Article Contents

Industry Insight: Dotless Led Strip Lights

The commercial and industrial lighting sector continuously demands solutions that merge superior aesthetics with robust functionality, driving a significant shift towards advanced linear LED technologies. Among these, dotless LED strip lights are rapidly gaining prominence as a critical innovation addressing long-standing challenges in high-end applications. Traditional dotted LED strips often create visible hotspots and uneven illumination, a major drawback in environments like luxury retail displays, premium hospitality venues, corporate offices, museums, and modern industrial facilities where seamless, uniform light distribution is non-negotiable for both visual appeal and task performance. Dotless technology, utilizing sophisticated optical diffusion methods over continuous LED arrays, eliminates these distracting points of light, delivering a truly smooth, homogeneous glow essential for creating sophisticated atmospheres and meeting stringent architectural lighting criteria. Crucially, for commercial and industrial adoption, these advanced strips must adhere to rigorous safety and performance standards. Compliance with ETL certification for the North American market and CE marking for Europe is not merely a regulatory formality but a fundamental requirement, assuring facility managers, architects, and electrical contractors of the product’s reliability, electrical safety, and suitability for demanding professional installations. Beauty STC Manufacturing Co., Ltd., a trusted leader in precision LED lighting solutions since 1998, brings decades of engineering expertise to this evolving space, developing high-performance dotless LED strips designed specifically to meet the exacting demands of commercial and industrial projects worldwide.

Technical Specs & Certifications

Dotless LED strip lights are a premium category of linear lighting designed to deliver smooth, continuous illumination without visible individual diodes—ideal for high-end architectural, residential, and commercial applications where visual comfort and design aesthetics are critical. At Beauty (STC) Manufacturing Co., Ltd., our dotless LED strip lights are engineered with precision to exceed industry benchmarks in performance, efficiency, and reliability.

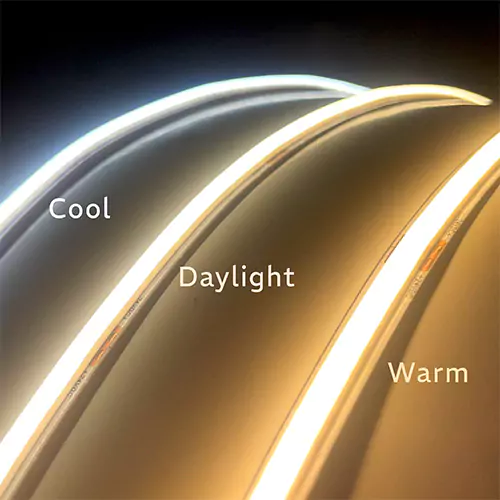

Our dotless LED strips achieve an efficacy range of 100 to 120 lumens per watt, depending on color temperature and density configuration. This high lumens-per-watt ratio ensures energy-efficient operation without sacrificing brightness, making them suitable for both accent and ambient lighting applications. The strips utilize high-density chip-on-board (COB) or dense surface-mounted device (SMD) arrays, often with 5050 or 3535 LEDs spaced at intervals of less than 10mm, creating the seamless “dotless” effect.

Color rendering is a key strength of Beauty STC’s dotless LED technology. All our high-CRI dotless strips deliver a Color Rendering Index (CRI) greater than 90, with options available up to CRI 95+ for applications requiring the most accurate color representation, such as retail displays, art galleries, and healthcare environments. This is achieved through the use of high-quality phosphor coatings and rigorously selected LED bins to ensure consistent chromaticity and minimal deviation across production batches.

In terms of environmental protection, Beauty STC offers dotless LED strips in multiple IP rating configurations. Our standard non-coated strips are rated IP20, suitable for dry, indoor environments. For damp or outdoor applications, we provide IP65-rated strips with a silicone encapsulation that protects against dust and low-pressure water jets. For fully submersible or high-humidity installations, our IP67 and IP68-rated versions are available, with robust silicone overmolding enabling safe operation in underwater settings up to 1 meter depth for extended periods.

Quality is central to Beauty STC’s manufacturing philosophy. Our dotless LED strips are produced in ISO-certified facilities using automated SMT production lines and undergo 100% aging and photometric testing. We use only premium-tier components, including high-conductivity flexible PCBs, high-purity gold-wire bonding, and thermally stable encapsulants to ensure long life—typically rated at L70 >50,000 hours. Each batch is tested for color consistency, lumen output, and thermal performance to ensure reliability across diverse operating conditions.

With superior optical performance, excellent CRI, versatile IP protection, and industry-leading build quality, Beauty STC’s dotless LED strip lights offer a trusted solution for designers and engineers who demand both aesthetic excellence and technical robustness.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting solutions, including our proprietary dotless LED strip lights. This modern factory integrates state-of-the-art equipment with stringent quality control protocols across approximately 20,000 square meters of dedicated manufacturing space. The facility is designed for high-volume production while maintaining flexibility for specialized OEM projects, supported by a workforce trained in precision electronics assembly and optical engineering.

Our SMT (Surface Mount Technology) production line forms the backbone of dotless LED strip manufacturing. We operate multiple high-speed JUKI FX-3 series placement machines capable of handling ultra-miniature 0201 components at placement accuracies of ±0.05mm. These machines are specifically configured for the unique demands of dotless technology, featuring specialized vision systems to align micro-LED chips at sub-millimeter intervals and precise solder paste deposition for thermal management. The line includes nitrogen-reflow ovens with 10-zone temperature profiling to ensure consistent solder joints for the densely packed LED arrays, critical for achieving the seamless illumination effect without visible dots. All SMT processes undergo real-time automated optical inspection (AOI) to verify component placement and solder quality before proceeding to subsequent stages.

Aging testing is a non-negotiable phase in our dotless LED strip production. Every reel undergoes a minimum 72-hour continuous aging cycle under controlled thermal and electrical stress conditions. This occurs in dedicated environmental chambers maintained at 65°C ambient temperature with 85% relative humidity, simulating accelerated real-world usage. We implement a dual-phase aging approach: initial aging immediately after SMT assembly to identify early-life failures, followed by final aging after final assembly and packaging. During testing, strips operate at 110% of rated voltage while our monitoring systems track lumen maintenance, color consistency (Δuv’ < 0.003), and thermal performance. Units exhibiting even marginal deviations in light output uniformity—critical for dotless technology—are automatically rejected, ensuring only strips meeting our 0.95+ uniformity standard reach customers.

For OEM partnerships focused on dotless LED strip lights, our Jiangmen factory provides comprehensive customization capabilities. We support full specification tailoring including lengths from 0.5m to 100m per reel, CCT ranges from 1800K to 6500K with CRI >90, and custom silicone encapsulation profiles for specific beam angles. Our engineering team collaborates with clients on circuit design modifications for specialized dimming protocols (0-10V, DALI, PWM) and develops application-specific IC programming for unique lighting effects. The facility accommodates private labeling with custom reel packaging, technical documentation in multiple languages, and flexible MOQs starting at 5,000 meters. All OEM projects benefit from our in-house optical laboratory for spectral validation and accelerated lifetime testing per IES LM-80 standards, ensuring brand integrity for partners seeking premium dotless solutions.

Application Scenarios

Dotless LED strip lights are ideal for environments where a seamless, continuous glow is desired without the visible pinpoint dots of individual LEDs. Their uniform illumination makes them particularly well-suited for high-end architectural and decorative applications. In hotels, they are commonly used in cove lighting along ceilings, under reception desks, within staircase risers, and in wardrobe or shelving areas where soft, even lighting enhances ambiance and guest experience. The absence of visible dots contributes to a clean, modern aesthetic that aligns with luxury interior design.

In malls, dotless LED strips are often installed in coves around atriums, above false ceilings, and along handrails or escalator edges to guide foot traffic with a smooth luminous trail. They are also used in display lighting for high-end retail kiosks where shadow-free, diffused light highlights products without glare or hotspots. Their continuous light output helps maintain a premium visual environment throughout large open spaces.

In offices, dotless strips are typically applied in suspended ceiling coves, under cabinets, or within partition systems to provide indirect ambient lighting that reduces eye strain and supports a professional atmosphere. They can also be used in executive offices or meeting rooms to accentuate branding features or architectural details with a refined glow.

For installation, ensure the mounting surface is clean, dry, and free of dust to promote strong adhesion of the strip’s backing. Use aluminum channels with diffusers whenever possible, as they not only protect the strip but also enhance light uniformity and heat dissipation—critical for maintaining longevity and performance. Always cut the strip only at designated cut marks to avoid damaging the circuitry. Power supply sizing is crucial; calculate total wattage accurately and include a 20% safety margin to prevent overloading. For long runs, consider feeding power from both ends to avoid voltage drop, especially in linear installations exceeding 16 feet (5 meters). Lastly, test the strip before final installation and secure all connections with proper waterproofing if used in humid or outdoor-adjacent areas.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium dotless LED strip lights, engineered to deliver truly seamless illumination without visible hotspots or uneven light distribution. Our advanced technology ensures a smooth, continuous glow ideal for high-end architectural cove lighting, retail displays, and luxury residential applications where flawless aesthetics are non-negotiable. Partner with Beauty STC to access industry-leading quality, customizable solutions, and dedicated engineering support that transforms your design vision into reality. Contact our partnership manager today at [email protected] to discuss how our precision-engineered dotless LED strips can enhance your next project with superior performance and elegance. Let us help you set new standards in professional lighting.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.