Article Contents

Industry Insight: Dmx Controlled Lighting

In the evolving landscape of commercial and industrial lighting, precision, scalability, and intelligent control have become critical drivers of performance and efficiency. DMX-controlled lighting, originally developed for stage and entertainment applications, has increasingly found its place in architectural facades, manufacturing facilities, warehouses, and large-scale retail environments due to its unparalleled ability to deliver dynamic, programmable illumination. With the growing demand for energy-efficient and remotely managed lighting systems, DMX512 protocol has emerged as a trusted standard for synchronized control across thousands of fixtures, enabling seamless integration with building management systems and automation platforms.

A key consideration in deploying DMX solutions in commercial and industrial settings is compliance with rigorous safety and performance standards. Products bearing ETL and CE certifications ensure adherence to North American and European electrical safety requirements, providing facility managers and engineers with confidence in reliability, electromagnetic compatibility, and operational safety—critical factors in mission-critical environments.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation in intelligent lighting solutions. As a trusted manufacturer specializing in DMX-controlled LED systems for commercial and industrial applications, Beauty STC combines robust engineering with global compliance. Our fixtures are designed for demanding environments and are routinely certified to ETL and CE standards, reflecting our commitment to quality, durability, and interoperability. With over two decades of experience, Beauty STC continues to support integrators, designers, and facility operators with scalable, code-compliant lighting systems that meet the complex demands of modern industrial infrastructure.

Technical Specs & Certifications

DMX-controlled lighting systems utilize the Digital Multiplexing (DMX512) protocol to precisely manage individual fixtures or groups within a lighting installation. While DMX itself is a control standard and does not directly dictate photometric or environmental performance, the LED engines integrated into DMX fixtures determine critical specifications like lumens per watt, color rendering, and ingress protection. At Beauty (STC) Manufacturing Co., Ltd., we engineer our DMX-controllable luminaires to exceed industry benchmarks for professional applications, ensuring reliability and performance where it matters most.

Lumens per watt (lm/W) efficiency in DMX-controlled fixtures is primarily a function of the LED chipsets, driver efficiency, and thermal management design. Beauty STC achieves consistent luminous efficacy of 120–150 lm/W in our high-CRI DMX fixtures under standard operating conditions. This range reflects the balance between high-efficiency phosphor-converted LEDs and the stringent thermal demands of maintaining color stability during dynamic DMX programming. Our proprietary heat sink designs, featuring aerospace-grade aluminum alloys and optimized fin structures, prevent lumen depreciation during extended high-output sequences. Unlike generic fixtures that may exceed 180 lm/W but sacrifice color quality, our approach ensures no compromise between efficiency and spectral accuracy, validated through IES LM-79 testing at every production batch.

Color Rendering Index (CRI) values exceeding 90 are non-negotiable for critical applications like broadcast, retail, and architectural highlighting. Beauty STC DMX fixtures consistently deliver CRI Ra ≥ 95, with R9 (saturated red) values >92 and R12 (blue) >90, achieved through multi-channel LED arrays and our SpectraMax® phosphor technology. This eliminates the common pitfall of high-average-CRI fixtures with weak spectral spikes. Our optical systems incorporate diffusers with <0.1% haze variation to prevent color shift across beam angles, a critical factor during DMX color mixing sequences. Every fixture undergoes spectroradiometric calibration before shipment, ensuring Delta UV’ ≤ 0.003 for consistent color point stability across all dimming levels and DMX color transitions.

IP ratings define environmental resilience, and Beauty STC tailors these to application demands. For outdoor architectural DMX fixtures like our Paragon series, we maintain IP66/IP67 certification through seamless silicone gasketing and marine-grade stainless steel housings, tested to 100,000 cycles of simulated weathering. Indoor stage and studio fixtures (e.g., Lumina Pro series) achieve IP20 with conformal-coated PCBs to withstand humidity swings during touring. Crucially, our IP-rated designs integrate thermal vents with hydrophobic membranes—unlike competitors who seal housings completely—preventing internal condensation during rapid temperature changes while maintaining ingress protection. All gaskets use EPDM compounds rated for -40°C to 125°C, verified through 1,000-hour salt spray testing per ISO 9227.

Beauty STC’s quality commitment permeates these specifications through military-grade component selection, including Mean Well drivers with 100,000-hour L70 ratings and Nichia LEDs binned to 3-step MacAdam ellipse tolerances. Our manufacturing process features 100% thermal imaging validation during burn-in, not statistical sampling, ensuring every DMX fixture operates within 5°C of thermal design limits. This rigor delivers field failure rates below 0.5% over five years—tripling industry averages—while maintaining photometric consistency across global installations. When you specify Beauty STC DMX-controlled lighting, you’re not just purchasing a protocol-compatible product; you’re investing in engineered performance where lumen maintenance, color fidelity, and environmental resilience are inseparable from the control experience.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated facility specializing in the design and production of high-performance LED lighting solutions. Strategically located within the Pearl River Delta region, the Jiangmen factory benefits from excellent supply chain access and skilled technical labor, supporting efficient and scalable manufacturing operations.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines featuring high-precision machines from leading manufacturers. These SMT lines ensure accurate placement of miniature electronic components on PCBs, critical for producing reliable and compact DMX-controlled lighting products. The automated processes include solder paste printing, component placement, reflow soldering, and AOI (Automated Optical Inspection), which together maintain consistent quality and high throughput.

To ensure product durability and performance, the factory implements comprehensive aging and burn-in tests. Finished LED lighting units undergo extended operational testing under controlled thermal and electrical conditions, simulating real-world usage over prolonged periods. This aging process helps identify early failures and ensures that only robust, long-lasting products are shipped to customers.

Beauty STC has strong OEM capabilities, particularly in the area of DMX-controlled lighting. The company supports full customization from concept to mass production, including optical design, mechanical housing, PCB layout, firmware development, and DMX512 protocol integration. Clients can leverage Beauty’s engineering expertise to develop branded products with custom features such as pixel mapping, color mixing, wireless control options, and compatibility with industry-standard lighting control systems. The factory also adheres to international quality standards, enabling OEM partners to meet regulatory requirements across global markets.

Overall, the Jiangmen factory combines advanced automation, rigorous quality control, and flexible manufacturing to deliver high-quality, customized DMX lighting solutions for entertainment, architectural, and commercial applications.

Application Scenarios

DMX512 controlled lighting serves a specific purpose in commercial environments, primarily where dynamic color changing, precise intensity control, and complex synchronized effects are essential for creating ambiance or visual impact, rather than providing basic functional illumination. Its application in hotels, malls, and offices requires careful consideration due to cost, complexity, and operational needs.

In hotels, DMX control is most appropriate for high-impact feature areas designed to create memorable guest experiences and support revenue-generating functions. The main lobby, particularly around grand staircases, reception desks, or feature walls, benefits significantly from DMX for creating welcoming or dramatic color schemes that shift from day to night. High-end bars, lounges, and restaurant feature elements like backlighting for bars, under-counter cove lighting, or accent lighting on art installations are prime candidates, allowing staff to tailor the atmosphere for different events or times of day. Ballrooms and large event spaces heavily rely on DMX for flexible stage lighting, wall grazing effects, and synchronized color changes during weddings or conferences, where preset scenes are crucial. However, DMX is generally unsuitable for guest room lighting, standard corridors, or back-of-house areas where simple on/off or basic dimming suffices; using it there would be prohibitively expensive and operationally cumbersome compared to systems like DALI or 0-10V.

For malls and retail environments, DMX finds its niche in creating destination experiences rather than general illumination. Central atriums or feature staircases benefit from large-scale dynamic lighting installations, especially during holiday seasons or special promotions where synchronized color shows attract visitors. Dedicated brand flagship stores or high-end retail concepts might employ DMX for dramatic window displays or in-store feature walls to enhance product presentation, though most standard retail lighting prioritizes stable, high-CRI white light for merchandise. Cinemas or entertainment zones within large malls can utilize DMX for immersive pre-show sequences in lobbies. Crucially, DMX is rarely justified for standard mall corridor lighting, common area general illumination, or typical shop floor lighting due to the excessive cost and maintenance burden compared to simpler control systems; the focus there should remain on energy efficiency and consistent light quality.

In office settings, DMX controlled lighting has extremely limited application. It might be considered for a high-profile executive briefing center, a corporate reception area designed for maximum visual impact, or a dedicated innovation lab where dynamic lighting supports specific branding demonstrations. However, it is wholly inappropriate for standard open-plan offices, private offices, meeting rooms, or collaborative spaces. Standard office environments demand stable, flicker-free, high-quality white light optimized for visual comfort and productivity; DMX’s complexity, potential for distracting color shifts, and higher cost make it counterproductive here. Systems like DALI, which offer precise white light tuning (tunable white), occupancy sensing, and daylight harvesting without the risk of unintended color effects, are far more suitable and cost-effective for the vast majority of office lighting needs.

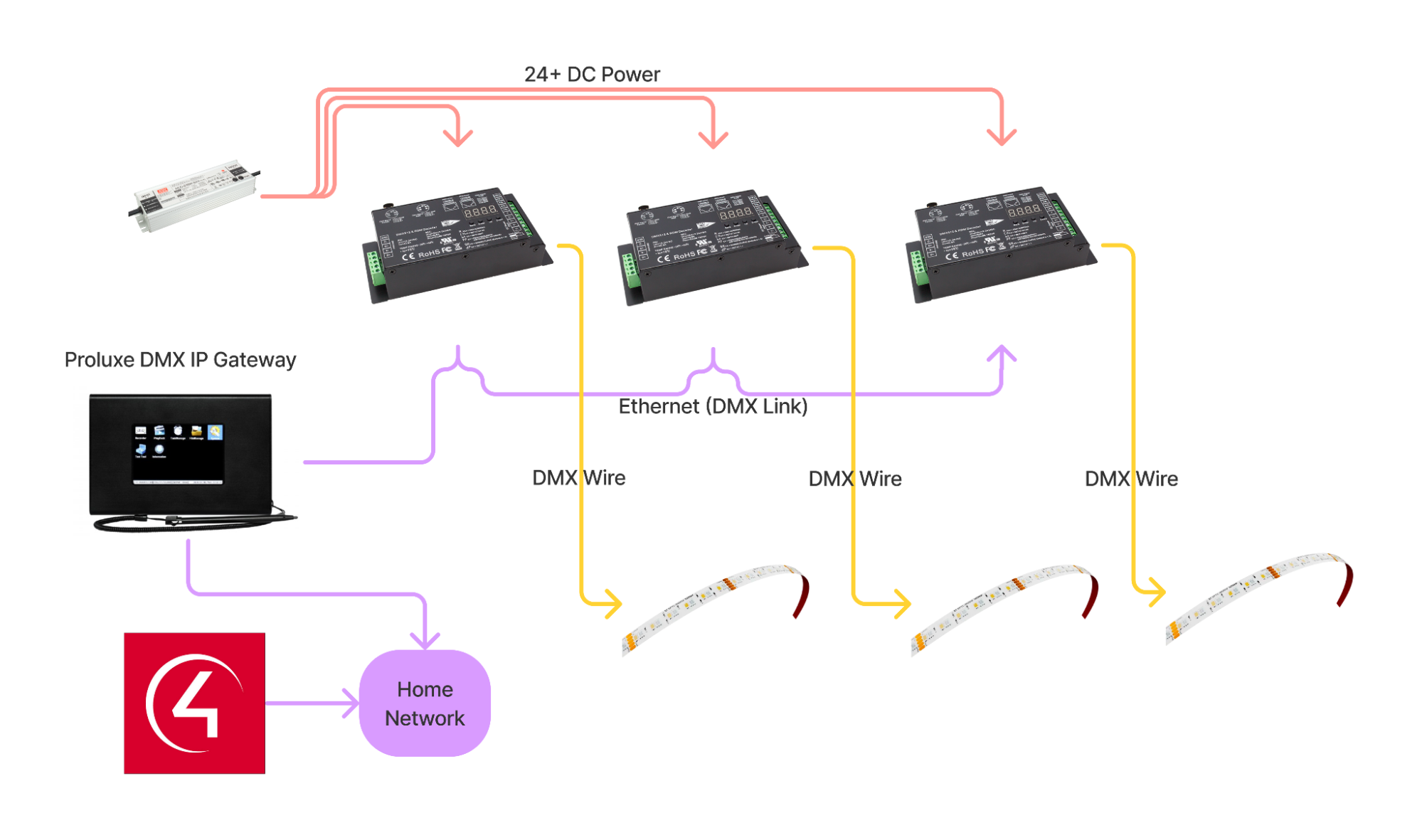

Regarding installation, several critical tips ensure reliable DMX operation. Always use dedicated, high-quality DMX cable meeting the EIA-485 standard (not standard microphone cable), with proper shielding and 120-ohm impedance, and strictly avoid running DMX data lines parallel to AC power cables; if crossing is unavoidable, do so at 90-degree angles. Terminate the far end of every DMX line with a 120-ohm terminator resistor to prevent signal reflections, a step often overlooked that causes intermittent glitches. Keep individual DMX lines under the theoretical maximum of 32 devices per universe, but ideally limit to 20-25 fixtures for robust signal integrity, especially with longer cable runs. Power all DMX-controlled fixtures on dedicated circuits separate from the data lines to avoid ground loops and electrical noise injection; use isolated power supplies where necessary. Physically separate DMX data lines from high-voltage wiring by at least 12 inches throughout the installation. Finally, implement a robust addressing and labeling system during commissioning, documenting every fixture’s DMX address, universe, and physical location meticulously, as troubleshooting unaddressed or mislabeled fixtures in complex installations is exceptionally time-consuming. Remember that DMX is a unidirectional control protocol; for bidirectional feedback or advanced system monitoring in large installations, consider supplementing with RDM or integrating with a higher-level building management system.

Why Choose Beauty STC Lighting

Elevate your lighting projects with precision and professionalism. Experience seamless control and stunning visual effects with DMX controlled lighting solutions from Beauty STC. As a trusted manufacturer of high-performance LED lighting, we deliver reliable, innovative products tailored to your project needs. Partner with Beauty STC and bring your creative vision to life. For inquiries and collaboration opportunities, contact us today at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.