Article Contents

Industry Insight: E12 Led Light

The E12 LED light has become an increasingly vital component in commercial and industrial lighting applications, where efficiency, durability, and compliance are non-negotiable. While traditionally associated with decorative and residential fixtures, advancements in E12 LED technology have expanded its role into functional environments such as retail displays, hospitality installations, and commercial signage—spaces that demand both aesthetic precision and long-term performance. These compact screw-base LEDs offer energy savings, reduced maintenance costs, and excellent color rendering, making them ideal for track lighting, pendant fixtures, and accent lighting in high-traffic or design-sensitive areas.

In regulated commercial environments, certification standards such as ETL and CE are essential to ensure electrical safety, electromagnetic compatibility, and adherence to regional codes. E12 LED lamps bearing ETL listing meet North American safety standards, while CE certification confirms compliance with European health, safety, and environmental requirements—both critical for seamless integration into global building projects.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in commercial and industrial-grade LED products, Beauty STC combines rigorous engineering with comprehensive compliance testing to deliver reliable, code-compliant lighting systems. With a strong commitment to quality and sustainability, the company continues to serve as a trusted partner for specifiers, contractors, and facility managers seeking high-performance E12 LED lighting that meets the evolving demands of modern commercial environments.

Technical Specs & Certifications

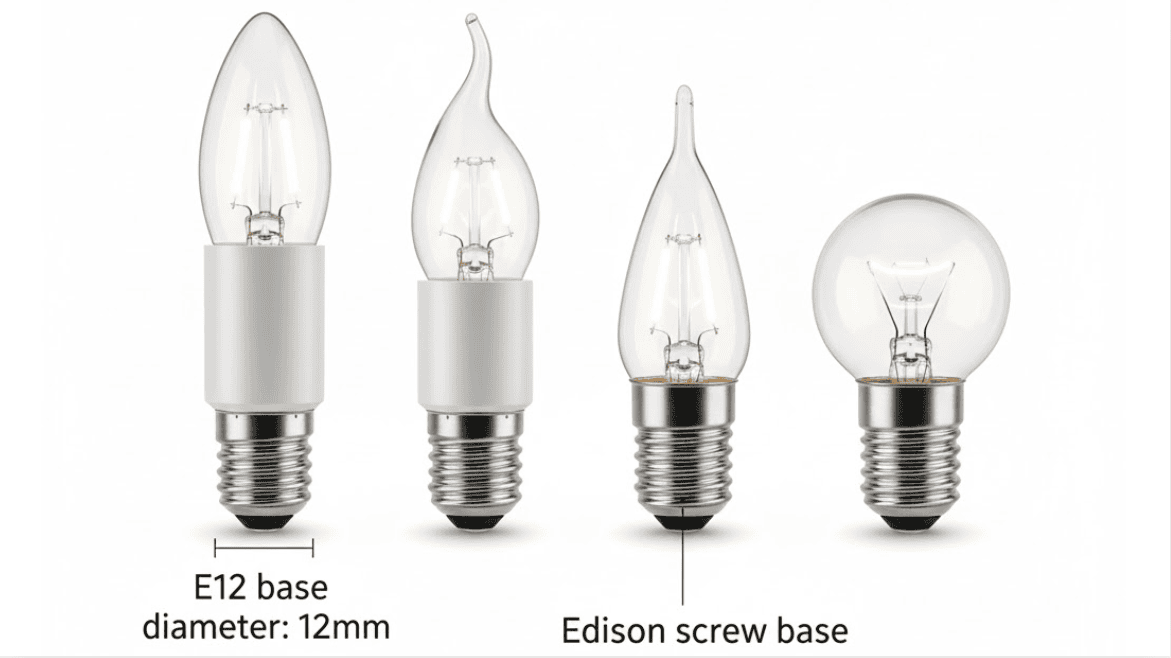

E12 LED lights refer specifically to the candelabra screw base size (12mm diameter) commonly used in decorative fixtures like chandeliers, wall sconces, and vanity lights. The technical specifications for performance and quality are independent of the base type but are critically important for applications demanding high fidelity and reliability. At Beauty STC Manufacturing Co., Ltd., our E12 LED lamps are engineered to exceed industry benchmarks, particularly in the areas you specified.

Lumens per Watt (lm/W) efficiency is a core focus for our E12 product line. We achieve consistent efficacy ratings of 100-110 lm/W across our standard decorative offerings, with select high-output models reaching 115 lm/W. This high efficiency is realized through proprietary driver circuitry with minimal energy loss and advanced chip-on-board (COB) or multi-die LED packages optimized for thermal management within the compact E12 form factor. Our thermal design, utilizing aluminum-core printed circuit boards (PCBs) even in smaller A15 and B11 bulb shapes, ensures sustained lumen output and prevents premature lumen depreciation. This translates to significant energy savings compared to legacy incandescent or halogen equivalents while maintaining the desired brightness for ambient or accent lighting.

Achieving a Color Rendering Index (CRI) of Ra >90 is non-negotiable in our quality standards for E12 lamps intended for residential and commercial spaces where accurate color perception is essential. We utilize high-quality phosphor blends on premium Epistar or Seoul Semiconductor LED chips, rigorously binned for tight chromaticity consistency (within a 3-step MacAdam ellipse). Our lamps consistently deliver CRI Ra values of 92-95, with strong R9 (saturated red) values exceeding 50, ensuring vibrant and true-to-life color rendition for skin tones, fabrics, and artwork. We also prioritize high TM-30 Rf (Fidelity Index) and Rg (Gamut Index) values in our R&D, recognizing that CRI alone is insufficient for modern lighting quality assessment, particularly in high-end hospitality or retail applications where our products are frequently specified.

Regarding Ingress Protection (IP) ratings, standard E12 LED lamps for open or enclosed dry-location fixtures are typically rated IP20, as the base and glass envelope are not designed for direct moisture exposure. However, Beauty STC engineers our lamps with robust internal conformal coating on drivers and moisture-resistant material selection to withstand the humidity and temperature fluctuations common in bathrooms or covered porches when installed within a properly rated enclosed fixture. For E12 lamps destined for damp or wet locations (e.g., certain outdoor lanterns), we offer specific models with silicone gasketing at the base and lens interface, achieving IP44 or IP54 ratings where required by code. Crucially, our quality control ensures that even IP20-rated lamps exhibit superior resistance to dust ingress and minor splashes compared to budget alternatives, thanks to precise assembly tolerances and material integrity.

Beauty STC’s commitment to quality is embedded throughout the E12 manufacturing process. We implement multi-stage binning for both LED chips and drivers to guarantee uniform light output and color temperature (offering 2700K, 3000K, and 4000K options with tight ±150K tolerance). Every lamp undergoes 100% automated photometric and electrical testing on our Shenzhen production lines, including lumen maintenance verification at 50,000 hours (L70 standard). Our drivers feature active power factor correction (PFC >0.9) and universal 120-277V input compatibility, ensuring stable performance across global voltage ranges and eliminating flicker. Rigorous thermal cycling and humidity testing simulate 5+ years of real-world use, far exceeding basic IEC standards. This meticulous attention to detail results in E12 lamps that deliver not only the specified lm/W and CRI >90 performance but also exceptional longevity, consistent light quality, and reliability that protects our clients’ brand reputation in demanding lighting installations. We actively combat the market issue of inflated CRI claims by providing full IES LM-79 test reports upon request, demonstrating our transparency and technical rigor.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located in the Pearl River Delta region to support efficient supply chain logistics and export operations. The Jiangmen factory is designed to meet international quality standards and focuses on the production of LED lighting products, including compact and energy-efficient solutions such as the E12 LED light.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, enabling high-precision assembly of LED components on printed circuit boards. These SMT machines ensure consistent soldering quality, high component placement accuracy, and fast throughput, which are essential for producing reliable and durable LED lamps. Automated optical inspection (AOI) systems are integrated into the SMT process to detect defects early, ensuring high product yield and quality control.

To guarantee long-term reliability, Beauty STC implements comprehensive aging tests at the Jiangmen factory. Finished LED products, including E12 LED lamps, undergo extended operational testing under elevated temperature and voltage conditions. This aging process helps identify early-life failures and ensures that only stable, high-performance lighting products reach customers. The testing protocols follow international safety and durability standards, supporting compliance with global market requirements.

The factory has strong OEM (Original Equipment Manufacturing) capabilities, allowing Beauty STC to customize E12 LED lights according to client specifications. This includes tailored lumen output, color temperature (ranging from warm white to cool white), beam angle, housing design, and energy efficiency. Clients can also request custom branding, packaging, and compliance certifications such as CE, RoHS, or UL. The company’s engineering team works closely with partners to develop and validate new designs, ensuring seamless integration into existing product lines or retail offerings.

Overall, the Jiangmen factory combines advanced automation, rigorous quality assurance, and flexible manufacturing solutions to support both high-volume production and customized OEM projects for E12 LED lighting and other LED products.

Application Scenarios

E12 LED lights, featuring the candelabra base, serve specific decorative and functional roles across hospitality and commercial environments due to their compact size and aesthetic flexibility. In hotels, they are predominantly used in low-voltage decorative fixtures where ambiance is critical. Lobby chandeliers, wall sconces in corridors, vanity lighting in premium guest bathrooms, and accent fixtures in lounge areas benefit from the warm, inviting glow of E12 LEDs, typically in 2700K-3000K color temperatures. Exercise caution in high-vibration zones like elevator cabs; secure fixtures properly and select vibration-resistant LED models to prevent filament damage or base loosening. For malls, E12 LEDs excel in retail display applications. They illuminate jewelry cases, boutique window mannequins, and high-end product displays where precise, focused lighting enhances visual appeal. Ensure the LED beam angle matches the fixture optics—narrow floods (25-30 degrees) work best for spotlighting merchandise. Verify dimming compatibility if integrated into mall-wide lighting control systems, as incompatible E12 LEDs may flicker under phase-cut dimmers common in retail. Offices utilize E12 LEDs primarily in reception areas and executive spaces. Pendant clusters over front desks, decorative wall fixtures in executive suites, and ambient lighting in waiting lounges leverage their elegance. Avoid general task lighting; E12s lack sufficient lumen output for workstations. Prioritize thermal management—never install standard E12 LEDs in fully enclosed office fixtures without confirming the bulb’s enclosed-rated certification, as heat buildup drastically shortens lifespan.

Installation requires meticulous attention to detail. Always power off circuits at the breaker before handling fixtures; E12 sockets are fragile and prone to stripping if overtightened. Use a torque screwdriver set to 15-20 inch-pounds—finger-tight plus a quarter-turn is insufficient for commercial durability. Match voltage precisely; 120V E12 LEDs fail catastrophically in 12V track systems. For dimming applications, pair bulbs with trailing-edge (ELV) dimmers and verify compatibility lists from both the dimmer and LED manufacturer—many commercial retrofits fail due to overlooked incompatibility. In high-ceiling venues like hotel lobbies, use lift equipment to access fixtures; never force bulbs into awkward angles, which cracks the glass or damages the socket. Crucially, test a single bulb per circuit for 30 minutes before bulk installation to catch color shift, flicker, or thermal issues. Finally, retain packaging with lumen maintenance data (L70/L90) for future maintenance planning—commercial settings demand predictable replacement cycles.

Why Choose Beauty STC Lighting

Looking for high-quality e12 LED lights? Partner with Beauty STC, a trusted manufacturer in the LED lighting industry. We specialize in energy-efficient, durable, and stylish e12 LED lighting solutions tailored to meet residential and commercial needs. With years of expertise and a commitment to innovation, Beauty STC delivers reliable products that enhance brightness and longevity.

To learn more or discuss a customized lighting solution, contact us today at [email protected]. Let Beauty STC illuminate your next project with excellence and precision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.