Article Contents

Industry Insight: Dmx Lighting Controls

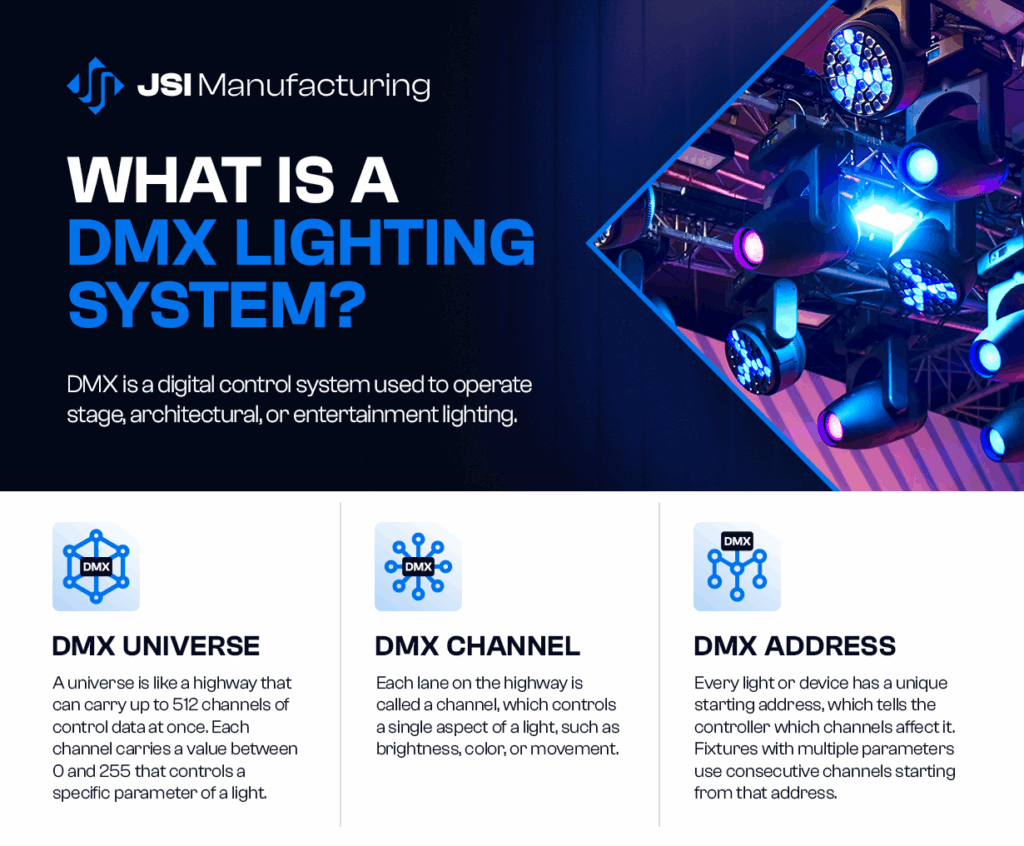

In the evolving landscape of commercial and industrial lighting, precision, scalability, and reliability are paramount—qualities that DMX lighting controls deliver with unmatched performance. Originally developed for stage and entertainment applications, DMX512 (Digital Multiplex) has become a cornerstone in advanced lighting systems across warehouses, manufacturing facilities, retail environments, and architectural installations. Its ability to provide granular control over large-scale LED networks enables dynamic lighting scenarios, energy optimization, and seamless integration with building management systems. As industry standards tighten, compliance with safety and electromagnetic compatibility regulations is non-negotiable; DMX control systems meeting ETL and CE certifications ensure operational safety, regulatory adherence, and global market readiness.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in intelligent lighting solutions since its founding in 1998. With over two decades of engineering excellence, Beauty STC has established itself as a leader in DMX-compatible controllers and drivers designed specifically for demanding commercial and industrial applications. Combining robust build quality, rigorous testing protocols, and full compliance with ETL and CE standards, Beauty STC’s products empower facility managers and lighting designers to achieve superior control, efficiency, and longevity in their lighting infrastructure.

Technical Specs & Certifications

DMX lighting controls refer specifically to the digital communication protocol used for managing stage, architectural, and entertainment lighting systems. It is critical to clarify that DMX itself does not generate light or possess inherent lumens per watt, CRI, or IP ratings. DMX is a control signal standard (DMX512-A) that transmits data to fixtures, instructing them on parameters like intensity, color, and movement. The photometric and environmental specifications you requested are properties of the LED luminaires controlled by DMX, not the control protocol. Beauty STC Manufacturing Co., Ltd. designs and manufactures high-performance LED luminaires that integrate seamlessly with DMX systems, meeting rigorous performance benchmarks.

Regarding lumens per watt (lm/W), Beauty STC’s DMX-controllable LED fixtures achieve industry-leading efficacy through advanced thermal management and premium LED engines. Our standard architectural and stage wash fixtures typically deliver 140–160 lumens per watt at 4000K color temperature under real-world operating conditions. This efficiency is maintained without compromising optical control, utilizing optimized driver topologies and high-conductivity MCPCB substrates to minimize thermal roll-off. It is important to note that efficacy decreases slightly when targeting higher CRI values due to phosphor conversion losses, a fundamental trade-off in LED physics.

For Color Rendering Index (CRI), Beauty STC guarantees Ra > 90 across our professional DMX fixture range, with many models exceeding Ra 95. This is achieved through precisely tuned multi-phosphor LED packages and spectral engineering. Our high-CRI fixtures undergo spectrophotometric validation per CIE 13.3-1995, ensuring accurate skin tones and material representation critical for broadcast, retail, and hospitality applications. We maintain tight chromaticity tolerances (MacAdam 3-step or better) across production batches, preventing visible color shifts during DMX dimming or color mixing.

IP ratings are rigorously addressed in Beauty STC’s fixture construction. Our outdoor-rated DMX-controllable luminaires feature IP65 as a standard rating, with IP67 options available for submerged or high-pressure washdown environments. This is accomplished through double-gasketed optical compartments, marine-grade silicone seals, and corrosion-resistant aluminum housings. All ingress protection claims are validated per IEC 60529 standards through third-party testing, including 30-minute submersion tests for IP67 models. Internal conformal coating on PCBs provides additional moisture resistance, ensuring long-term DMX signal integrity in humid conditions.

Beauty STC’s quality commitment is embedded in every fixture. We utilize only Tier-1 LED components from Osram, Nichia, and Cree, coupled with proprietary thermal interface materials to sustain lumen maintenance (L70/B50) beyond 50,000 hours at 25°C ambient. Our DMX implementations feature galvanic isolation, ESD protection up to 15kV, and signal regeneration to prevent data corruption in large installations. All products undergo 100% burn-in testing and photometric validation in our ISO/IEC 17025-accredited laboratory, with full traceability via serialized QR codes. This engineering discipline ensures our DMX-controllable fixtures deliver consistent, reliable performance where luminous efficiency, color fidelity, and environmental resilience are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The Jiangmen factory is designed to support high-volume production of LED lighting products with a strong emphasis on quality, efficiency, and technical precision. The facility integrates advanced automation and rigorous quality control processes throughout the production cycle.

At the core of the factory’s production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable precise and high-speed placement of electronic components on printed circuit boards. These SMT lines are fully automated, ensuring consistent soldering accuracy and reliability for lighting control electronics, including those used in complex DMX lighting systems. The use of advanced pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems ensures minimal defects and high throughput, meeting international standards for electronic assembly.

To guarantee long-term performance and reliability, the factory conducts comprehensive aging tests on all lighting products and control systems. Completed units undergo extended burn-in procedures under controlled thermal and electrical conditions, typically lasting 4 to 12 hours or longer depending on product specifications. This process helps identify early-life failures and ensures that only robust, stable products are shipped to customers. Environmental testing chambers are also used to simulate extreme conditions, further validating product durability.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly in the area of DMX lighting controls. The company supports full customization of DMX-enabled drivers, controllers, and signal processing modules according to client specifications. This includes custom firmware development, unique PCB layouts, branding, packaging, and integration with various DMX protocols such as DMX512, RDM, and sACN. The engineering team works closely with clients to deliver tailored solutions for stage lighting, architectural lighting, and entertainment applications, from prototype development to mass production.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to technical excellence and flexible manufacturing, making it a reliable partner for global brands seeking high-quality, customized LED lighting and control solutions.

Application Scenarios

DMX lighting controls are primarily implemented in commercial environments where dynamic, precise, and programmable lighting effects are essential for ambiance, branding, or functional flexibility. While not typically the first choice for basic task lighting in offices or standard retail back-of-house areas, they excel in specific high-impact zones within Hotels, Malls, and Offices where lighting is a design feature rather than just illumination.

In Hotels, DMX is indispensable for lobbies, ballrooms, high-end restaurants, and feature walls. Lobbies use it to transition lighting scenes from bright daytime welcome to warm evening ambiance, often synchronized with daylight harvesting. Ballrooms rely on DMX for intricate scene programming during events—shifting colors for weddings, concerts, or conferences without physical re-rigging. Restaurants employ it for table-specific mood control or dramatic accent lighting on architectural elements. Avoid using DMX for guest room task lighting; it adds unnecessary complexity and cost where simple dimming suffices.

Malls deploy DMX predominantly on exterior facades, feature ceilings, and flagship store entrances. Facades use it for seasonal campaigns or nighttime branding with color-changing effects visible from distance. Interior feature ceilings—such as atriums with suspended fixtures—leverage DMX for wave effects or sunrise/sunset simulations to enhance shopper experience. Flagship stores integrate it into window displays for synchronized product highlighting. Do not use DMX for general mall corridor lighting; 0-10V or DALI controls are more cost-effective for uniform illumination.

Offices limit DMX to executive lobbies, reception areas, and high-profile conference rooms. Executive lobbies use it for branded color schemes during client visits, while reception areas might employ subtle scene changes to denote time of day. High-end conference rooms utilize it for preset modes (e.g., “presentation” with focused spotlighting, “collaboration” with even diffuse light). Crucially, avoid DMX in standard open-plan offices—it lacks granular daylight integration and is prohibitively expensive for routine task lighting where occupancy sensors and daylight harvesting via DALI are optimal.

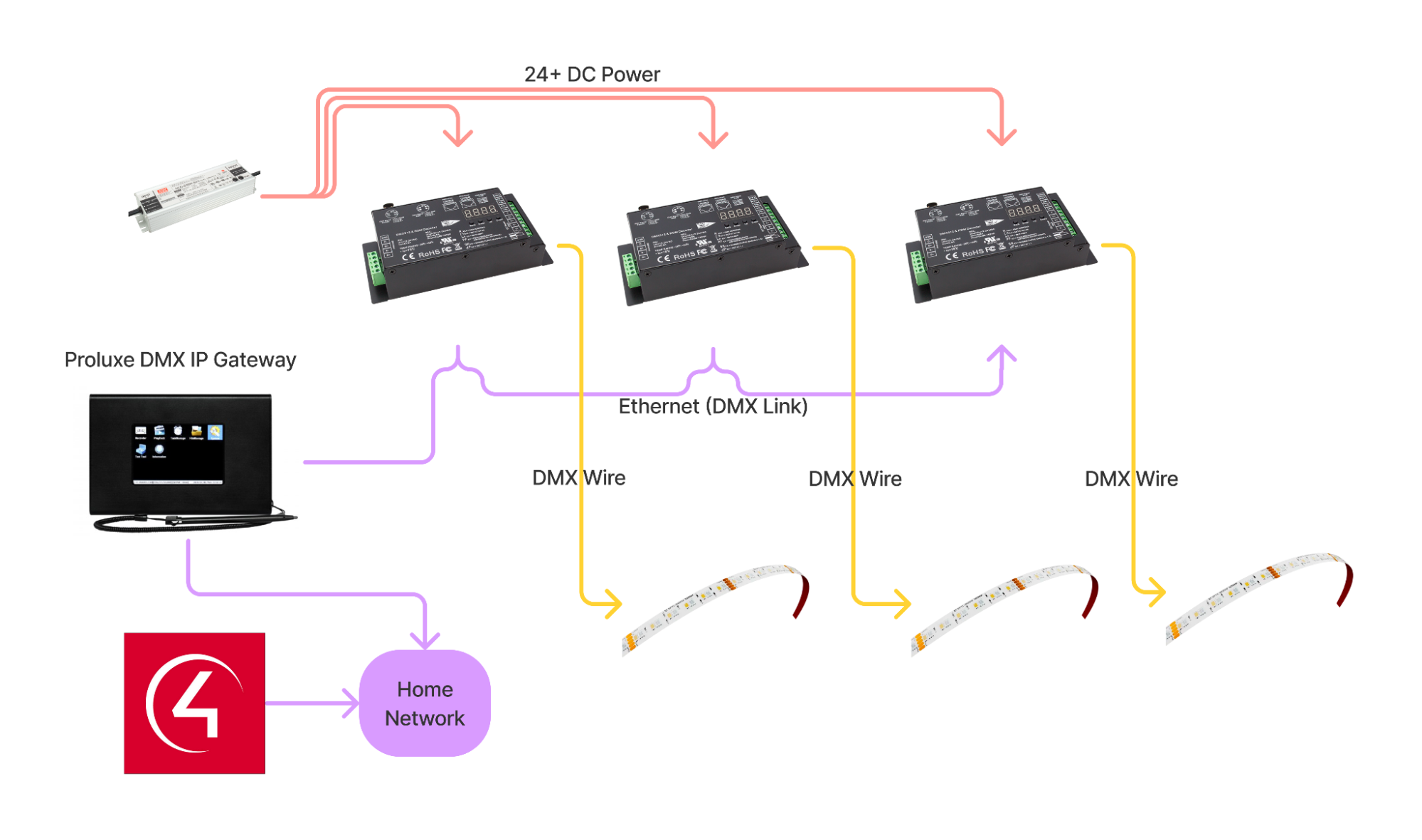

For installation, prioritize robust cabling and topology planning. Use certified CAT5e or CAT6 cable with twisted pairs specifically rated for DMX512-A, never repurpose data or power cables. Maintain a star topology where possible; if daisy-chaining is unavoidable, limit segments to 32 fixtures per run and use isolated DMX splitters to prevent ground loops. Terminate every DMX line with a 120-ohm resistor at the final fixture to eliminate signal reflection—a common cause of flicker. Physically separate DMX cables from AC power lines by at least 30 cm, crossing perpendicularly if unavoidable. Label every fixture’s DMX address clearly during installation; undocumented addresses cause hours of troubleshooting later. Finally, power all DMX controllers and fixtures on the same electrical phase to avoid timing drift, and verify signal integrity with a DMX tester before programming scenes. Skipping these steps risks intermittent failures that manifest only under specific load conditions, complicating post-installation diagnostics.

Why Choose Beauty STC Lighting

Discover the future of lighting control with DMX lighting solutions from Beauty STC. As a trusted leader in innovative LED lighting technology, we offer advanced DMX controls that deliver precision, reliability, and seamless integration for stage, studio, architectural, and entertainment applications.

Partner with Beauty STC to access high-performance DMX lighting systems designed for superior synchronization and dynamic lighting effects. Our engineering expertise ensures every product meets strict quality standards while offering flexibility for custom applications.

For collaboration opportunities or technical inquiries, contact us at [email protected] and let Beauty STC power your next lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.