Guide to Most Efficient Led Strip

- Introduction: Navigating the Global Market for most efficient led strip

- Understanding most efficient led strip Types and Variations

- Key Industrial Applications of most efficient led strip

- Strategic Material Selection Guide for most efficient led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for most efficient led strip

- Manufacturing and Quality Assurance of Highly Efficient LED Strips: Key Insights for International B2B Buyers

- Comprehensive Cost and Pricing Analysis for most efficient led strip Sourcing

- Spotlight on Potential most efficient led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for most efficient led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the most efficient led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of most efficient led strip

- Strategic Sourcing Conclusion and Outlook for most efficient led strip

Introduction: Navigating the Global Market for most efficient led strip

In today’s fast-evolving global lighting industry, selecting the most efficient LED strip is a strategic imperative for businesses aiming to optimize energy consumption, reduce operational costs, and enhance lighting quality. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of LED strip technology and supply chain intricacies is crucial to maintaining a competitive edge.

This comprehensive guide is designed to empower procurement professionals, project managers, and business owners with deep insights into the types of LED strips, key materials, manufacturing processes, and stringent quality control measures that define product efficiency and durability. By navigating supplier landscapes and cost variables, buyers will gain clarity on sourcing from reputable manufacturers and wholesalers who prioritize innovation and reliability.

Moreover, the guide addresses region-specific challenges such as logistics optimization, compliance with local standards, and scalability for diverse applications—from commercial installations in Mexico to industrial projects in Thailand. Through practical advice and detailed FAQs, international buyers will be equipped to make informed decisions that align with their unique operational demands and sustainability goals.

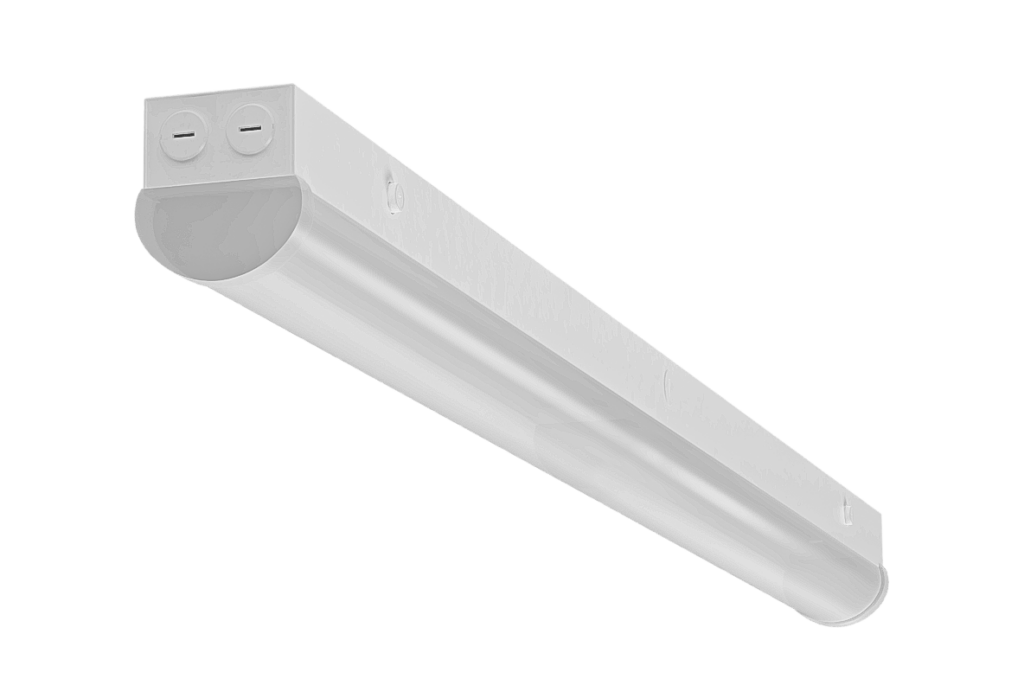

Illustrative Image (Source: Google Search)

Ultimately, this resource offers a strategic framework to streamline procurement, mitigate risks, and capitalize on the latest advancements in LED technology—ensuring your business secures the most efficient LED strip solutions that deliver superior performance and long-term value in a competitive global marketplace.

Understanding most efficient led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Density LED Strips | Closely spaced LEDs per meter for intense, uniform brightness | Retail displays, commercial lighting | + Superior brightness and color uniformity – Higher cost and power consumption |

| COB LED Strips | Chip-on-Board technology with continuous light source | Architectural lighting, hospitality | + Smooth, glare-free lighting – Limited color options, higher initial price |

| Waterproof LED Strips | Encapsulated with silicone or epoxy for moisture resistance | Outdoor installations, industrial sites | + Durable in harsh environments – Slightly reduced brightness due to coating |

| RGB & RGBW LED Strips | Multi-color LEDs with dynamic color-changing capabilities | Event venues, advertising, entertainment | + Versatile, customizable lighting effects – Requires controllers, more complex installation |

| Ultra-Low Power LED Strips | Designed for minimal energy consumption with moderate brightness | Energy-sensitive projects, residential | + Energy-efficient and cost-saving – Lower brightness, limited industrial use |

High-Density LED Strips

These strips feature a higher number of LEDs per meter, delivering bright and uniform illumination ideal for applications requiring intense light, such as retail displays and office environments. For B2B buyers, the focus should be on verifying LED quality and power requirements to balance brightness with energy costs. Bulk purchasing can reduce unit costs, but consider the higher power consumption in your operational budgeting.

COB LED Strips

Chip-on-Board LED strips provide a continuous, smooth light output without visible hotspots, making them perfect for architectural and hospitality lighting where aesthetic appeal is critical. Buyers should prioritize suppliers with proven COB technology and warranty coverage, as the upfront cost is higher but offers superior light quality and longevity, which benefits long-term projects.

Waterproof LED Strips

Encased in protective coatings, waterproof LED strips are essential for outdoor and industrial uses where exposure to moisture or dust is a concern. When sourcing, B2B buyers must verify IP ratings (commonly IP65 to IP68) and durability certifications. These strips may have slightly reduced brightness but offer resilience that minimizes replacement frequency and maintenance costs.

RGB & RGBW LED Strips

These strips allow dynamic color changes and are widely used in event venues, advertising, and entertainment industries. Buyers should assess compatibility with controllers and integration capabilities with existing lighting systems. While they offer high versatility, the complexity of installation and control systems means buyers must factor in additional training or technical support.

Ultra-Low Power LED Strips

Designed for projects with strict energy consumption targets, these strips offer moderate brightness at significantly reduced power usage. Suitable for residential or energy-conscious commercial applications, buyers should evaluate whether the brightness levels meet their needs and consider these strips for long-term cost savings. They are less suited for high-intensity industrial lighting but excellent for ambient or accent lighting.

Related Video: LED working & advantages | Semiconductors | Physics | Khan Academy

Key Industrial Applications of most efficient led strip

| Industry/Sector | Specific Application of most efficient led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and display lighting in stores and shopping malls | Enhances product visibility, attracts customers, reduces energy costs | High CRI for true color rendering, customizable lengths, dimmable features |

| Hospitality & Tourism | Ambient and decorative lighting in hotels, restaurants | Creates inviting atmosphere, improves guest experience, lowers maintenance | Waterproof and heat-resistant strips, compatibility with smart controls |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Improves worker safety and productivity, reduces downtime | Robust build quality, high lumen output, long lifespan, easy installation |

| Automotive & Transportation | Interior and exterior vehicle lighting, signage illumination | Energy-efficient illumination, enhances brand visibility, meets regulatory standards | Vibration-resistant, flexible design, temperature tolerance, certifications |

| Agriculture & Horticulture | Grow lights for controlled environment farming | Optimizes plant growth, reduces energy consumption, scalable setup | Specific light spectrum, waterproof, UV-resistant, energy efficiency ratings |

Retail & Commercial Lighting

In retail and commercial environments, the most efficient LED strips are widely used for accentuating product displays and architectural features. These strips help create visually appealing spaces that enhance customer engagement and increase sales. For international buyers, especially in emerging markets like Africa and South America, sourcing LED strips with high Color Rendering Index (CRI) is critical to showcase products accurately. Customizable lengths and dimmable functions allow businesses to tailor lighting to varied store layouts while controlling energy costs.

Hospitality & Tourism Ambiance

Hotels, restaurants, and resorts utilize efficient LED strips to craft ambient and decorative lighting that elevates guest experience. These strips contribute to a welcoming atmosphere while providing significant energy savings over traditional lighting. Buyers from regions such as the Middle East and Europe should prioritize waterproof and heat-resistant LED strips due to climatic conditions and the need for durability. Integration with smart lighting controls is increasingly important to offer dynamic lighting schemes that enhance brand identity and operational efficiency.

Manufacturing & Warehousing Safety

In industrial settings, efficient LED strips serve as task lighting on production lines and safety lighting in warehouses. Their bright, consistent illumination reduces accidents and improves worker productivity. International B2B buyers must focus on sourcing LED strips with high lumen output and robust build quality to withstand harsh environments. Easy installation and long lifespan are essential to minimize downtime and maintenance costs, which is especially relevant for large-scale operations in regions like Thailand and Mexico.

Automotive & Transportation Lighting

The automotive sector uses the most efficient LED strips for interior cabin lighting, exterior accent lights, and signage illumination. These applications demand LED strips that can resist vibrations, temperature fluctuations, and moisture exposure. B2B buyers should ensure compliance with regional safety and quality certifications. Flexible designs allow easy installation in diverse vehicle models, while energy efficiency contributes to overall vehicle performance and sustainability goals.

Agriculture & Horticulture Grow Lights

In controlled environment agriculture, efficient LED strips tailored for plant growth provide specific light spectra that enhance photosynthesis and crop yield. These strips are energy-efficient and scalable, making them ideal for commercial greenhouses and vertical farms. Buyers from Europe, South America, and Africa should look for waterproof, UV-resistant LED strips with verified energy efficiency ratings to ensure durability and cost-effectiveness in various climatic conditions. This application supports sustainable farming practices and reduces operational costs.

Strategic Material Selection Guide for most efficient led strip

Aluminum: The Industry Standard for Efficient LED Strips

Aluminum is the most widely used material for LED strip housings and heat sinks due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. It efficiently dissipates heat generated by LED chips, which is critical for maintaining luminous efficacy and prolonging lifespan. Aluminum alloys commonly used in LED strips can withstand moderate temperature ranges (up to around 150°C) and offer good resistance to environmental factors such as humidity and UV exposure.

Pros: Aluminum’s high thermal conductivity ensures optimal heat management, reducing the risk of LED degradation. It is relatively easy to extrude into various profiles, allowing for customizable designs. Aluminum is also recyclable, aligning with sustainability goals important to many international buyers.

Cons: While corrosion-resistant, aluminum can oxidize over time if not properly anodized or coated, especially in highly humid or saline environments. Manufacturing complexity is moderate, requiring precise extrusion and finishing processes, which can affect lead times.

Impact on Application: Aluminum LED strips are ideal for indoor and outdoor applications, including commercial lighting, architectural accents, and industrial environments. Its corrosion resistance makes it suitable for regions with high humidity or coastal areas, common in parts of Africa and the Middle East.

Considerations for International Buyers: Buyers from Africa, South America, and the Middle East should verify that aluminum components comply with international standards such as ASTM B221 for extrusion quality and ISO 209-1 for anodizing. European buyers often require RoHS compliance and adherence to REACH regulations. Ensuring suppliers provide proper certification for these standards helps avoid customs delays and ensures product reliability.

Flexible Printed Circuit Boards (FPC) with Polyimide Substrates

The flexible base material for LED strips is often a polyimide-based FPC, prized for its flexibility, high thermal stability, and electrical insulation properties. Polyimide can withstand temperatures up to 260°C, making it suitable for high-power LED strips that generate more heat.

Pros: Polyimide FPCs allow LED strips to bend and conform to irregular surfaces, expanding application possibilities. Their excellent thermal resistance supports high-efficiency LEDs without compromising safety. They also resist chemical corrosion and maintain electrical integrity over time.

Cons: Polyimide materials are more expensive than standard polyester substrates, increasing overall product cost. Handling and manufacturing require specialized equipment, which can impact supply chain complexity and lead times.

Impact on Application: Polyimide-based LED strips are preferred in applications requiring flexibility and durability, such as automotive lighting, wearable tech, and architectural installations. Their chemical resistance makes them suitable for industrial environments common in South America and Southeast Asia.

Considerations for International Buyers: Buyers should ensure polyimide FPCs meet IPC-4203 standards for flexible printed boards and verify compliance with UL94 V-0 flammability ratings, especially for markets with stringent safety regulations like Europe. Importers in Africa and the Middle East should confirm compatibility with local electrical codes and certifications.

Silicone Coating for Waterproof and Outdoor Durability

Silicone encapsulation or coating is frequently applied to LED strips to enhance waterproofing and protect against dust, UV radiation, and mechanical damage. Silicone’s elasticity and weather resistance make it superior to traditional epoxy coatings for outdoor and harsh environment applications.

Pros: Silicone coatings provide IP65 to IP68 waterproof ratings, enabling LED strips to operate reliably in wet or dusty conditions. They maintain flexibility and do not yellow significantly over time, preserving light quality. Silicone also offers excellent thermal stability, supporting efficient heat dissipation.

Cons: Silicone-coated strips are generally more expensive due to the additional material and processing steps. The coating process can increase manufacturing time and complexity. Silicone’s softness may reduce abrasion resistance compared to harder coatings.

Impact on Application: Ideal for outdoor signage, landscape lighting, and marine applications prevalent in Middle Eastern and African markets where extreme weather conditions are common. Silicone coatings also suit installations in humid tropical climates like Southeast Asia and parts of South America.

Considerations for International Buyers: It is important to verify that silicone coatings comply with IEC 60529 for ingress protection and UV resistance standards such as ASTM G154. Buyers should also assess the supplier’s quality control for consistent coating thickness and adhesion to prevent early failures.

Copper Traces for Electrical Efficiency

Copper is the standard conductive material used for the LED strip’s circuitry due to its excellent electrical conductivity and thermal performance. Copper traces on the PCB ensure minimal voltage drop and efficient power delivery to the LEDs.

Pros: Copper’s high conductivity reduces energy losses, contributing directly to the overall efficiency of the LED strip. It supports higher current loads, enabling brighter and longer strips without compromising performance. Copper is widely available and well-understood in manufacturing.

Cons: Copper is susceptible to oxidation if not properly coated or plated, which can degrade performance over time. It adds to the material cost compared to alternative metals like aluminum in circuitry. Manufacturing requires precise etching and plating processes to maintain quality.

Impact on Application: Copper-based LED strips are essential for high-performance lighting applications requiring consistent brightness and energy efficiency, such as commercial and industrial installations across Europe and South America.

Considerations for International Buyers: Buyers should ensure copper traces meet IPC-6012 standards for rigid PCBs or IPC-6013 for flexible PCBs. Compliance with RoHS directives restricting hazardous substances is critical, especially for European markets. Proper plating (e.g., tin or gold) should be confirmed to prevent corrosion in humid or saline environments common in Africa and the Middle East.

| Material | Typical Use Case for most efficient led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks and housings for indoor/outdoor LED strips | Excellent thermal conductivity and corrosion resistance | Can oxidize without proper coating; moderate manufacturing complexity | Medium |

| Polyimide FPC | Flexible LED strip bases for high-temperature and flexible applications | High thermal stability and flexibility | Higher cost and specialized manufacturing | High |

| Silicone Coating | Waterproofing and outdoor protection for LED strips | Superior waterproofing and UV resistance | Increased cost and softer surface prone to abrasion | High |

| Copper Traces | Electrical circuitry for efficient power delivery | High electrical conductivity and thermal performance | Susceptible to oxidation; requires plating | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for most efficient led strip

Manufacturing and Quality Assurance of Highly Efficient LED Strips: Key Insights for International B2B Buyers

Understanding the manufacturing processes and quality assurance (QA) practices behind the most efficient LED strips is essential for B2B buyers seeking reliable suppliers and superior products. This knowledge empowers buyers from Africa, South America, the Middle East, and Europe—including markets like Thailand and Mexico—to make informed procurement decisions, optimize supply chains, and ensure compliance with international standards.

Core Manufacturing Stages of Efficient LED Strips

The production of high-efficiency LED strips involves a series of precise and controlled steps. Each stage is critical to achieving optimal performance, durability, and energy efficiency.

-

Material Preparation

– Component Sourcing: High-quality LED chips (commonly SMD LEDs), flexible printed circuit boards (FPCBs), resistors, connectors, and phosphor coatings are sourced. The selection of premium semiconductor materials directly influences luminous efficacy and lifespan.

– Raw Material Inspection: Incoming materials undergo rigorous inspection for conformity in size, electrical properties, and purity to prevent defects downstream. -

Forming and Circuit Board Fabrication

– FPCB Manufacturing: Flexible circuit boards are fabricated using copper foil laminates and insulating substrates (polyimide or polyester). Precision etching and layering techniques ensure minimal resistance and heat dissipation.

– Solder Mask Application: Protective solder masks are applied to prevent short circuits and protect the circuitry from moisture and contaminants. -

Assembly

– LED Placement: Automated pick-and-place machines position LED chips onto the FPCB with micron-level accuracy, critical for uniform light distribution.

– Soldering: Reflow soldering or wave soldering techniques securely attach LEDs and components to the board, ensuring strong electrical and mechanical connections.

– Encapsulation: LEDs may be coated with phosphor or epoxy resin to enhance color consistency and protect against environmental factors. -

Finishing and Packaging

– Cutting and Sectioning: LED strips are cut into standard or custom lengths per client requirements.

– Waterproofing: For outdoor or industrial applications, strips receive conformal coatings or are sealed with silicone to achieve IP65/IP67 ratings.

– Labeling and Branding: Custom packaging and labeling ensure traceability and support branding needs.

– Final Inspection: Visual and functional checks confirm the absence of defects before shipment.

Quality Assurance Frameworks and Industry Standards

Adhering to internationally recognized quality standards is vital for ensuring product reliability and market acceptance.

- ISO 9001:2015 (Quality Management System)

-

This standard mandates a documented process approach, continual improvement, and customer focus. Suppliers certified under ISO 9001 demonstrate consistent quality control throughout manufacturing.

-

CE Marking (European Conformity)

-

Required for products sold in the European Economic Area, CE marking confirms compliance with health, safety, and environmental protection standards.

-

RoHS (Restriction of Hazardous Substances)

-

Ensures LED strips are free from hazardous materials like lead, mercury, and cadmium, important for environmental compliance globally.

-

UL Certification (Underwriters Laboratories)

-

Particularly relevant for North American and some international markets, UL certification verifies electrical safety.

-

IP Rating (Ingress Protection)

-

Defines the water and dust resistance level of LED strips, critical for outdoor and harsh environment applications.

-

Other Regional Standards

- Buyers from the Middle East and Africa should verify compliance with local electrical standards (e.g., SASO in Saudi Arabia).

- South American markets may require INMETRO certification for electrical products.

- Thailand and other ASEAN countries often align with IEC standards, but local certifications may apply.

Quality Control Checkpoints and Testing Methods

A robust QA process involves multiple inspection points to detect and mitigate defects early and maintain consistent product quality.

- Incoming Quality Control (IQC)

-

Inspects raw materials and components upon arrival for specifications such as LED lumen output, FPCB integrity, and connector compatibility.

-

In-Process Quality Control (IPQC)

-

Monitors manufacturing steps, including solder joint integrity, LED placement accuracy, and assembly parameters, using automated optical inspection (AOI) systems.

-

Final Quality Control (FQC)

-

Conducts end-of-line testing including:

- Electrical Testing: Verifies voltage, current, and power consumption to ensure efficiency targets.

- Photometric Testing: Measures brightness, color temperature, and uniformity.

- Environmental Testing: Includes thermal cycling and moisture resistance to simulate real-world conditions.

- Mechanical Testing: Checks flexibility, adhesion, and durability under bending or vibration.

-

Reliability Testing

- Extended aging tests under elevated temperatures to confirm long-term performance and lifespan estimates.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, particularly in diverse markets, verifying supplier QA practices is crucial to mitigate risks.

- Factory Audits

-

Conduct on-site or third-party audits assessing manufacturing capabilities, quality systems, and production environment.

-

Review of Quality Documentation

-

Request certificates such as ISO 9001, CE, RoHS, and test reports (e.g., photometric and electrical testing).

-

Sample Testing

-

Insist on receiving product samples for independent laboratory testing to confirm claimed efficiencies and compliance.

-

Third-Party Inspections

-

Employ inspection agencies to perform random batch testing before shipment, verifying conformity to specifications.

-

Supplier Performance Monitoring

- Track defect rates, delivery punctuality, and responsiveness to quality issues as ongoing performance indicators.

Considerations for International Buyers from Africa, South America, the Middle East, and Europe

- Regulatory Compliance

-

Understand and ensure compliance with both exporting country standards and importing country regulations to avoid customs delays or product rejection.

-

Supply Chain Transparency

-

Demand detailed production and QC process documentation to maintain traceability and accountability.

-

Localization of Quality Requirements

-

Some regions may have unique environmental or electrical standards; work with suppliers familiar with these nuances.

-

Logistics and Packaging

-

Ensure packaging protects against humidity and mechanical damage during long transit routes common in these regions.

-

After-Sales Support and Warranty

- Confirm warranty terms and availability of spare parts or replacements, critical for markets with limited local technical support.

In summary, a deep understanding of the manufacturing steps, quality control measures, and international standards governing efficient LED strip production empowers B2B buyers to select reliable suppliers, ensure product excellence, and reduce risks associated with bulk LED strip procurement. By leveraging factory audits, certifications, and sample verifications, buyers across Africa, South America, the Middle East, and Europe can confidently source LED strips that meet stringent performance and safety expectations, enabling successful project outcomes and customer satisfaction.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for most efficient led strip Sourcing

Understanding the Cost Structure of Efficient LED Strip Sourcing

When sourcing the most efficient LED strips for B2B purposes, understanding the detailed cost components is essential to optimize procurement and maximize ROI. The primary cost elements include:

- Materials: This is the largest component, encompassing LED chips, flexible circuit boards, drivers, connectors, and protective coatings. High-efficiency LEDs often use premium semiconductor materials, which can increase costs but improve energy savings and lifespan.

- Labor: Skilled labor for assembly, soldering, and quality checks impacts overall costs. Manufacturers in regions with lower labor costs may offer competitive pricing but must be vetted for quality standards.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient production lines with automation can reduce overhead per unit.

- Tooling: Custom molds, cutting dies, and assembly jigs represent upfront investments that spread over production volume. Tooling costs can be amortized better with larger orders.

- Quality Control (QC): Testing for brightness uniformity, color accuracy, waterproof ratings, and safety certifications (e.g., CE, RoHS) adds to costs but ensures reliability.

- Logistics: Freight, customs duties, insurance, and warehousing fees must be factored in, especially for international shipments to Africa, South America, the Middle East, and Europe.

- Margin: Suppliers include profit margins that vary based on market positioning, exclusivity, and order volume.

Key Price Influencers in LED Strip Procurement

Several factors influence the final price of LED strips, making it critical for buyers to evaluate these variables carefully:

- Order Volume / Minimum Order Quantity (MOQ): Larger volumes generally unlock tiered discounts and reduce per-unit tooling and logistics costs. However, very high MOQs may increase inventory holding costs.

- Product Specifications and Customization: Features such as color temperature, brightness (lumens), waterproofing (IP rating), dimmability, and smart controls (Wi-Fi or app integration) impact pricing. Customized lengths, packaging, or branding also add to costs.

- Material Quality and Certifications: Premium LEDs with certifications for energy efficiency and safety command higher prices but reduce long-term risk and maintenance costs.

- Supplier Location and Reliability: Proximity to buyer markets can reduce shipping time and costs. Established suppliers with proven track records may charge a premium but offer better service, warranty, and supply security.

- Incoterms and Shipping Terms: Terms like FOB, CIF, or DDP determine who bears shipping risks and costs. Understanding these can prevent unexpected expenses and simplify customs clearance.

Actionable Buyer Tips for Cost-Efficient LED Strip Sourcing

To ensure a competitive total cost of ownership (TCO) and avoid common pitfalls, international B2B buyers should consider the following strategies:

- Negotiate Based on Volume and Long-Term Partnerships: Leverage bulk purchasing power to negotiate better pricing, payment terms, and flexible MOQs. Building long-term supplier relationships can unlock preferential pricing and priority during supply chain disruptions.

- Evaluate Total Cost of Ownership Beyond Unit Price: Consider energy savings from higher-efficiency LEDs, reduced replacement frequency due to better durability, and warranty terms. Sometimes a higher upfront cost leads to lower TCO.

- Request Detailed Cost Breakdowns: Insist suppliers provide transparent pricing that separates material, labor, logistics, and margin components. This clarity aids in benchmarking and negotiating.

- Factor in Local Import Taxes and Compliance: Buyers from regions like Africa, the Middle East, and South America should research import duties, certification requirements, and customs procedures to avoid delays and additional costs.

- Consolidate Shipments and Optimize Logistics: Combining orders or choosing suppliers with local distribution centers in target markets can reduce freight charges and lead times.

- Test Samples Before Large Commitments: Especially for buyers in diverse markets such as Europe and Thailand, testing sample batches for quality, compatibility, and durability ensures the product meets local standards and customer expectations.

Indicative Pricing Disclaimer

Due to the variability in specifications, order sizes, supplier locations, and market conditions, LED strip prices can range widely. Buyers should treat quoted prices as indicative and conduct thorough due diligence to obtain accurate, up-to-date quotations tailored to their unique requirements.

By analyzing these cost and pricing factors and applying strategic procurement practices, international B2B buyers can confidently source the most efficient LED strips that balance upfront investment with long-term value and operational efficiency.

Spotlight on Potential most efficient led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘most efficient led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for most efficient led strip

Critical Technical Properties of the Most Efficient LED Strips

Understanding key technical specifications is essential for B2B buyers to ensure the LED strips meet project requirements, quality standards, and cost-effectiveness. Here are the most important properties to evaluate:

-

Luminous Efficacy (lm/W)

This measures how many lumens (light output) are produced per watt of electricity consumed. Higher luminous efficacy indicates better energy efficiency, which directly reduces operational costs and environmental impact. For international buyers, prioritizing strips with high efficacy is crucial for long-term savings and sustainability goals. -

Color Rendering Index (CRI)

CRI indicates how accurately the LED strip displays colors compared to natural light, rated on a scale from 0 to 100. A CRI above 80 is generally suitable for most commercial applications, while 90+ is preferred in retail or hospitality environments where true color representation is critical. Selecting strips with the appropriate CRI enhances the user experience and product appeal. -

IP Rating (Ingress Protection)

This rating defines the strip’s resistance to dust and water, essential for determining suitability for indoor or outdoor use. For example, IP20 is standard for indoor environments, whereas IP65 or higher is necessary for outdoor or wet locations. Knowing the IP rating helps buyers avoid premature product failures and costly replacements. -

LED Chip Quality and Type

The LED chip is the core light source; high-quality chips from reputable manufacturers (e.g., Cree, Samsung) ensure consistent brightness, longevity, and reliability. Different chip sizes and technologies (SMD 2835, 5050, 3528) affect brightness and power consumption. Buyers should specify chip types to match performance expectations and budget. -

Voltage and Power Consumption

Common LED strips operate on 12V or 24V DC. Higher voltage strips (24V) typically allow longer runs without voltage drop, improving efficiency for large installations. Understanding voltage requirements ensures compatibility with existing power supplies and reduces installation complexity. -

Material Grade and Tolerance

The quality of the strip’s PCB (printed circuit board) and soldering tolerance affects heat dissipation and durability. High-grade materials reduce the risk of overheating and failure, important for maintaining efficiency over the product lifespan. Buyers should request detailed material specs and quality certifications.

Key Industry and Trade Terminology for LED Strip Buyers

Navigating international LED strip procurement involves familiarity with common trade terms and jargon. Here are essential terms to know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be branded or customized for the buyer. OEM partnerships allow buyers to tailor product specifications, packaging, and branding, crucial for differentiation in competitive markets. -

MOQ (Minimum Order Quantity)

The smallest quantity of LED strips a supplier will accept per order. Understanding MOQ helps buyers plan inventory and cash flow, especially when balancing bulk discounts against storage capacity and project timelines. -

RFQ (Request for Quotation)

A formal process where buyers request pricing and terms from suppliers. RFQs enable buyers to compare costs, lead times, and service conditions, facilitating informed procurement decisions. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Clarifying Incoterms prevents misunderstandings and unexpected costs in international transactions. -

Bin Number

Refers to the classification of LED chips based on brightness and color consistency. Lower bin numbers indicate higher quality and tighter color tolerances. Buyers focused on uniformity and premium applications should request bin-specific products. -

Dimmability

Indicates whether the LED strip supports brightness adjustment via compatible controllers. Dimmable strips offer flexibility in lighting design and energy savings, often required for advanced commercial or hospitality projects.

By prioritizing these technical properties and mastering key trade terminology, international B2B buyers can confidently source the most efficient LED strips tailored to their operational needs, budget constraints, and market demands. This knowledge reduces risks, optimizes supply chain decisions, and ultimately drives better business outcomes across diverse regions including Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the most efficient led strip Sector

Market Overview & Key Trends

The global market for the most efficient LED strips is driven by increasing demand for energy-saving lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Thailand and Mexico—are capitalizing on LED strip technologies to reduce operational costs and meet stricter energy regulations. Governments worldwide are incentivizing energy-efficient lighting adoption, creating a robust growth trajectory for LED strips with superior luminous efficacy and longevity.

Illustrative Image (Source: Google Search)

Current market dynamics emphasize cost efficiency, scalability, and technological innovation. Buyers are increasingly seeking LED strips with integrated smart controls, dimmability, and customizable color options to cater to diverse applications. The surge in IoT-enabled smart lighting solutions is reshaping sourcing strategies, as businesses prioritize suppliers who can deliver advanced, interoperable products. Additionally, regional market preferences influence product specifications; for example, waterproof and UV-resistant strips are in high demand in Middle Eastern and African outdoor installations, whereas European buyers emphasize strict compliance with RoHS and CE certifications.

Supply chain agility remains a critical factor. B2B buyers benefit from suppliers who maintain diversified sourcing networks for key components such as LED modules and drivers, minimizing risks associated with geopolitical tensions or raw material shortages. Efficient logistics and inventory management are also pivotal, especially for buyers managing large-scale projects across multiple countries. Leveraging digital platforms for real-time inventory tracking and demand forecasting is becoming standard practice among forward-thinking businesses.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional in the LED strip sector; it is a strategic imperative. The environmental impact of lighting products—from raw material extraction to end-of-life disposal—has led B2B buyers to prioritize eco-friendly materials and responsible manufacturing practices. The most efficient LED strips now incorporate lead-free soldering, recyclable substrates, and low-impact packaging to reduce carbon footprints.

Ethical sourcing is equally critical. Buyers are increasingly demanding transparency and traceability in the supply chain to ensure compliance with labor standards and environmental regulations. Partnering with suppliers who hold recognized certifications such as Energy Star, UL Environment, and TÜV Rheinland’s Green Product Mark reassures buyers that products meet stringent sustainability criteria. Moreover, certifications like ISO 14001 for environmental management system compliance demonstrate a supplier’s commitment to minimizing ecological impact.

For regions with emerging markets, such as Africa and South America, sustainable sourcing is not only about environmental benefits but also social impact. Investing in suppliers that support fair labor practices and community development can enhance corporate social responsibility profiles and mitigate reputational risks. B2B buyers should actively engage in supplier audits and favor manufacturers who integrate sustainability into product design and lifecycle management, ensuring long-term value and regulatory adherence.

Evolution and Historical Context

The evolution of LED strip technology has been marked by rapid advancements in efficiency and versatility. Initially developed as simple decorative lighting, LED strips have transformed into sophisticated, high-performance lighting solutions over the past two decades. Early models suffered from limited brightness, poor color rendering, and short lifespans, restricting their application scope.

With breakthroughs in semiconductor technology and materials science, modern LED strips now achieve luminous efficacies exceeding 150 lumens per watt, rivaling traditional lighting while consuming a fraction of the energy. The integration of flexible printed circuit boards and miniaturized drivers has expanded installation possibilities across complex architectural and industrial environments.

This historical progression underscores the importance for B2B buyers to stay informed about technological milestones and emerging innovations. Investing in the most efficient LED strips today means leveraging decades of refinement, resulting in products that offer superior performance, reduced operational costs, and enhanced adaptability for diverse international markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of most efficient led strip

-

How can international B2B buyers verify the credibility of LED strip suppliers?

To ensure supplier reliability, buyers should conduct thorough due diligence by checking business licenses, certifications (such as ISO or CE), and customer reviews. Requesting factory audits or virtual tours can provide insight into manufacturing capabilities and quality control processes. Engaging with suppliers who have experience exporting to regions like Africa, South America, the Middle East, and Europe ensures familiarity with international trade regulations and logistics. Additionally, requesting product samples before large orders helps verify product quality firsthand. -

What customization options are typically available for most efficient LED strips in bulk orders?

Wholesale LED strip suppliers often offer customization in length, color temperature, brightness levels, waterproof ratings, and packaging. Buyers can also request custom branding on packaging and LED strips to align with their company identity. For specific projects, options like dimmable features, RGB color controls, or smart connectivity can be tailored. Clarifying these requirements upfront with suppliers helps avoid miscommunication and ensures the final product meets precise functional and aesthetic needs. -

What are the typical minimum order quantities (MOQs) and lead times for efficient LED strip orders?

MOQs vary widely depending on supplier and product complexity but generally range from 500 to 5,000 meters for standard LED strips. Custom orders may require higher MOQs due to setup costs. Lead times typically span 2 to 6 weeks, influenced by order size, customization, and current supply chain conditions. Buyers should confirm MOQs and lead times early to align procurement schedules, especially when managing projects with tight deadlines or coordinating multiple suppliers. -

Which payment terms and methods are advisable for international LED strip transactions?

Common international payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and escrow services. For new suppliers, using secure methods like L/Cs protects buyers by ensuring payment is only released upon meeting agreed terms. Established relationships may allow more flexible terms such as partial upfront payment with balance on delivery. Always negotiate clear payment schedules and verify supplier bank details to mitigate fraud risks and ensure smooth financial transactions. -

How can buyers ensure the quality and efficiency of LED strips meet international standards?

Requesting compliance certificates such as CE (Europe), RoHS (environmental safety), UL (safety standards), and Energy Star (energy efficiency) is critical. Insist on third-party testing reports to verify lumen output, power consumption, and lifespan claims. Incorporating sample testing and quality assurance checkpoints during production helps detect defects early. Partnering with suppliers who have robust quality management systems and transparent QA procedures reduces the risk of receiving substandard or inefficient products. -

What logistics considerations should international buyers keep in mind for LED strip imports?

Understanding import regulations, customs duties, and documentation requirements in the destination country is essential to avoid delays. Choose suppliers with experience in international shipping and who offer reliable freight options (air, sea, or express courier) suited to your timeline and budget. Packaging must protect LED strips from moisture and physical damage during transit. Additionally, consider warehousing and last-mile delivery capabilities to ensure efficient distribution within your region. -

How should disputes regarding product quality or delivery delays be managed in international B2B transactions?

Establish clear contractual terms covering quality standards, inspection rights, penalties for delays, and return policies before placing orders. In case of disputes, maintain detailed communication records and provide evidence such as photos or inspection reports. Utilizing third-party arbitration or mediation can facilitate resolution without costly litigation. Building strong supplier relationships and transparent communication channels often preempt misunderstandings and foster quicker conflict resolution. -

What strategies can buyers use to mitigate supply chain risks when sourcing efficient LED strips internationally?

Diversifying suppliers across different regions reduces dependency on a single source and buffers against geopolitical or logistical disruptions. Employing supply chain management software enhances visibility into inventory, order status, and shipping progress. Planning orders with buffer stock and flexible delivery schedules accommodates unforeseen delays. Finally, cultivating close partnerships with LED module suppliers ensures priority access to critical components, supporting consistent product quality and timely fulfillment.

Strategic Sourcing Conclusion and Outlook for most efficient led strip

Efficient sourcing of LED strip lights is a cornerstone for businesses aiming to optimize costs, ensure product quality, and meet evolving market demands. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, building strong supplier relationships and diversifying procurement channels are essential strategies to mitigate risks and secure consistent supply. Prioritizing suppliers who provide high-performance LED modules, transparent warranties, and customization options enables companies to tailor solutions that align with diverse application needs and regional requirements.

Moreover, leveraging technology-driven supply chain management tools enhances inventory visibility and responsiveness, reducing lead times and improving customer satisfaction. Bulk purchasing not only delivers cost advantages but also ensures scalability for large-scale projects, a critical factor for rapidly growing markets in emerging economies.

Looking ahead, buyers should stay attuned to innovations such as smart LED strips and energy-efficient designs that offer competitive differentiation. Embracing a proactive, data-informed sourcing approach will empower businesses to capitalize on the full potential of LED lighting technology while navigating global supply dynamics effectively.

Take the next step by engaging with trusted global suppliers, requesting product samples, and investing in supply chain optimization—position your business to lead in the sustainable, cost-efficient lighting revolution worldwide.