Guide to Remote Led Strip

- Introduction: Navigating the Global Market for remote led strip

- Understanding remote led strip Types and Variations

- Key Industrial Applications of remote led strip

- Strategic Material Selection Guide for remote led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for remote led strip

- Comprehensive Cost and Pricing Analysis for remote led strip Sourcing

- Spotlight on Potential remote led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for remote led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the remote led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of remote led strip

- Strategic Sourcing Conclusion and Outlook for remote led strip

Introduction: Navigating the Global Market for remote led strip

In today’s rapidly evolving lighting industry, remote LED strips have emerged as a pivotal technology, combining energy efficiency with advanced control capabilities. For international B2B buyers—especially those operating across Africa, South America, the Middle East, and Europe—understanding the nuances of remote LED strip solutions is essential to capitalizing on market opportunities and meeting diverse client demands. These lighting systems offer unparalleled flexibility, from customizable color settings to remote operation, making them ideal for commercial, industrial, and architectural applications worldwide.

This comprehensive guide is designed to empower buyers with critical insights into the global remote LED strip market. It covers a broad spectrum of topics including types of remote LED strips, material quality, manufacturing and quality control processes, supplier selection strategies, cost considerations, and regional market trends. Additionally, practical FAQs address common procurement challenges and technical specifications, enabling buyers to make well-informed sourcing decisions.

By navigating this guide, businesses can optimize their supply chains, minimize risks associated with quality and delivery, and leverage the latest technological advancements. Whether sourcing for large-scale infrastructure projects in the UAE, retail installations in Europe, or emerging markets in Africa and South America, this resource provides the actionable knowledge required to select the right products and partners. Ultimately, it bridges the gap between innovation and procurement efficiency, ensuring buyers remain competitive and responsive in a dynamic global marketplace.

Understanding remote led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color Remote LED Strip | Emits one fixed color controlled via remote; simple interface | Retail displays, accent lighting, hospitality | + Cost-effective, easy installation; – Limited customization |

| RGB Remote LED Strip | Supports Red, Green, Blue colors with remote color mixing | Event venues, advertising, residential projects | + Versatile color options; – Higher cost, requires compatible controllers |

| RGBW Remote LED Strip | Adds a dedicated white LED to RGB for enhanced color accuracy | Architectural lighting, museums, luxury retail | + Improved white tones; – More complex wiring, higher price |

| Waterproof Remote LED Strip | Encased in silicone or epoxy for outdoor/moist environments | Outdoor signage, landscaping, marine lighting | + Durable, weather-resistant; – Slightly bulkier, cost premium |

| Smart Wi-Fi/Bluetooth Remote LED Strip | Controlled via smartphone app and remote, with automation features | Smart buildings, offices, hotels | + Advanced control, integration; – Dependent on network, higher initial investment |

Single-Color Remote LED Strip

This type offers a fixed color output controlled by a basic remote, making it ideal for businesses seeking straightforward, cost-effective lighting solutions. Its simplicity supports quick installation and minimal training for end-users. For B2B buyers in retail or hospitality sectors, this strip is suitable for accent lighting or enhancing brand colors without the complexity of multi-color management. Key purchasing considerations include ensuring compatibility with existing power supplies and remote controllers to avoid integration issues.

RGB Remote LED Strip

RGB strips provide dynamic color-changing capabilities through remote control, allowing businesses to create vibrant and customizable lighting environments. This versatility is beneficial for event organizers, advertising agencies, and residential developers who require adaptable lighting solutions. Buyers should evaluate the quality of the controller and LED chips, as well as the ease of remote use, to ensure smooth operation and color accuracy. Bulk orders often yield better pricing but verifying supplier reliability is crucial.

RGBW Remote LED Strip

By incorporating an additional dedicated white LED, RGBW strips deliver more precise white light alongside full RGB color mixing. This makes them highly desirable for architectural projects, museums, or luxury retail spaces where lighting quality and color fidelity are paramount. B2B buyers should focus on the supplier’s consistency in LED quality and the compatibility of remotes with advanced color presets. The slightly higher cost is justified by enhanced lighting performance and customer satisfaction.

Waterproof Remote LED Strip

Designed for outdoor or moisture-prone environments, these strips feature protective coatings like silicone or epoxy, ensuring durability against weather, dust, and water ingress. Ideal for landscaping companies, outdoor signage providers, and marine applications, these LED strips require consideration of IP ratings and robustness during procurement. Buyers must assess the trade-off between durability and flexibility, as waterproof strips tend to be less pliable and costlier than indoor variants.

Smart Wi-Fi/Bluetooth Remote LED Strip

These advanced LED strips integrate remote controls with smartphone apps, enabling automation, scheduling, and integration with smart building systems. They are increasingly favored in offices, hotels, and smart city projects. For B2B buyers, the focus should be on network compatibility, security features, and supplier support for firmware updates. Although the initial investment is higher, the long-term benefits include enhanced user experience and energy management efficiencies.

Key Industrial Applications of remote led strip

| Industry/Sector | Specific Application of remote led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Ambient and accent lighting in stores and malls | Enhances customer experience, increases product visibility, and drives sales | Color accuracy, dimmability, ease of installation, and remote control range |

| Hospitality & Events | Dynamic mood lighting in hotels, restaurants, and event venues | Creates customizable atmospheres, improves guest satisfaction, and reduces energy costs | Waterproofing, flexible length options, compatibility with smart controls |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Improves worker productivity and safety, reduces downtime due to better visibility | Durability, brightness levels, remote control for zone-specific lighting |

| Automotive & Transportation | Interior lighting in vehicles and public transport | Enhances passenger comfort and safety, allows for customizable lighting schemes | Vibration resistance, power efficiency, remote control integration |

| Healthcare & Laboratories | Controlled lighting for examination rooms and sterile environments | Provides precise illumination, supports hygiene protocols, and allows remote adjustments | Non-toxic materials, easy cleaning, adjustable brightness and color temperature |

In the Retail & Commercial sector, remote LED strips are widely used to create ambient and accent lighting that highlights products and enhances store aesthetics. This lighting solution allows businesses to remotely adjust brightness and color to match different marketing campaigns or times of day, improving customer engagement and potentially increasing sales. For international buyers, especially in regions like Europe and the Middle East, sourcing LED strips with consistent color rendering and reliable remote control functionality is crucial to maintain brand standards across multiple locations.

Within Hospitality & Events, remote LED strips enable dynamic mood lighting that can be tailored to different themes or guest preferences. Hotels and restaurants benefit from the ability to adjust lighting remotely, reducing manual labor and energy consumption. Buyers from Africa and South America should prioritize waterproof and durable LED strips that can withstand diverse climatic conditions, while also ensuring compatibility with smart lighting systems popular in modern venues.

In Manufacturing & Warehousing, remote LED strips serve as efficient task and safety lighting solutions. They can be installed in production lines and storage areas to improve visibility and worker safety, with the added benefit of remote control for adjusting lighting zones without disrupting operations. For international buyers, especially in industrial hubs in the UAE and Australia, sourcing LED strips with high brightness, long lifespan, and robust remote control features is essential to withstand harsh working environments and streamline operations.

The Automotive & Transportation industry utilizes remote LED strips for interior lighting in vehicles and public transport systems, enhancing passenger comfort and safety. These strips allow for customizable lighting schemes that can be controlled remotely for convenience and efficiency. Buyers from Europe and the Middle East must focus on sourcing LED strips that offer vibration resistance, low power consumption, and seamless integration with existing vehicle control systems to ensure reliability and compliance with transport safety standards.

Lastly, in Healthcare & Laboratories, remote LED strips provide controlled lighting environments necessary for examinations and sterile procedures. The ability to remotely adjust brightness and color temperature supports precise illumination needs while maintaining hygiene standards. International B2B buyers should seek LED strips made from non-toxic materials, easy to clean, and compliant with health regulations, ensuring the lighting solutions meet the strict requirements of medical facilities across diverse regions.

Related Video: How To Use the LED Light Remote! – Explaining Every Button! [Tutorial]

Strategic Material Selection Guide for remote led strip

Common Materials for Remote LED Strip Construction: An In-Depth B2B Analysis

When selecting materials for remote LED strips, international B2B buyers must consider factors such as environmental conditions, durability, cost, and compliance with regional standards. Below is a detailed analysis of four prevalent materials used in remote LED strip manufacturing.

1. Flexible Printed Circuit Board (FPCB) – Polyimide-Based

Key Properties:

Polyimide FPCBs are prized for their excellent thermal stability (typically up to 260°C), high flexibility, and good dielectric strength. They resist moderate chemical exposure and have excellent dimensional stability, making them ideal for intricate LED strip layouts.

Pros & Cons:

– Pros: High flexibility allows for installation in curved or tight spaces; excellent heat resistance prolongs LED lifespan; lightweight and thin design reduces bulk.

– Cons: Higher cost compared to standard rigid PCBs; manufacturing complexity requires specialized equipment; limited mechanical strength compared to rigid substrates.

Impact on Application:

Ideal for indoor and some outdoor applications where flexibility and heat dissipation are critical. Polyimide-based FPCBs perform well in commercial and decorative lighting but require protective coatings for harsh environments.

Considerations for International Buyers:

Buyers in regions with high ambient temperatures (e.g., Middle East, Africa) benefit from polyimide’s thermal resistance. Compliance with IPC standards (IPC-2223 for flexible circuits) and regional certifications such as CE (Europe) or SASO (Saudi Arabia) is essential. Buyers should verify supplier adherence to these standards to ensure product reliability.

2. Rigid Printed Circuit Board (FR4)

Key Properties:

FR4 is a glass-reinforced epoxy laminate with good mechanical strength and moderate heat resistance (up to ~130°C). It offers excellent electrical insulation and is widely used due to its cost-effectiveness.

Pros & Cons:

– Pros: Low manufacturing cost; robust mechanical support; widely available and standardized.

– Cons: Limited flexibility restricts use in curved installations; lower temperature tolerance may reduce LED longevity in high-heat environments.

Impact on Application:

Best suited for fixed, flat installations such as signage or architectural lighting where rigidity is acceptable. Less ideal for applications requiring bending or exposure to high temperatures.

Considerations for International Buyers:

FR4 is globally standardized (e.g., UL94 V-0 flame rating, IEC standards), making it a safe choice for buyers in Europe, South America, and Australia. However, buyers in hot climates should consider potential thermal management challenges. Ensuring suppliers provide RoHS and REACH compliance is critical for European markets.

3. Silicone Encapsulation (for Waterproofing)

Key Properties:

Silicone encapsulants provide excellent moisture resistance, UV stability, and flexibility. They operate effectively across a wide temperature range (-50°C to 200°C) and offer good electrical insulation.

Pros & Cons:

– Pros: Superior waterproofing for outdoor and industrial use; flexible and durable; resistant to environmental degradation.

– Cons: Adds cost and weight; can complicate manufacturing and repair; potential yellowing over time under intense UV exposure.

Impact on Application:

Essential for outdoor, marine, or humid environments common in regions like South America’s coastal areas or the Middle East’s desert climates. Silicone encapsulation ensures LED strips maintain performance despite exposure to water and dust.

Considerations for International Buyers:

Buyers must verify IP ratings (IP65, IP67, or IP68) and confirm compliance with international waterproofing standards (IEC 60529). Additionally, regional environmental regulations may affect material choice, particularly in Europe where eco-friendly materials are favored.

4. Aluminum Substrate (Aluminum PCB)

Key Properties:

Aluminum substrates provide excellent thermal conductivity, mechanical strength, and corrosion resistance. They typically withstand temperatures up to 150°C and offer efficient heat dissipation critical for high-power LED strips.

Pros & Cons:

– Pros: Enhances LED lifespan by reducing thermal stress; robust and lightweight; corrosion-resistant, suitable for harsh environments.

– Cons: Higher material cost than FR4; less flexible, limiting use in curved applications; manufacturing requires specialized bonding techniques.

Impact on Application:

Ideal for industrial, commercial, and outdoor installations requiring high brightness and long operational life. Aluminum substrates are preferred in regions with high ambient temperatures or where heat dissipation is a priority, such as UAE and Australia.

Considerations for International Buyers:

Compliance with ASTM B209 (aluminum sheet standards) and regional corrosion resistance standards is important. Buyers should ensure suppliers provide certifications for thermal performance and corrosion resistance, especially for installations exposed to salty or humid air (e.g., coastal South America).

Summary Table: Material Selection for Remote LED Strips

| Material | Typical Use Case for remote led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide Flexible PCB | Flexible installations requiring heat resistance | High flexibility and thermal stability | Higher cost and manufacturing complexity | High |

| FR4 Rigid PCB | Flat, fixed installations with moderate heat levels | Cost-effective and mechanically robust | Limited flexibility and heat tolerance | Low |

| Silicone Encapsulation | Outdoor/waterproof LED strips in harsh environments | Excellent waterproofing and UV resistance | Adds cost and complicates repairs | Medium |

| Aluminum Substrate PCB | High-power, high-heat dissipation applications | Superior thermal management and durability | Less flexible, higher cost | Medium to High |

This guide empowers B2B buyers from diverse regions to make informed decisions about remote LED strip materials by balancing performance requirements, environmental conditions, and compliance demands. Selecting the right material ensures product longevity, customer satisfaction, and competitive advantage in international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for remote led strip

Manufacturing Process of Remote LED Strips

The production of remote LED strips involves a series of carefully controlled stages to ensure both performance and durability. Understanding these stages helps international B2B buyers assess supplier capabilities and ensure product consistency.

1. Material Preparation

This foundational stage involves sourcing and preparing high-quality raw materials:

– LED Chips and Modules: High-efficiency LEDs are selected based on brightness, color temperature, and energy consumption.

– Flexible Printed Circuit Boards (FPCBs): These serve as the substrate for LED mounting and must meet flexibility and heat dissipation requirements.

– Remote Control Components: Infrared (IR) or radio frequency (RF) receivers, microcontrollers, and wireless communication modules are prepared for integration.

– Adhesives and Protective Coatings: Materials such as silicone or epoxy are readied for waterproofing and durability.

Suppliers often collaborate closely with LED module manufacturers to secure reliable components, which directly impact final product quality.

2. Forming and Circuit Assembly

- FPCB Fabrication: The flexible circuit board is patterned using photolithography and etching to create precise conductive pathways.

- LED Mounting: Surface-mount technology (SMT) machines place LEDs and other components onto the FPCB with high accuracy.

- Soldering: Automated soldering processes, such as reflow soldering, ensure strong electrical connections.

- Remote Control Integration: Microcontrollers and IR/RF receivers are assembled either on the strip or in a connected control module.

Advanced manufacturing lines utilize automated optical inspection (AOI) post-assembly to detect placement errors or soldering defects early.

3. Testing and Finishing

- Encapsulation: LED strips are coated with waterproof materials or encased in silicone tubes for protection against moisture and dust.

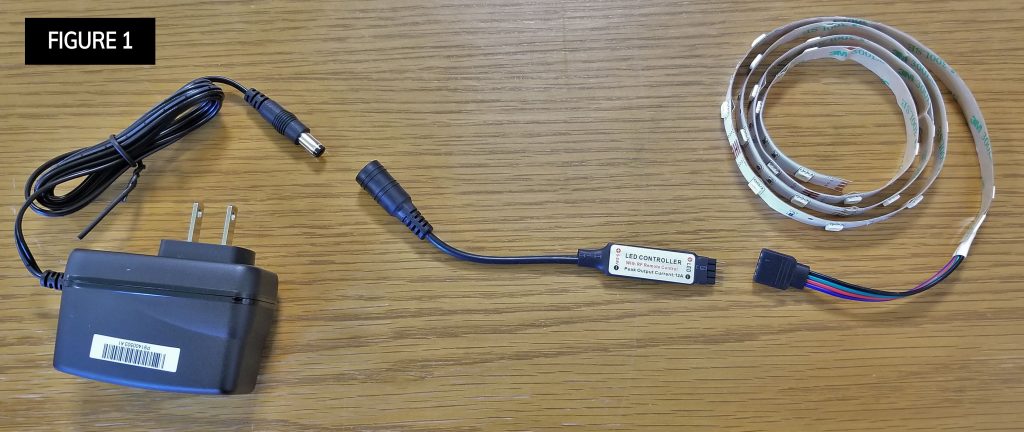

- Cutting and Packaging: Strips are cut to standard or custom lengths, labeled, and packaged with remote control units and power adapters.

- Functional Testing: Each batch undergoes lighting tests to confirm color accuracy, brightness uniformity, and remote responsiveness.

Automated test benches simulate real-world operating conditions to verify product reliability before shipment.

Quality Assurance and Control (QA/QC) Framework

For B2B buyers, especially across Africa, South America, the Middle East, and Europe, understanding the rigorous quality control processes and international standards is essential to mitigate risks and ensure product compliance.

Illustrative Image (Source: Google Search)

Key International and Industry Standards

- ISO 9001: This globally recognized quality management system standard ensures suppliers maintain consistent quality processes, from procurement to delivery.

- CE Marking: Mandatory for products sold in the European Economic Area, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restriction of hazardous substances ensures LED strips are free from harmful materials like lead and mercury, critical for environmental safety.

- FCC Certification: For remote control modules operating via radio frequencies, compliance with FCC rules is mandatory, especially for buyers in the Americas.

- IP Ratings: Waterproof and dustproof ratings (e.g., IP65, IP67) certify protection levels important for outdoor or industrial applications.

- Other Regional Certifications: Buyers in the Middle East and Australia should verify compliance with local electrical safety standards such as SASO (Saudi Arabia) or RCM (Australia).

QC Checkpoints Throughout Manufacturing

-

Incoming Quality Control (IQC):

– Verification of raw materials and components before entering production.

– Testing LED chips for luminosity and electrical characteristics.

– Inspection of FPCB quality and remote control components. -

In-Process Quality Control (IPQC):

– Monitoring assembly line processes for solder joint integrity, component placement accuracy, and circuit continuity.

– Environmental controls to prevent contamination or static damage.

– Sampling functional tests at different production stages.

Illustrative Image (Source: Google Search)

- Final Quality Control (FQC):

– Comprehensive testing of finished LED strips including:- Electrical safety tests (voltage, current, insulation resistance).

- Light output and color uniformity verification using spectrometers.

- Remote control responsiveness and range testing.

- Physical inspection for defects, waterproofing integrity, and packaging accuracy.

Testing Methods and Verification Techniques

- Electrical Testing: Automated testers measure voltage, current, and power consumption to ensure energy efficiency and safety.

- Optical Testing: Instruments check LED brightness, color temperature, and chromaticity coordinates for consistency.

- Environmental Stress Testing: Samples undergo temperature cycling, humidity exposure, and vibration tests to simulate harsh conditions.

- EMC Testing: Ensures electromagnetic compatibility, minimizing interference with other devices.

How B2B Buyers Can Verify Supplier Quality Control

For buyers across diverse regions, verifying supplier quality control is critical to avoid costly defects and delays:

- Factory Audits: Conduct on-site or virtual audits to review production processes, equipment, and quality management systems.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and product testing before shipment.

- Request Quality Documentation: Obtain ISO 9001 certificates, test reports (CE, RoHS, FCC), and batch-specific quality control records.

- Sample Testing: Insist on receiving samples for independent laboratory testing to validate performance claims.

- Supplier Performance Reviews: Regularly evaluate supplier delivery punctuality, defect rates, and responsiveness to quality issues.

QC and Certification Nuances for International Buyers

- Africa and South America: Regulatory frameworks may vary widely; buyers should prioritize suppliers with internationally recognized certifications (ISO, CE, RoHS) to ensure global market acceptance.

- Middle East (e.g., UAE): Emphasis on SASO certification and adherence to GCC standards is common; buyers should verify supplier compliance with these regional requirements.

- Europe: CE marking and strict RoHS compliance are non-negotiable. Buyers should also be mindful of WEEE directives on electronic waste.

- Australia: RCM certification and compliance with Australian electrical safety standards are essential. Remote control frequency regulations must be verified to avoid interference issues.

Summary for B2B Buyers

- Insist on transparency in manufacturing processes and quality control protocols.

- Prioritize suppliers with robust ISO 9001 systems and relevant regional certifications.

- Implement multi-layered QC verification: from IQC through FQC, supported by third-party audits.

- Understand regional certification nuances to ensure smooth customs clearance and market acceptance.

- Leverage technology and data in supplier management to track quality trends and reduce risk.

This comprehensive insight into manufacturing and quality assurance empowers international B2B buyers to make informed decisions, ensuring that remote LED strips meet exacting standards for performance, safety, and reliability.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for remote led strip Sourcing

Understanding the cost structure and pricing dynamics of remote LED strip sourcing is essential for international B2B buyers aiming to optimize procurement strategies while ensuring product quality and supply reliability. Below is a detailed analysis of the key cost components, price influencers, and actionable buyer tips tailored to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Remote LED Strip Sourcing

-

Materials: The primary cost driver includes LED chips, flexible circuit boards, resistors, connectors, and protective coatings (e.g., silicone for waterproofing). High-quality LEDs and advanced materials like copper-based PCBs increase durability and brightness but come at a premium.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Countries with lower labor costs can offer competitive pricing but may require due diligence to ensure quality standards are met.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor involved in assembly, testing, and packaging. Efficient manufacturing processes reduce overhead impact on unit costs.

-

Tooling and Customization: Custom lengths, colors, packaging, or integration of smart control modules require specialized tooling and setup, which add upfront costs that are amortized over the order quantity.

-

Quality Control (QC): Rigorous QC processes, including lifespan testing, waterproofing certification, and color consistency checks, contribute to higher production costs but reduce defect rates and returns.

-

Logistics and Shipping: Freight charges, customs duties, and insurance affect landed costs, especially for buyers in Africa and South America where shipping routes may be less direct. Consolidated shipments and choosing optimal Incoterms (e.g., FOB, CIF) can mitigate these expenses.

-

Supplier Margin: Suppliers include their profit margin based on market positioning, order volume, and relationship strength. Margins tend to be lower for large-volume contracts or long-term partnerships.

Influential Factors Affecting Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Higher volumes typically secure lower per-unit prices due to economies of scale. MOQ requirements vary by supplier but can be negotiated, especially when combining multiple product variants.

-

Product Specifications and Customization: Advanced features like dimmability, RGB color options, waterproof ratings (IP65+), or smart remote compatibility increase unit costs. Custom branding and packaging also affect pricing.

-

Material Quality and Certifications: Products meeting international standards such as CE, RoHS, UL, or Energy Star command higher prices but are essential for regulatory compliance in Europe and the Middle East.

-

Supplier Reputation and Location: Established suppliers with proven quality records may price higher but reduce risks of defects and delays. Proximity to buyers can reduce shipping time and costs, important for markets like the UAE and Europe.

-

Incoterms and Payment Terms: Incoterms define risk and cost responsibility. For example, CIF includes shipping and insurance costs in the price, while FOB places these on the buyer. Favorable payment terms (e.g., letters of credit) can improve cash flow.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO): Look beyond unit price to include shipping, customs, installation, and potential warranty claims. A slightly higher upfront cost may lead to lower TCO through better reliability and support.

-

Request Samples and Test for Compatibility: Especially important when sourcing for diverse markets with varying electrical standards and environmental conditions. Samples also help verify quality before large orders.

-

Consolidate Orders to Reduce Shipping and MOQ Pressure: Pooling demand across multiple projects or regions can unlock better pricing tiers and reduce per-shipment logistics costs.

-

Leverage Local Partnerships and Agents: Collaborating with local distributors or agents familiar with import regulations and supplier networks can streamline procurement and mitigate risks.

-

Be Aware of Currency Fluctuations and Tariffs: Exchange rate volatility can impact landed costs. Structuring contracts in stable currencies and understanding tariff implications for regions like the EU or MERCOSUR enhances budgeting accuracy.

-

Prioritize Suppliers Offering Flexible Incoterms and Warranty Policies: This flexibility can ease cash flow management and reduce risks associated with damaged or substandard goods.

Disclaimer: Pricing for remote LED strips varies widely depending on specifications, volumes, supplier capabilities, and geopolitical factors. The above insights serve as a general guide; buyers should conduct detailed cost analyses and supplier evaluations tailored to their specific sourcing contexts.

Spotlight on Potential remote led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘remote led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for remote led strip

Critical Technical Properties of Remote LED Strips

When sourcing remote LED strips for international B2B projects, understanding key technical specifications is vital for ensuring product performance, durability, and compatibility with your applications. Here are the primary properties to focus on:

-

LED Chip Quality and Type

The core of any LED strip is the LED chip itself, commonly measured by chip size (e.g., 3528, 5050, 2835) and brand. Higher-quality chips deliver better brightness, color consistency, and longer lifespan. For B2B buyers, selecting premium chips ensures reliability and reduces post-installation failures, which is critical in commercial or large-scale projects. -

IP Rating (Ingress Protection)

The IP rating indicates the strip’s resistance to dust and water. For example, IP20 is suitable for indoor use, while IP65 or IP67 offers waterproofing for outdoor or humid environments. Understanding this helps buyers specify strips that meet environmental requirements, avoiding costly replacements or warranty claims. -

Voltage and Power Consumption

Common voltage standards are 12V or 24V DC. Power consumption (measured in watts per meter) affects energy costs and compatibility with power supplies. Choosing the correct voltage and power rating is essential to optimize energy efficiency and ensure safe, stable operation across installations. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, ranging from warm white (~2700K) to daylight (~6500K). CRI indicates color accuracy, with values above 80 preferred for commercial and retail settings. These factors influence ambiance and product presentation, important for buyers targeting hospitality, retail, or architectural markets. -

Material and Flexibility

LED strips are typically mounted on flexible PCBs (printed circuit boards). The thickness, copper content, and substrate material affect durability and heat dissipation. Flexible strips allow installation in curved or tight spaces, expanding application possibilities. Buyers should verify material specs to match installation demands and longevity expectations. -

Remote Control Compatibility and Signal Type

Since remote LED strips integrate with wireless controllers, understanding the communication protocol (e.g., RF, IR, Bluetooth, Wi-Fi) is crucial. RF (Radio Frequency) remotes offer longer range and wall penetration compared to IR (Infrared). Selecting the right remote technology ensures seamless user experience, especially in commercial or smart building projects.

Common Industry and Trade Terminology for Remote LED Strips

Navigating international LED strip procurement involves familiarity with key trade terms that facilitate clear communication and smooth transactions:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED strips that can be rebranded or customized by buyers. OEM partnerships allow businesses to offer unique products under their brand, which is valuable for differentiation in competitive markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and negotiate terms, especially important for businesses balancing cost efficiency with storage limitations. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific LED strip models or custom orders. RFQs are essential for comparing offers and securing the best value in bulk purchases. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers manage logistics, costs, and risk effectively. -

Lumen Output

A measurement of the total light emitted by the LED strip, expressed in lumens per meter. Higher lumen output indicates brighter light, which is critical for task lighting or large commercial spaces. -

Dimmability

Indicates whether the LED strip supports brightness adjustment via compatible controllers. Dimmable strips offer flexibility in lighting design and energy savings, an important consideration for commercial and hospitality sectors.

By mastering these technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can make informed purchasing decisions. This ensures that remote LED strip products not only meet project specifications but also align with budgetary and operational requirements, ultimately driving business success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the remote led strip Sector

Market Overview & Key Trends

The global remote LED strip market is experiencing robust growth, driven by increasing demand for energy-efficient, customizable lighting solutions across residential, commercial, and industrial sectors. For international B2B buyers, especially in Africa, South America, the Middle East, and Europe, this market presents unique opportunities and challenges shaped by regional infrastructure development, urbanization, and technological adoption.

Key Market Drivers:

– Energy Efficiency and Cost Savings: Remote LED strips offer substantial energy savings over traditional lighting, a critical factor for markets with rising electricity costs or limited power infrastructure. This is particularly relevant in emerging economies in Africa and South America, where cost-effective and reliable lighting solutions can significantly impact operational expenses.

– Smart Lighting Integration: Buyers increasingly seek LED strips compatible with IoT and smart home systems, enabling remote control, automation, and integration with building management systems. The Middle East and Europe are at the forefront of adopting smart lighting, driven by tech-savvy consumers and stringent energy regulations.

– Customization and Versatility: Remote LED strips come in various colors, brightness levels, and waterproof ratings, making them adaptable for diverse applications—from architectural accent lighting to outdoor commercial signage. This flexibility appeals to B2B buyers looking to differentiate their offerings or tailor solutions to specific client needs.

Sourcing Trends:

– Direct Sourcing from Manufacturers: To optimize costs and supply chain transparency, many businesses now source directly from manufacturers, particularly in China and Southeast Asia, where production costs remain competitive. However, buyers are increasingly demanding suppliers with robust quality controls and certifications.

– Consolidated Supply Chains: Buyers prefer suppliers offering end-to-end solutions, including LED modules, controllers, and accessories, to streamline procurement and reduce lead times. This trend is especially pronounced in regions like the UAE and Australia, where efficient logistics and quick order fulfillment are critical.

– Emphasis on Warranty and After-Sales Support: Given the technical nature of remote LED strips, B2B buyers prioritize suppliers that provide comprehensive warranties and responsive customer service to minimize downtime and protect investments.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the procurement of remote LED strips. The environmental impact of lighting products encompasses raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling.

Environmental Impact and Green Certifications:

Remote LED strips are inherently more energy-efficient than incandescent or fluorescent alternatives, contributing to reduced carbon footprints over their lifecycle. However, sourcing components such as LED chips, circuit boards, and packaging materials sustainably is critical. Buyers should seek products with certifications such as RoHS (Restriction of Hazardous Substances), Energy Star, and UL Environmental Claims Validation, which ensure compliance with environmental and safety standards. Additionally, certifications from recognized bodies like TÜV Rheinland or CE mark adherence to quality and sustainability.

Ethical Supply Chains:

For international buyers, ensuring ethical practices in sourcing is essential, particularly when suppliers operate in regions with varying labor and environmental regulations. Transparency in the supply chain helps mitigate risks related to forced labor, unfair wages, and unsafe working conditions. Partnering with suppliers who conduct regular audits and adhere to ISO 14001 environmental management standards or SA8000 social accountability standards can strengthen corporate social responsibility credentials and appeal to increasingly conscientious end-users.

Sustainable Materials and Circular Economy:

Innovations such as using recyclable substrates, low-impact soldering techniques, and biodegradable packaging are gaining traction. B2B buyers can encourage suppliers to adopt circular economy principles, including product take-back programs and refurbishment options, thereby reducing waste and promoting long-term sustainability.

Brief Evolution of Remote LED Strip Technology

Remote LED strip technology has evolved significantly since its inception in the early 2000s. Initially, LED strips were simple, single-color light sources controlled by wired switches. The integration of remote controls marked a turning point, enabling users to adjust colors, brightness, and effects wirelessly, enhancing convenience and functionality.

Advancements in microcontroller technology and wireless protocols such as RF, Wi-Fi, and Bluetooth have expanded the capabilities of remote LED strips, allowing seamless integration with smartphones, voice assistants, and smart home ecosystems. This evolution has transformed LED strips from basic decorative elements to sophisticated lighting solutions that provide dynamic ambiance control, energy management, and interactive user experiences.

For B2B buyers, understanding this technological progression is crucial to selecting products that align with current market expectations and future-proof their investments, especially in regions where digital infrastructure and smart building technologies are rapidly advancing.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of remote led strip

-

How can I effectively vet suppliers of remote LED strips for international B2B purchases?

To vet suppliers, start by reviewing their business licenses, certifications (such as ISO, CE, RoHS), and years of operation. Request product samples to assess quality firsthand. Check references or customer reviews, especially from buyers in your region (Africa, Middle East, South America, Europe). Verify their supply chain transparency and after-sales support. Confirm if they offer warranties and clear return policies. Engaging in direct communication and visiting supplier facilities, if possible, also helps establish trust and ensures they meet your compliance and quality standards. -

What customization options are typically available for remote LED strips in wholesale orders?

Most wholesale suppliers offer customization in length, color temperature, LED density, and remote control features (e.g., app compatibility, color modes). Packaging can also be tailored for branding purposes, which is crucial for resale markets. Discuss your specific project needs upfront, including voltage requirements and IP rating for waterproofing. Custom firmware or remote functionalities may be available for smart LED strips. Ensure customization requests are confirmed in writing, including any additional costs and lead times, to avoid misunderstandings. -

What are the common minimum order quantities (MOQs) and lead times for remote LED strip orders, especially for buyers in Africa, South America, and the Middle East?

MOQs vary widely but typically start from 100 to 500 meters per SKU for customized orders. Standard, off-the-shelf products often have lower MOQs. Lead times depend on order size and customization but generally range from 2 to 6 weeks. For international buyers, factor in additional shipping and customs clearance time, which can add 1-3 weeks depending on the logistics route and local regulations. Early communication with suppliers about your timeline is essential to align expectations and plan inventory accordingly. -

Which payment terms are standard for international B2B transactions involving remote LED strips, and how can buyers protect themselves?

Common payment terms include 30% upfront deposit with the balance paid upon shipment or after inspection. Letters of credit (LC) and escrow services are safer options for larger transactions, providing protection for both parties. Use secure payment platforms and avoid full prepayment without verified supplier credibility. Always request a proforma invoice detailing product specs, pricing, and delivery terms. Negotiate payment schedules that allow inspection or quality checks before final payment to mitigate risks. -

What quality assurance certifications should I look for when sourcing remote LED strips internationally?

Look for internationally recognized certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and FCC (Federal Communications Commission) depending on your target market. These certifications indicate compliance with safety, electromagnetic compatibility, and environmental standards. Additionally, ISO 9001 certification for the manufacturer ensures consistent quality management processes. Request test reports and certificates before purchasing to ensure the products meet your country’s regulatory requirements and reduce the risk of customs issues. -

How can I optimize logistics and shipping costs when importing remote LED strips to regions like Africa or South America?

Consolidate orders to maximize container space and reduce per-unit freight costs. Choose suppliers with experience shipping to your region who can recommend reliable freight forwarders familiar with local customs procedures. Opt for sea freight for large volumes due to cost efficiency, but use air freight for urgent orders despite higher costs. Negotiate shipping terms (Incoterms) clearly, commonly FOB or CIF, to understand your responsibilities. Plan for customs clearance delays by working with local customs brokers and ensuring all documentation (invoices, packing lists, certificates) is accurate and complete. -

What dispute resolution mechanisms are advisable for international B2B transactions involving remote LED strips?

Include clear dispute resolution clauses in your purchase agreement specifying jurisdiction and governing law, often choosing neutral arbitration forums such as ICC or SIAC. Maintain detailed records of communications, contracts, and quality inspections. Use escrow or payment terms that release funds only after satisfactory delivery and inspection. In case of product defects or shipment issues, try to resolve disputes amicably first through supplier negotiation or mediation. If escalation is necessary, having legal support familiar with international trade law is crucial for enforcing agreements. -

How do I ensure consistent quality and performance across large remote LED strip orders for multi-location projects?

Standardize product specifications and request production samples for approval before full-scale manufacturing. Establish quality checkpoints during production, either through third-party inspection services or factory audits. Use batch numbers and traceability to track product lots, facilitating recall or replacement if needed. Agree on strict tolerance levels for brightness, color consistency, and remote functionality. For multi-location deployments, coordinate shipments to minimize variation between batches and maintain uniformity across sites, which is critical for brand reputation and customer satisfaction.

Strategic Sourcing Conclusion and Outlook for remote led strip

Strategic sourcing of remote LED strips presents a compelling opportunity for international B2B buyers aiming to optimize cost, quality, and innovation in their lighting solutions. Key takeaways emphasize the importance of partnering with reputable suppliers who offer customizable products, competitive pricing through bulk purchasing, and access to the latest LED technologies. Ensuring robust supply chain management—from reliable LED module sourcing to efficient logistics—can significantly reduce lead times and enhance project scalability.

For buyers in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices unlocks cost efficiencies and product consistency critical to large-scale commercial or industrial deployments. Prioritizing suppliers with strong warranties, flexible customization, and proven quality controls will safeguard investments and support seamless integration into diverse environments and applications.

Looking ahead, the remote LED strip market is poised for continued innovation, including smarter, energy-efficient solutions tailored to evolving business needs. International buyers are encouraged to cultivate long-term supplier relationships and adopt technology-driven supply chain tools to maintain competitive advantage. By embracing these strategic sourcing principles today, businesses can confidently illuminate their projects while driving sustainable growth in an increasingly dynamic global marketplace.