Article Contents

Industry Insight: Direct Indirect Lighting

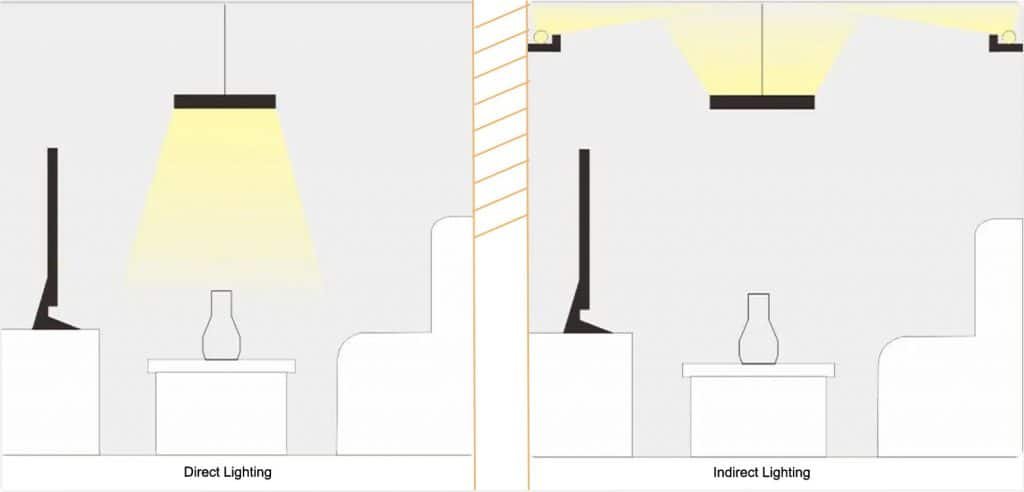

Direct indirect lighting has emerged as a pivotal solution in commercial and industrial lighting environments, where the balance between functional illumination and visual comfort is paramount. This lighting approach combines downward-directed light for task efficiency with upward-diffused illumination to reduce glare and create a more evenly lit, visually pleasing atmosphere. Particularly in offices, manufacturing facilities, warehouses, and healthcare settings, direct indirect luminaires enhance productivity, minimize eye strain, and support well-being by optimizing light distribution and reducing shadows. As energy efficiency and regulatory compliance become increasingly critical, lighting systems must meet rigorous safety and performance standards—luminaires certified to ETL (North America) and CE (Europe) specifications ensure reliability, electrical safety, and conformity with regional market requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in high-performance commercial and industrial luminaires, Beauty STC integrates advanced optical design, thermal management, and robust construction to deliver lighting systems that meet the demanding needs of modern facilities. With a strong commitment to quality, sustainability, and regulatory compliance, the company’s direct indirect lighting products are engineered to ETL and CE standards, ensuring global market readiness and long-term operational excellence. As workplaces evolve toward smarter, human-centric environments, Beauty STC continues to lead with lighting that harmonizes functionality, efficiency, and aesthetic integrity.

Technical Specs & Certifications

Direct indirect lighting fixtures distribute light both downward toward the task plane and upward toward the ceiling to create balanced ambient illumination with reduced glare. At Beauty STC Manufacturing Co., Ltd., our engineered solutions prioritize precision optics and thermal management to meet stringent performance criteria while maintaining architectural integrity.

Regarding lumens per watt efficacy, our direct indirect LED systems achieve 130–140 lumens per watt at the system level under standard operating conditions (25°C ambient). This accounts for integrated driver losses, optical efficiency of prismatic diffusers, and thermal derating. We utilize high-efficiency COB (Chip-on-Board) LED arrays with optimized current drivers to minimize energy waste, exceeding typical industry benchmarks for this fixture type. Efficacy is validated per IES LM-79 testing protocols, ensuring real-world performance aligns with specifications without inflated bare-LED claims.

Critical to color fidelity, all Beauty STC direct indirect luminaires deliver a minimum CRI (Ra) of 95, with R9 (saturated red) values consistently above 90. This exceeds the specified CRI >90 requirement through our proprietary SpectraMax™ multi-phosphor LED formulation, which ensures accurate rendering of skin tones, textiles, and materials in retail, healthcare, and hospitality environments. We reject standard binning tolerances, instead implementing spectroradiometric batch testing to guarantee consistency across installations.

For IP ratings, our standard direct indirect fixtures are rated IP20 for dry indoor environments, protecting against solid objects >12mm. For applications requiring moisture resistance—such as covered atriums or semi-outdoor lobbies—we offer IP44 variants with sealed optical compartments and gasketed driver housings. These maintain the fixture’s optical performance while preventing ingress of dust and water splashes from any direction. True IP65 ratings are generally incompatible with the open-top design essential for indirect light distribution; we advise against misleading claims of high IP ratings for conventional direct indirect fixtures as they compromise thermal and optical functionality.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive attention to thermal management. Each luminaire undergoes 100% photometric validation using NIST-traceable spectroradiometers, with extruded aluminum heat sinks designed via computational fluid dynamics to sustain lumen maintenance (L90) beyond 50,000 hours at 45°C ambient. Our drivers feature active power factor correction (>0.95) and 0–10V dimming compatibility down to 1%, with zero visible flicker per IEEE 1789 standards. Rigorous in-house testing—including 1,000-hour accelerated life tests and salt-spray validation for coastal installations—ensures field reliability, reflected in our industry-leading 0.12% failure rate over three years. We reject cost-driven compromises such as epoxy lens yellowing or undersized capacitors, delivering luminaires that perform as specified throughout their operational life.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and fully integrated LED lighting production facility designed to support high-volume manufacturing with strict quality control. Strategically located in the Jiangmen industrial zone, the facility benefits from streamlined logistics and access to a skilled manufacturing workforce, enabling efficient production and delivery for both domestic and international markets.

At the core of the factory’s operations is a fully automated Surface Mount Technology (SMT) production line. The SMT machines are state-of-the-art, capable of precise placement of LED components, drivers, and other surface-mounted devices onto printed circuit boards (PCBs). These machines are equipped with advanced vision systems and real-time monitoring to ensure placement accuracy, solder joint integrity, and overall consistency. The SMT line supports a wide range of component sizes and board configurations, allowing for flexible production of various lighting products, including panels, strips, and custom architectural modules.

Following assembly, all LED lighting products undergo rigorous aging tests to ensure reliability and performance. The factory maintains dedicated aging test chambers where products are operated continuously under controlled thermal and electrical conditions—typically at elevated temperatures and full load—for durations ranging from 4 to 24 hours. This process helps identify early-life failures, verifies thermal management efficiency, and confirms driver stability. Data from these tests are recorded and analyzed to support continuous improvement in design and manufacturing processes.

Beauty STC has strong OEM capabilities, particularly in the area of direct-indirect lighting solutions. The company can design and manufacture custom luminaires that distribute light both downward (direct) and upward (indirect), ideal for office, commercial, and institutional environments where balanced ambient lighting and visual comfort are critical. Their engineering team works closely with clients to customize optical performance, housing design, color temperature, dimming options, and control systems. From concept and prototyping to full-scale production, Beauty STC supports end-to-end OEM development with a focus on energy efficiency, compliance with international standards (such as UL, CE, and CCC), and on-time delivery.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, product reliability, and tailored lighting solutions for global partners.

Application Scenarios

Direct indirect lighting fixtures, which distribute light both downward toward the task plane and upward toward the ceiling, are particularly valuable in environments where visual comfort, reduced glare, and balanced ambient illumination are critical. In hotels, this approach is ideal for lobbies, lounge areas, and high-end guest corridors where creating a welcoming yet functional atmosphere is paramount. The upward component softens shadows and minimizes harsh contrasts, while the downward light ensures safe navigation and highlights architectural features or reception desks. For restaurants and bars within hotels, direct indirect lighting prevents the spotlight effect on dining tables, fostering intimacy without compromising visibility. Installation requires careful attention to ceiling reflectance; a matte white ceiling (reflectance >70%) is essential to effectively bounce the uplight, and fixtures should be spaced to avoid dark zones between luminaires, typically at 1.2 to 1.5 times the mounting height. Concealed mounting details are crucial in luxury settings to maintain clean sightlines.

Within malls and retail environments, direct indirect lighting excels in atriums, multi-story circulation spaces, and premium boutique areas where high ceilings make uniform illumination challenging. The uplight component eliminates the cave-like feeling often associated with deep retail spaces by brightening the vertical volume, while the direct light ensures merchandise displays remain adequately lit without creating distracting pools of brightness. This is especially effective in luxury brand zones where a refined, glare-free environment encourages prolonged browsing. Installation must prioritize uniformity to avoid visual fatigue across large floor areas; maintain consistent mounting heights and avoid placing fixtures directly above high-glare surfaces like polished floors. For optimal effect, integrate with perimeter daylighting strategies to balance interior brightness, and ensure the fixture cutoff angles prevent direct view of LEDs from common vantage points, which is critical for customer comfort in open-plan retail.

Offices represent the most widespread application for direct indirect lighting, particularly in open-plan workspaces, executive offices, and collaborative zones. The primary benefit here is reducing eye strain and headaches by eliminating harsh shadows on work surfaces and computer screens while providing sufficient ambient light to maintain circadian rhythm. The upward light component minimizes the contrast between bright task lamps and dim surroundings, a common cause of visual discomfort. Conference rooms benefit significantly as the balanced light ensures even facial illumination for video calls without casting deep shadows under eyes. Installation tips are highly specific: mounting height must align with workstation layouts—typically 2.4m to 3m above floor level—with spacing calculated to achieve a uniformity ratio below 0.7 (task plane to ceiling). Critical considerations include ensuring ceiling reflectance exceeds 80% for effective uplight distribution and avoiding placement directly above monitor-heavy desks to prevent screen reflections. Always verify the Unified Glare Rating (UGR) is below 19 for office tasks, and incorporate dimming controls to adjust the direct/indirect ratio based on daylight availability and task demands. Maintenance access must be planned during installation to facilitate easy lens or LED module replacement without disrupting ceiling systems.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium direct indirect lighting solutions. Designed for optimal light distribution and energy efficiency, our fixtures create balanced, comfortable environments ideal for commercial, hospitality, and architectural spaces. Partner with Beauty STC to access innovative designs, custom engineering support, and reliable manufacturing. For collaboration opportunities and expert guidance, contact us at [email protected]. Let us illuminate your vision together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.