Article Contents

Industry Insight: Diffused Led Strip

The evolution of LED strip lighting has reached a critical inflection point for commercial and industrial environments, where visual comfort, operational efficiency, and stringent safety standards are non-negotiable. Traditional LED strips, while energy-efficient, often produce harsh glare, visible dotting, and uneven illumination – shortcomings that directly undermine productivity in offices, detract from merchandise presentation in retail, and create safety hazards in warehouses or manufacturing facilities. Diffused LED strip technology has emerged as the definitive solution, utilizing advanced optical materials and precise engineering to deliver exceptionally uniform, shadow-free light that eliminates hotspots and reduces eye strain. This seamless luminance is no longer a luxury but a fundamental requirement for modern architectural integration, task lighting, and creating human-centric spaces that meet rigorous occupational health standards.

Crucially, deploying LED lighting in commercial and industrial settings demands absolute confidence in safety and regulatory compliance. Products must consistently adhere to regional electrical safety certifications, with ETL listing being essential for the North American market and CE marking mandatory for entry into the European Union. These certifications are not merely checkboxes; they validate critical aspects like electrical insulation, thermal management, and fire resistance, directly impacting facility safety, insurance requirements, and long-term operational reliability. Specifiers and facility managers prioritize suppliers who rigorously engineer and certify their diffused LED strips to meet these exacting benchmarks, ensuring installations are both high-performing and legally sound.

Beauty STC Manufacturing Co., Ltd. stands at the forefront of this precision lighting evolution. Established in 1998, we have dedicated over two decades to mastering the science of LED illumination, specifically focusing on the demanding requirements of commercial and industrial applications. Our engineering expertise is deeply rooted in solving real-world challenges – from developing diffusion profiles that maintain optimal lumen output while achieving perfect uniformity, to ensuring every meter of our LED strip is manufactured and rigorously tested to exceed ETL, CE, and other global safety standards. This unwavering commitment to engineered quality and regulatory compliance positions Beauty STC as a trusted partner for projects where lighting performance, safety, and durability are paramount.

Technical Specs & Certifications

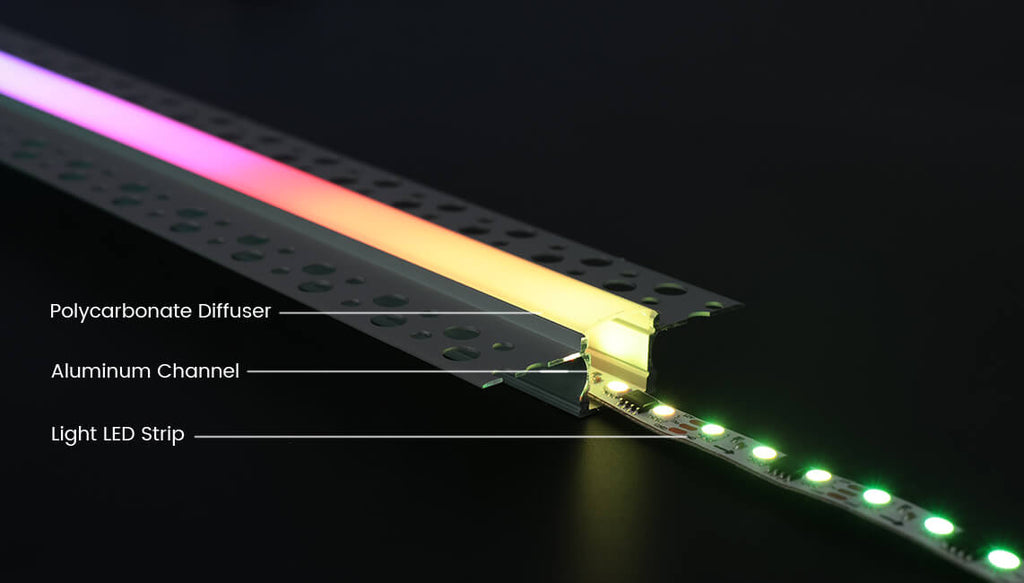

The diffused LED strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and consistent light quality, making it ideal for architectural, commercial, and premium residential lighting applications. These strips feature a specially designed silicone or PVC diffuser that ensures uniform light distribution with minimal dotting, delivering a smooth and continuous glow.

In terms of efficiency, Beauty STC’s diffused LED strips achieve a luminous efficacy ranging from 110 to 130 lumens per watt, depending on the specific configuration and color temperature. This high efficiency is maintained without compromising light quality, allowing for energy savings and reduced operational costs in both indoor and outdoor installations.

Color Rendering Index (CRI) is a critical focus for Beauty STC, and their diffused LED strips consistently deliver a CRI greater than 90, with select high-CRI models reaching up to 95. This ensures accurate and vibrant color representation, which is essential in environments where visual clarity and aesthetic appeal are paramount, such as retail displays, museums, and high-end hospitality settings.

Regarding environmental protection, Beauty STC provides diffused LED strips in multiple IP rating configurations to suit diverse application needs. Standard non-encapsulated strips are rated IP20, suitable for dry indoor environments. For damp or outdoor use, silicone-coated versions are available with IP65 rating, offering protection against dust and low-pressure water jets. Fully encapsulated strips with robust sealing achieve IP67 or even IP68 ratings, making them suitable for submersion in water up to 1 meter for limited durations, ideal for outdoor signage, landscape lighting, or marine environments.

Beauty STC maintains rigorous quality control throughout the manufacturing process, using high-grade SMD LEDs, precision-printed circuit boards, and durable diffuser materials. Their products undergo extensive thermal, electrical, and environmental testing to ensure long-term reliability, consistent lumen maintenance, and resistance to color shift over time. With a focus on innovation and durability, Beauty STC’s diffused LED strips represent a benchmark in performance, efficiency, and build quality within the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a dedicated LED lighting production facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta manufacturing hub. This modern 15,000 square meter factory is purpose-built for high-volume, precision LED product manufacturing, featuring climate-controlled production floors and stringent ESD protection protocols throughout. The facility is certified to ISO 9001 and ISO 14001 standards, ensuring rigorous quality management and environmental compliance across all operations.

Our surface mount technology (SMT) production lines form the core of our manufacturing capability for LED strips and modules. We deploy eight high-speed Yamaha YS24 and YSM20 SMT placement machines, configured in dual-gantry setups for maximum efficiency. These systems handle components from 0201 metric packages up to large LEDs and capacitors, achieving placement speeds exceeding 100,000 components per hour per line with ±25µm accuracy at 3 sigma. Each line integrates automated optical inspection (AOI) systems for real-time solder paste and component placement verification, coupled with in-circuit testing (ICT) stations for final electrical validation before aging. This infrastructure supports both high-mix prototyping and large-scale production runs with minimal changeover time.

Aging and reliability testing are critical to our quality assurance process, particularly for LED strip products. We maintain a dedicated 1,200 square meter aging chamber area with programmable environmental test systems. All diffused LED strips undergo mandatory 72-hour continuous aging at 50°C and 85% relative humidity, simulating years of operational stress in accelerated conditions. During this phase, strips operate at 110% of rated voltage while automated monitoring systems track luminous flux depreciation, chromaticity shift, and thermal performance. Any unit exhibiting flux drop exceeding 3% or color shift beyond MacAdam Step 3 is automatically rejected. This protocol ensures only units meeting our stringent reliability benchmarks reach customers.

Our OEM capability for diffused LED strips is a key strength, leveraging the factory’s integrated production flow from extrusion to final packaging. We specialize in custom diffused strips using proprietary polycarbonate (PC) covers that achieve consistent 120-degree beam angles with minimal hotspots. Clients can specify critical parameters including length per reel (from 1m to 500m), input voltage (12V/24V/48V DC), lumen output (800-2200 lm/m), color temperature (2200K-6500K CCT), and CRI (Ra>80 standard, Ra>90 optional). The factory supports custom diffusion levels through adjustable PC cover formulations, enabling tailored light distribution profiles. We accommodate specialized requests such as cut-point customization, bespoke labeling, unique packaging configurations, and integration of proprietary connectors. This end-to-end control from raw material sourcing to final aging allows us to deliver fully validated OEM diffused LED strip solutions meeting exact technical and aesthetic requirements within compressed lead times.

Application Scenarios

Diffused LED strips are ideal for environments where soft, uniform, and glare-free illumination is desired. Their frosted or milky silicone cover helps blend individual LED points into a continuous line of light, making them perfect for applications requiring aesthetic appeal and visual comfort.

In hotels, diffused LED strips are commonly used in guest rooms to outline headboards, under bed frames, or along cove ceilings to create a relaxing ambiance. They are also effective in hallways, lobbies, and restrooms where gentle indirect lighting enhances the guest experience. Backlighting mirrors in bathrooms with diffused strips provides even, flattering illumination without harsh shadows.

In malls, these strips are frequently installed in coves, soffits, and display niches to highlight architectural features or guide foot traffic with subtle lighting. They work well in signage backlighting, particularly for channel letters or illuminated logos, offering a smooth glow that improves brand visibility. Retail areas within malls also use diffused strips in shelving or product displays to enhance merchandise without causing glare.

Offices benefit from diffused LED strips in drop ceilings, under cabinets, or along stair edges for safety and modern aesthetics. They are often used in reception areas or meeting rooms to create a professional yet welcoming atmosphere. Task lighting under desks or shelves can also utilize diffused strips to reduce eye strain during prolonged work hours.

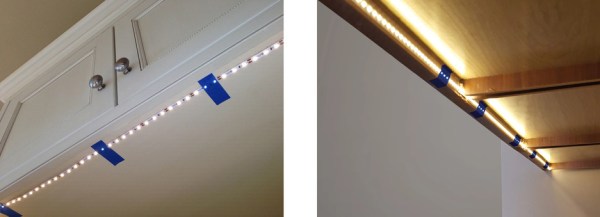

For installation, ensure the mounting surface is clean, dry, and free of dust to promote proper adhesion of the strip’s backing. Use aluminum channels whenever possible to improve heat dissipation and further enhance light diffusion. Always measure the run length accurately and avoid cutting the strip except at designated cut points. Connect the strips to a compatible low-voltage power supply, and consider using a dimmer for adjustable lighting levels. For longer runs, inject power from both ends to prevent voltage drop and maintain consistent brightness. Finally, ensure all connections are properly sealed, especially in high-humidity areas like restrooms, to prolong the lifespan of the installation.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with professional-grade diffused LED strips engineered for flawless, glare-free illumination. At Beauty STC Manufacturing Co. Ltd. we specialize in high-performance diffused LED solutions that eliminate visible dots and hotspots delivering seamless light distribution ideal for cove lighting retail displays architectural accents and premium interior applications. Our strips feature advanced opal silicone diffusers and precision binning to ensure consistent color temperature and optimal lumen output across every installation.

Partner with Beauty STC to access custom diffused LED strip configurations including flexible PCB options multiple CCT ranges and IP-rated variants tailored to your specific project demands. Our engineering team collaborates closely with clients from prototyping through production guaranteeing you receive a solution that meets rigorous performance standards and aesthetic requirements.

Contact our dedicated lighting solutions manager directly at [email protected] to discuss your diffused LED strip needs. Share your project specifications and we will provide technical guidance samples and a competitive quotation within 24 business hours. Trust Beauty STC’s decade of LED manufacturing excellence to elevate your next lighting design with reliable uniform illumination. Reach out today to start your collaboration.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.