Article Contents

Industry Insight: Dmx Led Strip Lights

Commercial-Grade DMX LED Strip Lights: Why Certification & Factory Pedigree Matter

Market Snapshot: From “Tape” to Mission-Critical Lighting

Architects and system integrators no longer treat LED strip as decorative “tape.”

Today it is the backbone of façade washing, arena pixel mapping, retail POP, and 24/7 industrial visualisation.

These projects share three non-negotiables:

- Reliability over 50 000 h L70 – failure means crane-rent or store shutdown.

- Code compliance on day one – AHJ inspections, insurance underwriters, rebate programmes.

- Seamless DMX512 / RDM handshake – no flicker on broadcast camera, no address drift after firmware update.

Low-price strips that skip UL/ETL or TUV CE listing may survive a one-off bar install, but they are a liability when the specification calls for 50 m runs on 120-277 V, -30 °C cold-storage corridors, or IP66 coastal towers. A single field failure can erase the profit on an entire roll.

Certification Matrix: What ETL & TUV CE Actually Cover

| Standard | Scope | Consequence of Non-Compliance |

|---|---|---|

| UL 2108 / ETL Listed (NRTL) | 120–277 V supply, fire & shock | Job-site red-tag, voided CGL insurance |

| UL 879 (Sign Components) | Channel-letter & outline lighting | Sign-off by local electrical inspector |

| TUV EN 60598-2-20 | 230 V EU market, IP rating verified | Customs seizure, GDPR-scale fines |

| TUV EN 62368-1 | LED driver, SELV limits | Installer liability if shock occurs |

| EN 55015 / FCC Part 15 | EMI, 30–1000 MHz | Broadcast studio blacklisting |

| EN 61000-3-2 | Harmonics ≤ 25 W | Utility penalty or transformer overheating |

Factory-direct implication: A listed product must be built on an ISO-9001 line with full traceability (PCB date code, driver IC lot, adhesive UL file). Random third-party audits keep the file active—paperwork that no trading-house re-brand can fake.

Beauty (STC) Manufacturing Co., Ltd – 1998 to Present

25 years continuous operation in Jiangmen, Guangdong.

60 000 m² vertically integrated campus: SMT → reflow → silicone extrusion → 48 h ageing.

In-house DMX/RDM engineering team—firmware written in C, not copied from GitHub.

ETL & TUV CE files held under our own CCN / CE 0123, not “borrowed” from sister factory.

OEM/ODM MOQ 500 m per spec, 3-week standard lead-time, 5-year factory warranty.

We solve the recurring pain points distributors face:

| Pain Point | Beauty STC Counter-Measure |

|---|---|

| Colour drift batch-to-batch | MacAdam 3-step binning, 3-in-1 closed-loop spectrometer on every 0.5 m segment. |

| Voltage drop >10 % on 5 m | 2 oz rolled-annealed copper, 24 V heavy-current bus, power-inject every 5 m. |

| Pixel failure after 6 months | Gold-wire 5050 RGB, 30 mA derate to 18 mA, silicone sleeve rated –40 °C to 90 °C. |

| DMX addressing lost | On-board 485 TVS diode, RDM-compatible, EEPROM write-cycle ≥ 1 M. |

| Customs holds shipment | ETL & TUV CE labels laser-etched on PCB; DoC, RoHS, REACH, SCIP database ready. |

Specification Preview – DMX512 Addressable Strip (Model: BSTC-DMX60-24RGB)

| Parameter | Value |

|---|---|

| LED type | SMD 5050 RGB, 3-in-1 |

| Pixel density | 60 LED/m, 20 pixel/m (3 LED / pixel) |

| PCB width | 12 mm, 2-layer, 2 oz Cu |

| Input | 24 VDC ±10 %, 14.4 W/m |

| Control | DMX512-A, RDM, Art-Net optional |

| Beam angle | 120° |

| IP rating | IP20 (indoor) standard; IP65 silicone sleeve; IP67 silicone tube + gel |

| Certifications | ETL cETL (UL 2108), TUV CE, RoHS, REACH |

| Operating temp | –30 °C to +55 °C |

| Lifetime | L70 ≥ 50 000 h @ 45 °C Ta |

| Warranty | 5 years factory limited |

Takeaway for Importers & Specifiers

When the project folder says “DMX LED strip,” the real cost is not the $/m on the PI—it is the installed cost after freight, duty, field failure, and inspection re-visit. A 1998-established, ETL & TUV CE-listed factory with captive R&D is the lowest-risk line item on your BoM.

Next step: Send your specification matrix to [email protected] or +86-1390 288 5704 (WhatsApp).

We will return a compliant datasheet, IES file, and DFMEA within 24 h.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Professional DMX LED Strip Lighting

As a manufacturer with over 25 years of engineering expertise since 1998, Beauty STC Lighting delivers DMX LED strip solutions engineered for reliability and precision. Our products comply with ETL (USA/Canada) and TUV CE (Europe) certifications, ensuring adherence to international safety and performance standards. This section details the technical specifications and quality control protocols that distinguish our products from generic market alternatives.

Comparative Technical Specifications

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens per Watt | 100–120 lm/W (unverified claims) | 130–150 lm/W (LM-79 tested) |

| CRI (Ra) | 80–85 (inconsistent batch variation) | 90–95+ (CIE 15:2011 compliant) |

| IP Rating | IP20 (indoor only, no environmental testing) | IP65/IP67 (certified for wet/dust environments) |

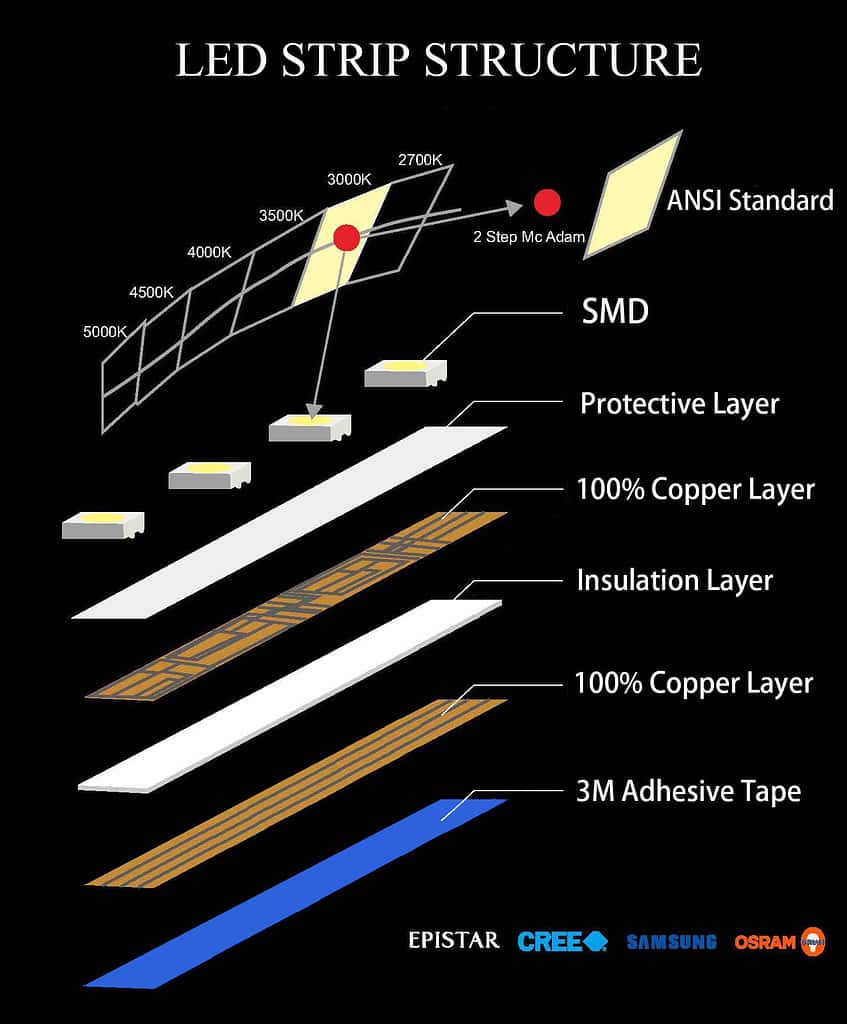

| PCB Construction | 1oz copper, standard FR-4 | 2oz copper, high-Tg FR-4 (170°C+) |

| Thermal Management | Passive cooling, no validation | Optimized thermal pathways, thermal cycling validated per IEC 60068-2-14 |

| Consistency | Batch variations common | 100% electrical testing, spectral analysis per batch |

Quality Assurance and Consistency Control

At Beauty STC, consistency is maintained through a multi-stage quality control process. Each production batch undergoes automated optical inspection (AOI) for solder joint integrity, thermal imaging validation to ensure uniform heat distribution, and spectral analysis to verify color consistency. All products are tested against LM-79 standards for photometric performance and comply with IEC 62471 for photobiological safety. Our ISO 9001-certified manufacturing processes ensure traceability from raw materials to finished goods, providing clients with confidence in every installation.

Our OEM/ODM capabilities are built on the same rigorous quality standards. Engineering teams work directly with clients to tailor specifications—such as lumen output, CRI, or IP rating—without compromising certification compliance. All custom solutions undergo the same batch testing and traceability protocols as our standard products, ensuring seamless integration into large-scale commercial, architectural, and industrial projects.

For project-specific technical documentation or certification reports, contact our engineering team at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Factory Footprint & Legacy

12,000 m² vertically-integrated plant, purpose-built in 1998 on Jiangmen’s Caihong Road high-tech corridor

6 fully-separated production modules (SMT→Reflow→Assembly→Aging→Waterproofing→Pack-out) under one roof

ISO 9001:2015 + ETL/cETL + TUV CE audited annually; test data retained ≥10 years for traceability

SMT & Precision Placement

| Parameter (DMX Pixel Strip) | Beauty STC Spec | Tolerance |

|---|---|---|

| LED type | SMD 5050 RGB+IC / 2835 mono | ±1 bin |

| Pixel pitch | 33.3 mm (30 LED/m) → 16.6 mm (60 LED/m) | ±0.2 mm |

| Copper weight | 2 oz (70 µm) double-layer | +10 / −0 µm |

| SMT line | Yamaha YSM-20R × 8 lines | ±30 µm placement |

| Solder paste | SAC305, 3 % silver | J-STD-004 |

| AOI inspection | 100 % every panel | <50 PPM defect |

Burn-in & Reliability Protocol

- 2 h room-temperature power-on at 24 V (120 % rated current)

- 4 h 85 °C / 85 % RH chamber (reference IEC 60068-2-78)

- −25 °C ↔ +65 °C 50-cycle thermal shock (IEC 60068-2-14)

- 1000 h continuous light measurement drift <3 % (IES LM-80 spot-check)

QC Gates

| Stage | Tool / Record | Accept / Reject |

|---|---|---|

| Incoming PCB | Flying-probe + TDR | 50 Ω ±5 % |

| After SMT | AOI + X-ray (BGA IC) | IPC-A-610 Class II |

| After waterproofing | IP67 immersion 30 min | <1 mA leakage |

| Final cartons | AQL 0.65 Level II | C=0 critical |

OEM / ODM Customisation Matrix

| Attribute | Standard Range | Custom Option | MOQ | Lead-Time |

|---|---|---|---|---|

| Length / cut-unit | 0.5–5 m | 10 cm–50 m continuous | 100 m | 10 days |

| CCT (white) | 2200–6500 K | 3-SDCM single bin | 500 m | 7 days |

| PCB width | 10 mm, 12 mm | 8–20 mm | 1000 m | 12 days |

| Pixel IC | UCS1903, SM16703 | WS2818, GS8208, custom | 500 m | 15 days |

| Cable exit | 150 mm tail | IP68 conduit, JST, XLR, RJ45 | 200 m | 10 days |

| Packaging | neutral brown | colour sleeve, QR code, private label | 100 pcs | 5 days |

Engineering Support

12 R&D staff (6 electrical, 3 optical, 3 mechanical) average 11 years LED strip experience

Free DMX addressing map & Art-Net/sACN patch file for projects >500 m

DXF, STEP, IES, LDT files released within 24 h

Logistics

Daily FCL/LCL consolidation to Shenzhen & Guangzhou ports; 35 km to Jiangmen High-Speed Rail freight terminal

HS code 9405.40, CO, Form A, and REACH statement provided on shipment date

Contact the factory technical desk: [email protected] | +86-139-0288-5704

Installation & Application Scenarios

Application Scenarios for Professional DMX LED Strip Lighting Systems

DMX-controlled LED strip lighting systems are engineered for precision and versatility in commercial and architectural applications. With over 25 years of manufacturing experience since 1998 and ETL/CE certification for global markets, Beauty STC Lighting provides reliable, factory-direct solutions for demanding projects across 50+ countries. Our OEM/ODM capabilities ensure seamless integration of technical specifications into project-specific requirements, from voltage configurations to IP-rated housings.

Architectural Facades & Building Outlines

DMX LED strips provide dynamic control for building exteriors, enabling synchronized color changes, animations, and accent lighting for landmarks, bridges, and commercial structures. These applications require robust weatherproofing, consistent color performance, and long-term reliability.

| Parameter | Specification |

|---|---|

| IP Rating | IP67 (Outdoor-rated) |

| LED Chip | SMD5050 High-Output |

| Density | 60 LEDs/m |

| Voltage | 24V DC (optimized for long runs) |

| CRI | >80 (Standard), >90 (Custom) |

| Max Run Length | 15m without power injection |

| Beam Angle | 120° |

Beauty STC’s facade-grade strips undergo rigorous thermal and environmental testing per TUV CE standards. Custom IP68 options and extended run lengths (up to 30m with power injection) are available for large-scale installations.

Hospitality & Entertainment Venues

Hotels, theaters, and nightclubs utilize DMX strips for mood lighting, stage effects, and branded ambiance. High CRI values and precise color control are critical for creating immersive environments while maintaining energy efficiency.

| Parameter | Specification |

|---|---|

| CRI | ≥90 (True-color rendering) |

| Dimming Range | 0–100% (Smooth, flicker-free) |

| Color Consistency | <3 SDCM (MacAdam Ellipse) |

| Operating Temp | -25°C to +45°C |

| Power Consumption | 14.4W/m (24V DC) |

| DMX Protocol | DMX512-A compliant |

All hospitality-grade strips are ETL-certified for North American safety compliance. OEM options include custom color temperatures (2700K–6500K) and integrated DMX decoders for synchronized multi-zone control.

Retail Environments & Shopping Malls

Retail spaces leverage DMX strips for product highlighting, signage, and architectural accents. High CRI (>90) ensures accurate color representation of merchandise, while seamless integration with building management systems supports dynamic retail experiences.

| Parameter | Specification |

|---|---|

| CRI | ≥95 (Premium retail-grade) |

| Lumen Output | 1,019 lm/ft (UltraBright™ series) |

| Beam Angle | 120° (Wide dispersion) |

| Thermal Management | Aluminum channel compatibility |

| Voltage Drop | <5% over 5m runs |

| Certification | ETL, TUV CE, RoHS |

Beauty STC’s retail-specific strips feature industrial-grade PCBs and 3M VHB adhesive for secure mounting. Custom channel profiles and diffuser lenses are available for glare-free illumination in high-end boutiques and malls.

Commercial & Office Spaces

Offices use DMX strips for accent lighting, task illumination, and smart building integration. Energy-efficient designs with tunable white capabilities support circadian lighting systems, improving occupant well-being.

| Parameter | Specification |

|---|---|

| CCT Range | 2700K–6500K (Tunable White) |

| Efficacy | >120 lm/W |

| Dimming Protocol | 0–10V / DALI compatible |

| Power Efficiency | 92% (Low harmonic distortion) |

| Fire Rating | UL94 V-0 (Flame-retardant PCB) |

| Warranty | 5-year (Industry-standard) |

Our commercial-grade strips comply with IEC 60598 for office lighting safety. OEM services include custom dimming curves and integrated motion sensors for adaptive lighting scenarios.

Installation Best Practices for Contractors

Proper installation ensures optimal performance and longevity of DMX LED systems. Key considerations include power management, thermal control, and signal integrity.

| Best Practice | Technical Consideration |

|---|---|

| Power Supply Calculation | Use 1.2x the total wattage of the strip. For 24V systems, inject power every 5m to avoid voltage drop exceeding 5%. |

| Aluminum Channel Integration | Use extruded aluminum channels (e.g., 10–12mm width) for thermal dissipation. Extends LED lifespan by 30%+ per IEC 62612 testing. |

| DMX Signal Termination | Install a 120Ω resistor at the final DMX node to prevent signal reflection. Max chain length: 300m (with shielded cable). |

| Polarity & Wiring | Verify polarity before powering. Use 18–22 AWG stranded copper wire for low-resistance connections. |

| Environmental Sealing | For outdoor/industrial use, apply silicone sealant at all junctions. Ensure IP67-rated connectors and conduit entries. |

Beauty STC provides free technical documentation for all projects, including voltage drop calculators and installation diagrams. Our 25+ years of global field experience ensures compliance with regional electrical codes and project-specific requirements.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – 25 Years of Factory-Direct DMX LED Strip Reliability

Why Global Specifiers Choose a 1998-Certified OEM

| Competency | Beauty STC Record |

|---|---|

| Plant Established | 1998, 41,000 m² Jianghai high-tech zone, Guangdong |

| Export Footprint | 50+ countries, repeat shipments to EU, NAFTA, AU, RU, JP, KR |

| Safety Credentials | ETL/cETL (US/Canada), TUV CE / CB / RoHS (EU) – file numbers on request |

| DMX Strip Range | 5 V / 12 V / 24 V / 48 V; 30–144 LED/m; SMD 2835/5050/COB; pixel pitch 16.6 mm–100 mm; RDM-ready PCB |

| OEM/ODM Throughput | 1.5 million metres/month, 24-hour engineering response, custom binning ≤3 SDCM, CRI 80–98 |

| QC Protocol | 100 % ICT, 2-hour ageing @ 75 °C, 3-year/50 000 h written warranty, <0.2 % RMA |

What You Get Beyond the Strip

Certified for Western tenders – no field-site surprises; ETL & TUV CE files pre-submitted to UL and Nemko.

One-stop BOM – DMX512 decoder, power trunking, IP67 silicone extrusion, and extruded aluminium channel from the same ISO 9001 line.

24 h sample dispatch – standard reels in stock; custom PCB colour or logo within 7 days.

Duty optimisable – HS 9405.40, COO Guangdong, FOB Shenzhen or EXW Jiangmen, LCL or FCL.

Next Step – Send the Spec

E-mail your lighting schedule or DMX channel map to:

[email protected]

Tel | WhatsApp: +86-139 0288 5704

We will return a fully-costed, code-compliant DMX strip solution in 24 hours—backed by 25 years of factory data and Western safety marks.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).