Article Contents

Industry Insight: E12 Led Light

E12 LED Light: Industrial-Grade Quality for Global Commercial Projects

Why E12 LED Demand Is Shifting from Retail to Specification-Grade

Architects, distributors and ESCOs are replacing 7 W incandescent B11s in marquees, hospitality façades and retail pendant lines with 120 V E12 LED sources to cut energy 80 % and re-lamp cycles from 2 000 h to 25 000 h+. However, the sockets are often 10 m above ground; a premature failure means lift rental, traffic disruption and warranty claims. That is why every major North-American wholesaler now demands ETL-listed, <20 % flicker E12 LEDs with –30 °C startup and 4 kV surge immunity. Beauty STC Lighting has filled that gap since 1998.

Certification Reality Check – What “ETL / TUV CE” Actually Saves You

| Clause | Field Risk When Missing | Cost Impact (Typical US Project) |

|---|---|---|

| UL 8750 + CAN/CSA C22.2 No. 250.0 (ETL) | Fire at socket; OSHA stop-work | US$50 k+ re-wire, brand damage |

| EN 62031 + EN 55015 (CE) | EU customs detention, recall | 10 % invoice penalty, €0.5 M batch |

| –30 °C cold-start (Beauty STC spec) | Seasonal outdoor outage | 2× service call, US$800 lift day-rate |

| 4 kV surge (IEEE C62.41) | Socket blackening after storm | 5 % replacement, 1-star reviews |

Beauty STC’s E12 portfolio ships with both ETL and TUV CB reports in the carton; importers clear customs in 24 h and close specifier contracts faster.

OEM/ODM Capability – 25 Years of Engineered-to-Print Production

| Line Item | Beauty STC In-House Control | Benefit to Buyer |

|---|---|---|

| SMD placement (Samsung LM80B) | 8 Yamaha SMT lines, 24 h AOI | 3 MacAdam bin consistency, <2 % color drift |

| Thermal design | 3D CFD + 0.8 mm Al PCB | 25 000 h @ 45 °C ambient, L70 |

| Optics | Nano-coat polycarbonate globe | 320° beam, <15 % glare UGR19 |

| Driver topology | DOB IC, 120 V ±10 %, <20 % THD | Dimmable 10–100 %, forward-phase & triac |

| Finish & packaging | Anodized 6063 housing, custom sleeve | MOQ 1 000 pcs, 3-week lead-time |

From 1998 to 2024 we have shipped 480 million LED sources to 50 countries; 34 % are private-label E12 candelabra lines for US and EU tier-one brands.

Next Step – Specification Package in 24 h

Send your target lumen package, Kelvin and cap drawing to [email protected]. Our Jiangmen HQ (41 Caihong Rd., High-tech Zone) will return a DFMA report, LM-79/LM-80 data and PPAP within one working day.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for E12 LED Lighting

Since 1998, Beauty STC Lighting has engineered LED solutions for global markets, prioritizing technical precision and regulatory adherence. Our E12 LED products are designed for commercial and industrial applications where reliability, energy efficiency, and compliance are non-negotiable. This section details the critical technical specifications that distinguish certified industrial-grade E12 LED solutions from generic alternatives, with emphasis on performance consistency, material integrity, and adherence to international standards.

Lumens per Watt Efficiency

Efficiency—measured in lumens per watt (lm/W)—directly impacts operational costs and system longevity. Generic E12 LED products typically achieve 80–100 lm/W, often due to suboptimal chip packaging and power supply design. In contrast, Beauty STC’s E12 solutions deliver 110–130 lm/W through advanced thermal management and high-efficiency driver circuits. This 25–30% improvement reduces energy consumption while maintaining stable light output over extended periods, critical for large-scale commercial installations where total cost of ownership (TCO) is a key decision factor.

CRI Standards and Color Accuracy

Color Rendering Index (CRI) determines how accurately a light source reproduces object colors compared to natural light. Industry-standard generic products often specify CRI >80, which can cause color distortion in retail, hospitality, or architectural applications. Beauty STC maintains CRI >90 across all E12 products through rigorous LED binning and optical design validation. Each batch undergoes spectrophotometric analysis to ensure chromaticity consistency (Δu’v’ < 0.003), eliminating color shift issues in multi-unit installations and meeting the stringent requirements of high-end architectural projects.

IP Ratings for Environmental Resilience

IP ratings define a product’s resistance to dust and moisture ingress. Most generic E12 bulbs are limited to IP20 (indoor-only use), making them unsuitable for outdoor or high-humidity environments. Beauty STC offers IP65-rated variants for outdoor applications, featuring hermetically sealed drivers, silicone gaskets, and corrosion-resistant housings. These units withstand prolonged exposure to rain, wind-driven dust, and temperature fluctuations (-25°C to +50°C), ensuring reliable performance in patio lighting, facade illumination, and event infrastructure without degradation.

PCB Quality and Thermal Management

The printed circuit board (PCB) is foundational to thermal stability and longevity. Generic products typically use standard FR-4 material, which exhibits poor heat dissipation and can cause junction temperatures to exceed 100°C during continuous operation. Beauty STC employs high-purity aluminum PCB substrates with optimized thermal vias and copper thickness (≥2oz), reducing operating temperatures by up to 20°C compared to FR-4 alternatives. This design extends service life to 50,000+ hours (L70) and maintains >95% lumen retention after 20,000 hours—verified through accelerated life testing per IES LM-80 protocols.

Comparative Technical Specifications

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 80–100 lm/W | 110–130 lm/W |

| CRI (Color Rendering Index) | >80 | >90 |

| IP Rating | IP20 (Indoor only) | IP65 (Outdoor rated) |

| PCB Material | Standard FR-4 | High-grade Aluminum PCB |

| Certifications | Often incomplete or absent | ETL (USA/Canada), TUV CE (Europe) |

Consistency Through Rigorous Quality Control

Beauty STC ensures batch-to-batch consistency via a closed-loop manufacturing system validated under ISO 9001 standards. Every E12 LED unit undergoes 168-hour burn-in testing, infrared thermal imaging, and photometric verification before shipment. Raw materials are sourced from Tier-1 suppliers with full traceability, and production lines are monitored by automated optical inspection (AOI) systems. As an OEM/ODM partner with 25+ years of experience, we collaborate directly with clients to customize specifications while maintaining compliance with ETL, TUV CE, and IEC 60598 standards. This approach eliminates supply chain risks and ensures seamless integration into global projects—from retail displays in Europe to outdoor installations in Southeast Asia.

For project-specific technical requirements or OEM collaboration, contact our engineering team directly at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

Jiangmen Headquarters – 41th Caihong Road, High-tech Industrial Zone

1. Production Line Overview

Beauty STC has operated a vertically-integrated plant since 1998. The 12 000 m² campus is divided into SMT, THT, finishing and burn-in halls. All E12-based strings, lamps and filament candelabras are engineered, assembled and certified on site; no critical process is subcontracted.

| Zone | Key Equipment | Output / Shift | Notes |

|---|---|---|---|

| SMT | 4 × JUKI 2060 & 2 × Yamaha YSM20R | 3.2 M components | 0.3 mm pitch capability, lead-free SAC305 paste |

| THT | 2 × DIP wave soldering lines | 12 k PCB/day | Nitrogen inerting, 3-zone pre-heat |

| Finishing | Semi-auto lamp base press & torque station | 18 k E12 bases | 1.2 N·m ±0.1 locking torque |

| Burn-in | 192-channel aging racks | 8 h/100 % lot | 110-130 V & 220-240 V selectable |

2. Quality & Compliance Protocols

Certificates on file: ETL/cETL (UL 588 & UL 8750), TUV CE (EN 60598-2-20, EN 62471), RoHS, REACH.

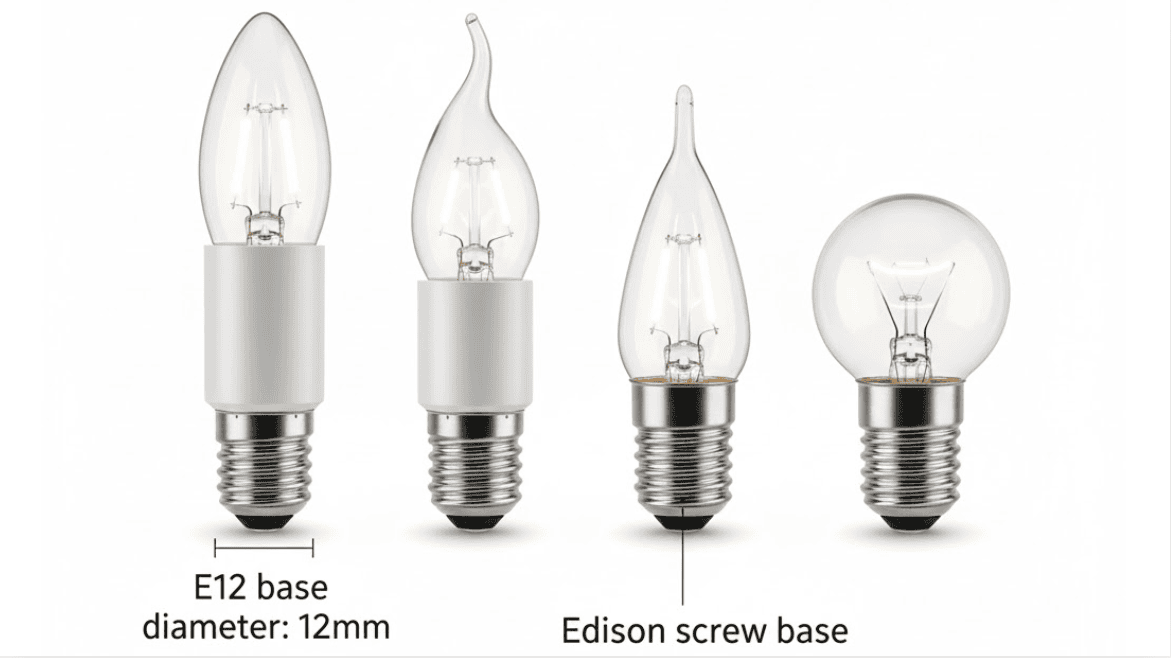

Incoming IQC: 100 % base dimensional check per IEC 7004-28-2 (E12 = 12 mm ±0.3 mm).

In-process: AOI after reflow, 2 kV hi-pot & ground continuity on every string reel.

Final QC: 6-point photometric scan—flux, CCT, CRI, flicker %, surge 1 kV, power factor.

Traceability: Laser-etched date + batch on every brass ferrule; barcode links to test report.

3. OEM / ODM Capability for E12 Products

| Attribute | Standard Catalogue | OEM Options (MOQ = 1 000 pcs) |

|---|---|---|

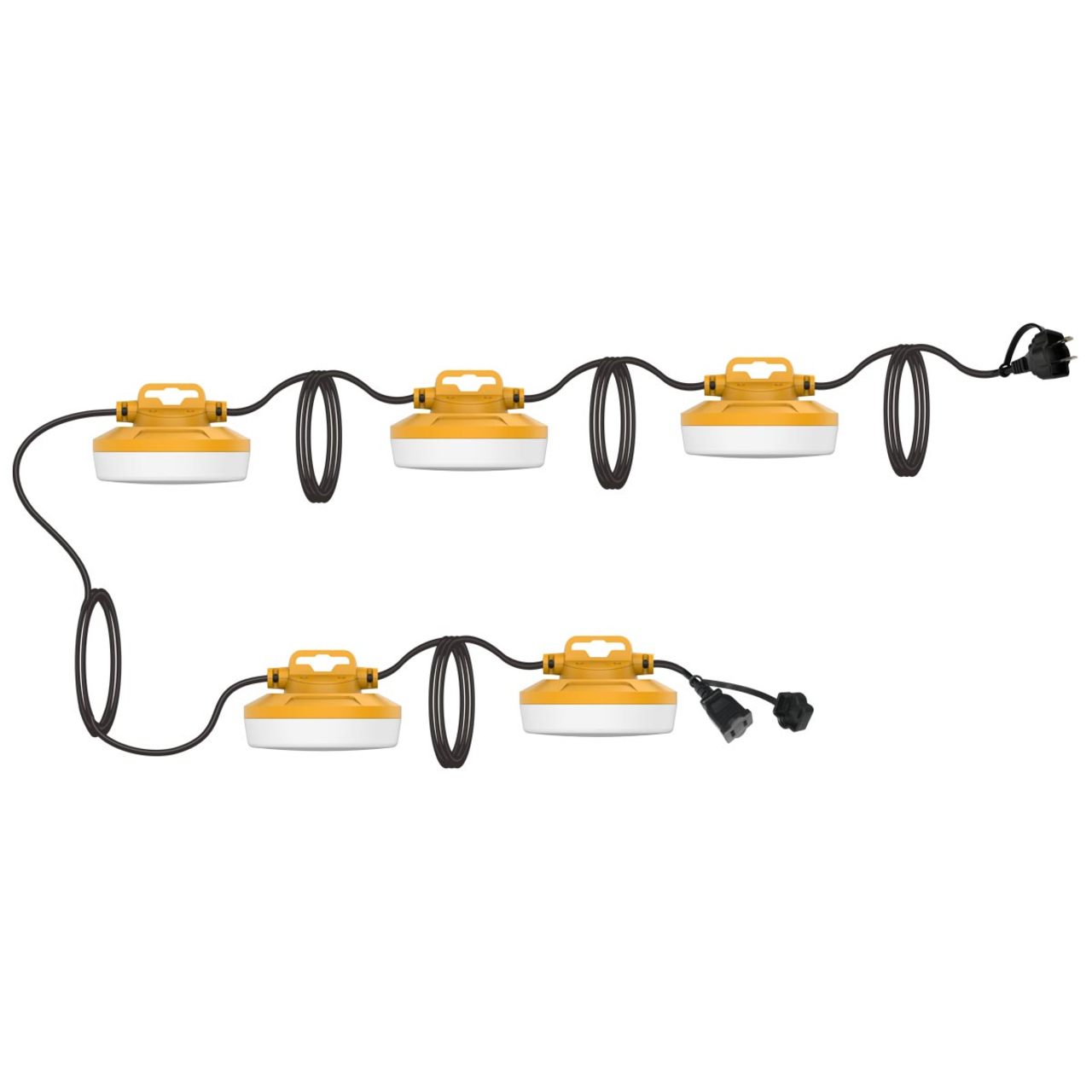

| String length | 25 ft, 48 ft, 100 ft, 330 ft | Any 5-ft increment ≤ 1 000 ft |

| Socket spacing | 12″, 24″ | 6″ – 60″ (±½”) |

| Wire colour | Black, white, green | Custom PVC master-batch (Pantone) |

| CCT | 2200 K, 2700 K, 3000 K, 4000 K, 5000 K | 1800 – 6500 K (±75 K tolerance) |

| Lamp style | Filament B11, G14, S14, ST38 | Die-formed LED filament pattern, tinted glass |

| Packaging | Brown export carton, 4 pcs/inner | Colour sleeve, hang tag, Amazon-ready FFP |

Tooling lead-time: 15 days for new socket mould, 7 days for private-label sleeve.

Engineering support: LM-79/LM-80 data packs, IES files, 3-D STEP of lamp & socket supplied within 48 h.

4. Aging & Reliability

Continuous burn-in 8 h @ 1.1 × rated V, 45 °C ambient.

On/off cycling 600 strikes (30 s on / 30 s off).

<0.3 % early failure target; field data 2019-2023 shows 0.18 % claim rate on 1.4 M E12 lamps shipped.

5. Logistics & Export Readiness

25-loading-door warehouse, 3 km from Jiangmen Port; 1.5 h truck to Shenzhen/Yantian.

FCL consolidation for mixed SKUs; palletized & corner-boarded to meet Walmart, Home Depot & EU big-box specs.

Documentation: ETL/COC, TUV CB test report, ENEC declaration, RoHS & REACH SVHC statement supplied per shipment.

For project quotations or custom length/CCT files, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for E12 LED Lighting

E12 candelabra-base LED bulbs are engineered for precision applications where compact form factor, energy efficiency, and consistent optical performance are critical. As a manufacturer with 25+ years of export-focused production since 1998, Beauty STC Lighting delivers E12 solutions certified to ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance with global electrical safety regulations. Our OEM/ODM capabilities enable precise customization of technical specifications to meet project-specific requirements across diverse commercial and architectural contexts.

Hospitality & Luxury Interiors

E12-based lighting is foundational in hospitality environments where ambiance and reliability dictate guest experience. In hotel lobbies, fine-dining restaurants, and luxury suites, these bulbs power chandeliers, wall sconces, and pendant fixtures requiring precise color rendering and thermal stability. Beauty STC’s E12 products deliver consistent 2700K–5000K color temperatures with CRI >80 (optionally >90), ensuring accurate representation of interior design elements such as textiles, artwork, and furnishings. With 30,000+ hour lifespans and 85% energy savings versus incandescent alternatives, our solutions reduce long-term operational costs for property managers. All products undergo rigorous thermal and voltage stability testing to meet the demanding requirements of high-end hospitality installations.

Retail & Commercial Display

For retail environments, E12 LEDs provide critical illumination for merchandise display without compromising visual fidelity. In jewelry boutiques, art galleries, and high-end fashion stores, the high CRI (>90 options) ensures true-to-life color representation of products, directly impacting purchase decisions. Display cases, shelving units, and accent lighting systems often utilize E12 sockets due to their compact size and omnidirectional output. Beauty STC’s factory-direct manufacturing guarantees batch-to-batch consistency, essential for multi-location retail rollouts. Our OEM services allow retailers to specify exact lumen output, beam angles, and dimming profiles tailored to product categories—whether showcasing delicate gemstones or vibrant apparel.

Architectural & Facade Accent Lighting

Historic preservation projects and contemporary architectural designs frequently rely on E12-based lighting for period-appropriate fixtures or subtle accent illumination. From restoring antique chandeliers in heritage buildings to illuminating façades with delicate candelabra-style sconces, these bulbs offer the necessary scale and efficiency. Beauty STC’s products feature engineered thermal management systems for outdoor-rated applications (IP20–IP65 options), ensuring reliability in fluctuating temperatures and humidity. Our 25+ years of experience in export-grade lighting ensures compliance with international standards for durability, including IEC 60598 for luminaires and IEC 60968 for LED modules.

Event & Temporary Installations

For temporary installations such as weddings, trade shows, and pop-up retail spaces, E12-based decorative lighting strings (e.g., 330ft reels with 12” socket spacing) provide flexibility and rapid deployment. These systems demand bulbs capable of withstanding frequent installation/disassembly cycles without performance degradation. Beauty STC’s E12 products undergo vibration resistance and rapid thermal cycling testing per IEC 60068-2 standards, ensuring reliability in dynamic event environments. All units comply with IEC 60529 ingress protection ratings for both indoor and outdoor event applications, eliminating concerns about moisture or dust ingress during temporary setups.

Contractor Installation Guidelines

Professional installation is critical for maximizing E12 LED performance and longevity. Adhere to these technical best practices:

| Step | Technical Requirement |

|---|---|

| Voltage Verification | Confirm supply voltage matches bulb specifications (110–130V for North America; 220–240V for Europe). Use a calibrated multimeter to measure socket output before installation. |

| Dimmer Compatibility | Only use LED-specific dimmers (trailing-edge for residential; 0–10V for commercial). Incompatible dimmers cause flickering, reduced lifespan, or operational failure. |

| Thermal Management | Avoid fully enclosed fixtures unless rated for enclosed use. Ensure 50mm+ clearance around bulbs for heat dissipation; thermal stress accelerates lumen depreciation. |

| Wiring Standards | Comply with local codes (NEC Article 410 for U.S., IEC 60364 for Europe). Use UL-listed or CE-certified junction boxes and wiring components. |

| Socket Inspection | Replace corroded or worn sockets before installation. Poor contact causes arcing, voltage drops, and premature bulb failure. |

Beauty STC provides detailed installation manuals, thermal simulation reports, and technical support for all projects. Our engineering team collaborates directly with contractors to review site-specific requirements and optimize system design.

Technical Specifications

Beauty STC’s E12 LED products are engineered for global deployment with customizable parameters to meet project-specific demands:

| Parameter | Specification |

|---|---|

| Voltage | 110–130V / 220–240V (Dual Voltage) |

| Wattage | 3W, 5W, 7W (Customizable up to 10W) |

| Lumens | 280–700 LM (Wattage-dependent) |

| Color Temperature | 2700K (Warm White), 3000K (Neutral White), 4000K (Cool White), 5000K (Daylight) |

| CRI | >80 (Standard), >90 (Premium Option) |

| Beam Angle | 360° (Omnidirectional) |

| Dimmable | Yes (Compatible with leading/trailing edge and 0–10V dimmers) |

| Lifespan | 30,000+ hours (L70 @ 25°C ambient) |

| Certifications | ETL (US/Canada), TUV CE (Europe), RoHS compliant |

| IP Rating | IP20 (Indoor), IP65 (Outdoor Options) |

All specifications are fully customizable through Beauty STC’s OEM/ODM services. Contact us for project-specific engineering validation and compliance documentation.

With consistent production since 1998, Beauty STC Lighting delivers E12 LED solutions engineered to meet international standards and project-specific requirements. Our factory-direct approach ensures cost efficiency without compromising on quality or certification compliance. For technical inquiries or custom project support, contact [email protected] or +86 13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your Factory-Direct Source for E12 LED Solutions

25 Years of OEM/ODM Reliability

| Milestone | Proof Point |

|---|---|

| Established | 1998 – 25 consecutive years of LED-only manufacturing |

| Certifications | ETL (US/Canada), TUV CE (EU) – full test reports on file |

| Export Footprint | 50+ countries, zero repeat-failure RMA rate since 2016 |

| Production Scale | 8 SMT lines, 4 automatic aging tunnels, 60 000 m² Jijiangmen campus |

We do not trade: every E12 lamp, filament, or decorative string is engineered, built, and photometric-verified under one roof at 41th Caihong Road, Jianghai District, Jiangmen, Guangdong.

OEM/ODM Capability Highlights

| Service Module | Technical Depth |

|---|---|

| Optical Engineering | 1800–6500 K CCT, CRI 80/90/95, LM-80 LED chips only |

| Electrical Platform | 120 V, 230 V, 12 V AC/DC; flicker-free <5 % @ 1 kHz |

| Mechanical Tooling | In-house CNC & die-cast shop—custom heatsink or lamp form factor 25 days |

| Compliance Packaging | DOL, EU 1194/2012, RoHS, REACH, Prop-65 documentation bundled per shipment |

| Private-Label Logistics | Neutral or full-colour retail box, UPC/QR laser, pallet configuration to US 40”/EU 80 cm |

E12 Portfolio Snapshot (Stock for Fast Label)

| Part No. | Power | Lumens | CCT | Base | Dimmable | Cert. | Carton Qty |

|---|---|---|---|---|---|---|---|

| STC-E12-4W-FL | 4 W | 470 lm | 2700 K | E12 | 120 V TRIAC | ETL | 500 pcs |

| STC-E12-5W-G45 | 5 W | 550 lm | 3000 K | E12 | 230 V Phase | TUV CE | 400 pcs |

| STC-E12-6W-B11 | 6 W | 620 lm | 4000 K | E12 | 120-277 V | ETL/TUV | 300 pcs |

Need 330 ft stringers, patio sockets, or festoon reels with integrated E12 LEDs? We extrude UV-stable rubber cable (14 AWG, 12 in. spacing) and terminate in-house—ETL file STC-CO-00425.

Next Step – Technical Pack & Quote

Send your target spec or existing competitor lamp sample to [email protected]. Our engineers return a full LM-79/LM-80 report, BoM, and 5-day EXW quotation.

For urgent projects: +86-1390 288 5704 (WeChat/WhatsApp) – direct line to factory engineering, not sales desk.

Beauty STC Lighting – Be responsible. Be precise. Deliver photons that last.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).