Article Contents

Industry Insight: Diffuser Led Strip Light

The demand for high-performance, energy-efficient lighting solutions in commercial and industrial environments continues to accelerate, driven by evolving building standards, sustainability goals, and the need for uniform, glare-free illumination. Among the most innovative advancements in modern architectural and functional lighting is the diffuser LED strip light—a versatile and aesthetically refined system designed to deliver smooth, continuous light output with minimal hotspots. These systems are increasingly specified in offices, retail spaces, warehouses, healthcare facilities, and industrial plants where visual comfort, durability, and compliance with international safety standards are paramount.

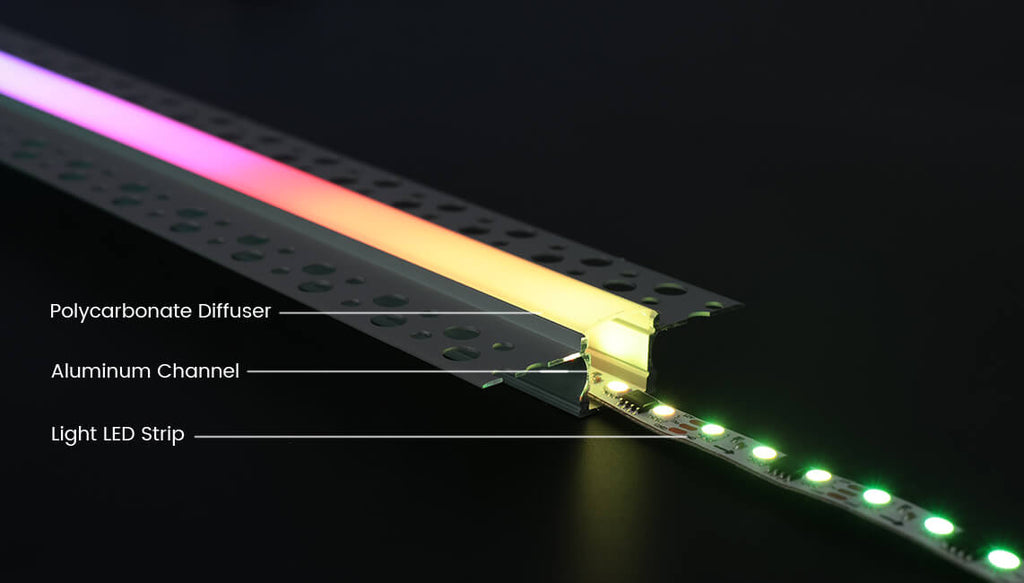

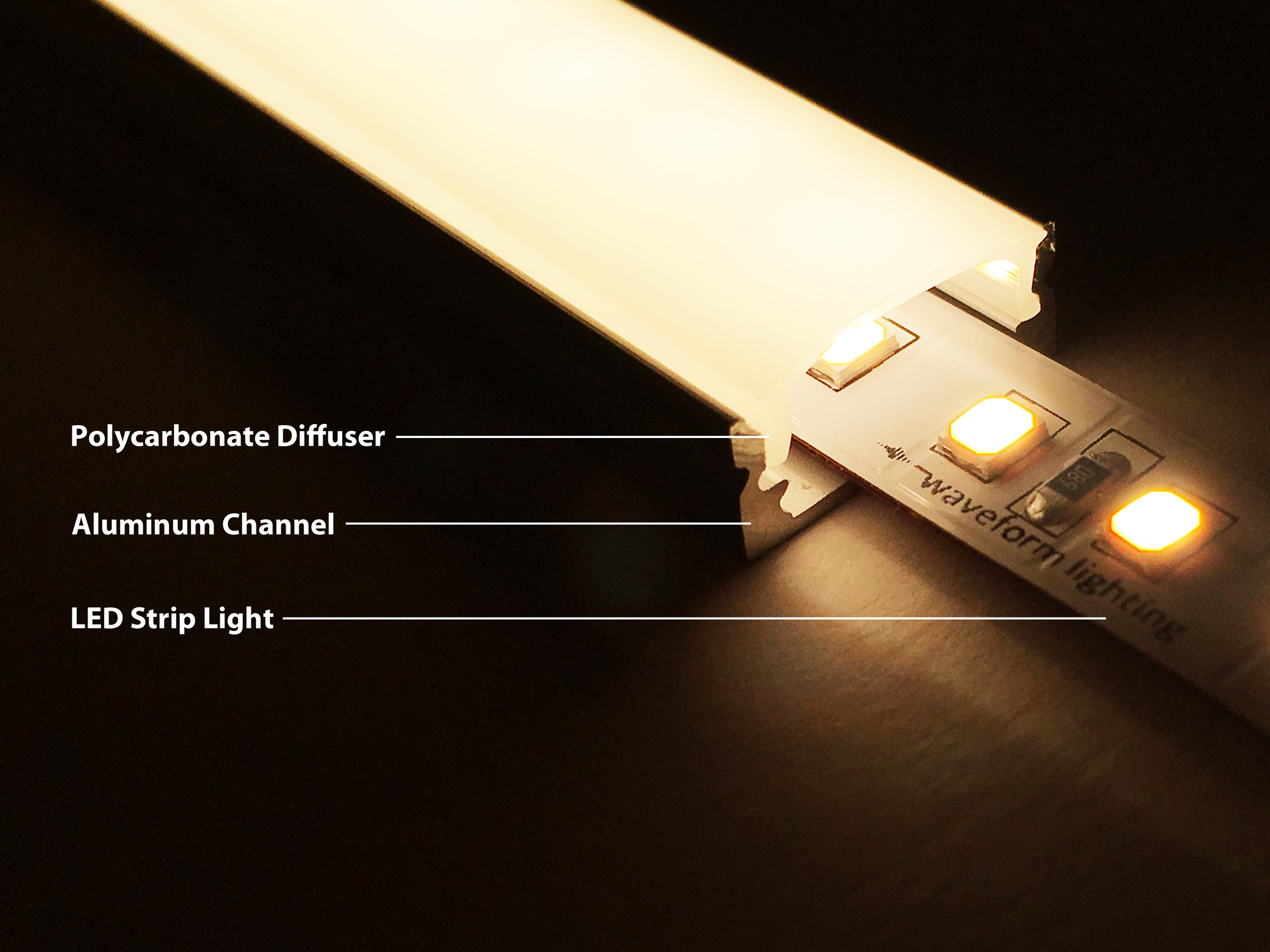

Diffuser LED strip lights integrate a polycarbonate or acrylic cover that evenly spreads light across the length of the strip, eliminating the pixelation effect common in bare LED tapes. This makes them ideal for cove lighting, under-shelf illumination, indirect ambient lighting, and task lighting applications where visual quality is critical. As commercial projects place greater emphasis on design integrity and energy efficiency, diffuser LED strips offer a seamless blend of form and function.

Compliance with recognized certifications such as ETL and CE ensures these lighting systems meet rigorous North American and European standards for electrical safety, performance, and electromagnetic compatibility—essential considerations for large-scale commercial deployments and regulatory approval. With mounting requirements for sustainable and low-maintenance lighting, diffuser LED strip lights not only reduce energy consumption but also offer long lifespans and minimal degradation over time.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-quality, code-compliant LED solutions for commercial and industrial applications, Beauty STC combines advanced optical engineering with robust manufacturing practices to deliver reliable, certified lighting systems trusted by architects, engineers, and contractors worldwide. As the industry shifts toward smarter, more integrated lighting ecosystems, Beauty STC remains committed to setting new benchmarks in performance, safety, and design flexibility with its diffuser LED strip light portfolio.

Technical Specs & Certifications

Beauty STC Manufacturing Co. Ltd. designs and produces diffuser LED strip light systems meeting stringent performance criteria for professional architectural and commercial applications. Our diffuser LED strip lights achieve a typical luminous efficacy range of 110 to 130 lumens per watt at 25°C ambient temperature under standard drive currents. This efficiency is maintained even with high CRI specifications through the use of premium bin-selected Samsung or Epistar LED chips and optimized constant current drivers. Efficacy naturally varies based on color temperature selection and drive current, with warmer CCTs (2700K-3000K) exhibiting slightly lower lm/W than neutral whites (4000K), though our engineering minimizes this delta.

Color rendering is a critical focus for Beauty STC. All diffuser LED strip light models targeting high-end retail, hospitality, and healthcare applications guarantee a minimum CRI (Ra) of 92, with typical production batches achieving Ra 94-96. Crucially, we prioritize R9 (saturated red) values of at least 50 and R12 (saturated blue) values exceeding 75 to ensure accurate rendering of vibrant colors and skin tones. This exceeds basic CRI>90 requirements and is validated using Konica Minolta CS-2000 spectroradiometers during final QA testing. The diffuser itself utilizes high-purity optical-grade PMMA with UV stabilizers to prevent yellowing and maintain spectral integrity over the product lifespan.

Regarding environmental protection, Beauty STC offers diffuser LED strip light systems in multiple IP-rated configurations. IP20 systems feature our standard opal or frosted polycarbonate diffusers for dry indoor use. For damp locations like bathrooms or covered outdoor areas, we provide IP65-rated solutions where the silicone diffuser cap forms a continuous seal over the LED strip within an aluminum profile, preventing water ingress from any direction. True IP67 models utilize welded end caps and specialized gaskets within robust aluminum housings, allowing temporary submersion. It is essential to note that the IP rating applies to the complete assembly (strip + profile + diffuser + end caps), not the diffuser alone. Beauty STC rigorously tests final assemblies per IEC 60529 standards in our in-house environmental chamber.

Beauty STC’s commitment to quality is embedded in every diffuser LED strip light system. We enforce strict component sourcing from Tier-1 suppliers, including Mean Well drivers and 6063-T5 aluminum profiles with anodized finishes for superior thermal management. Our manufacturing process incorporates automated SMT assembly with 100% AOI inspection and thermal stress testing. Each production batch undergoes extended burn-in and photometric validation, ensuring lumen maintenance of L70 >50,000 hours at 25°C. All products comply with UL, CE, and RoHS standards, with full traceability through our ERP system. This systematic approach results in diffuser LED strip lights delivering consistent optical performance, exceptional color fidelity, and reliable operation in demanding environments, reflecting Beauty STC’s reputation for engineering excellence in professional lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The Jiangmen factory is equipped with advanced surface mount technology (SMT) production lines, featuring high-precision SMT machines from leading manufacturers. These automated systems ensure accurate placement of LED components and other surface-mounted devices onto flexible and rigid printed circuit boards used in LED strip lights. The SMT lines are integrated with automatic optical inspection (AOI) systems to guarantee soldering quality and component alignment, significantly enhancing production efficiency and product reliability.

Following the SMT process, all diffuser LED strip lights undergo comprehensive aging tests within the Jiangmen facility. These tests simulate extended operational conditions, typically running the strips at full power for durations of 24 to 72 hours under controlled temperature and humidity environments. This rigorous testing ensures consistent performance, color stability, and longevity before any product is cleared for shipment. Additional quality checks include waterproof testing for relevant IP-rated models, electrical safety verification, and photometric measurements.

The factory has robust OEM and ODM capabilities specifically tailored for diffuser LED strip lights. Beauty STC can customize strip length, color temperature, lumen output, CRI, voltage (12V/24V), and control protocols (including dimmable and smart versions). The company supports private labeling, custom packaging, and bespoke diffuser profiles—such as frosted, transparent, or silicone-coated options—to meet specific design and performance requirements. With in-house R&D, tooling, and molding support, the Jiangmen facility efficiently handles small pilot runs as well as large-scale mass production for global clients, maintaining strict compliance with international standards such as CE, RoHS, and UL.

Application Scenarios

Diffuser LED strip lights are specifically engineered to eliminate the visible dotting effect of individual LEDs, creating a seamless, uniform glow ideal for high-end commercial environments where visual comfort and aesthetic refinement are critical. In hotels, these strips excel in guest room cove lighting above headboards or along perimeter ceilings to establish a soft, relaxing ambiance without harsh shadows. They are equally valuable in hotel lobbies for backlit reception desks or feature walls, where the diffused light enhances material textures while avoiding glare for guests. Corridor soffits also benefit from diffused strips, providing even illumination that guides movement without creating disorienting hotspots.

For malls and retail spaces, diffuser LED strips are indispensable in suspended ceiling coves to wash walls with light, highlighting architectural details or seasonal displays without distracting LED points. They are particularly effective in high-end jewelry or cosmetic counters where under-shelf mounting with a diffuser ensures products are illuminated evenly, eliminating shadows that could obscure details. Escalator undersides and feature stair treads also utilize diffused strips for safety lighting that blends seamlessly into the architecture rather than appearing as discrete light sources.

In office environments, diffuser LED strips solve common glare issues by mounting under desk surfaces to illuminate workspaces softly, reducing eye strain during prolonged computer use. They are equally effective in partition walls or suspended ceiling baffles to create indirect ambient lighting that minimizes contrast between screens and surroundings. Conference room perimeter coves with diffused strips foster a professional atmosphere during video calls by eliminating harsh facial shadows.

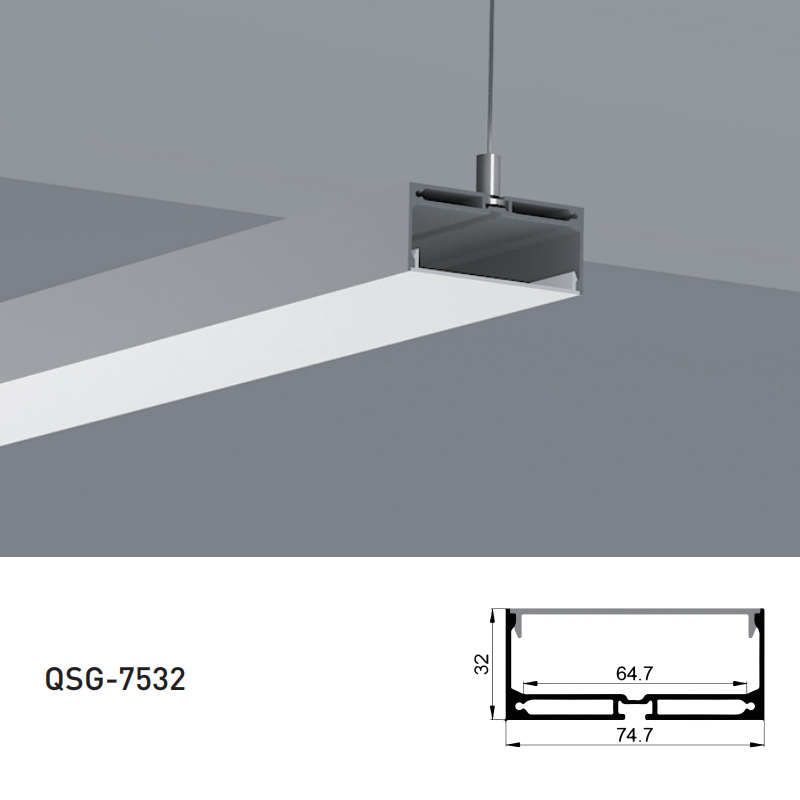

Installation requires strict adherence to technical protocols to maintain performance. Always mount diffuser strips within aluminum channels designed for thermal management; the channel’s heat-sinking capacity is non-negotiable for longevity, especially in enclosed coves. Maintain a 10-15mm gap between the strip and diffuser lens to prevent overheating and ensure optimal light mixing—less distance risks hotspots, while more causes light leakage. For runs exceeding 5 meters, power from both ends to counteract voltage drop, which manifests as dimming at the strip’s far end. Cut only at designated solder points marked on the strip, as improper cuts will disconnect LEDs and create dark sections. Finally, select diffusers matched to the strip’s beam angle; a 120-degree strip requires a wider diffuser profile than a 30-degree narrow-beam variant to achieve true uniformity. Neglecting these steps will compromise the seamless effect these products are engineered to deliver.

Why Choose Beauty STC Lighting

Discover the perfect solution for seamless, glare-free illumination with our diffuser LED strip lights. Engineered for superior light distribution and a clean, uniform glow, these strips are ideal for residential, commercial, and architectural applications. At Beauty (STC) Manufacturing Co., Ltd., we combine advanced technology with precision manufacturing to deliver high-performance lighting that meets the highest industry standards.

Partner with Beauty STC to elevate your lighting projects with reliable, energy-efficient, and beautifully diffused LED solutions. Our team is ready to support your business with custom options, bulk production, and dedicated service.

For collaboration or inquiries, contact us today at [email protected] and let’s create exceptional lighting together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.