Introduction: Navigating the Global Market for solar led strip

The global shift towards sustainable energy solutions has positioned solar LED strip lighting as a transformative technology for businesses worldwide. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, solar LED strips represent a compelling fusion of energy efficiency, cost-effectiveness, and environmental responsibility. These products enable off-grid lighting solutions, reduce dependency on unstable power grids, and enhance operational resilience in diverse commercial and industrial applications.

This guide offers a comprehensive roadmap tailored to international buyers navigating the complexities of sourcing solar LED strips. It delves into critical aspects including the variety of solar LED strip types, advanced materials used in manufacturing, and stringent quality control processes that ensure product longevity and performance. Additionally, it provides actionable insights on evaluating suppliers, understanding pricing structures, and adapting to regional market dynamics and regulatory requirements.

By exploring key factors such as customization options, technological innovations, and logistical considerations, this resource empowers buyers to make informed procurement decisions that align with their project specifications and budget constraints. Whether you are sourcing for large-scale infrastructure projects in Brazil, sustainable urban lighting initiatives in Vietnam, or renewable energy deployments across the Middle East and Africa, this guide equips you with the knowledge to mitigate risks, optimize costs, and secure reliable supply partnerships.

Unlock the potential of solar LED strips to drive sustainable growth and competitive advantage in your markets—strategically sourced, expertly implemented, and future-ready.

Understanding solar led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Solar LED Strip | Bendable, thin strips with integrated solar cells and LEDs | Outdoor decorative lighting, garden pathways, signage | + Easy installation, versatile; – Lower power output, limited length |

| Rigid Solar LED Strip | Solid PCB with solar cells and LEDs, designed for durability | Security lighting, commercial outdoor displays | + Robust, higher output; – Less flexible, heavier |

| Waterproof Solar LED Strip | Encased in waterproof materials (IP65+), suitable for harsh environments | Street lighting, outdoor advertising, coastal areas | + Weather resistant, long lifespan; – Higher cost, requires proper mounting |

| RGB Solar LED Strip | Multi-color LED strips with solar power, color-changing options | Event lighting, hospitality, retail displays | + Dynamic lighting effects, customizable; – More complex control, higher price |

| High-Efficiency Solar LED Strip | Uses advanced solar cells and LEDs for maximum brightness and energy conversion | Industrial sites, large-scale outdoor installations | + Superior brightness, energy savings; – Higher upfront cost, supply chain complexity |

Flexible Solar LED Strip

These strips are characterized by their slim, bendable design, integrating small solar cells with LEDs on a flexible substrate. Ideal for landscaping, garden lighting, and signage where irregular shapes or curved surfaces are common, they offer quick installation and adaptability. For B2B buyers, assessing power output relative to length is critical, as flexibility often comes with trade-offs in brightness. Volume buyers should verify supplier quality control and solar cell efficiency to ensure consistent performance in diverse climates.

Rigid Solar LED Strip

Constructed on a solid PCB, rigid solar LED strips provide enhanced durability and higher light output compared to flexible variants. They are favored in commercial outdoor lighting applications such as security and signage, where robustness and consistent illumination are priorities. B2B purchasers should consider weight and mounting requirements, as well as the supplier’s warranty and certification compliance to meet regional standards, especially in demanding environments found in Africa, the Middle East, and Europe.

Waterproof Solar LED Strip

Encapsulated with IP65 or higher-rated materials, waterproof solar LED strips withstand rain, dust, and extreme weather, making them suitable for street lighting, coastal installations, and outdoor advertising. These strips reduce maintenance costs and downtime for large outdoor projects. Buyers must factor in higher costs and ensure proper installation techniques to maintain waterproof integrity. Verifying supplier testing reports and durability certifications is essential for reliable long-term procurement.

RGB Solar LED Strip

Featuring multi-color LEDs powered by integrated solar cells, RGB solar LED strips enable dynamic lighting effects controlled via remote or smart systems. These are popular in hospitality, event venues, and retail displays aiming to attract attention with color-changing capabilities. B2B buyers should evaluate the complexity of control systems, compatibility with existing infrastructure, and total cost of ownership, including potential technical support from suppliers.

High-Efficiency Solar LED Strip

Designed with advanced solar cells and high-lumen LEDs, these strips maximize energy conversion and brightness, suitable for industrial sites and large-scale outdoor projects requiring reliable, powerful illumination. While they entail higher upfront investment and may involve more complex supply chains, the long-term energy savings and performance consistency offer strong ROI. Buyers should prioritize suppliers with proven technology, international certifications, and after-sales support tailored to large-volume orders.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of solar led strip

| Industry/Sector | Specific Application of solar led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Agritech | Solar-powered greenhouse and outdoor crop lighting | Enables extended growing hours, reduces energy costs, and improves crop yield | Durability in harsh outdoor conditions, waterproofing, long battery life, and local climate adaptability |

| Outdoor Retail & Hospitality | Solar LED strips for signage and landscape lighting | Enhances brand visibility and customer experience with sustainable lighting | Customizable brightness/color, weather resistance, and compliance with local lighting regulations |

| Transportation & Infrastructure | Solar LED strips for road/pathway illumination and signage | Improves safety and reduces grid dependency in remote or off-grid areas | High lumen output, rugged design, and certifications for safety and weatherproofing |

| Warehousing & Logistics | Solar LED strips for warehouse perimeter and emergency lighting | Lowers operational costs and ensures safety during power outages | Reliable battery backup, ease of installation, and compliance with industrial safety standards |

| Renewable Energy & Smart Cities | Integration of solar LED strips in smart street lighting and public spaces | Supports green initiatives, reduces carbon footprint, and lowers maintenance costs | Compatibility with IoT controls, modular design, and scalability for urban projects |

Solar LED strips have become a vital solution across diverse industries, especially for businesses operating in regions such as Africa, South America, the Middle East, and Europe, where energy access and sustainability are critical concerns.

In Agriculture & Agritech, solar LED strips are extensively used for greenhouse and outdoor crop lighting. They provide an energy-efficient way to extend daylight hours, promoting faster growth cycles and higher yields without escalating electricity costs. Buyers from regions with variable sunlight, like parts of Brazil and Vietnam, must ensure the strips have robust solar panels and batteries that perform well under local weather conditions and high humidity.

For Outdoor Retail & Hospitality, solar LED strips illuminate signage, pathways, and outdoor seating areas, enhancing ambiance while signaling eco-conscious branding. Businesses in tourist hubs or urban centers in the Middle East and Europe benefit from low operational costs and compliance with stringent local lighting codes. Sourcing considerations include customizable lighting effects and durability against dust, heat, and occasional rain.

In the Transportation & Infrastructure sector, solar LED strips are applied to roadways, pedestrian paths, and traffic signs, particularly in remote or off-grid locations common in African and South American rural areas. These strips improve safety and visibility without reliance on unreliable grid power. Buyers must prioritize high lumen output, robust weatherproofing, and certifications like IP67 to withstand environmental stress.

Within Warehousing & Logistics, solar LED strips provide cost-effective perimeter and emergency lighting. This is critical for facilities in regions with frequent power outages or limited grid infrastructure. International buyers should focus on sourcing products with reliable battery backups, easy installation features, and compliance with industrial safety standards to ensure uninterrupted operations.

Lastly, in Renewable Energy & Smart Cities, solar LED strips integrate into smart street lighting and public space illumination projects. This supports municipal green initiatives and reduces the carbon footprint while lowering maintenance costs. Buyers targeting European and Middle Eastern smart city projects should look for IoT compatibility, modular designs for scalability, and adherence to regional energy efficiency and safety regulations.

By understanding these key industrial applications and their sourcing nuances, B2B buyers can make informed decisions that align with their operational goals and regional challenges.

Related Video: DIY Solar Shed Lighting! Affordable LED Setup

Strategic Material Selection Guide for solar led strip

Material Analysis for Solar LED Strip Construction

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a highly durable thermoplastic known for its excellent impact resistance, high temperature tolerance (up to 135°C continuous use), and good UV stability when treated with additives. It offers strong resistance to moisture and many chemicals, making it suitable for outdoor solar LED strip housings.

Pros & Cons:

PC is lightweight and can be easily molded into complex shapes, facilitating versatile solar LED strip designs. Its transparency supports optimal light diffusion and protection of LEDs. However, untreated PC can yellow over time under prolonged UV exposure, and it is more expensive than common plastics like PVC. Manufacturing complexity is moderate due to injection molding requirements.

Impact on Application:

Ideal for outdoor solar LED strips exposed to harsh sunlight and varying weather conditions, especially in tropical and desert climates common in Africa, the Middle East, and parts of South America. Its UV resistance ensures longevity without significant degradation in brightness or structural integrity.

B2B Considerations:

Buyers in regions like Europe and the Middle East should verify compliance with ASTM D3935 (UV resistance) and ISO 4892 standards. Polycarbonate sourced from certified suppliers ensures conformity with RoHS and REACH regulations, critical for European markets. For African and South American buyers, ensuring local availability or reliable import channels is key due to higher cost and specialized manufacturing.

2. Silicone Rubber

Key Properties:

Silicone rubber is prized for its outstanding flexibility, excellent thermal stability (-60°C to 230°C), and superior resistance to weathering, ozone, and UV radiation. It also exhibits excellent electrical insulation properties, which is crucial for LED safety.

Pros & Cons:

Its flexibility allows solar LED strips to bend around irregular surfaces, expanding installation possibilities. Silicone’s weather resistance ensures durability in extreme climates, including high humidity zones in Vietnam or coastal Brazil. However, silicone is generally more expensive and less rigid, which can complicate mounting and structural support.

Impact on Application:

Best suited for flexible solar LED strips requiring waterproofing and resistance to environmental stressors. Its electrical insulation properties reduce the risk of short circuits in humid or rainy environments prevalent in Africa and South America.

B2B Considerations:

International buyers should confirm compliance with ASTM D2000 (rubber classification) and IEC 60529 (IP ratings for waterproofing). For Middle Eastern and European markets, certifications for fire retardancy (UL 94 V-0 or equivalent) may be required. Sourcing from manufacturers with ISO 9001 quality management certification helps assure product consistency.

3. Aluminum Alloy

Key Properties:

Aluminum alloys used in solar LED strip housings provide excellent thermal conductivity, corrosion resistance (especially anodized types), and mechanical strength. They typically withstand temperatures up to 200°C and resist oxidation in marine or desert environments.

Pros & Cons:

Aluminum’s superior heat dissipation extends LED lifespan by preventing overheating. It offers a premium feel and robust protection but increases weight and cost compared to plastics. Manufacturing involves extrusion or CNC machining, which can increase lead times and tooling costs.

Impact on Application:

Highly recommended for solar LED strips deployed in high-temperature or industrial environments, such as commercial installations in the Middle East or Europe where thermal management is critical. Its corrosion resistance suits coastal regions in South America and Africa exposed to salt air.

B2B Considerations:

Buyers should ensure materials meet ASTM B221 (aluminum extrusion) or EN 755 standards for European markets. Anodizing or powder coating certifications enhance corrosion resistance claims. Aluminum sourcing should consider the carbon footprint and supply chain transparency, increasingly important for European buyers focused on sustainability.

4. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a cost-effective, versatile plastic with good chemical resistance and moderate temperature tolerance (-15°C to 60°C). It is commonly used for insulation and protective coatings in LED strips but has limited UV resistance unless specially treated.

Pros & Cons:

PVC’s low cost and ease of manufacturing make it attractive for budget-conscious projects. However, it is less durable under prolonged sun exposure and can become brittle in cold climates. Its environmental impact is a concern due to chlorine content and challenges in recycling.

Impact on Application:

Suitable for indoor or shaded solar LED strips or regions with milder climates. In Africa and South America, PVC may be used for cost-sensitive projects with limited outdoor exposure. Not recommended for harsh outdoor environments without UV stabilizers.

B2B Considerations:

Buyers must verify compliance with ASTM D1784 (PVC specifications) and regional fire safety standards. European buyers should consider REACH compliance and look for phthalate-free formulations. For markets like Vietnam and Brazil, local regulations on plastic additives and import restrictions may apply.

Summary Table of Materials for Solar LED Strip

| Material | Typical Use Case for solar led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Outdoor housings requiring UV and impact resistance | High durability and UV resistance | Higher cost; potential yellowing without treatment | High |

| Silicone Rubber | Flexible, waterproof strips for harsh environments | Excellent flexibility and weather resistance | Higher cost; less structural rigidity | High |

| Aluminum Alloy | Industrial and high-temperature applications | Superior heat dissipation and corrosion resistance | Higher weight and manufacturing complexity | Medium to High |

| PVC | Indoor or budget-sensitive outdoor applications | Low cost and easy manufacturing | Poor UV resistance; environmental concerns | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for solar led strip

Manufacturing Processes for Solar LED Strip

The production of solar LED strips involves a combination of advanced electronics manufacturing and specialized solar technology assembly. For international B2B buyers targeting markets in Africa, South America, the Middle East, and Europe, understanding these manufacturing stages is critical to evaluating supplier capabilities and ensuring product reliability.

1. Material Preparation

This initial stage focuses on sourcing and preparing raw materials, including flexible printed circuit boards (PCBs), LED chips, photovoltaic cells, and encapsulants. High-quality PCBs must be flexible yet durable, often made with materials such as polyimide or PET substrates. The photovoltaic cells—typically thin-film or monocrystalline silicon—are pre-tested for efficiency before integration. Material traceability is essential, as consistent input quality directly affects the final product’s performance.

2. PCB Forming and Circuit Printing

The flexible PCB is fabricated using precision circuit printing techniques, including photolithography and etching, to create conductive pathways. For solar LED strips, special attention is paid to the circuit layout to accommodate both LED chips and solar cells, enabling efficient power management. Automated machines deposit conductive silver or copper inks to ensure low resistance and high conductivity.

3. Component Mounting and Assembly

Surface-Mounted Device (SMD) LEDs and solar cells are placed on the PCB using pick-and-place machines, ensuring exact positioning and alignment. This automated process enhances repeatability and reduces defects. Following placement, soldering (usually reflow soldering) secures components to the board. Additional components such as resistors, microcontrollers for light control, and charging circuits for solar energy storage may also be assembled.

4. Encapsulation and Waterproofing

Solar LED strips are frequently used outdoors, making protection against environmental factors critical. The assembly is coated with UV-resistant, waterproof encapsulants—such as silicone or epoxy resins—to shield the circuitry and solar cells from moisture, dust, and mechanical damage. This step involves precise dispensing and curing processes to maintain flexibility and transparency while maximizing durability.

5. Finishing and Packaging

After assembly, strips undergo cutting to standard or custom lengths, along with the attachment of connectors or adhesive backing for installation ease. Packaging is designed to protect strips during transit and may include branding or compliance labeling. Some manufacturers offer customization options here, including tailored packaging for specific markets or bulk orders.

Quality Assurance Framework for Solar LED Strips

Robust quality assurance (QA) is indispensable for solar LED strip suppliers to meet international standards and satisfy diverse regional requirements. Buyers must scrutinize supplier QA systems to mitigate risks associated with defective products, warranty claims, and regulatory non-compliance.

Relevant International and Industry Standards

– ISO 9001: This global quality management standard ensures that suppliers maintain consistent processes, continuous improvement, and customer satisfaction. ISO 9001 certification is a fundamental indicator of a reliable manufacturer.

– CE Marking (Europe): Indicates compliance with European safety, health, and environmental protection directives, including RoHS (Restriction of Hazardous Substances) and EMC (Electromagnetic Compatibility).

– IP Ratings: For solar LED strips, ingress protection (IP) ratings such as IP65 or IP67 certify resistance to dust and water, critical for outdoor applications.

– IEC Standards: International Electrotechnical Commission standards for electrical safety and performance (e.g., IEC 60598 for luminaires) apply to lighting products.

– Local Certifications: Markets like Brazil require INMETRO certification, while some Middle Eastern countries may mandate SASO (Saudi Standards) compliance. Buyers should verify that suppliers understand and meet these region-specific requirements.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials and components undergo inspection for specifications, defects, and certifications before entering production. This step prevents faulty inputs from affecting final products.

– In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, component placement accuracy, and encapsulation uniformity. Automated optical inspection (AOI) and functional tests are common here.

– Final Quality Control (FQC): Completed strips are tested for electrical functionality, light output consistency, solar cell efficiency, waterproofing integrity, and mechanical durability before packaging.

Common Testing Methods

– Electrical Testing: Verifying voltage, current, power consumption, and LED brightness uniformity.

– Spectral Testing: Ensuring color temperature and light quality meet specifications.

– Solar Cell Performance: Testing photovoltaic conversion efficiency and charge retention under simulated sunlight.

– Environmental Stress Testing: Thermal cycling, humidity exposure, and UV aging tests simulate real-world conditions to assess durability.

– Waterproofing Tests: Immersion or spray tests confirm IP rating compliance.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers in diverse international markets, validating supplier QA practices is essential to secure high-quality solar LED strips and reduce risks.

1. Supplier Audits

Conduct on-site or virtual audits to evaluate manufacturing processes, quality management systems, and compliance with certifications. Audits should include review of process documentation, equipment calibration records, and employee training programs. For buyers in regions with logistical challenges, partnering with local inspection agencies can facilitate these audits.

2. Quality Documentation and Reports

Request comprehensive quality reports such as First Article Inspection (FAI), batch test results, and Certificates of Conformity (CoC). These documents provide traceability and evidence of compliance with agreed specifications.

3. Third-Party Inspections

Engage independent quality inspection firms to perform pre-shipment inspections (PSI) or in-process checks. Third-party verification adds credibility and impartiality, especially for buyers unfamiliar with the supplier’s location or manufacturing culture.

4. Sample Testing

Obtain and test samples in accredited labs within the buyer’s region or trusted third-party labs. Testing can validate performance claims and detect any non-compliance before placing bulk orders.

5. Supplier Certification Verification

Verify authenticity of certifications (ISO, CE, INMETRO, SASO, etc.) through official registries or certification bodies. Beware of counterfeit or expired certificates.

Quality Assurance Nuances for International Buyers by Region

-

Africa & South America: Infrastructure and regulatory frameworks can vary widely. Buyers should prioritize suppliers with proven export experience and compliance with international standards, while also understanding local certification requirements (e.g., INMETRO in Brazil). Logistical reliability and after-sales support are critical considerations.

-

Middle East: Markets here often require strict compliance with safety and environmental standards (SASO, Gulf Conformity Mark). Suppliers must demonstrate understanding of these regulations. Additionally, environmental durability (high heat, dust) is paramount, so QA must include rigorous environmental testing.

-

Europe: Buyers face the most stringent regulations, including RoHS, CE, and WEEE directives. Solar LED strips must meet high safety, electromagnetic compatibility, and environmental standards. European buyers should insist on full certification documentation and may require product testing by notified bodies.

-

Emerging Manufacturing Hubs (e.g., Vietnam): While cost-effective, manufacturing quality may vary. Due diligence via audits, sample testing, and third-party inspections is essential to ensure consistent quality and compliance with buyer country regulations.

Summary for B2B Buyers

Understanding the comprehensive manufacturing process and quality assurance protocols for solar LED strips empowers B2B buyers to:

- Select suppliers with robust production capabilities and reliable quality systems.

- Mitigate risks by verifying compliance with international and local standards.

- Ensure product longevity and performance through rigorous testing and quality checkpoints.

- Navigate regional regulatory landscapes effectively, optimizing market entry and customer satisfaction.

Investing in supplier quality verification—through audits, certifications, sample testing, and third-party inspections—is not just prudent but essential for successful procurement and sustainable business growth in the global solar LED strip market.

Related Video: solar cell manufacturing and solar panel production by suntech

Comprehensive Cost and Pricing Analysis for solar led strip Sourcing

When sourcing solar LED strips for international B2B procurement, understanding the comprehensive cost structure and pricing dynamics is essential to optimize purchasing decisions and ensure profitability. The pricing landscape is influenced by multiple factors spanning production inputs, supplier capabilities, and market-specific considerations. Below is an in-depth breakdown of the key cost components, price influencers, and strategic buyer tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in Solar LED Strip Production

-

Materials: Constituting the largest portion of cost, materials include high-quality solar cells, LED chips (often SMD or COB types), flexible PCB substrates, protective coatings, and battery components. The choice of materials directly impacts product durability, efficiency, and certifications required for different markets.

-

Labor: Labor costs vary widely depending on the manufacturing location. Countries with established electronics manufacturing hubs often have lower labor expenses, but quality control standards may demand skilled labor, impacting overall costs.

-

Manufacturing Overhead: This covers factory utilities, equipment depreciation, and indirect labor. Efficient production lines with automation can reduce overhead but may require higher initial tooling investments.

-

Tooling and Setup: Custom tooling for specific solar LED strip designs or packaging adds upfront costs. For buyers requiring customized lengths, colors, or integrated smart features, tooling expenses must be factored in.

-

Quality Control (QC): Rigorous QC processes—including photometric testing, waterproofing checks, and electrical safety tests—are crucial to ensure compliance with international standards such as CE, RoHS, or regional certifications like INMETRO for Brazil.

-

Logistics and Shipping: International freight costs, customs duties, and insurance vary by origin and destination. Bulk shipments usually benefit from economies of scale, but buyers should anticipate fluctuations due to fuel prices, seasonal demand, and geopolitical factors.

-

Supplier Margin: Suppliers incorporate profit margins based on market demand, competition, and brand positioning. Established manufacturers with proven quality may command premium pricing but offer lower risk.

Influential Factors Affecting Pricing

-

Order Volume and Minimum Order Quantities (MOQ): Larger volumes typically yield lower per-unit prices. Many suppliers set MOQs to optimize production runs; negotiating MOQs or consolidating orders can improve cost-efficiency.

-

Product Specifications and Customization: Tailored solar LED strips with specific lumen outputs, waterproof ratings (IP65 or higher), integrated sensors, or smart connectivity features command higher prices due to complexity and specialized components.

-

Material Quality and Certifications: Certified materials and compliance with international standards add to cost but are critical for market access and long-term reliability, particularly in regulated markets like Europe and the Middle East.

-

Supplier Reputation and Location: Manufacturers with a strong track record and localized support networks may price products higher but reduce hidden costs related to delays, defects, or warranty claims.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) significantly affects landed cost. Buyers should clarify responsibilities for shipping, insurance, and customs clearance to avoid unexpected expenses.

Strategic Buyer Tips for Cost-Efficient Procurement

-

Negotiate Beyond Unit Price: Engage suppliers on payment terms, shipping methods, and after-sales support to improve overall value. Flexible payment options or extended warranties can offset higher upfront costs.

-

Assess Total Cost of Ownership (TCO): Consider installation, maintenance, and energy savings enabled by solar LED strips. Higher initial investment in quality products often results in lower lifecycle costs.

-

Leverage Regional Sourcing Hubs: For buyers in Africa and South America, sourcing from regional hubs or suppliers with local warehouses can reduce lead times and logistics costs.

-

Request Detailed Quotations Including All Fees: Ensure quotations itemize costs such as packaging, certification fees, and testing to avoid surprises.

-

Sample and Pilot Testing: Before committing to large orders, procure samples to verify quality and compatibility with local conditions, minimizing costly returns or replacements.

-

Stay Informed on Market Trends and Currency Fluctuations: Currency volatility in emerging markets like Brazil or Vietnam can affect final pricing. Locking in contracts or using hedging strategies may protect margins.

Disclaimer on Pricing

Prices for solar LED strips vary widely depending on product complexity, volume, and supplier terms. The above analysis provides a framework for understanding cost drivers but should be complemented with direct supplier engagement and market research tailored to specific procurement needs.

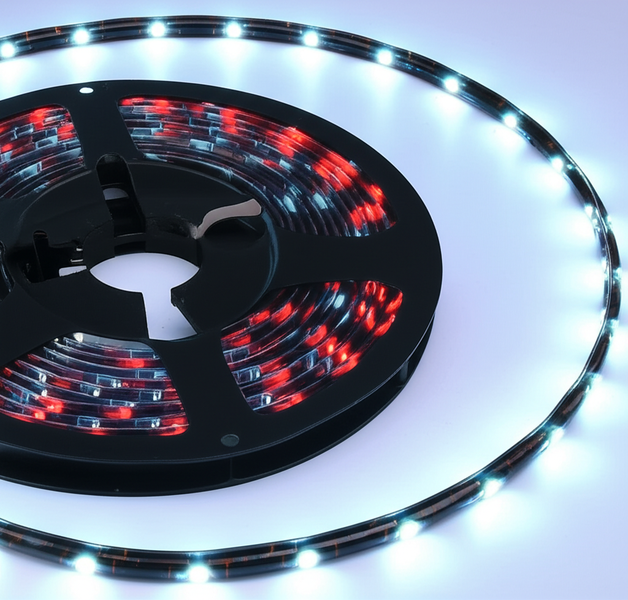

Illustrative Image (Source: Google Search)

By carefully analyzing these cost elements and price influencers, international B2B buyers can negotiate smarter deals, reduce risks, and ensure sustainable procurement of solar LED strips that meet both budgetary and quality expectations across diverse global markets.

Spotlight on Potential solar led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solar led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solar led strip

Key Technical Properties of Solar LED Strips

When sourcing solar LED strips for commercial use, understanding the critical technical properties is essential to ensure product performance, durability, and compatibility with your project requirements. Here are the top specifications to evaluate:

-

Solar Panel Efficiency (%)

This measures how effectively the integrated solar panel converts sunlight into electrical energy. Higher efficiency panels generate more power, crucial for regions with variable sunlight like parts of Africa or Europe. For B2B buyers, selecting solar strips with optimized efficiency means longer operation times and reduced reliance on auxiliary power sources. -

LED Chip Type and Lumen Output

The quality and type of LED chips (commonly SMD LEDs) determine brightness and energy consumption. Lumen output indicates light intensity; higher lumens mean brighter illumination. Buyers should match lumen levels to application needs—outdoor security lighting requires higher lumens compared to decorative garden strips. -

Battery Capacity and Type

Solar LED strips typically incorporate rechargeable batteries (often lithium-ion or lithium-polymer). Battery capacity (measured in mAh or Wh) affects how long the strip can operate after sunset. For projects in regions with extended nighttime hours, larger capacity batteries enhance reliability and customer satisfaction. -

Ingress Protection (IP) Rating

The IP rating defines the strip’s resistance to dust and water ingress. For outdoor or harsh environment installations common in Middle East or South America, IP65 or higher is recommended to ensure durability against rain, dust storms, and humidity. -

Operating Temperature Range

This indicates the environmental temperature limits within which the solar LED strip can function optimally. Buyers in regions with extreme climates (e.g., hot deserts or cold European winters) should verify this spec to avoid product failure or performance degradation. -

Material Quality and Flexibility

The substrate and coating materials impact the strip’s lifespan and flexibility. High-grade flexible PCBs and UV-resistant coatings prevent cracking and discoloration, which is vital for installations on curved surfaces or exposed to direct sunlight over long periods.

Common Trade Terminology in Solar LED Strip Procurement

Navigating international B2B transactions requires familiarity with key industry terms that impact pricing, logistics, and contract terms. Here are essential trade terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce solar LED strips that can be branded and customized by the buyer. OEM partnerships allow businesses to tailor product design, packaging, and specifications, enhancing brand differentiation in competitive markets like Europe and South America. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is critical for budgeting and inventory planning, especially for startups or regional distributors in emerging markets such as Africa or the Middle East, where cash flow and storage capacity might be limited. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain detailed pricing, lead times, and terms for specific solar LED strip orders. Crafting clear RFQs with technical specs and volume estimates ensures suppliers provide accurate and comparable offers, streamlining vendor evaluation. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers control costs and manage risks, particularly for cross-continental shipments from manufacturing hubs in Asia to buyers in Europe or South America. -

Binning

A quality control process where LED chips are sorted based on color temperature, brightness, and voltage. Consistent binning ensures uniform light output across large installations, which is important for projects requiring aesthetic consistency, such as retail or hospitality lighting in upscale markets. -

Lead Time

The time interval between placing an order and receiving the goods. Accurate knowledge of lead times is crucial for project scheduling and avoiding delays, especially when coordinating multiple suppliers or meeting seasonal demand spikes in regions with fluctuating solar conditions.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed procurement decisions, mitigate risks, and optimize the value of their solar LED strip investments across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solar led strip Sector

Market Overview & Key Trends

The global solar LED strip market is witnessing robust growth driven by increasing demand for energy-efficient, off-grid lighting solutions. For international B2B buyers—particularly in Africa, South America, the Middle East, and Europe—solar LED strips represent a strategic investment that aligns with regional electrification challenges, sustainability goals, and cost optimization efforts. Countries like Brazil and Vietnam are rapidly adopting solar-powered lighting due to expanding rural electrification programs and government incentives promoting renewable energy.

Key market dynamics include the integration of advanced photovoltaic cells with flexible LED strip technology, enabling versatile applications from outdoor signage and architectural accent lighting to agricultural and security lighting. The modularity and ease of installation make solar LED strips attractive for large-scale infrastructure projects as well as smaller commercial ventures. Moreover, improvements in battery storage and LED efficiency are reducing total cost of ownership, making solar LED strips competitive against traditional grid-dependent lighting.

B2B sourcing trends reveal a growing preference for suppliers who offer customization—such as adjustable brightness levels, waterproofing, and integrated smart controls—tailored to local climatic conditions and usage patterns. Additionally, buyers increasingly prioritize suppliers with strong logistics capabilities that ensure timely delivery across diverse geographies, including remote areas in Africa and South America. Strategic partnerships with manufacturers that provide scalable production and compliance with international certifications (e.g., CE for Europe, IEC standards) are critical for mitigating risks and ensuring product reliability.

Emerging technologies such as IoT-enabled solar LED strips are gaining traction, allowing remote monitoring of energy consumption and predictive maintenance. This trend is particularly relevant for large commercial buyers and public sector projects seeking to optimize operational efficiency. In summary, B2B buyers in these regions should focus on sourcing from suppliers who combine technological innovation, customization, and robust after-sales support to capitalize on the growing solar LED strip market.

Sustainability & Ethical Sourcing in B2B

Sustainability is a core consideration in the procurement of solar LED strips, given their role in reducing carbon footprints and promoting renewable energy use. Buyers must evaluate the entire supply chain—from raw materials to manufacturing processes—to ensure environmental impact is minimized. This includes selecting suppliers that use eco-friendly photovoltaic materials, recyclable components, and energy-efficient production methods.

Ethical sourcing is equally critical, especially for buyers in regions where labor standards and environmental regulations may vary. Partnering with manufacturers that adhere to internationally recognized certifications such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) helps ensure compliance with ethical labor practices and environmental stewardship. Certifications like RoHS (Restriction of Hazardous Substances) guarantee that solar LED strips are free from harmful materials like lead and mercury, supporting safer disposal and recycling efforts.

For B2B buyers, prioritizing suppliers with transparent supply chains and documented sustainability policies can significantly mitigate reputational risks and align procurement with corporate social responsibility (CSR) mandates. Furthermore, sourcing solar LED strips that comply with green building standards such as LEED or BREEAM can enhance project credentials, particularly in Europe and the Middle East, where sustainable construction is a growing priority.

Ultimately, investing in sustainably produced solar LED strips not only supports global climate goals but also delivers long-term cost savings through improved product lifespan and energy efficiency. Buyers should engage suppliers in sustainability dialogue and request environmental impact disclosures to ensure alignment with their green procurement strategies.

Evolution and Historical Context

The solar LED strip sector has evolved significantly over the past decade, transitioning from niche applications to mainstream adoption in commercial and industrial markets. Initially, solar-powered lighting solutions were bulky and limited in functionality, with low efficiency and high costs restricting widespread use. Advances in LED technology—characterized by smaller, more efficient diodes—and breakthroughs in thin-film photovoltaic cells have enabled the development of flexible, lightweight solar LED strips.

This evolution aligns with broader global trends toward decentralized energy generation and smart lighting. Early adopters in off-grid regions demonstrated the potential of solar LED strips for enhancing energy access, which spurred investment and innovation. Over time, manufacturers refined product designs to improve durability, waterproofing, and integration with energy storage systems, making solar LED strips suitable for diverse environments and applications.

For B2B buyers, understanding this historical trajectory highlights the maturation of the market and underscores the importance of partnering with suppliers who leverage the latest technological advancements while maintaining proven reliability. This knowledge also supports informed decision-making when evaluating product lifespan, warranty terms, and total cost of ownership in procurement negotiations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of solar led strip

-

How can I effectively vet suppliers of solar LED strips for international B2B purchases?

Start by verifying the supplier’s business credentials, including manufacturing licenses and export certifications. Assess their product quality through samples and review third-party certifications such as CE, RoHS, or IEC relevant to your market. Check customer testimonials and case studies, especially from buyers in your region (Africa, South America, Middle East, Europe). Evaluate their after-sales support and warranty policies. Finally, consider visiting the supplier’s factory or requesting a virtual tour to confirm production capabilities and quality control processes. -

What customization options are typically available for solar LED strips, and how should I approach this with suppliers?

Common customization options include length, LED color temperature, waterproof ratings (IP65 or higher for outdoor use), mounting types, and packaging. Some suppliers also offer branding customization like private labeling or specific packaging designs. Clearly communicate your project requirements upfront and ask for a feasibility assessment. Ensure the supplier can meet your specifications without compromising quality or significantly increasing lead times. Request prototypes or samples of customized products before placing large orders to verify compliance. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for solar LED strip wholesale orders?

MOQs vary widely but typically range from 500 to 5,000 meters depending on the supplier and customization level. Lead times usually span 3 to 8 weeks, influenced by order size, customization, and production schedules. Payment terms often include a 30% deposit upfront with balance upon shipment or letter of credit for larger orders. Negotiate flexible terms that suit your cash flow, and clarify any penalties for delays or quality issues. Consolidating orders can reduce per-unit costs and shipping fees. -

Which quality assurance certifications should I prioritize when sourcing solar LED strips for different international markets?

Prioritize certifications that ensure safety, environmental compliance, and performance, such as CE and RoHS for Europe, CB for global compliance, and IEC standards for electrical safety. For African and South American markets, check if local certifications or approvals are required (e.g., INMETRO for Brazil). Solar-specific certifications related to durability and UV resistance can be critical for outdoor applications. Always request test reports and verify their authenticity with accredited labs to avoid counterfeit documentation. -

What logistical considerations are critical for importing solar LED strips into regions like Africa, South America, the Middle East, and Europe?

Understand import duties, taxes, and customs clearance procedures specific to your country. Choose suppliers with experience in international shipping and reliable freight forwarders to minimize delays. Consider shipping methods—air freight for speed, sea freight for cost-efficiency—and plan inventory accordingly. Ensure proper packaging to protect strips from moisture and damage during transit. Coordinate with customs brokers to preempt compliance issues and maintain transparent communication with suppliers about shipment tracking. -

How can I mitigate risks related to product disputes or defects in international solar LED strip procurement?

Establish clear contractual terms covering product specifications, quality standards, inspection procedures, and remedies for defects. Insist on pre-shipment inspections or third-party quality audits. Maintain documentation such as purchase orders, quality certificates, and communication records. In case of disputes, leverage supplier warranties and negotiate replacements or refunds promptly. Building strong relationships with suppliers and choosing those with proven track records reduces risk. Consider trade insurance or payment methods like letters of credit to safeguard financial exposure.

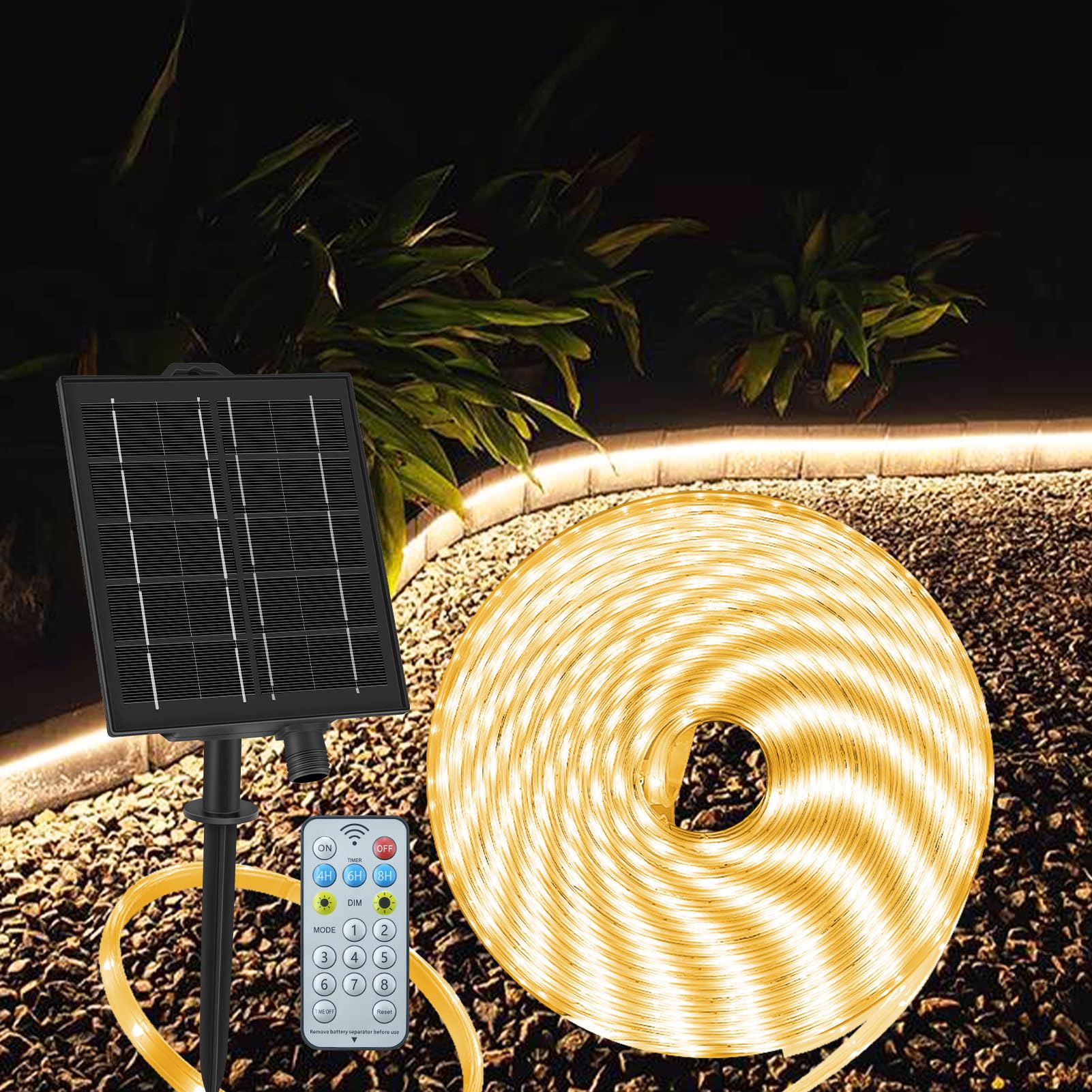

Illustrative Image (Source: Google Search)

-

Are there any region-specific challenges or opportunities I should be aware of when sourcing solar LED strips from overseas?

Yes, regulatory environments differ significantly: Europe demands stringent energy efficiency and safety compliance, while Africa and South America may have less rigid standards but require robust products for harsher climates. The Middle East’s high temperatures necessitate UV-resistant and waterproof designs. Currency fluctuations and payment restrictions can impact cost and timelines. However, growing solar adoption in these regions offers expanding markets. Partner with suppliers familiar with local conditions and regulations to optimize product suitability and market entry. -

How do I ensure scalability and consistent quality when ordering large quantities of solar LED strips for diverse international projects?

Work with suppliers who have scalable production capacity and robust quality management systems (e.g., ISO 9001 certified). Implement batch testing and random inspections throughout production runs. Use consistent product specifications and maintain open communication channels for real-time updates. Plan orders to allow buffer stock for urgent needs while avoiding overstocking. Establish long-term contracts with key suppliers to lock in pricing, lead times, and service levels, ensuring smooth supply for multiple projects across different markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar led strip

Strategic sourcing of solar LED strip lighting presents a compelling opportunity for international B2B buyers to optimize costs, enhance sustainability, and deliver innovative lighting solutions tailored to diverse markets. Key takeaways include the importance of partnering with reliable suppliers who offer quality certifications, customization options, and scalable order volumes. For buyers in Africa, South America, the Middle East, and Europe, aligning procurement strategies with regional compliance standards and logistical realities is essential to ensure smooth supply chain operations and product performance.

Emphasizing value beyond price, strategic sourcing integrates thorough supplier evaluation, quality assurance, and technology adoption—such as energy-efficient solar integration and smart control features—that can differentiate offerings in competitive markets. Bulk purchasing not only reduces unit costs but also supports large-scale projects with consistent quality and timely delivery.

Looking ahead, the solar LED strip market is poised for growth driven by global shifts toward renewable energy and smart infrastructure. Buyers are encouraged to leverage these trends by cultivating supplier partnerships that prioritize innovation, sustainability, and flexibility. Proactive sourcing strategies will empower businesses to meet evolving customer demands while capitalizing on emerging opportunities across fast-developing regions like Vietnam and Brazil. Engage early with trusted manufacturers and explore tailored solutions to position your enterprise at the forefront of this dynamic lighting revolution.