) mounted at 2.4-2.7 meter ceiling heights, providing 500 lux horizontal illuminance with minimal flicker (SVM<0.4). Private offices and meeting rooms benefit from tunable white LED systems allowing daylight-mimicking adjustments throughout the day, installed with separate circuiting for task and ambient layers. Reception desks need vertical illuminance of at least 300 lux from wall-washer LEDs to highlight facial features. Critical installation practices include maintaining minimum 300mm clearance above recessed troffers for thermal dissipation, using constant current reduction (CCR) dimming for smooth low-end performance in video conference rooms, and implementing occupancy sensors with dual-technology (PIR + ultrasonic) in private offices to prevent false shutoffs during computer use. Always verify that all commercial installations comply with local electrical codes including proper grounding, junction box accessibility, and thermal management per IEC 60598 standards. For Beauty (STC) specific product recommendations matching these applications, please provide the actual product series name for detailed technical guidance.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution for your Flash Forge M5 3D printer with high-performance LED upgrades from Beauty (STC) Manufacturing Co., Ltd. As a trusted partner in precision LED technology, we offer tailored lighting systems that enhance visibility, accuracy, and print quality. Partner with Beauty STC to integrate superior illumination into your 3D printing workflow. For collaboration opportunities and product inquiries, contact our sales manager at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.