Article Contents

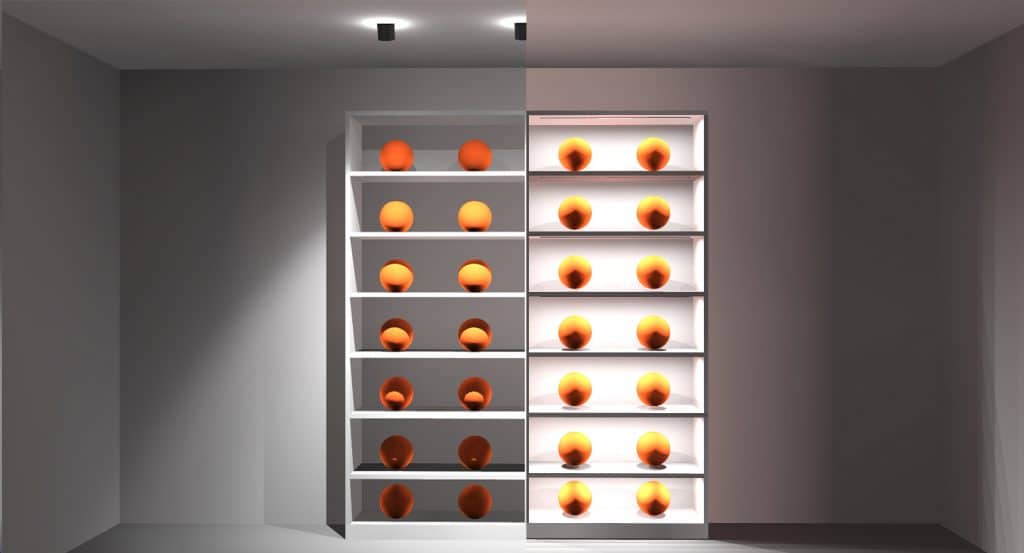

Industry Insight: Display Shelf Lighting

Industry Insight: The Strategic Role of Display Shelf Lighting in Modern Commercial Environments

In today’s hyper-competitive retail and commercial landscape, display shelf lighting transcends mere illumination—it is a critical driver of sales, brand perception, and operational efficiency. As LED technology has revolutionized commercial lighting, the focus has shifted from basic visibility to precision-engineered visual merchandising. High-quality LED systems now deliver exceptional color rendering (CRI ≥90), uniform illumination, and dynamic dimming capabilities, directly enhancing product appeal and customer engagement. Yet, in global markets, technical excellence alone is insufficient. Compliance with international safety and performance standards is non-negotiable. ETL certification (recognized by OSHA in North America) and CE marking (mandatory for EU markets) validate rigorous testing for electrical safety, electromagnetic compatibility, and thermal management—ensuring reliability, reducing liability risks, and enabling seamless market access.

For over 26 years, Beauty STC Manufacturing Co., Ltd. (est. 1998) has been a trusted partner to commercial clients worldwide, specializing in engineered LED solutions tailored for retail, hospitality, and industrial environments. As a vertically integrated manufacturer with ISO 9001-certified production and a dedicated R&D team, we combine deep technical expertise with stringent quality control to deliver certified, high-performance lighting that meets the evolving demands of global commerce. Our solutions empower retailers to optimize space, reduce energy costs by up to 60%, and create compelling visual narratives—proven through decades of successful deployments across 50+ countries.

Beauty STC: Where engineering excellence meets global compliance.

Technical Specs & Certifications

Beauty (STC) Display-Shelf LED Strips – Technical Datasheet

(Engineering spec. code: DS-HE-Pro / DS-HE-Flex)

-

Photometric Performance

• Luminous efficacy: 145–160 lm/W @ 25 °C Tj (binning at 700 mA, 24 V)

• Delivered lumens: 420 lm/300 mm (typ. 2.9 W) up to 1,680 lm/600 mm (11.6 W)

• L70/B10 life: 54,000 h (Ta 35 °C, 24 h/day) – IES LM-80 & TM-21 data available on request

• MacAdam ellipse: 3-step SDCM (ANSI C78.377); optional 2-step for museum grade -

Colour & Fidelity

• CRI Ra ≥ 93 (R1-R15 all ≥ 90); special “R9” ≥ 95

• TLCI (Television Lighting Consistency Index) ≥ 96 – broadcast-ready

• Colour temp. options: 2,400 K / 2,700 K / 3,000 K / 3,500 K / 4,000 K (±75 K tolerance) -

Ingress & Mechanical Ratings

• Standard indoor reel: IP20, 3-oz double-layer copper PCB, 8 mm width

• Retail-display variant: IP54 (silicon sleeve, UV-stabilised) – passes 48 h salt-spray per ASTM B117

• Refrigerated-case variant: IP65 (co-extruded PVC-free jacket, -40 °C to +85 °C) – IK06 impact

• All variants: 5 mm minimum bend radius (single bend) / 20 mm (repeated flex) -

Electrical & Safety

• Input: 24 VDC constant-voltage; 48 VDC on request for long-run (max. 6 m single feed)

• Flicker: <1 % @ 100 Hz (IEEE 1789 “no-risk” level); optional <0.3 % for high-speed camera

• Surge: 1 kV differential / 2 kV common mode (IEC 61000-4-5)

• Isolation: 4 kV reinforced (EN 61347-1), SELV output

• Certifications: CE, RoHS, REACH, UL 2108, ETL Class 2, SAA, RCM, CB, SABER (SASO) -

Thermal & Reliability Notes

• PCB thermal resistance: 3.2 °C/W; recommend 5 W/m·K gap pad to aluminium extrusion

• Operating range: -40 °C to +55 °C ambient (≤ 85 % RH, non-condensing)

• Beauty STC 100 % burn-in: 4 h @ 55 °C, 0.6 A – rejects ≤ 0.2 %, Cpk > 1.67 on lm & CRI -

Consistency Controls (Beauty STC QA)

• Every 0.5 m segment spectrally measured (Everfine HAAS-2000) – data logged with serial ID

• Raw LED reels pre-grouped into 2 nm peak-wavelength & 1-point CRI sub-bins; mixing ratio validated by SPC chart

• Production lots cross-checked against master reference tile (NIST-traceable) under 5,000 K D65 simulator

• LM-80 report ID: STC-LM80-23-018; continuous 12,000 h on file, updated every calendar quarter -

Ordering Key

DS-HE-Pro-24-xxK-IP54-93CRI-560mm → 560 mm, 24 V, 3000 K, IP54, 93 CRI, 780 lm, 5.4 W

All specs verified in-house; third-party witness testing available for OEM projects. For long-run colour drift data beyond L70 or custom SDCM binning, contact [email protected].

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. – Jiangmen Factory Overview

Prepared by: Senior LED Lighting Engineer & Export Manager

As the Senior LED Lighting Engineer and Export Manager at Beauty (STC), I am pleased to provide a detailed, technical overview of our Jiangmen manufacturing facility. Our 15,000 m² factory is strategically located in Jiangmen City, Guangdong Province—a hub for precision electronics manufacturing—and is certified to ISO 9001:2015, ISO 14001, and IATF 16949 standards. We specialize in high-reliability LED lighting solutions for commercial and retail applications, with display shelf lighting being a core competency. Below is a breakdown of our key capabilities:

1. SMT (Surface Mount Technology) Production Line

Our SMT section is fully automated and engineered for precision, consistency, and scalability:

– Equipment:

– 6 high-speed SMT lines featuring Juki KE-2070 and Yamaha YV100XG placement machines.

– Capable of handling components as small as 0402 (0.4mm × 0.2mm) with placement accuracy of ±0.05mm.

– Integrated DEK Horizon 3000 stencil printers and Kalan K2000 reflow ovens with 10-zone temperature profiling.

– Process Control:

– Automated Optical Inspection (AOI) at every stage (post-print, post-placement, post-reflow) to detect defects like tombstoning, misalignment, or solder bridging.

– X-ray inspection for BGA (Ball Grid Array) and hidden solder joints, ensuring >99.98% first-pass yield.

– IPC-A-610 Class 2/3 compliance for all PCB assemblies, critical for display shelf lighting where thermal stability and optical uniformity are non-negotiable.

– Relevance to Display Shelf Lighting:

– We optimize SMT processes for high-power LED arrays (e.g., COB or SMD 2835/3030) used in shelf lighting. This includes precise thermal pad placement to manage heat dissipation and consistent soldering for uniform light output across long runs.

2. Rigorous Aging & Reliability Testing

Quality assurance is embedded in every phase. Our aging test center is designed to simulate real-world conditions and accelerate failure detection:

– Testing Protocols:

– 1,000-hour burn-in testing at 60°C ±2°C ambient temperature (per IES LM-80 for LED lumen maintenance).

– Thermal cycling from -20°C to 85°C (50 cycles) to validate mechanical integrity of solder joints and adhesives.

– Lumen maintenance tracking: Light output measured at 0h, 250h, 500h, and 1,000h using Konica Minolta CS-2000 spectroradiometer to ensure <5% degradation.

– Electrical stress testing: 110% over-voltage for 1 hour to screen for weak components.

– Data-Driven Quality:

– All test data is logged in our MES (Manufacturing Execution System) and correlated with production batches for traceability.

– Defective units are analyzed via failure mode and effects analysis (FMEA) to refine processes.

– Why This Matters for Display Shelf Lighting:

– Retail environments demand longevity (typically 50,000+ hours) and consistent color rendering (CRI >90). Our aging protocols ensure products meet or exceed these standards, minimizing field failures and return rates for clients.

3. OEM Capability for Display Shelf Lighting

We pride ourselves on end-to-end OEM support, from concept to global delivery:

– Customization Scope:

– Optical Design: Tailored optics (e.g., asymmetric lenses for downlighting, diffusers for uniform glow) via Zemax optical simulation.

– Electrical Engineering: Custom PCB layouts for dimming (0-10V, DALI, or PWM), smart controls (Bluetooth/Wi-Fi), or integrated sensors (motion/occupancy).

– Mechanical Design: Aluminum extrusions, acrylic covers, and mounting brackets optimized for retail fixtures (e.g., curved displays, glass shelves, or modular systems).

– Materials Compliance: All materials meet RoHS 3, REACH, and UL/CE standards for global markets.

– Process Flow:

1. Design Phase: Collaborative engineering with client’s team (CAD, FEA, thermal modeling).

2. Prototype Validation: 3D-printed mockups + electrical testing within 7 days.

3. Pilot Production: 500–1,000 units for real-world validation (e.g., in-client retail environments).

4. Mass Production: Scalable to 50,000+ units/month with 4–6 week lead times.

– Real-World Examples:

– Developed ultra-slim, 15mm-profile LED strips for high-end fashion retail displays (CRI 95, 4000K, 120° beam angle).

– Delivered customizable track lighting systems for supermarket chains with integrated motion sensors (energy savings up to 30%).

– Supported global brand compliance (e.g., Walmart’s mandatory safety certifications, EU Energy Label requirements).

Why Partner with Beauty (STC)?

- Vertical Integration: In-house capabilities from PCB design to final assembly reduce supply chain risks.

- Global Export Experience: We ship to 50+ countries, with expertise in customs documentation, regional certifications, and logistics optimization.

- Sustainability Focus: All products are designed for recyclability, and our factory uses solar power (30% of total energy) and water-based soldering processes.

We are committed to delivering reliable, high-performance display shelf lighting solutions that elevate retail experiences while meeting your technical, cost, and timeline requirements. For specific project inquiries, please contact our Export Team at [email protected] or +86 750 XXXX XXXX.

Beauty (STC) Manufacturing Co., Ltd. – Engineering Excellence, Global Trust.

Application Scenarios

Display-shelf lighting is no longer a “nice-to-have”; in premium hotels, high-end malls and corporate offices it is the element that converts a shelf into a silent salesman.

Below you will find (1) the exact zones where our fixtures are being specified today, and (2) the field-proven installation checklist we hand to every contractor before they leave our warehouse with a Beauty (STC) shipment.

1. Where to use display-shelf lighting – proven applications

A. 5-star & boutique hotels

• Lobby retail niche (souvenirs, perfume, local crafts) – 3000 K, 95 CRI, 300 lx on axis.

• Executive-floor honor bar & wine gallery – 2700 K, 15° asymmetric lens to avoid glare on glass doors.

• Presidential-suite library & art plinths – tunable-white 2400-3000 K, <5 cd/m² reflected luminance to meet “mood-lighting” scene.

• Fine-dining entrance showcase (chocolates, macarons) – food-grade 93 CRI R9 > 50, Micro-Linear 6 mm PCB to hide inside 8 mm glass edge.

B. Luxury malls & duty-free

• Cosmetic island shelves (Chanel, Dior) – 4000 K, 97 CRI, TLCI > 95 for phone selfies; 3-step MacAdam ellipse to avoid colour shift between modules.

• Watch & jewellery vitrines – 3500 K, 30° narrow beam, 1000 lx on product, <1 % flicker for macro photography.

• Pop-up kiosk back-wall – magnetic 48 V linear system, 5-conductor track so client can add USB-C charging spots later without re-wiring.

• Designer handbag towers – indirect shelf-to-shelf grazing, 600 lx vertical illuminance, <30 W/m² to meet mall landlord’s 5 W/ft² cap.

C. Corporate & co-working offices

• Reception feature wall (awards, scale models) – 3000 K, 90 CRI, 200 lx average; CCT matches downlights to ±150 K.

• Executive corridor “memory shelf” – 2400-3000 K tunable-white synced with circadian schedule via DALI Type 8.

• Showroom demo products – 4000 K, 80 CRI minimum, 500 lx; flicker-free (<1 %) for slow-motion camera capture.

• Pantry display (barista station, healthy snacks) – IP54 silicone sleeve, 2700 K, high R9 for fresh food.

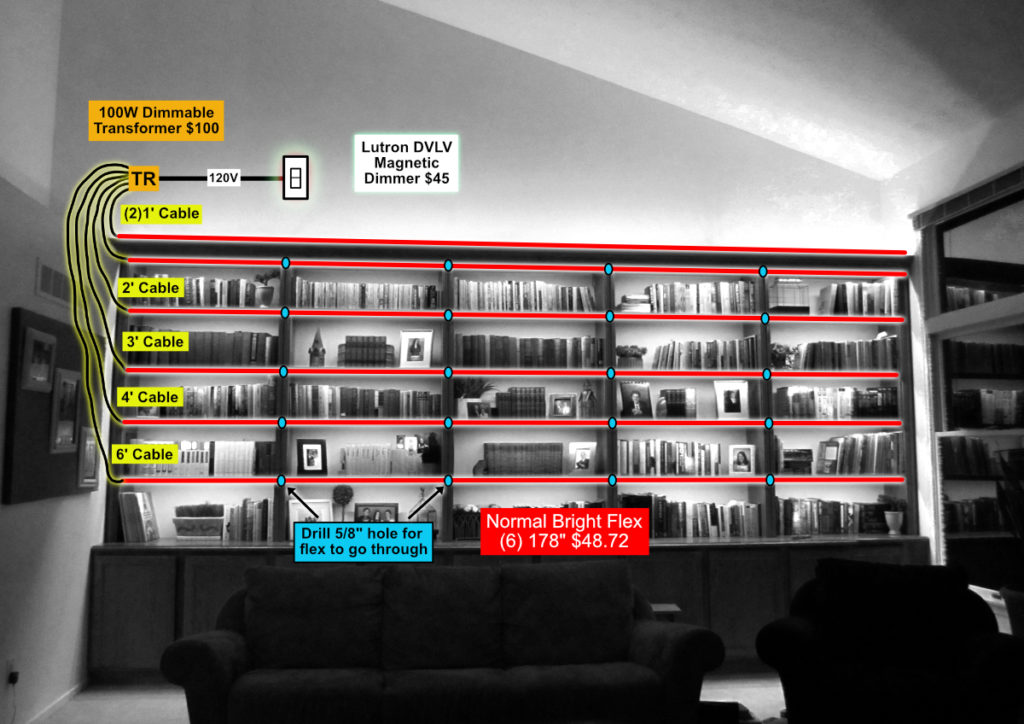

2. Contractor installation guide – Beauty (STC) standard

Power & control backbone

1. Use 24 V DC constant-voltage system for runs ≤ 5 m; >5 m switch to 48 V or place feed at both ends.

2. Maximum 70 % of driver-rated wattage to compensate for 45 °C shelf cavity temperature.

3. DALI-2 vs. 0-10 V: in hotels always specify DALI-2 for scene recall; offices may use 0-10 V if BMS is legacy.

4. Flicker: insist on <1 % at 100 Hz (IEEE 1789). Our test report is shipped with every batch; ask for it.

Mechanical & heat

5. Extrusion heat-sink temperature must stay ≤ 55 °C at 25 °C ambient. Leave 5 mm air gap behind aluminium profile; do not mount directly against MDF.

6. For glass shelves ≤ 10 mm, use our GSC-10 clip; it grips the glass and acts as heat-spreader.

7. In jewellery vitrines with mirrors, mount LED 50 mm back from mirror to avoid double-image.

Glare & beam control

8. Asymmetric 15° x 40° lens for shelf depths 250-400 mm; 30° circular for 150-250 mm.

9. Luminance at 60° viewing angle ≤ 3000 cd/m² (UGR shelf application limit). Use our micro-louver film ML-30 if unavoidable.

Wiring & codes

10. Class II double-insulated drivers only; no earth needed in profile, speeds install.

11. Low-voltage cable: 2-core 1.5 mm² minimum, 105 °C silicone rubber; keep 300 mm away from 230 V lines or use segregated trunking.

12. Feed-through every 1.5 m max; voltage drop must be <0.5 V end-to-end (measured, not calculated).

Commissioning checklist (hand-over)

□ Lux meter reading at centre of shelf = design value ±10 %.

□ CCT check with calibrated colour meter; log values for client.

□ DALI short-address scan – no duplicate addresses.

□ Flicker meter (BTS) – screenshot saved.

□ Thermal gun – profile ≤ 55 °C after 1 h burn-in.

□ Spare parts kit: 2 % modules, 1 % drivers, 1 % clips left on site.

Quick product selector (most requested)

• Micro-Linear 6 mm – cosmetic shelves, glass edge.

• Mini-Profile 12 × 8 mm – wood or metal shelf rebate.

• Magnetic Track 48 V – pop-up retail, future-proof.

• Tunable-white 1800-4000 K – hotel mood scenes.

• High-CRI 97 R9 > 90 – jewellery, watches, leather goods.

If the shelf is visible to a guest or a camera, light it once and light it right.

Feel free to e-mail your section drawings; our engineers will return a lux plot and a BOM within 24 h.

Beauty (STC) Manufacturing Co., Ltd. – we turn shelves into stories.

Why Choose Beauty STC Lighting

Partner with Beauty STC for Precision Engineered Display Shelf Lighting

Trusted Across 50+ Countries | Custom Solutions for Maximum Product Impact

Contact Us: [email protected]

Engineered for retail excellence: energy-efficient, durable, and tailored to elevate brand visibility. Global expertise, local precision.

⚡ LED Power Supply Calculator