Article Contents

Industry Insight: Double Sided Tape For Led Strip Lights

The critical role of seemingly simple components like double-sided tape in commercial and industrial LED strip lighting installations is often underestimated, yet its performance directly impacts project longevity, safety, and operational efficiency. In demanding environments such as warehouses, retail spaces, healthcare facilities, and manufacturing plants, where fixtures endure constant vibration, wide temperature fluctuations, humidity, and rigorous cleaning protocols, substandard adhesion leads to costly failures: strips detaching, creating safety hazards, disrupting illumination, and necessitating expensive rework. Unlike residential applications, commercial projects demand tapes engineered for superior initial grab, long-term bond strength on diverse substrates (metal, drywall, concrete), and resilience under sustained stress. Crucially, the entire lighting system, including the mounting solution, must comply with stringent safety standards; tapes used in assemblies bearing ETL or CE marks must contribute to the system’s overall certification, ensuring electrical safety and fire resistance are not compromised by the mounting method. Beauty STC, a trusted leader in LED lighting solutions since 1998, understands these high-stakes requirements intimately. We engineer and rigorously test our double-sided tapes not as mere accessories, but as integral, performance-critical components designed specifically for the rigors of professional commercial and industrial lighting installations, ensuring reliability, safety compliance, and reduced lifecycle costs for facility managers and contractors.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. specializes in high-performance LED lighting solutions, including precision-engineered accessories such as double-sided tape for LED strip lights. While the double-sided tape itself is a mechanical mounting component and does not generate lumens or influence electrical efficiency, it plays a critical role in the reliable and long-term installation of LED strips that meet high photometric standards. Below are the technical considerations and performance benchmarks relevant to the LED strips typically used with our recommended mounting solutions.

LED strip lights paired with Beauty STC’s premium double-sided adhesive tapes are designed to deliver exceptional luminous efficacy, commonly achieving 120 to 140 lumens per watt (lm/W), depending on the LED density and configuration. These high-efficiency strips utilize top-bin SMD LEDs—such as 2835 or 5050 types—ensuring optimal light output with minimal power consumption. When installed using our high-bonding, temperature-resistant double-sided tape, the strips maintain consistent thermal contact and alignment, supporting sustained lumen maintenance over extended operation.

A hallmark of Beauty STC’s LED strip systems is the availability of high Color Rendering Index (CRI) options exceeding 90. Strips with CRI >90 provide excellent color fidelity, making them ideal for retail, residential, and professional environments where accurate color representation is essential. This high CRI performance is maintained through precise phosphor coating and binning processes during manufacturing, ensuring uniform light quality across installations.

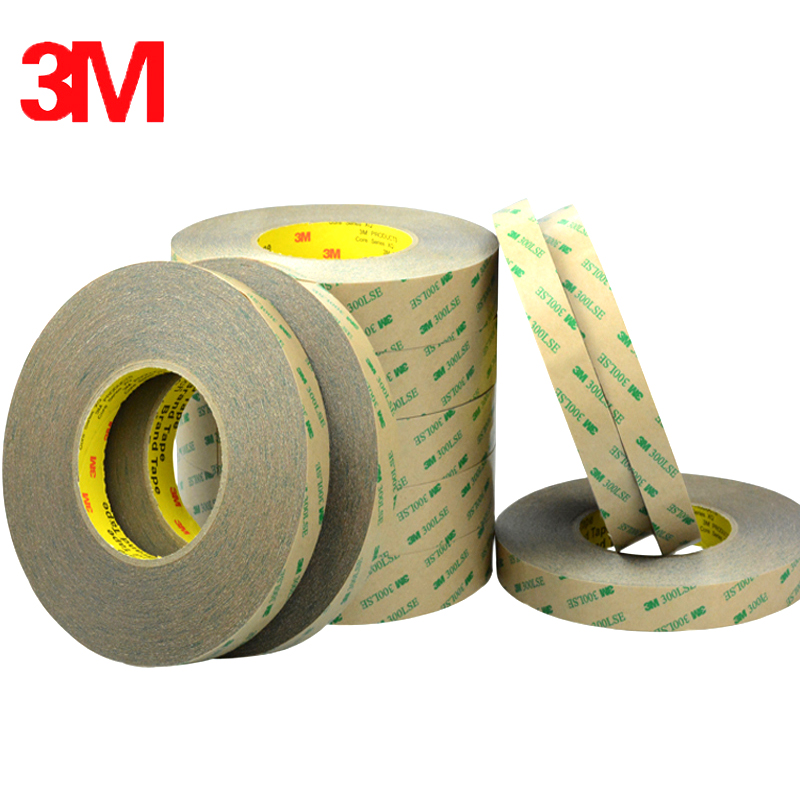

Regarding environmental protection, Beauty STC offers LED strip solutions in various IP ratings, commonly including IP20 (basic indoor use), IP65 (water-resistant with silicone coating), and IP67 (fully waterproof, suitable for outdoor or damp locations). The double-sided tape used for mounting must be compatible with these ratings—our recommended adhesive tapes are UV-resistant, thermally stable from -20°C to +80°C, and maintain strong adhesion on a range of substrates including metal, plastic, and painted surfaces. For IP65 and IP67 strips, we recommend using the tape in conjunction with proper channel or sealing systems to preserve the rated ingress protection.

Beauty STC’s double-sided tape is manufactured to stringent quality standards, featuring high initial tack, long-term durability, and resistance to yellowing or delamination. It is specifically formulated to support the thermal and mechanical demands of LED strip applications, ensuring secure mounting even in challenging environments. This commitment to quality reflects Beauty STC’s broader engineering philosophy—delivering reliable, high-performance lighting solutions built for real-world conditions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern, vertically integrated LED lighting production facility in Jiangmen, Guangdong Province. This strategic location within the Pearl River Delta provides excellent access to the region’s extensive electronics supply chain and skilled manufacturing labor pool. The factory spans a significant footprint designed for efficient high-volume production while maintaining stringent quality control throughout the manufacturing process.

Our Surface Mount Technology (SMT) production lines represent a core strength of the Jiangmen facility. We utilize multiple high-speed, precision Yamaha YS Series SMT machines capable of placing components ranging from minuscule 0201 passives to larger LED packages and integrated circuits with exceptional accuracy and speed. These lines are fully automated, featuring sophisticated feeders, vision alignment systems, and controlled reflow soldering profiles optimized specifically for LED thermal management requirements. The integration of Automated Optical Inspection (AOI) systems immediately after reflow soldering ensures 100% board-level quality checks, detecting solder defects, component misalignment, or missing parts before progression to the next stage. This advanced SMT capability allows us to handle complex LED driver and module assemblies efficiently for both standard and custom products.

Rigorous reliability testing is fundamental to our quality assurance protocols, with comprehensive aging test procedures being a critical component. The Jiangmen factory houses dedicated environmental aging chambers capable of simultaneously subjecting large batches of finished LED strip lights and other luminaires to accelerated life testing. Products undergo extended operational periods, typically 48 to 72 hours, under controlled elevated temperatures (commonly 60°C to 70°C) and constant full-power operation. During this phase, sophisticated monitoring systems continuously track key parameters such as light output (lumen maintenance), chromaticity shift, forward voltage, and thermal performance. Any unit exhibiting significant deviation from specification thresholds is automatically flagged and removed from the production stream. This systematic aging process effectively screens out infant mortality failures, ensuring only units demonstrating inherent reliability reach our customers.

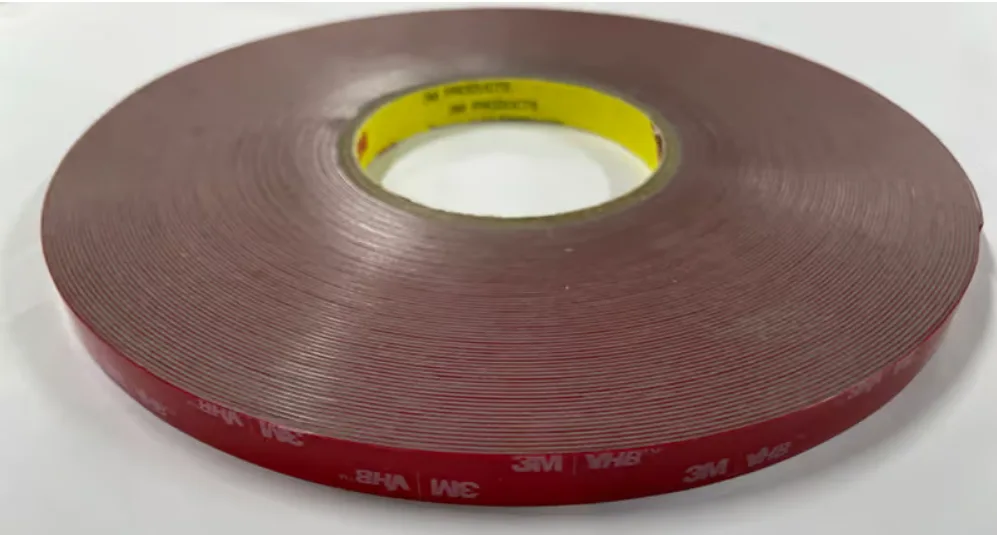

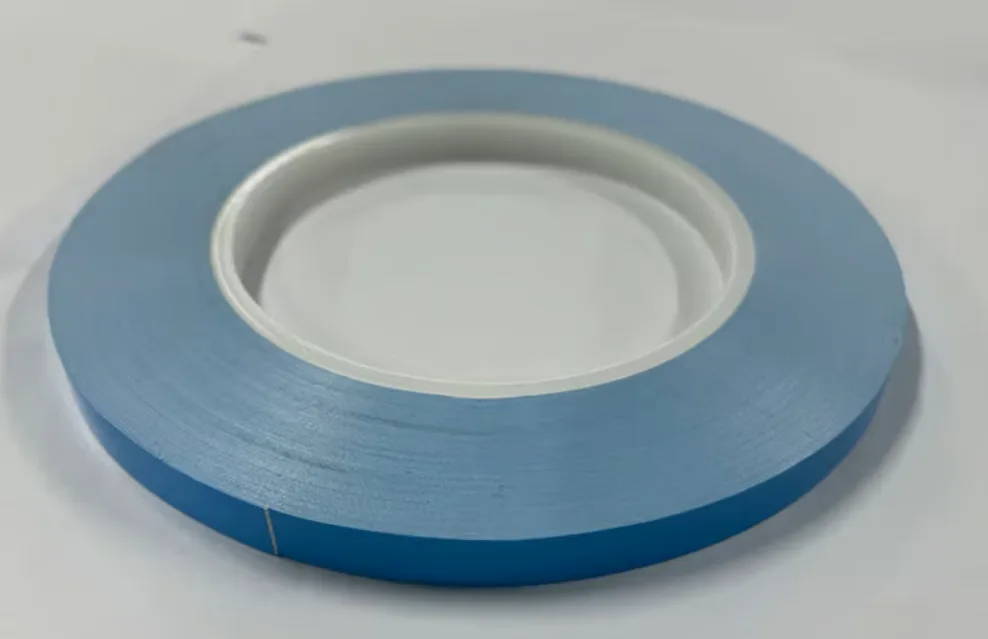

Regarding the specific inquiry about OEM capability for ‘double sided tape for led strip lights’, it is important to clarify the scope of our manufacturing. Beauty STC specializes in the design, engineering, and production of complete LED lighting solutions, including LED strip lights. While double-sided adhesive tape is an integral component integrated onto our LED strip light products during final assembly, we do not manufacture standalone double-sided tape as a separate OEM product line. Our core competency and OEM services focus on the LED strip light assembly itself. However, as part of our extensive OEM/ODM capabilities for LED strip lights, we offer significant customization regarding the adhesive system. This includes sourcing and applying various high-performance double-sided tapes to the back of the flexible PCBs based on specific customer requirements. Options can cover different adhesive strengths (for varying surface types like metal, plastic, or painted walls), temperature resistance levels (standard, high-temp), UV resistance, and tape thicknesses. We work closely with specialized adhesive suppliers to select and integrate the optimal tape solution directly onto the LED strip during our production process, ensuring strong, durable bonding for the end application. Therefore, while we do not produce the raw adhesive tape material independently, we provide full OEM integration and customization of the adhesive backing as a critical feature of the finished LED strip light product we manufacture for our clients.

Application Scenarios

Double sided tape for LED strip lights is widely used across various commercial environments including hotels, malls, and offices due to its convenience, clean appearance, and reliable adhesion when applied correctly. In hotels, it is commonly used to install LED strips under cabinetry in bathrooms and vanities, along the edges of mirrors, beneath bed frames for ambient lighting, and in cove lighting within hallways or lobbies. The discreet illumination enhances guest experience while maintaining a sleek, modern aesthetic.

In malls, double sided tape is ideal for accent lighting in display areas, under signage, within architectural coves, and along handrails or stair edges for both decorative and safety purposes. The tape allows for quick and non-invasive installation, which is crucial in high-traffic areas where minimizing disruption is important. Retail spaces within malls also use it to highlight product displays or shelving with LED strip lighting, creating visual appeal without visible fixtures.

Offices benefit from double sided tape when installing LED strips for under-cabinet lighting in workstations, in drop ceilings or perimeter coves, and for indirect lighting in conference rooms or reception areas. It supports a professional, glare-free lighting environment that boosts productivity and comfort. The tape enables a clean, cable-free look that aligns with modern office design standards.

When installing LED strip lights using double sided tape, proper surface preparation is essential. Clean the mounting surface thoroughly with isopropyl alcohol to remove dust, grease, or residue, ensuring maximum adhesion. Press the strip firmly along its entire length for at least 30 seconds after placement, especially in corners or along curves. Allow the adhesive to cure for 24 hours before powering the lights, particularly in cooler environments where initial bond strength may be reduced. Avoid installing on porous, uneven, or low-surface-energy materials like certain plastics or painted drywall without additional mechanical support. In high-vibration or high-temperature areas, consider supplementing the tape with clips or brackets to prevent delamination over time.

Why Choose Beauty STC Lighting

Upgrade your LED strip installations with Beauty STC’s engineered double-sided mounting tape, specifically formulated for demanding lighting applications. Our high-performance adhesive delivers exceptional bond strength on diverse surfaces while withstanding the thermal output of continuous LED operation, ensuring secure, long-term mounting without slippage or residue. Trusted by manufacturers for professional-grade reliability, this tape is essential for clean, permanent, and vibration-resistant installations in both residential and commercial projects. Partner with Beauty STC to integrate our proven mounting solution into your product line or project specifications, backed by our engineering expertise and quality manufacturing standards. Contact our dedicated engineering team directly at [email protected] to discuss volume pricing, technical support, and how our double-sided tape can enhance your LED strip light performance and customer satisfaction.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.