Guide to Small Led Strip

- Introduction: Navigating the Global Market for small led strip

- Understanding small led strip Types and Variations

- Key Industrial Applications of small led strip

- Strategic Material Selection Guide for small led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for small led strip

- Comprehensive Cost and Pricing Analysis for small led strip Sourcing

- Spotlight on Potential small led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for small led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the small led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of small led strip

- Strategic Sourcing Conclusion and Outlook for small led strip

Introduction: Navigating the Global Market for small led strip

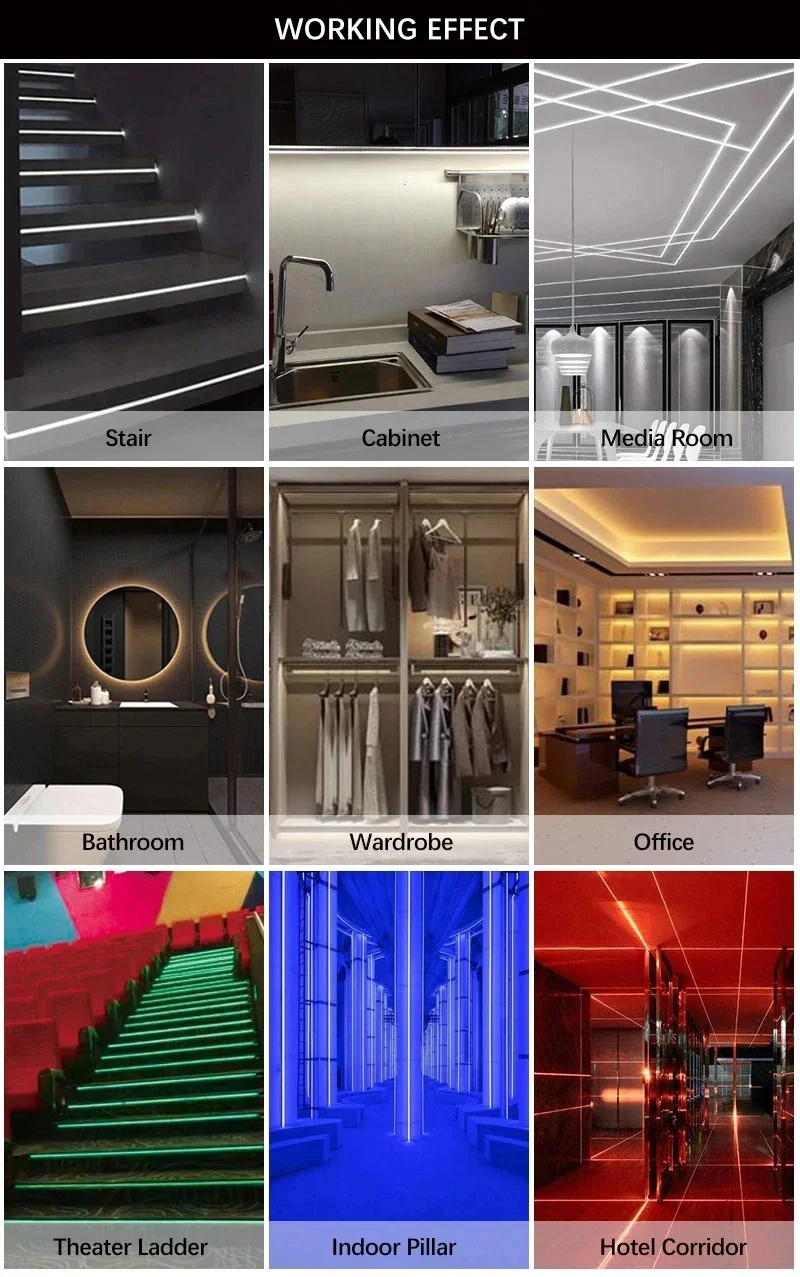

The global demand for small LED strips is rapidly growing as businesses across diverse industries seek versatile, energy-efficient lighting solutions that combine functionality with aesthetic appeal. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the intricate dynamics of this market is crucial to securing competitive advantages. Whether sourcing for retail, architectural projects, automotive applications, or smart home integrations, small LED strips offer unparalleled customization and scalability.

This comprehensive guide is designed to empower buyers with actionable insights into every critical aspect of small LED strip procurement. You will gain a clear understanding of the various types and specifications, including single-color, RGB, waterproof, and flexible variants, alongside the raw materials and technologies that influence durability and performance. Detailed sections on manufacturing standards and quality control will help you evaluate supplier reliability and product compliance, essential for navigating international trade complexities.

Additionally, the guide offers practical advice on selecting reputable suppliers, optimizing cost structures, and understanding regional market trends, with a focus on the unique challenges and opportunities faced by businesses in Argentina, Saudi Arabia, and other key markets. A dedicated FAQ section addresses common concerns, from shipping logistics to certification requirements, ensuring you are well-prepared to make informed sourcing decisions.

By leveraging this resource, international B2B buyers can confidently navigate the global small LED strip market, minimize risks, and maximize value in their procurement strategies.

Understanding small led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color LED Strip | Uniform color LEDs, often white or warm white | Retail lighting, signage, residential & commercial accent lighting | Pros: Cost-effective, simple installation; Cons: Limited color flexibility |

| RGB LED Strip | LEDs capable of producing Red, Green, and Blue colors, often with remote control | Hospitality, event lighting, architectural design | Pros: Versatile color options, dynamic effects; Cons: Higher cost, requires controllers |

| Waterproof LED Strip | Encased in silicone or epoxy for moisture and dust resistance | Outdoor signage, marine applications, industrial environments | Pros: Durable in harsh conditions; Cons: Slightly bulkier, more expensive |

| High-Density LED Strip | Higher LED count per meter for brighter, more uniform light | Task lighting, commercial displays, automotive lighting | Pros: Superior brightness and uniformity; Cons: Increased power consumption, higher price |

| Flexible PCB LED Strip | Ultra-thin and bendable circuit boards, suitable for curved surfaces | Wearables, custom installations, automotive interiors | Pros: Highly adaptable to complex shapes; Cons: Fragile, requires careful handling |

Single-Color LED Strip

These strips feature LEDs that emit a single color, predominantly white or warm white, making them ideal for straightforward illumination needs. They are cost-effective and easy to install, appealing to buyers prioritizing budget and simplicity. For B2B buyers in retail or residential sectors, these strips provide reliable accent lighting but lack the flexibility for dynamic color changes, which may limit their use in more creative or branding-focused projects.

RGB LED Strip

RGB strips incorporate tri-color LEDs allowing a wide spectrum of colors through mixing red, green, and blue light. This versatility is highly valued in hospitality, events, and architectural lighting where mood and ambiance are key. B2B buyers should consider the need for compatible controllers and power supplies, as these strips involve more complex installation and higher upfront costs, balanced by their dynamic lighting capabilities.

Waterproof LED Strip

Encased in protective silicone or epoxy, waterproof LED strips withstand moisture, dust, and harsh environments, making them essential for outdoor signage, marine, and industrial applications. Buyers targeting markets in regions with high humidity or outdoor installations, such as parts of Africa or the Middle East, will find these strips indispensable. The trade-off is a slightly bulkier profile and increased cost, which should be factored into project budgets.

High-Density LED Strip

Featuring a greater number of LEDs per meter, these strips deliver brighter and more uniform illumination, suitable for task lighting and high-visibility commercial displays. B2B buyers focusing on automotive lighting or retail displays requiring intense brightness will benefit from this type. However, they consume more power and come at a premium price, necessitating careful consideration of energy costs and power supply compatibility.

Flexible PCB LED Strip

These strips use ultra-thin, flexible printed circuit boards, enabling installation on curved or irregular surfaces. Ideal for wearables, custom design projects, and automotive interiors, they offer unique adaptability. B2B buyers should be aware of their fragility and the need for careful handling during installation. Their niche applications often justify the higher handling care and associated costs in specialized markets.

Related Video: Ultimate Guide to Programming LED Strips with Arduino | Wiring, Powering & Code with FastLED

Key Industrial Applications of small led strip

| Industry/Sector | Specific Application of small led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Visual Merchandising | Shelf and display lighting | Enhances product visibility, attracts customers | Color accuracy (CRI), flexible design, energy efficiency |

| Automotive Manufacturing | Interior ambient lighting in vehicles | Improves cabin aesthetics and user experience | Durability under vibration, heat resistance, compact form factor |

| Hospitality & Interior Design | Accent and mood lighting in hotels and restaurants | Creates ambiance, enhances guest satisfaction | Customizable color options, ease of installation, IP rating |

| Electronics & Consumer Devices | Backlighting for displays and keyboards | Improves readability, reduces power consumption | Uniform brightness, low heat emission, size compatibility |

| Architecture & Urban Planning | Cove and pathway lighting | Adds aesthetic appeal, improves safety in public spaces | Weatherproofing, long lifespan, compliance with local standards |

Small LED strips are increasingly pivotal in retail and visual merchandising environments, where they are installed on shelves and display cases to highlight products. For B2B buyers in regions like South America and Europe, sourcing LED strips with high color rendering index (CRI) ensures that merchandise colors appear true-to-life, directly influencing consumer purchasing decisions. Flexibility in strip design allows seamless integration into varied retail layouts, while energy-efficient options reduce operational costs.

In the automotive manufacturing sector, small LED strips serve as interior ambient lighting solutions that enhance vehicle aesthetics and user comfort. Buyers from the Middle East and Africa should prioritize LED strips that withstand high temperatures and mechanical vibrations common in automotive environments. Compact form factors are essential to fit into tight cabin spaces without compromising design.

The hospitality and interior design industry leverages small LED strips for accent and mood lighting in hotels, restaurants, and lounges. This application demands customizable color options and dimmable features to create diverse atmospheres. International buyers, especially in Saudi Arabia and Argentina, need to ensure the products meet IP ratings for moisture resistance and are easy to install within existing infrastructure to minimize downtime.

Within electronics and consumer device manufacturing, small LED strips are critical for backlighting displays, keyboards, and control panels. Uniform brightness and low heat emission are vital to maintain device performance and longevity. Buyers should verify that LED strips comply with size and electrical specifications to integrate smoothly into compact electronic assemblies.

Finally, in architecture and urban planning, small LED strips are utilized for cove lighting and pathway illumination to enhance both aesthetics and safety in public and commercial spaces. For B2B purchasers across Europe and Africa, sourcing weatherproof and long-lasting LED strips that comply with local safety and electrical standards is crucial for sustainable infrastructure projects. This ensures durability against environmental factors while maintaining visual appeal.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for small led strip

Material Analysis for Small LED Strip Selection

1. Flexible Printed Circuit Board (FPCB) Substrate (Polyimide or PET)

Key Properties:

FPCB substrates such as polyimide and polyethylene terephthalate (PET) offer excellent flexibility, high thermal resistance (up to 200°C for polyimide), and good electrical insulation. Polyimide is particularly resistant to heat and chemicals, while PET is more cost-effective but has lower temperature tolerance (~120°C). Both materials provide good dimensional stability and moisture resistance.

Pros & Cons:

Polyimide-based FPCBs are highly durable under thermal cycling and mechanical bending, making them ideal for compact and curved LED strip designs. However, they are more expensive and complex to manufacture compared to PET. PET substrates are cheaper but less robust under high-temperature applications and prolonged exposure to UV light.

Impact on Application:

FPCB substrates are essential for small LED strips requiring flexible installation, such as architectural lighting or automotive interiors. Polyimide substrates are preferred in harsh environments or where heat dissipation is critical. PET substrates suit indoor, low-heat applications like retail displays.

International B2B Considerations:

Buyers in regions with high ambient temperatures such as Saudi Arabia or parts of Africa should prioritize polyimide for reliability. Compliance with IPC standards (e.g., IPC-2221 for PCB design) is common globally, but European buyers may also require RoHS and REACH compliance to meet environmental regulations. South American markets like Argentina often emphasize cost-effectiveness, making PET a viable option if environmental conditions permit.

2. Copper Foil (Conductive Layer)

Key Properties:

Copper foil is the primary conductive material in LED strips, valued for excellent electrical conductivity and thermal management. Thickness typically ranges from 12µm to 35µm, affecting current capacity and heat dissipation.

Pros & Cons:

Thicker copper layers improve durability and reduce voltage drop but increase material cost and strip rigidity. Thin copper foils reduce cost and flexibility but may limit current carrying capacity and lifespan under high load.

Impact on Application:

For small LED strips used in high-current or long-run applications, thicker copper foil ensures stable performance and longevity. For decorative or low-power applications, thinner copper is sufficient and cost-effective.

International B2B Considerations:

European and Middle Eastern buyers often require adherence to ASTM B187 (standard specification for copper foil) to ensure quality and consistency. African and South American buyers should assess local supply chain capabilities for copper foil sourcing, as quality variations can impact product reliability. Copper price volatility globally can affect procurement costs, so buyers should negotiate contracts with price adjustment clauses.

3. Silicone or Epoxy Resin (Encapsulation/Coating)

Key Properties:

Silicone and epoxy resins are common encapsulants protecting LEDs and circuitry from moisture, dust, and mechanical damage. Silicone offers superior UV resistance, flexibility, and temperature tolerance (-50°C to 200°C), while epoxy provides harder, more rigid protection but is less flexible and more prone to yellowing under UV exposure.

Pros & Cons:

Silicone encapsulation extends LED strip lifespan in outdoor or high-humidity environments but is costlier and requires specialized curing processes. Epoxy coatings are more economical and suitable for indoor use but may crack under mechanical stress or degrade faster outdoors.

Impact on Application:

For outdoor lighting in regions like the Middle East or coastal Africa, silicone encapsulation is recommended to withstand harsh weather and UV exposure. Epoxy-coated strips are better suited for indoor commercial or residential applications in Europe or South America where environmental stress is lower.

International B2B Considerations:

Buyers should verify compliance with IEC 60529 (IP rating standards) to ensure appropriate ingress protection levels. In markets like Saudi Arabia, high temperature and sand exposure necessitate silicone encapsulation for durability. European buyers may require certification for fire retardancy (UL94 or EN 13501-1). South American buyers should balance cost and performance based on end-use environment.

4. Adhesive Backing Material (3M or Equivalent)

Key Properties:

Adhesive backing materials are critical for installation ease and strip longevity. Common adhesives include acrylic and silicone-based tapes, offering varying degrees of tackiness, temperature resistance, and residue-free removal.

Pros & Cons:

Acrylic adhesives provide strong bonding and good temperature resistance (up to 80°C), suitable for most indoor applications. Silicone adhesives offer higher temperature tolerance (up to 200°C) and better resistance to UV and chemicals but at a higher cost.

Impact on Application:

For small LED strips installed in automotive or industrial environments (e.g., South America’s manufacturing sectors), silicone adhesives ensure reliable adhesion under thermal cycling. For indoor retail or residential use (common in Europe and Africa), acrylic adhesives offer sufficient performance at a lower price point.

International B2B Considerations:

Buyers should confirm adhesive compatibility with substrate surfaces common in their markets (metal, plastic, glass). Regulatory standards such as REACH in Europe influence adhesive chemical composition. In hot climates like the Middle East, selecting adhesives with high temperature and UV resistance is critical to prevent peeling and failure.

Summary Table of Material Selection for Small LED Strip

| Material | Typical Use Case for small led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide FPCB Substrate | Flexible, high-temp LED strips for harsh environments | High thermal resistance, flexibility | Higher cost, complex manufacturing | High |

| PET FPCB Substrate | Cost-sensitive, indoor LED strip applications | Low cost, good flexibility | Lower heat resistance, less durable | Low |

| Copper Foil | Conductive layer for electrical and thermal management | Excellent conductivity and heat dissipation | Cost fluctuates, thicker foil increases cost | Medium |

| Silicone Encapsulation | Outdoor, high-UV, high-moisture environments | Superior UV and temperature resistance | Higher cost, specialized processing | High |

| Epoxy Encapsulation | Indoor, low-stress environments | Cost-effective, rigid protection | Less flexible, prone to yellowing | Low |

| Acrylic Adhesive Backing | Indoor installations with moderate temperature | Strong bond, cost-effective | Limited high-temp resistance | Low |

| Silicone Adhesive Backing | Automotive, industrial, high-temp installations | High temp and UV resistance | Higher cost | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for small led strip

Overview of Manufacturing Processes for Small LED Strips

The production of small LED strips involves a series of carefully coordinated stages, each critical to ensuring product quality, efficiency, and compliance with international standards. For B2B buyers, understanding these stages helps in selecting reliable suppliers and anticipating production timelines.

1. Material Preparation

This initial phase focuses on sourcing and preparing the raw materials:

– Flexible PCB (Printed Circuit Board) substrate: Usually made from polyimide or fiberglass materials, cut to size.

– LED chips and components: High-quality LEDs, resistors, capacitors, and connectors are procured, often from certified vendors.

– Adhesives and protective coatings: Specialized adhesives and silicone coatings are prepared for assembly and finishing.

2. Forming and PCB Fabrication

The PCB is formed and prepared for component placement:

– Etching and layering: The copper layers are etched to form the circuit paths.

– Solder mask application: Protects the circuitry and prevents short circuits.

– Cutting and punching: The PCB is cut into strips of the desired length and punched with mounting holes or connectors.

3. Component Assembly

This critical stage involves placing and securing components on the PCB:

– Surface Mount Technology (SMT): Automated pick-and-place machines position LEDs and other surface-mount components with high precision.

– Reflow soldering: Components are soldered using controlled heat profiles to ensure strong and reliable joints.

– Manual soldering: For components requiring special attention or customization.

4. Finishing Processes

Final touches enhance durability and usability:

– Encapsulation and coating: Silicone or epoxy layers protect LEDs from moisture, dust, and physical damage.

– Cutting and packaging: Strips are cut to standard or custom lengths and packaged with protective materials for shipment.

– Labeling and documentation: Product information, batch numbers, and compliance marks are added.

Quality Assurance Framework and Checkpoints

For B2B buyers, stringent quality control (QC) is vital to ensure product reliability and compliance with regulatory requirements. QC is integrated throughout the manufacturing process, typically following international best practices and standards.

Key International and Industry Standards:

– ISO 9001: The global standard for quality management systems, ensuring consistent production quality and continual improvement.

– CE Marking: Mandatory for European markets, certifying compliance with safety, health, and environmental requirements.

– RoHS Compliance: Restricts hazardous substances in electronic products, crucial for European and some Middle Eastern markets.

– UL Certification: Widely recognized in the Americas and Middle East for electrical safety.

– IEC Standards: International Electrotechnical Commission standards often referenced for LED lighting products.

– API and other regional certifications: Relevant for specific industrial applications and markets like Saudi Arabia and Argentina.

QC Checkpoints in Manufacturing:

– Incoming Quality Control (IQC): Inspection of raw materials and components before entering production. This includes verifying supplier certificates, visual inspections, and basic electrical tests.

– In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, LED placement accuracy, and reflow soldering profiles.

– Final Quality Control (FQC): Comprehensive testing of finished products, including functionality, durability, and safety checks before packaging.

Common Testing Methods for Small LED Strips

To maintain high standards, manufacturers employ a range of tests that B2B buyers should verify:

- Electrical Testing: Ensures correct voltage, current, and resistance values; checks for shorts or open circuits.

- Light Output and Color Testing: Measures luminous intensity, color temperature, and uniformity using photometers and spectrometers.

- Thermal Testing: Assesses heat dissipation and thermal stability under operating conditions.

- Waterproof and Environmental Testing: For outdoor or industrial strips, IP rating tests check resistance to moisture, dust, and chemicals.

- Mechanical Testing: Includes bend tests, adhesion tests for coatings, and vibration resistance.

- Aging Tests: Continuous operation over extended periods to identify early failures or degradation.

Verifying Supplier Quality Control: Practical Tips for B2B Buyers

Due diligence on suppliers’ QC practices is essential, especially for international buyers from Africa, South America, the Middle East, and Europe who face diverse regulatory environments and logistical challenges.

1. Request Documentation and Certifications

– Obtain copies of ISO 9001 certificates, CE declarations of conformity, and test reports.

– Verify authenticity through certification bodies or online databases.

2. Conduct Factory Audits

– On-site or third-party audits evaluate manufacturing processes, QC systems, and working conditions.

– Remote audits using video conferencing can be an alternative amid travel restrictions.

3. Review Sample Testing and Inspection Reports

– Request detailed inspection reports for sample batches, including test methods and results.

– Use third-party inspection agencies to perform random batch testing before shipment.

4. Understand Regional QC Nuances

– In Africa and South America, infrastructure for advanced testing might be limited; buyers should emphasize supplier certifications and third-party inspections.

– Middle Eastern buyers, such as those in Saudi Arabia, often require compliance with GCC Standards Organization (GSO) regulations alongside international ones.

– European buyers must ensure strict adherence to EU directives like RoHS and CE marking, with a focus on environmental and safety standards.

Strategic Considerations for International B2B Buyers

- Custom Compliance Needs: Clarify with suppliers how products meet country-specific import regulations and certification requirements.

- Supplier Quality Evolution: Prefer manufacturers with continuous improvement programs and transparent QC data sharing.

- After-Sales Support: Confirm warranty terms, return policies, and availability of technical support to mitigate risks.

- Batch Consistency: For large orders, verify that QC processes ensure uniformity across production batches, which is crucial for installation projects and resale.

By thoroughly understanding the manufacturing stages and quality assurance mechanisms for small LED strips, international B2B buyers can make informed decisions, reduce supply chain risks, and secure products that meet both performance and regulatory expectations.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for small led strip Sourcing

Breakdown of Cost Components in Small LED Strip Sourcing

When sourcing small LED strips, understanding the underlying cost components is essential to optimize procurement and negotiate effectively. The primary cost drivers include:

- Materials: This encompasses the LED chips, flexible PCB substrates, resistors, adhesives, and encapsulation materials. High-quality LEDs and premium substrates increase durability and luminosity but add to costs.

- Labor: Skilled labor for assembly, soldering, and testing affects pricing, especially in regions with higher wage standards.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor.

- Tooling Costs: Initial setup costs for molds, assembly lines, and testing jigs can be amortized over large orders but impact pricing for smaller volumes.

- Quality Control (QC): Rigorous QC processes, including photometric testing and reliability checks, ensure product consistency but add to unit costs.

- Logistics: Freight, customs duties, insurance, and local delivery fees vary significantly depending on the buyer’s location and chosen shipping methods.

- Supplier Margin: This is the markup suppliers add to cover profit, marketing, and operational expenses.

Key Price Influencers for International Buyers

Several factors influence the final price of small LED strips, which buyers should carefully evaluate:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically secure better per-unit pricing. MOQ requirements can vary widely among suppliers, impacting cost-efficiency for smaller buyers.

- Specifications and Customization: Custom colors, lengths, IP ratings (waterproofing), and integrated controllers increase manufacturing complexity and cost.

- Material Quality: Premium LEDs (e.g., Samsung, Cree) and higher-grade PCBs command higher prices but deliver better performance and lifespan.

- Certifications and Quality Standards: Compliance with CE, RoHS, UL, or other regional certifications adds to cost but is often necessary for market access, especially in Europe and the Middle East.

- Supplier Reputation and Location: Established suppliers with robust supply chains might charge more but reduce risk. Proximity to manufacturing hubs (e.g., China, South Korea) reduces logistics costs.

- Incoterms: Shipping terms like FOB, CIF, or DDP influence the buyer’s responsibility for freight and customs, affecting total landed cost.

Strategic Tips for B2B Buyers in Africa, South America, the Middle East, and Europe

- Negotiate Based on Volume and Commitment: Buyers from emerging markets such as Argentina or Saudi Arabia should leverage order consolidation and multi-year agreements to secure discounts.

- Assess Total Cost of Ownership (TCO): Beyond unit price, consider warranty terms, replacement policies, and after-sales support to avoid hidden expenses.

- Optimize Logistics: Choose Incoterms aligning with local import processes and preferred carriers to minimize delays and customs fees.

- Request Samples and Certifications: Always verify product quality via samples and ensure compliance with local regulations to prevent costly returns or bans.

- Explore Local and Regional Distributors: Sometimes sourcing through regional partners can reduce lead times and import duties.

- Factor Currency Fluctuations and Payment Terms: Negotiate favorable payment terms (e.g., letters of credit) and monitor currency risks, especially when dealing in USD or EUR.

Pricing Nuances for International Markets

Buyers in Africa and South America often face higher freight and customs costs, making CIF or DDP Incoterms preferable despite potentially higher upfront prices. European buyers typically demand strict certifications and environmental compliance, influencing supplier selection and price premiums. Middle Eastern buyers might prioritize supplier reliability and product warranty due to harsher climate conditions affecting product performance.

Disclaimer on Pricing

Prices for small LED strips can vary widely based on supplier, order size, customization level, and prevailing market conditions. The insights provided are indicative and should be validated with direct supplier quotations and market research tailored to your specific sourcing requirements.

By comprehensively analyzing cost components and price influencers, international B2B buyers can make informed decisions, negotiate effectively, and optimize procurement strategies for small LED strips across diverse global markets.

Spotlight on Potential small led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘small led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for small led strip

When sourcing small LED strips for international B2B transactions, understanding their technical specifications and industry terminology is crucial. This knowledge ensures clear communication with suppliers and helps in selecting products that meet your project requirements efficiently.

Key Technical Properties of Small LED Strips

-

LED Chip Quality and Material Grade

The quality of the LED chips, often measured by the manufacturer’s grade (e.g., A+, A, B), directly impacts brightness, longevity, and energy efficiency. Higher-grade chips usually mean better performance and reliability, which is critical for projects requiring consistent illumination over time. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the hue of the light, ranging from warm white (~2700K) to cool white (~6500K). CRI indicates how accurately the LED light renders colors compared to natural light. For B2B buyers, especially in retail or hospitality sectors, selecting strips with appropriate color temperature and a CRI above 80 ensures appealing and true-to-life lighting. -

Power Consumption and Voltage

Small LED strips typically operate at 12V or 24V DC. Understanding power consumption (watts per meter) helps in planning power supply and installation costs. Lower power consumption with high brightness is ideal for energy-conscious projects and reducing operational expenses. -

IP Rating (Ingress Protection)

IP ratings indicate protection against dust and water. For example, IP20 suits indoor use, while IP65 or higher is necessary for outdoor or humid environments. Buyers in regions with high humidity or outdoor applications (e.g., Saudi Arabia or coastal cities) should prioritize appropriate IP ratings to ensure product durability. -

Cutting and Soldering Tolerance

Small LED strips can be cut at specified intervals to fit custom lengths. Knowing the tolerance for cutting and soldering points is essential for flexible installation without damaging the strip. This is especially important for complex architectural lighting designs. -

Luminous Flux and LED Density

Luminous flux (measured in lumens) indicates brightness, while LED density (LEDs per meter) affects uniformity of light distribution. Higher density strips produce smoother, more continuous light, preferred in high-end commercial or retail environments.

Common Trade and Industry Terms for B2B Buyers

-

OEM (Original Equipment Manufacturer)

Refers to products made by one company to be rebranded and sold by another. Many LED strip suppliers offer OEM services, allowing buyers to customize packaging, branding, or product specifications to suit their market needs. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs vary widely and can impact pricing and inventory decisions. Buyers from emerging markets should negotiate MOQs that balance cost-effectiveness with manageable stock levels. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for detailed pricing, lead times, and product specifications. Providing clear RFQs with technical requirements ensures accurate quotations and smooth procurement. -

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms is vital for managing logistics and cost allocation effectively. -

Lead Time

The time between placing an order and receiving the goods. Shorter lead times are often critical in fast-moving markets or seasonal demand spikes. Clarifying lead times upfront helps avoid project delays. -

Bin Code

A classification that indicates the binning of LEDs based on brightness and color consistency. This affects product uniformity, especially important for high-precision lighting projects.

By grasping these technical properties and trade terms, international buyers can better assess product quality, negotiate favorable terms, and ensure seamless supply chain management when procuring small LED strips. This foundation supports smarter purchasing decisions tailored to diverse markets across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the small led strip Sector

Market Overview & Key Trends

The global market for small LED strips is experiencing robust growth driven by increasing demand for energy-efficient lighting solutions across commercial, industrial, and residential sectors. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, this growth is underpinned by urbanization, infrastructure development, and rising awareness of cost-effective lighting technologies. Countries such as Saudi Arabia and Argentina are investing heavily in smart city projects and modern retail environments, boosting demand for customizable, small-format LED strips that offer flexible design and superior energy savings.

Key market dynamics include the shift toward smart lighting systems integrating IoT capabilities, allowing for remote control, automation, and enhanced energy management. Buyers are increasingly sourcing LED strips with advanced features such as tunable white light, RGB color control, and improved longevity. Additionally, supply chain diversification is becoming critical as geopolitical uncertainties and logistics challenges prompt buyers to explore alternative manufacturing hubs beyond traditional centers in East Asia, including emerging suppliers in Eastern Europe and the Middle East.

Sourcing trends emphasize customization and shorter lead times, with manufacturers offering modular small LED strips tailored to specific applications—from architectural accents to automotive lighting. Digital platforms and B2B marketplaces are facilitating direct connections between buyers and manufacturers, improving transparency and pricing competitiveness. Moreover, regional trade agreements and tariff adjustments impact procurement strategies, making it essential for buyers to stay informed on regulatory changes affecting imports and certifications in their respective markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a non-negotiable factor for international B2B buyers in the small LED strip sector. The environmental impact of lighting products spans raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal. Buyers from environmentally conscious regions such as Europe and progressive markets in the Middle East are demanding LED strips manufactured with low carbon footprints and recyclable materials.

Ethical supply chain management is equally critical, with buyers prioritizing suppliers who demonstrate responsible labor practices and compliance with international standards such as ISO 14001 for environmental management and SA8000 for social accountability. Certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are baseline requirements to ensure product safety and environmental compliance.

Green materials such as lead-free solder, phosphor coatings free of heavy metals, and halogen-free substrates are increasingly sought after. Additionally, energy efficiency ratings and product lifespan certifications help buyers quantify sustainability benefits. For B2B buyers in Africa and South America, partnering with suppliers offering transparent sustainability reporting and eco-friendly innovations can enhance brand reputation and meet growing regulatory pressures for greener procurement.

Brief Evolution of Small LED Strips in B2B Context

Small LED strips have evolved from simple decorative lighting components to sophisticated, multifunctional tools integral to modern lighting design and energy management. Initially adopted for accent lighting due to their compact size and flexibility, technological advancements have expanded their applications to include backlighting, signage, automotive interiors, and architectural illumination.

The integration of smart controls and improvements in LED chip efficiency have transformed small LED strips into key components for intelligent lighting systems. This evolution has made them indispensable for B2B buyers seeking scalable, customizable lighting solutions that align with digital transformation and sustainability goals. Understanding this progression helps buyers appreciate the value propositions and emerging opportunities within the small LED strip market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of small led strip

-

How can I effectively vet suppliers of small LED strips from different regions like Africa or South America?

To ensure reliability, start by verifying the supplier’s business license and certifications such as ISO or CE relevant to your market. Request product samples to assess quality firsthand. Check references and reviews from other international buyers, especially those in your region. Use platforms that offer verified supplier credentials and consider conducting factory audits or third-party inspections. Establish clear communication channels early to gauge responsiveness and professionalism, which are crucial for ongoing partnerships. -

Is customization of small LED strips available for bulk orders, and what should I consider?

Yes, many manufacturers offer customization such as length, color temperature, IP rating, and connector types. When negotiating customization, clarify technical specifications and request prototypes or samples before full production. Consider the impact on minimum order quantities (MOQs) and lead times, as custom products often require longer production schedules. Ensure your supplier can meet your compliance and certification requirements for your target markets to avoid regulatory issues. -

What are typical MOQ and lead times for small LED strip orders, and how can I negotiate them?

MOQ varies widely, commonly ranging from 500 to 2,000 meters, depending on the supplier’s production capacity and customization level. Lead times typically span 2 to 6 weeks, influenced by order size and customization complexity. To negotiate better terms, demonstrate your potential for repeat business, consolidate orders to increase volume, or agree on longer lead times. For buyers in regions like the Middle East or Europe, factor in additional time for customs clearance and shipping. -

Which payment terms are standard for international B2B purchases of small LED strips?

Common terms include a 30% deposit upfront with the balance paid before shipment or upon receipt of documents. Letters of credit (LC) are also widely used for secure transactions, especially when working with new suppliers. For trusted partners, net 30 or net 60 terms might be negotiated. Always clarify currency, payment method (T/T, PayPal, etc.), and any transaction fees. Using escrow services can mitigate risks when dealing with new international suppliers. -

What quality assurance measures and certifications should I require from suppliers?

Request proof of compliance with international standards such as CE, RoHS, UL, or FCC depending on your target market. Quality assurance should include in-line testing during production and final inspection reports. Ask for warranty terms and understand the supplier’s defect rate policies. For critical applications, consider third-party lab testing or factory audits to verify product durability and safety. Documentation of quality control processes boosts confidence and reduces risk. -

How should I manage logistics and shipping when importing small LED strips internationally?

Choose reliable freight forwarders experienced with electronics shipments to handle customs and ensure timely delivery. Decide between air freight for speed or sea freight for cost efficiency, balancing budget and urgency. Understand Incoterms (e.g., FOB, CIF) to clarify who bears shipping risks and costs. Plan for potential delays at customs, especially in countries with strict import regulations like Saudi Arabia or Argentina. Consolidating shipments can reduce costs but may extend lead times. -

What steps can I take to resolve disputes or quality issues with overseas LED strip suppliers?

Document all communications and agreements clearly, including specifications and delivery terms. If defects arise, request detailed photos or videos and negotiate returns or replacements per the contract. Engage third-party inspection or mediation services if disputes escalate. Maintain a professional tone and seek amicable solutions to preserve long-term partnerships. Including arbitration clauses in contracts can provide a structured dispute resolution path. -

Are there specific considerations for sourcing small LED strips for markets in Africa, South America, or the Middle East?

Yes, local regulatory standards, voltage requirements, and environmental conditions vary widely. For example, dust and humidity levels in some African or Middle Eastern regions may necessitate higher IP-rated strips. Currency fluctuations and import duties can impact pricing; factor these into your cost analysis. Building relationships with suppliers familiar with your target market’s compliance and logistics challenges enhances supply chain resilience. Tailored marketing and packaging may also be necessary to meet regional preferences.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for small led strip

Strategic sourcing of small LED strips presents a compelling opportunity for international B2B buyers aiming to optimize cost, quality, and supply reliability. Key takeaways emphasize the importance of building strong supplier relationships, leveraging regional manufacturing hubs, and prioritizing product certifications and compliance to meet diverse market standards across Africa, South America, the Middle East, and Europe. These factors collectively reduce risk and enhance the agility of your supply chain.

Investing in a strategic sourcing approach enables buyers to navigate fluctuating raw material costs and evolving technology trends more effectively. By focusing on suppliers that demonstrate innovation in energy efficiency and durability, businesses can future-proof their product offerings while meeting sustainability goals increasingly valued worldwide.

Looking ahead, international buyers should adopt a proactive stance—engaging suppliers early, exploring collaborative development opportunities, and continuously monitoring geopolitical and trade developments affecting the LED strip market. This forward-thinking mindset will unlock competitive advantages and ensure steady growth in dynamic markets such as Argentina and Saudi Arabia.

Take action now: deepen your market intelligence, refine your sourcing strategy, and partner with trusted manufacturers to capitalize on the expanding global demand for small LED strips. The path to sustainable success lies in strategic sourcing excellence.