Article Contents

Industry Insight: E-12 Led Light Bulbs

The commercial and industrial lighting sector continues its decisive shift toward LED technology, driven by relentless demands for energy efficiency, reduced maintenance costs, and enhanced operational sustainability. Within this transformation, the often-overlooked E-12 candelabra base LED bulb is experiencing significant growth beyond traditional residential applications. Commercial spaces, particularly in hospitality, high-end retail, lobbies, and boutique environments, increasingly rely on decorative fixtures—chandeliers, wall sconces, and pendant arrays—that utilize E-12 bases. The transition from incandescent and halogen to LED in these fixtures is no longer optional; it’s a critical operational imperative to lower energy consumption in high-occupancy areas and minimize the disruptive, costly process of relamping in hard-to-reach installations. Crucially, specifying E-12 LED solutions for these professional settings demands rigorous adherence to safety and performance standards. ETL certification for the North American market and CE marking for Europe are non-negotiable requirements, ensuring electrical safety, thermal management under continuous operation, and reliability in demanding commercial environments. These certifications mitigate liability risks and guarantee that the bulbs perform consistently within the tightly regulated parameters required by building codes and facility managers.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution in specialized lighting solutions. With over 25 years of dedicated engineering and manufacturing expertise, we understand the unique challenges of integrating high-performance LED technology into compact, aesthetically driven form factors like the E-12 base. Our deep industry knowledge, forged through decades of collaboration with commercial lighting specifiers and facility operators, allows us to develop E-12 LED bulbs that not only meet but exceed stringent ETL and CE requirements. We focus on delivering the precise color quality, dimming performance, and thermal resilience essential for maintaining ambiance and operational efficiency in professional settings, moving far beyond simple retrofit capability to provide engineered solutions for the modern commercial landscape.

Technical Specs & Certifications

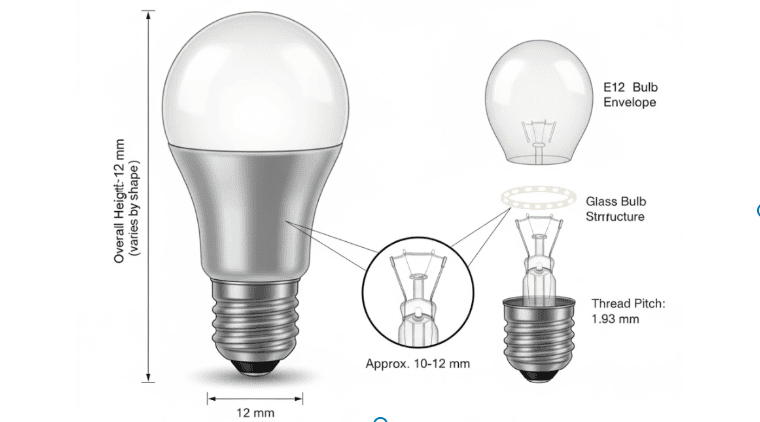

The e-12 LED light bulbs manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high performance, energy efficiency, and superior light quality for residential and commercial applications. These candelabra-base LED bulbs are designed to fit standard e-12 sockets commonly found in chandeliers, wall sconces, and decorative fixtures.

In terms of efficiency, Beauty STC’s e-12 LED bulbs achieve an impressive lumen output relative to power consumption, typically delivering between 80 to 100 lumens per watt. This high lumens-per-watt ratio ensures significant energy savings compared to traditional incandescent or halogen bulbs, reducing electricity costs while maintaining bright, consistent illumination.

A key feature of Beauty STC’s premium e-12 LED offerings is a Color Rendering Index (CRI) greater than 90. This high CRI ensures accurate and vibrant color representation, making these bulbs ideal for environments where true color perception is critical—such as retail displays, hospitality spaces, and high-end residential interiors. The natural and crisp light enhances visual comfort and ambiance.

Regarding environmental protection and durability, many models in the Beauty STC e-12 LED line carry an IP42 or IP54 rating, depending on the specific product variant. The IP42 rating indicates protection against solid objects larger than 1mm and against vertically dripping water, making them suitable for indoor use in dry to damp locations. Select models with IP54 offer enhanced protection against dust and water splashes from any direction, allowing for use in semi-outdoor or bathroom applications where moisture resistance is required.

Beauty STC is recognized for its commitment to quality and reliability in LED lighting. Their e-12 bulbs are built with high-grade LED chips, robust heat dissipation materials, and advanced driver technology to ensure long lifespan—typically rated for 25,000 to 30,000 hours of operation. Each bulb undergoes rigorous quality control and testing to meet international safety and performance standards, including CE, RoHS, and UL certifications where applicable.

Overall, Beauty STC’s e-12 LED light bulbs combine exceptional luminous efficacy, excellent color rendering, and dependable build quality, making them a trusted choice for customers seeking durable, energy-efficient, and high-fidelity lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen is strategically situated within the Jiangmen National High-Tech Industrial Development Zone, occupying a dedicated space of approximately 20,000 square meters. This modern factory is purpose-built for the efficient and high-quality production of LED lighting products, featuring controlled environmental conditions, stringent cleanliness protocols in critical production areas, and a well-organized layout separating raw material storage, SMT lines, assembly, testing, and packaging zones. The facility operates under ISO 9001 and ISO 14001 management systems, ensuring consistent quality and environmental responsibility throughout the manufacturing process.

Our Surface Mount Technology (SMT) production lines are a core strength of the Jiangmen factory, equipped with state-of-the-art machinery to handle the precision assembly required for modern LED components. We utilize multiple high-speed SMT lines featuring Yamaha YS24 series placement machines alongside complementary Siemens high-precision platforms. These systems operate with placement accuracy down to ±25μm and speeds capable of exceeding 80,000 components per hour per line, essential for handling the miniature LEDs, drivers, and control ICs used in compact bulbs. Each line integrates fully automated solder paste printing, component placement, reflow soldering with nitrogen-assisted ovens for superior joint quality, and crucially, multiple automated optical inspection (AOI) stations. These AOI systems perform rigorous real-time checks on solder paste deposition, component placement, polarity, and solder joint integrity immediately after reflow, significantly reducing defects before products move to subsequent assembly stages. The SMT area is supported by advanced material handling systems and strict ESD control protocols.

Comprehensive aging and reliability testing is a non-negotiable step in our quality assurance process at the Jiangmen facility. We maintain dedicated, climate-controlled aging rooms housing large-scale automated test racks specifically designed for LED bulbs like the E12 base type. Every production batch undergoes a minimum 24-hour continuous aging test under operational load, typically conducted at elevated temperatures between 50°C and 60°C to accelerate potential early failures. During this period, automated monitoring systems track critical parameters including light output (lumen maintenance), color temperature stability, power consumption, and functional reliability. We also conduct extended aging tests of 100, 500, and 1000 hours on sample batches for quality validation and lifetime projection. Beyond standard aging, our in-house laboratory performs additional reliability tests such as thermal cycling, high-temperature operating life (HTOL) tests, and ingress protection verification as required by specific customer or regional standards.

Beauty STC possesses extensive OEM capability specifically tailored for E12 LED light bulbs, leveraging the full production and engineering resources of the Jiangmen factory. We offer complete customization starting from the initial concept stage, including filament design and layout optimization for the E12 base form factor, driver circuit selection for global voltage compatibility (120V, 230V, or universal input), precise color temperature tuning across the range of 2200K to 6500K, and lumen output calibration to meet specific customer requirements. Our engineering team works closely with clients to integrate custom optics for beam angle control, develop unique thermal management solutions within the constrained E12 envelope, and ensure compliance with target market regulations such as UL, ETL, CE, RoHS, and Energy Star. We support low to high-volume production runs with flexible manufacturing setups, rapid prototyping capabilities for design validation, and strict adherence to customer branding and packaging specifications. Our deep understanding of the E12 bulb’s thermal and electrical constraints allows us to deliver reliable, high-performance OEM products optimized for manufacturability and cost-effectiveness.

Application Scenarios

E12 LED light bulbs, which feature a candelabra base measuring 12 millimeters in diameter, are commonly used in decorative and accent lighting applications where smaller, aesthetically pleasing fixtures are required. While they are not typically used for primary illumination in large commercial spaces like hotels, malls, or offices due to their lower lumen output, they do have specific applications in these environments where style and ambiance are important.

In hotels, E12 LED bulbs are often found in chandeliers, wall sconces, vanity fixtures in lobbies or upscale guest bathrooms, and decorative pendant lights in lounges or restaurants. These areas benefit from the warm, inviting glow and elegant appearance that candelabra-style bulbs provide. Their use enhances the overall atmosphere without needing high-intensity lighting.

In malls, E12 LEDs may be used in decorative lighting within high-end retail storefronts, food courts with themed lighting, or in ornamental fixtures in common areas. While general mall illumination relies on higher-output lighting such as linear fluorescents or high-lumen LED troffers, E12 bulbs serve a supplementary role in creating visual interest and enhancing design elements.

In office environments, E12 LED bulbs are less common but may appear in executive suites, reception areas, or conference rooms with decorative fixtures. Their use is generally limited to spaces where aesthetics take precedence over functional brightness.

When installing E12 LED bulbs, ensure the fixture is compatible with LED technology, especially if using dimmers—always pair with dimmable LEDs and compatible dimmer switches to avoid flickering or reduced lifespan. Turn off power at the circuit breaker before installation to ensure safety. Gently screw the bulb into the socket by hand, avoiding overtightening which can damage the base or socket. Match the bulb’s color temperature to the space—warmer tones (2700K–3000K) for hospitality settings, cooler tones (3500K–4000K) for professional areas. Finally, verify the maximum wattage rating of the fixture and choose an LED bulb that stays within those limits, keeping in mind that LEDs consume far less power than incandescent equivalents.

Why Choose Beauty STC Lighting

Upgrade your decorative lighting projects with reliable E12 LED light bulbs engineered for exceptional performance and longevity. At Beauty STC Manufacturing Co., Ltd., we specialize in precision-crafted E12 LED solutions that deliver consistent brightness, energy efficiency, and seamless dimming for chandeliers, wall sconces, and other specialty fixtures. Our bulbs undergo rigorous thermal management and quality testing to ensure zero flicker and extended lifespan in demanding applications. Partner with Beauty STC to access custom engineering support, bulk-order flexibility, and lighting solutions trusted by industry professionals worldwide. Contact our dedicated team today at [email protected] to discuss your E12 LED requirements and elevate your product offerings with certified quality. Let us help you reduce maintenance costs while enhancing customer satisfaction through superior illumination technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.