Introduction: Navigating the Global Market for w2812 led strip

The WS2812 LED strip has emerged as a pivotal component in the global lighting and digital display markets, offering unparalleled flexibility and precision through its individually addressable RGB LEDs. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of WS2812 LED strips is crucial to sourcing high-quality products that meet diverse application needs, from architectural lighting to interactive installations.

This comprehensive guide delves deeply into the various types of WS2812 LED strips, highlighting distinctions in LED density, waterproofing options, and form factors. It also examines critical aspects such as material specifications, manufacturing standards, and quality control protocols that influence product reliability and longevity. Buyers will find detailed insights into supplier landscapes across key regions, enabling strategic selection based on cost-efficiency, supply chain stability, and compliance with international standards.

Moreover, this guide addresses market trends and pricing considerations, empowering buyers to negotiate effectively and forecast procurement budgets with confidence. A dedicated FAQ section clarifies common technical and logistical queries, streamlining the decision-making process.

By integrating these multifaceted perspectives, this resource equips international B2B buyers with actionable intelligence to optimize their sourcing strategies, mitigate risks, and capitalize on emerging opportunities in the vibrant global WS2812 LED strip market. Whether procuring for cutting-edge commercial projects or scalable industrial applications, this guide is an essential tool for making informed, strategic purchasing decisions.

Understanding w2812 led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard WS2812B Strip | Addressable RGB LEDs, 30 LEDs/meter density, 5V power, flexible PCB | Architectural lighting, retail displays, event decoration | + Cost-effective, easy integration – Lower LED density limits fine detail |

| High-Density WS2812B Strip | Increased LED density (60 LEDs/meter or more), enhanced brightness | Digital signage, high-detail visual effects, interactive installations | + Superior color resolution and brightness – Higher power consumption, costlier |

| Waterproof WS2812B Strip | Silicone or epoxy coating for moisture protection, IP65 to IP67 ratings | Outdoor advertising, landscape lighting, marine applications | + Weather resistant, durable – Slightly reduced flexibility, higher price |

| Dual-Row WS2812B Strip | Two parallel rows of LEDs for greater brightness and uniformity | Large-scale displays, stage lighting, commercial signage | + Increased luminosity and coverage – Bulkier, more complex installation |

| Custom Length & Segment Strips | Pre-cuttable segments, customizable lengths, varied LED spacing | Custom projects, prototyping, bespoke installations | + Tailored to project needs, reduces waste – Requires precise planning, potential supply complexity |

The Standard WS2812B Strip is the most common variant, featuring 30 addressable RGB LEDs per meter. Its flexibility and ease of integration make it ideal for general-purpose lighting such as architectural accents and retail environments. For B2B buyers, this type offers a balance of cost efficiency and functionality, suitable for projects where ultra-high resolution lighting is not critical.

High-Density WS2812B Strips double the LED count to 60 or more per meter, delivering finer color gradients and enhanced brightness. These are preferred in markets demanding detailed visual effects such as digital signage and interactive displays. Buyers should consider the increased power requirements and upfront costs, which are justified by superior performance in demanding installations.

The Waterproof WS2812B Strip variant is coated with silicone or epoxy, offering protection against moisture and dust with IP ratings ranging from IP65 to IP67. This makes them indispensable for outdoor or harsh environment applications like landscape lighting and marine signage. While these strips cost more and may sacrifice some flexibility, their durability and weather resistance are key purchasing criteria for international buyers targeting outdoor solutions.

Dual-Row WS2812B Strips arrange LEDs in two parallel lines, significantly boosting brightness and light uniformity. These are often used in large-scale commercial signage and stage lighting where visual impact is critical. Buyers should be aware that these strips require more complex installation and space considerations but provide enhanced luminosity for high-profile displays.

Finally, Custom Length & Segment Strips offer pre-cuttable segments and variable LED spacing, catering to bespoke projects and prototyping needs. This flexibility reduces material waste and adapts to unique design specifications. B2B purchasers should plan carefully to align supply with project demands, as customization may affect lead times and inventory management.

Related Video: WS2811 VS WS2812 LED Strip Light

Key Industrial Applications of w2812 led strip

| Industry/Sector | Specific Application of w2812 led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Dynamic store displays and signage lighting | Enhances customer engagement and brand visibility | Waterproofing for outdoor displays, flexible strip length, consistent color control for branding |

| Entertainment & Events | Stage lighting and immersive visual effects | Creates captivating experiences, customizable lighting | High LED density for smooth effects, durable build for frequent setup/teardown |

| Hospitality & Tourism | Ambient lighting in hotels, restaurants, and resorts | Improves guest experience with mood lighting | Energy efficiency, ease of installation, long lifespan to reduce maintenance costs |

| Automotive & Transportation | Customizable interior and exterior vehicle lighting | Differentiates vehicle aesthetics, improves safety | Compliance with local electrical standards, robust waterproof designs, flexible form factors |

| Smart Building & Automation | Intelligent lighting systems with IoT integration | Enables energy savings and adaptive lighting control | Compatibility with controllers, scalability, reliable supply chain for large projects |

The Retail & Commercial sector leverages WS2812 LED strips primarily in dynamic store displays and signage lighting. These strips allow businesses to create vivid, eye-catching lighting effects that can be programmed to change colors and patterns, attracting customer attention and enhancing brand visibility. For international buyers, especially from regions like Africa and South America where outdoor advertising faces environmental challenges, sourcing waterproof and UV-resistant strips with precise color control is essential to maintain durability and consistent brand representation.

Illustrative Image (Source: Google Search)

In Entertainment & Events, WS2812 strips are widely used for stage lighting and immersive visual effects. Their ability to control each LED individually enables complex animations and synchronized light shows that elevate performances and events. Buyers from the Middle East and Europe should prioritize high LED density strips for smooth gradients and ensure the products are rugged enough to withstand repeated installation and transport, as well as compatible with popular lighting control systems.

The Hospitality & Tourism industry integrates WS2812 LED strips for ambient lighting in hotels, restaurants, and resorts. These strips help create tailored atmospheres that enhance guest comfort and satisfaction. Energy efficiency and ease of installation are critical factors for buyers in this sector, particularly in regions like the UK and Mexico, where energy costs and labor efficiency are key concerns. Long lifespan and low maintenance LED strips reduce operational costs over time.

In the Automotive & Transportation sector, WS2812 LED strips are employed for customizable interior and exterior vehicle lighting. These applications include accent lighting, dashboard illumination, and safety signals. International B2B buyers must ensure compliance with local electrical and safety standards, especially in Europe and South America, where regulatory requirements can be stringent. Additionally, waterproof and vibration-resistant strips are vital for automotive durability.

Finally, Smart Building & Automation projects utilize WS2812 LED strips as part of intelligent lighting systems integrated with IoT platforms. These systems provide adaptive lighting control, contributing to energy savings and enhanced user comfort. Buyers should look for LED strips that are compatible with common microcontrollers and smart home protocols, scalable to large installations, and sourced from reliable suppliers capable of supporting large volume orders, a consideration important for markets in Africa and the Middle East embarking on smart infrastructure development.

Related Video: The BEST FastLED Tutorial | WS2812b LED Strip Arduino Nano

Strategic Material Selection Guide for w2812 led strip

When selecting materials for WS2812 LED strips, international B2B buyers must carefully evaluate options based on environmental conditions, durability, cost, and compliance with regional standards. The material choice directly impacts the strip’s longevity, performance, and suitability for specific applications, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

1. Flexible PCB (Polyimide or FR4 Substrate)

Key Properties:

Flexible PCBs used in WS2812 strips typically employ polyimide or FR4 substrates. Polyimide offers excellent thermal stability (up to 260°C), chemical resistance, and flexibility, while FR4 is rigid and less heat tolerant (up to ~130°C). Both materials provide good electrical insulation and mechanical strength.

Pros & Cons:

Polyimide flexible PCBs are highly durable under bending and twisting, making them ideal for dynamic installations. They resist moisture and moderate chemical exposure but are more expensive than FR4. FR4 PCBs are cost-effective and widely available but lack flexibility and are prone to cracking under stress.

Impact on Application:

Flexible PCBs enable custom shapes and curved installations, common in architectural lighting or wearable tech. Polyimide’s higher temperature tolerance suits environments with fluctuating heat, such as outdoor installations in hot climates (e.g., Middle East, parts of Africa). FR4 is better suited for static, indoor applications.

B2B Considerations:

Buyers in Europe and the UK often require compliance with RoHS and REACH standards, which polyimide substrates typically meet. In South America and Africa, cost sensitivity may favor FR4, but buyers should ensure material certification to avoid counterfeit or substandard PCBs. Polyimide’s durability justifies higher costs for premium projects, especially in harsh environments.

2. Silicone Encapsulation (Weatherproof Coating)

Key Properties:

Silicone encapsulation provides waterproofing, UV resistance, and flexibility. It withstands temperatures from -50°C to 200°C and resists dust, moisture, and many chemicals, making it ideal for outdoor or industrial applications.

Pros & Cons:

Silicone coating offers excellent protection against environmental factors, extending product life in harsh conditions. However, it increases manufacturing complexity and cost. The material can also slightly reduce heat dissipation compared to bare strips, necessitating proper thermal management.

Impact on Application:

Silicone-encapsulated WS2812 strips are preferred for outdoor lighting, signage, and marine environments. In regions with high humidity or heavy rainfall (e.g., parts of South America and Africa), silicone ensures reliability. It also meets IP65-IP67 standards, crucial for buyers targeting regulated markets in Europe and the Middle East.

B2B Considerations:

International buyers should verify IP rating certifications and compliance with local electrical safety standards (e.g., IEC, DIN). Silicone encapsulation is favored in Europe and the Middle East for outdoor projects, while buyers in emerging markets must balance cost versus environmental durability.

3. PVC (Polyvinyl Chloride) Coating

Key Properties:

PVC coatings provide basic moisture resistance and mechanical protection. They are generally less flexible than silicone and have a narrower temperature range (-20°C to 60°C). PVC is prone to degradation under UV exposure and may emit harmful fumes if burned.

Pros & Cons:

PVC is a low-cost option with decent durability for indoor applications. It is easier to manufacture and widely available, making it attractive for budget-conscious buyers. However, its environmental resistance is limited, and it is not recommended for prolonged outdoor use.

Impact on Application:

PVC-coated WS2812 strips are suitable for indoor decorative lighting, retail displays, and controlled environments. They are less appropriate for outdoor or industrial settings, especially in regions with high UV exposure or temperature extremes.

B2B Considerations:

Buyers in Europe and the UK must consider stringent environmental and safety regulations restricting PVC use due to toxicity concerns. In South America and Africa, PVC may be acceptable for cost-sensitive indoor projects but requires caution for export to regulated markets.

4. Aluminum Backing (Heat Dissipation Layer)

Key Properties:

Aluminum backing provides excellent thermal conductivity, helping to dissipate heat generated by the LEDs. It also adds mechanical rigidity and corrosion resistance when anodized or coated.

Pros & Cons:

Aluminum-backed strips enhance LED lifespan by preventing overheating and improve mounting options on metal surfaces. The downside is increased weight and cost, and reduced flexibility compared to pure flexible PCB strips.

Impact on Application:

Ideal for high-brightness installations, industrial lighting, or environments with poor airflow. Aluminum backing is beneficial in hot climates (Middle East, parts of Africa) where thermal management is critical.

B2B Considerations:

European and Middle Eastern buyers often require anodized aluminum for corrosion resistance and compliance with local standards (e.g., DIN EN). South American and African buyers should verify aluminum quality and surface treatment to avoid premature corrosion in humid or coastal areas.

| Material | Typical Use Case for WS2812 LED Strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB (Polyimide/FR4) | Indoor/outdoor flexible lighting, wearable tech | High thermal stability and flexibility (polyimide); cost-effective (FR4) | FR4 lacks flexibility and lower heat tolerance; polyimide is costly | Polyimide: High; FR4: Low-Med |

| Silicone Encapsulation | Outdoor, waterproof, and industrial lighting | Excellent environmental protection and flexibility | Increased manufacturing complexity and cost; potential heat retention | High |

| PVC Coating | Indoor decorative lighting and budget projects | Low cost and easy manufacturing | Limited UV and temperature resistance; environmental concerns | Low |

| Aluminum Backing | High-brightness, industrial, and heat-sensitive applications | Superior heat dissipation and mechanical strength | Reduced flexibility and higher weight | Medium-High |

This guide equips international B2B buyers with insights to select materials that align with their regional requirements, application demands, and budget constraints, ensuring optimal performance and compliance for WS2812 LED strip deployments.

In-depth Look: Manufacturing Processes and Quality Assurance for w2812 led strip

Manufacturing Processes of WS2812B LED Strips

The production of WS2812B LED strips involves a series of carefully controlled stages designed to ensure high functionality, durability, and visual performance. Understanding these stages helps B2B buyers assess supplier capabilities and product quality.

1. Material Preparation

- Raw Materials Sourcing: High-quality flexible printed circuit boards (FPCBs), WS2812B LEDs (each containing integrated control IC), resistors, capacitors, and waterproof coatings are sourced. Suppliers often require traceability and certifications for components, especially for electronics destined for regulated markets.

- Substrate Preparation: The FPCB substrate is cleaned and prepared to ensure strong adhesion and electrical conductivity. Copper traces are etched to form the circuit pathways.

- LED and Component Inspection: Incoming LEDs and electronic components undergo initial quality checks (Incoming Quality Control – IQC) to verify electrical parameters, packaging integrity, and compliance with specifications.

2. Forming and Circuit Assembly

- Surface Mount Technology (SMT): Automated SMT machines place WS2812B LEDs and associated components onto the FPCB with precision. This stage demands high accuracy to avoid misalignment which can cause malfunction.

- Soldering: Reflow soldering is typically used to secure LEDs and components. Consistent temperature control is critical to avoid damaging the integrated chips inside each LED.

- Visual and Automated Optical Inspection (AOI): Post-soldering, the strips undergo AOI to detect soldering defects such as bridges, cold joints, or missing components.

3. Programming and Functional Testing

- Data Line Programming: Each WS2812B LED contains a built-in IC that requires programming for addressability and color control. This is done through automated testing fixtures that send signals and verify responses.

- Electrical Testing: Power consumption, voltage levels, and signal integrity are tested to confirm each LED responds correctly to control inputs.

- Burn-in Testing: LED strips are powered on for extended periods under controlled conditions to identify early-life failures.

4. Finishing and Protection

- Encapsulation: Depending on intended use (indoor/outdoor), strips may be coated with silicone, epoxy, or waterproof resin. This enhances durability against moisture, dust, and mechanical stress.

- Cutting and Connector Attachment: Strips are cut into standard lengths or customized sizes. Connectors or solder pads are affixed for ease of installation.

- Labeling and Packaging: Final products are labeled with batch numbers, certifications, and handling instructions before packaging. Packaging often includes anti-static and moisture barrier materials.

Quality Assurance and Control (QA/QC) Framework

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality assurance practices is crucial to mitigate risks associated with electronic component failures and compliance issues.

Relevant International Standards and Certifications

- ISO 9001: The foundational quality management system standard ensuring consistent manufacturing processes, documentation, and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area (EEA), verifying compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restriction of hazardous substances is critical for electronics sold in Europe and increasingly demanded worldwide.

- UL Certification: Ensures electrical safety, particularly important for buyers in the Americas and some Middle Eastern markets.

- REACH Compliance: Pertains to chemical safety regulations relevant for Europe.

- Industry-Specific Certifications: Some buyers may require additional marks like FCC (for electromagnetic compatibility) or API certifications for specialized industrial applications.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components before assembly. This prevents defective or substandard parts from entering production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, placement accuracy, and electrical functionality. Automated optical inspection and manual visual checks are common.

- Final Quality Control (FQC): Comprehensive testing of finished strips, including:

- Visual inspection for physical defects

- Electrical testing for LED functionality and color accuracy

- Waterproofing integrity tests if applicable

- Packaging inspection to ensure correct labeling and protection

Common Testing Methods for WS2812B LED Strips

- Electrical Performance Tests: Measure voltage, current, and signal response of each LED to ensure correct operation under varying loads.

- Color Calibration: Verify that each LED produces the intended RGB color output at specified brightness levels.

- Environmental Testing: Simulate exposure to humidity, temperature extremes, and UV to validate durability for outdoor or industrial use.

- Mechanical Flexibility Tests: Evaluate the strip’s ability to bend without damage, critical for installation in curved or irregular surfaces.

- Burn-in and Aging Tests: Long-duration operation under full load to detect early failures or degradation.

How B2B Buyers Can Verify Supplier QC

1. Factory Audits

- On-site Visits: Inspect manufacturing processes, equipment, and worker training. Confirm adherence to documented quality standards.

- Process Capability Review: Assess supplier’s ability to maintain consistent production quality and meet volume demands.

- Compliance Verification: Check documentation for certifications (ISO 9001, CE, RoHS, UL, etc.) and traceability of components.

2. Quality Reports and Documentation

- Material Certificates: Supplier should provide certificates of conformity (CoC) for raw materials and components.

- Test Reports: Request batch-level test results including electrical performance, visual inspections, and environmental tests.

- Failure Analysis Records: Review how the supplier addresses defects and implements corrective actions.

3. Third-Party Inspections

- Engage independent inspection agencies to conduct pre-shipment inspections, including:

- Random sampling and testing of finished products

- Packaging and labeling verification

- Compliance with buyer-specific requirements

QC and Certification Nuances for International Buyers

- Africa & South America: Buyers often face challenges due to varying local regulations and import requirements. Ensuring that suppliers have international certifications like CE, RoHS, and UL can ease customs clearance and guarantee product safety.

- Middle East: Compliance with regional standards such as GSO (Gulf Standards Organization) may be necessary alongside international marks. Waterproof and high-temperature tolerant versions of WS2812B strips are preferred due to climate.

- Europe (e.g., UK): Post-Brexit, UKCA marking may be required in addition to CE. Buyers should verify that suppliers keep abreast of evolving regulations.

- Mexico: NAFTA/USMCA trade agreements facilitate import, but Mexican standards (NOM) compliance and proper documentation remain important.

Key Takeaways for International B2B Buyers

- Prioritize suppliers with robust quality management systems certified under ISO 9001 and relevant product certifications (CE, RoHS, UL).

- Verify that the manufacturing process includes rigorous IQC, IPQC, and FQC checkpoints to reduce defect rates and ensure reliability.

- Request detailed test reports and consider third-party inspections to independently confirm quality claims.

- Understand regional regulatory requirements to avoid customs issues and ensure market compliance.

- Insist on clear traceability of components and transparent communication on failure analysis and corrective actions.

By thoroughly evaluating manufacturing processes and quality assurance protocols, B2B buyers can confidently source WS2812B LED strips that meet their performance needs and regulatory obligations across diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for w2812 led strip Sourcing

When sourcing WS2812 LED strips for international B2B projects, understanding the detailed cost structure and pricing drivers is crucial for optimizing procurement strategies and ensuring competitive margins. This analysis breaks down the key cost components, price influencers, and practical tips tailored for buyers from Africa, South America, the Middle East, and Europe, including markets like the UK and Mexico.

Core Cost Components in WS2812 LED Strip Manufacturing

-

Materials: The primary cost driver is the raw components—WS2812B LEDs, flexible PCB substrates, protective coatings (silicone or epoxy for waterproofing), connectors, and solder. Higher LED density strips (e.g., 60 LEDs/meter) and waterproof versions command premium material costs.

-

Labor: Assembly of LED strips involves precise soldering and quality checks, often done in regions with competitive labor rates to maintain cost efficiency. Labor intensity increases with customization and quality requirements.

-

Manufacturing Overhead: Includes factory utilities, machine depreciation, and indirect labor. Facilities with automation capabilities may offer better pricing due to efficiency gains.

-

Tooling: Initial setup for manufacturing WS2812 strips—such as PCB stamping molds and soldering jigs—incurs one-time or amortized costs impacting unit pricing, especially for low-volume or customized orders.

-

Quality Control (QC): Rigorous QC processes to test LED functionality, color accuracy, and waterproofing integrity add to cost but are essential for reducing returns and warranty claims, particularly important for buyers seeking certifications.

-

Logistics and Shipping: International freight (air or sea), customs duties, and local delivery costs vary significantly by region. For buyers in Africa and South America, longer transit times and customs complexities can increase landed cost.

-

Supplier Margin: Margins vary based on supplier scale, exclusivity of components, and service level. Established suppliers with certifications and consistent quality may price higher but reduce risk and Total Cost of Ownership (TCO).

Key Price Influencers for WS2812 LED Strips

-

Order Volume and Minimum Order Quantities (MOQ): Bulk orders substantially reduce per-unit costs due to economies of scale. Buyers should negotiate MOQs aligned with demand forecasts to avoid excessive inventory holding costs.

-

Specifications and Customization: Custom LED densities, waterproofing levels, strip length, and connector types increase costs. Standardized products typically offer better price points.

-

Material Quality and Certifications: Strips with ROHS compliance, CE certification, or UL listing command premiums but open access to regulated markets in Europe and parts of the Middle East.

-

Supplier Location and Reliability: Proximity to manufacturing hubs in Asia (notably China) often lowers costs but may increase lead times. Verified suppliers with transparent supply chains reduce risks.

-

Incoterms and Payment Terms: Understanding Incoterms (e.g., FOB, CIF, DDP) affects pricing transparency and risk allocation. Buyers in emerging markets should factor in customs clearance complexity and consider DDP for smoother delivery.

Strategic Buyer Insights for International B2B Procurement

-

Negotiate on Volume and Payment Terms: Leverage larger orders or long-term contracts to secure discounts. Flexible payment terms can improve cash flow without compromising supplier relationships.

-

Evaluate Total Cost of Ownership (TCO): Go beyond unit price to include shipping, import duties, potential rework costs, and warranty services. For example, a slightly higher price for certified waterproof strips can reduce replacement and maintenance expenses in humid climates.

-

Prioritize Quality and After-Sales Support: Especially in regions like Africa and South America where replacement logistics may be challenging, reliable quality and supplier support reduce downtime and additional costs.

-

Understand Regional Pricing Nuances: European buyers may face stricter compliance requirements, increasing price but lowering regulatory risk. Middle Eastern buyers should consider local VAT and import policies. Latin American and African buyers should prepare for variable customs delays impacting inventory planning.

-

Use Incoterms Wisely: Choosing DDP (Delivered Duty Paid) can simplify import procedures for buyers unfamiliar with customs but may increase upfront cost. FOB (Free On Board) reduces supplier responsibility post-shipment but requires buyers to manage logistics and clearance.

Indicative Pricing Disclaimer

WS2812 LED strip pricing varies widely based on specifications, order size, and market conditions. Typical FOB factory prices for standard 5-meter strips with 30 LEDs/meter range approximately from USD 5 to USD 15 per unit. Higher-density or waterproof versions and custom lengths increase costs accordingly. Buyers should request detailed quotations considering their exact requirements and negotiate based on total landed cost.

By carefully analyzing these cost factors and market dynamics, international B2B buyers can make informed sourcing decisions, optimize procurement budgets, and ensure consistent supply of WS2812 LED strips tailored to their project needs.

Spotlight on Potential w2812 led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘w2812 led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for w2812 led strip

Critical Technical Properties of WS2812B LED Strips

1. LED Density (LEDs per Meter)

This defines how many individual LEDs are packed within one meter of strip, commonly 30 or 60 LEDs/meter. Higher density strips offer smoother color gradients and more detailed lighting effects, which is crucial for applications requiring high precision and visual quality. For buyers, selecting the right density impacts both cost and project outcome.

2. Power Consumption and Voltage

WS2812B strips operate at a nominal 5V DC. Each LED can draw up to 60mA at full brightness (white color), making power supply capacity a critical factor. Underestimating power needs can cause voltage drops and inconsistent lighting. B2B buyers must ensure their power infrastructure matches strip length and density to avoid operational failures.

3. Waterproof Rating (IP Code)

Many WS2812B strips come with IP65, IP67, or IP68 ratings, indicating resistance to water and dust. This property is essential for outdoor or industrial installations in climates common across Africa, the Middle East, and Europe. Selecting the appropriate waterproof rating ensures durability and reduces maintenance costs.

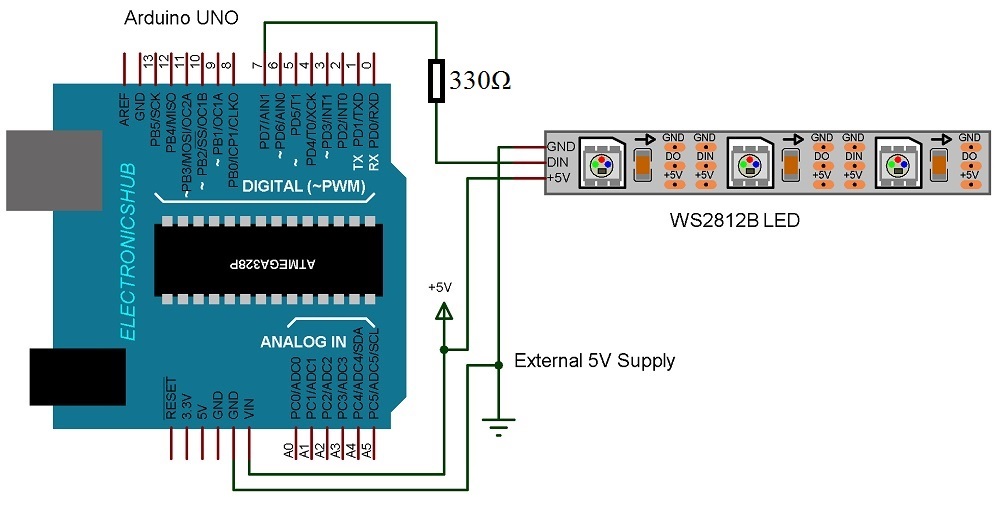

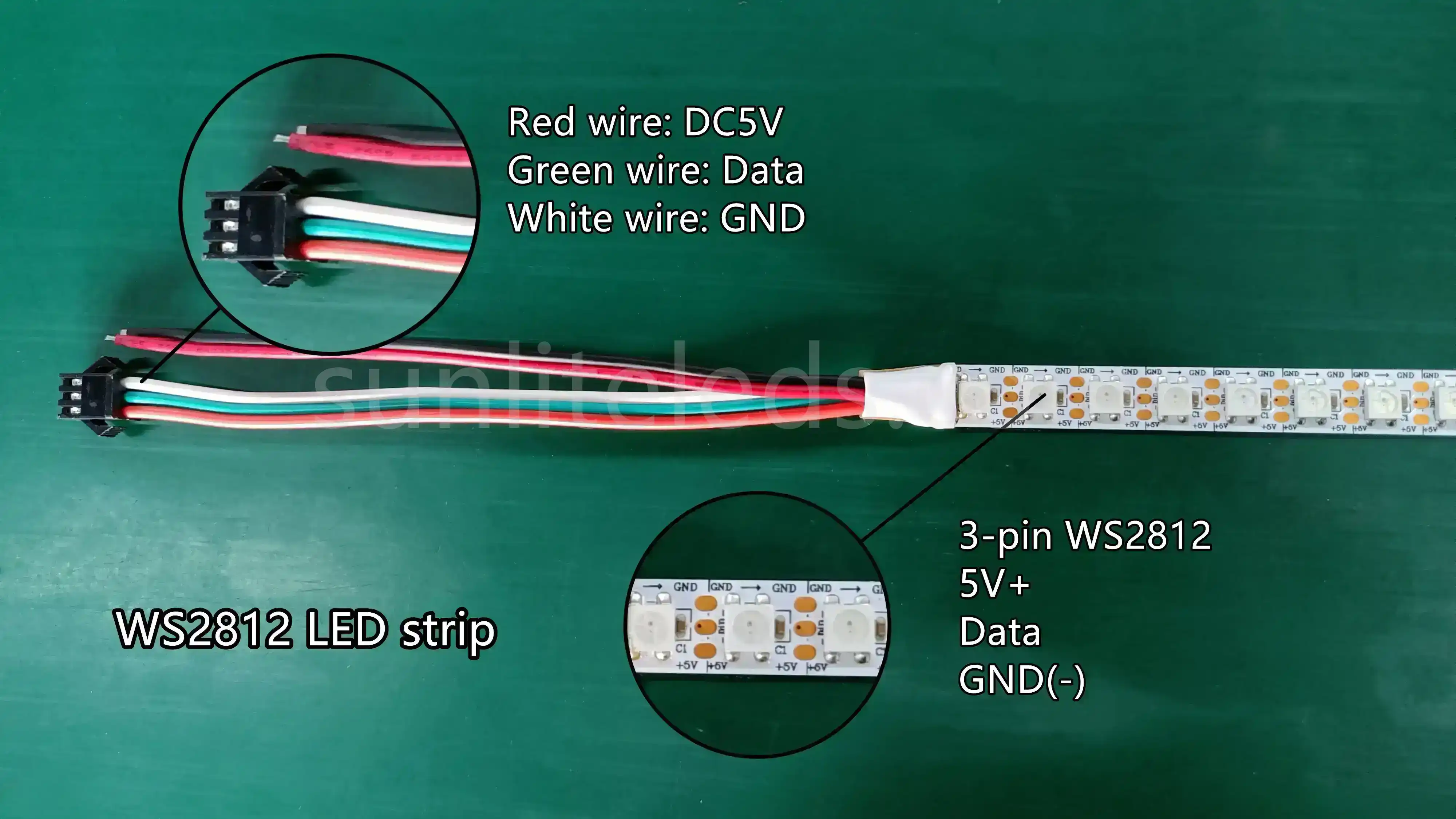

4. Control Protocol and Signal Type

WS2812B uses a single-wire digital control protocol with an integrated IC per LED for individual addressability. Understanding this protocol is important for system integration, especially when connecting with microcontrollers like Arduino or Raspberry Pi. It affects compatibility and complexity of programming in B2B projects.

5. Flexibility and Cut-ability

The physical flexibility of the strip and the ability to cut it into segments (usually at marked intervals of one LED) allows customization to fit diverse application environments. This reduces waste and enables tailored installations, which is a valuable cost-saving feature for large-scale deployments.

6. Material Quality and Adhesive Backing

High-quality WS2812B strips use durable PCB materials and strong adhesives (often 3M brand) for secure mounting. Material grade impacts heat dissipation and longevity, while adhesive quality affects installation ease and strip stability on various surfaces. Buyers should verify these specs to ensure reliability and ease of deployment.

Key Industry and Trade Terms for WS2812B LED Strip Buyers

OEM (Original Equipment Manufacturer)

Refers to companies that produce LED strips which other brands repackage and sell. OEM partnerships allow buyers to customize products (e.g., branding, packaging, LED density) while benefiting from lower manufacturing costs. For international buyers, OEM options can offer competitive pricing and unique product differentiation.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order, often ranging from hundreds to thousands of meters for WS2812B strips. Understanding MOQ is vital for budgeting and inventory planning, especially for businesses in emerging markets where capital and storage space may be limited.

RFQ (Request for Quotation)

A formal process where buyers invite suppliers to provide price and delivery terms for specific quantities and specifications. RFQs are crucial for comparing offers from multiple manufacturers and negotiating favorable terms in international trade, ensuring transparency and cost-efficiency.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities and risks between buyers and sellers during shipping, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight). Knowledge of Incoterms helps buyers understand who handles transportation, customs, and insurance, which is essential for smooth cross-border transactions.

IP Rating (Ingress Protection Rating)

An international standard denoting the level of protection against solids and liquids. For WS2812B strips, common IP ratings indicate suitability for indoor or outdoor use. Buyers must specify IP ratings to suppliers based on installation environments to ensure compliance with regional standards and durability requirements.

Batch Consistency

Refers to uniformity in color output, brightness, and electrical performance across a production batch. Consistency is critical for projects requiring multiple strips to function seamlessly together, such as architectural lighting or large-scale advertising displays. Buyers should request batch testing data or certifications to guarantee quality.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed purchasing decisions, optimize cost-efficiency, and ensure reliable integration of WS2812B LED strips in diverse markets and applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the w2812 led strip Sector

Market Overview & Key Trends

The global market for WS2812B LED strips is experiencing robust growth driven by increasing demand for customizable, energy-efficient lighting solutions across commercial, industrial, and creative sectors. Key markets such as Africa, South America, the Middle East, and Europe—including the UK and Mexico—are witnessing accelerated adoption due to urbanization, expanding smart city initiatives, and growing interest in digital signage and entertainment lighting.

Key drivers for B2B buyers include:

- Customization and Control: WS2812B LED strips’ addressable RGB technology allows independent control of each LED, enabling intricate lighting effects critical for architectural projects, retail displays, and experiential marketing.

- Integration with IoT and Automation: Increasing use of microcontrollers (Arduino, Raspberry Pi) supports integration into smart systems, appealing to buyers focused on automation and interactive installations.

- Scalability and Flexibility: The modular nature of WS2812B strips, with options for different LED densities (30 to 60 LEDs per meter) and waterproof variants, meets diverse application needs—from indoor decorative lighting to outdoor and industrial environments.

- Supply Chain Localization: Buyers in emerging markets prioritize suppliers with regional distribution hubs or partnerships to minimize lead times and customs complexities, especially amid global supply chain disruptions.

- Sourcing Trends: There is a growing preference for suppliers offering turnkey solutions—combining hardware, firmware, and technical support—facilitating faster project deployment and reducing integration risks.

For buyers in Africa and South America, cost-effectiveness and supplier reliability are paramount, while European and Middle Eastern buyers increasingly demand compliance with stringent quality and safety standards (CE, RoHS). Collaborative sourcing platforms and digital marketplaces are becoming essential for discovering vetted manufacturers and negotiating volume discounts.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration in the procurement of WS2812B LED strips, reflecting broader industry commitments to reducing environmental footprints and promoting ethical manufacturing practices.

Environmental Impact:

WS2812B strips are inherently energy-efficient compared to traditional lighting, consuming low voltage (5V DC) and offering long operational lifespans, which reduces waste. However, the production involves electronic components, including semiconductors and soldered circuitry, which can contribute to e-waste if not properly managed.

Ethical Supply Chains:

International buyers are increasingly scrutinizing supplier transparency to ensure compliance with labor laws, fair wages, and safe working conditions, especially when sourcing from regions with less regulatory oversight. Certifications such as ISO 14001 (environmental management) and SA8000 (social accountability) are becoming key differentiators.

Green Certifications & Materials:

Buyers should prioritize WS2812B LED strips that adhere to RoHS (Restriction of Hazardous Substances) to avoid toxic elements like lead and mercury. Additionally, sourcing suppliers who use recyclable packaging and eco-friendly adhesives aligns with corporate sustainability goals. Some manufacturers offer products with extended warranties and options for recycling or take-back programs, reducing lifecycle environmental impact.

For B2B buyers in Europe and the Middle East, compliance with the EU’s Ecodesign Directive and REACH regulations is often mandatory, while buyers in Africa and South America can leverage these standards to access premium markets and demonstrate corporate responsibility.

Evolution and Industry Impact

The WS2812B LED strip emerged as a breakthrough in LED technology by integrating a smart control IC within each RGB LED, enabling addressability and independent control—a significant advancement over traditional LED strips. Since its introduction, the WS2812B has revolutionized decorative and functional lighting by simplifying wiring and enabling complex color effects through a single data line.

This evolution has empowered businesses and developers worldwide to implement innovative lighting solutions without extensive hardware complexity. The strips’ compatibility with popular microcontrollers like Arduino and Raspberry Pi has democratized advanced lighting design, fostering rapid growth in applications from entertainment to industrial signaling.

For B2B buyers, understanding this evolution highlights the importance of selecting suppliers who can provide not only the product but also technical expertise and integration support, ensuring that the full potential of WS2812B technology is realized in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of w2812 led strip

-

How can I effectively vet suppliers of WS2812B LED strips for international B2B purchases?

When sourcing WS2812B LED strips internationally, especially from regions like Asia or Europe, conduct thorough supplier due diligence. Request detailed company profiles, production capabilities, and quality certifications such as ISO 9001 or RoHS compliance. Ask for samples to verify product quality and test performance. Check references or customer reviews, and consider factory audits or third-party inspections. For buyers in Africa, South America, and the Middle East, partnering with suppliers offering transparent communication and proven export experience reduces risk and ensures reliable supply chains. -

What customization options are typically available for WS2812B LED strips in bulk orders?

Most manufacturers offer customization including LED density (e.g., 30 or 60 LEDs/meter), waterproofing levels (IP65, IP67), strip length, and connector types. You can also request specific PCB colors, adhesive backing types, and packaging tailored to your market needs. For advanced B2B projects, custom firmware or pre-programmed effects may be available. Clarify minimum order quantities (MOQs) for custom specs, as these vary. Buyers from Europe and South America should also verify compliance with regional electrical standards when requesting customized products. -

What are typical MOQ requirements and lead times for WS2812B LED strip orders?

MOQ varies widely depending on supplier and customization level; standard MOQs range from 500 to 2,000 meters per order. Lead times generally span 3 to 6 weeks, including production and quality checks. For urgent projects, negotiate expedited manufacturing or stock availability. Buyers in the Middle East and Africa should factor in additional shipping time and customs clearance. Early communication on order volume and delivery schedules helps suppliers allocate resources efficiently and ensures smoother fulfillment. -

Which payment terms are common for international B2B transactions of WS2812B LED strips?

Common payment terms include 30% advance deposit with 70% balance before shipment or upon delivery, often secured via Letter of Credit (L/C) for higher-value orders. PayPal and T/T (telegraphic transfer) are widely accepted. For trusted partners, net 30 or net 60 terms may be negotiated. To mitigate risks, use escrow services or trade assurance platforms. Buyers from emerging markets such as Africa or South America should clarify currency exchange and banking restrictions early to avoid delays. -

What quality assurance measures and certifications should I expect from WS2812B LED strip suppliers?

Reliable suppliers provide quality control reports, including electrical testing (voltage, current, brightness uniformity), waterproof testing for sealed models, and lifespan estimates. Certifications like CE, RoHS, FCC, and UL demonstrate compliance with international safety and environmental standards. Request sample batch testing results and inquire about in-line and final product inspections. For buyers in Europe and the UK, CE marking is often mandatory. Ensuring suppliers follow strict QA protocols minimizes defective products and warranty claims. -

How should I approach logistics and shipping for WS2812B LED strips to Africa, South America, or the Middle East?

Choose suppliers experienced with international freight forwarding, offering options like air freight for speed or sea freight for cost efficiency. Clarify Incoterms (e.g., FOB, CIF) to understand cost responsibilities and risk transfer. For remote or customs-challenged regions, engage a reliable local customs broker to facilitate clearance. Plan for potential delays during peak seasons. Packaging should protect strips from moisture and mechanical damage. Consolidated shipments may reduce costs but require careful inventory planning. -

What steps can I take if I encounter product quality issues or disputes with a WS2812B LED strip supplier?

First, document all issues with photos, videos, and batch numbers. Communicate promptly with the supplier to negotiate solutions such as replacements, refunds, or discounts. Refer to your purchase agreement’s dispute resolution clause, which may specify mediation or arbitration venues. Engage third-party inspection agencies for impartial assessment if needed. Maintain professional and clear communication to preserve long-term partnerships. Buyers should also consider trade insurance to cover losses from defective or delayed shipments. -

Are there regional considerations for compliance or usage of WS2812B LED strips in different international markets?

Yes. For example, Europe and the UK require CE marking and RoHS compliance to ensure environmental safety. Some Middle Eastern countries may have specific electrical safety certifications or import restrictions. African and South American markets might require documentation for customs clearance, such as certificates of origin or conformity. Additionally, power supply standards differ (e.g., 220V vs. 110V mains), so ensure compatibility with local electrical infrastructure. Understanding these regional regulations early helps avoid costly delays and ensures smooth market entry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for w2812 led strip

Effective sourcing of WS2812B LED strips demands a clear understanding of both the product’s technical capabilities and the dynamic global supply landscape. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—prioritizing suppliers who offer consistent product quality, customization options (such as LED density and waterproofing), and reliable logistics is essential to maintaining competitive advantage.

Key takeaways for strategic sourcing include:

- Supplier vetting: Engage manufacturers with proven expertise in WS2812B technology and certifications that ensure product durability and compliance with regional standards.

- Customization and scalability: Opt for suppliers capable of tailoring LED density and strip length to your project needs, supporting both small-scale and large volume orders.

- Power and integration support: Ensure availability of technical support for power requirements and microcontroller compatibility to optimize product performance.

- Logistics and after-sales service: Prioritize partners with strong distribution networks and responsive customer service to mitigate supply chain disruptions.

Looking ahead, the increasing demand for smart lighting solutions across diverse industries presents significant growth opportunities. Buyers in emerging and established markets should leverage strategic partnerships and invest in flexible sourcing models that accommodate rapid innovation cycles and evolving consumer preferences. Embrace the future of programmable lighting by aligning procurement strategies with cutting-edge WS2812B LED strip technologies and trusted global suppliers.