Introduction: Navigating the Global Market for led strip lamp

LED strip lamps have become a cornerstone technology in modern lighting solutions, offering unparalleled flexibility, energy efficiency, and design versatility. For international B2B buyers across Africa, South America, the Middle East, and Europe, including key markets like the UK and Mexico, understanding the complexities of sourcing these products is essential to gaining a competitive advantage. The global demand for LED strip lamps is rapidly expanding, driven by applications ranging from commercial and industrial lighting to architectural and decorative uses.

This comprehensive guide is designed to equip buyers with critical insights into the LED strip lamp market, covering a broad spectrum of topics such as product types, material quality, manufacturing standards, and quality control measures. It also delves into supplier evaluation, cost considerations, and market dynamics to help businesses make well-informed procurement decisions. Special attention is given to navigating supply chain challenges and leveraging the latest technological advancements in LED modules and smart lighting systems.

By exploring these facets, the guide empowers international buyers to optimize their sourcing strategies, reduce operational risks, and secure high-quality products tailored to their specific project needs. Whether managing large-scale commercial installations or retail distribution, businesses will find actionable knowledge to streamline procurement processes and build resilient supplier relationships. Ultimately, this resource serves as a vital tool for any B2B buyer aiming to thrive in the evolving global LED strip lamp market.

Understanding led strip lamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Color LED Strip | Emits a fixed color; available in various white tones (warm, neutral, cool) | Retail lighting, office illumination, architectural accents | + Cost-effective, simple installation – Limited flexibility, no color change |

| RGB LED Strip | Capable of producing multiple colors via RGB diodes | Hospitality, event lighting, advertising displays | + Versatile color options, dynamic effects – Higher cost, requires controllers |

| Waterproof LED Strip | Encased in silicone or epoxy for moisture resistance | Outdoor signage, landscape lighting, industrial environments | + Durable in harsh conditions, versatile outdoor use – Slightly higher price, reduced flexibility |

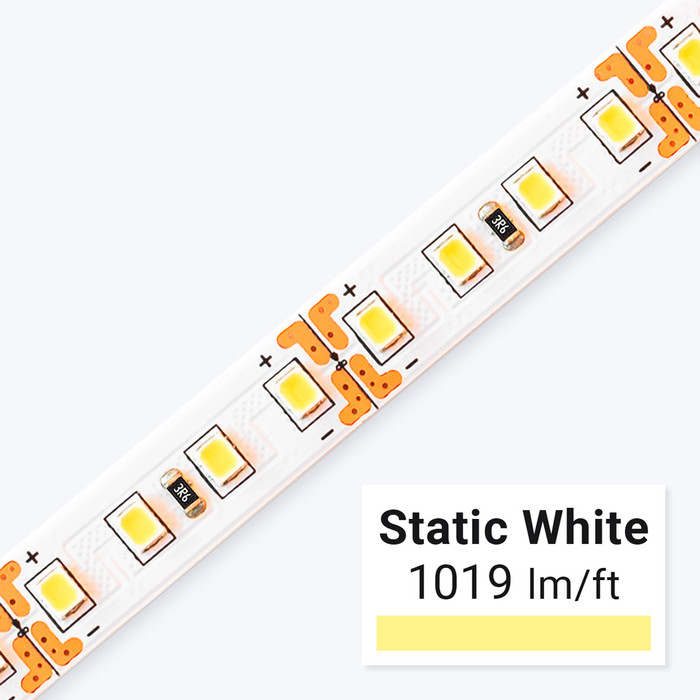

| High Lumen LED Strip | High brightness output, often with dense LED placement | Task lighting, warehouses, factories, commercial spaces | + Superior illumination, energy-efficient – More heat generation, may need better heat dissipation |

| Smart LED Strip | Integrated with smart controls (Wi-Fi, Bluetooth) for remote operation | Smart buildings, retail innovation, experiential marketing | + Advanced control, integration with IoT – Higher upfront cost, technical complexity |

Single Color LED Strip

Single color LED strips are the most straightforward type, delivering consistent light in a single hue, typically available in a range of white temperatures. Their simplicity makes them ideal for businesses seeking reliable, cost-effective lighting solutions for offices, retail environments, or architectural highlights. For B2B buyers, the focus should be on the quality of LED chips and the strip’s length customization to fit specific projects. These strips are a low-risk investment with minimal technical requirements, ensuring easy integration and maintenance.

RGB LED Strip

RGB LED strips offer dynamic color-changing capabilities by combining red, green, and blue LEDs within a single strip. This makes them highly suitable for hospitality venues, event spaces, and advertising displays where visual impact is crucial. B2B purchasers should consider the compatibility of controllers and power supplies, as well as the supplier’s ability to provide customization and support for complex installations. While costlier than single color strips, RGB strips add value through enhanced user experience and branding opportunities.

Waterproof LED Strip

Designed with protective coatings like silicone or epoxy, waterproof LED strips are built to withstand moisture, dust, and other environmental factors. These strips are essential for outdoor applications such as landscape lighting, signage, and industrial settings. International buyers, particularly from regions with high humidity or outdoor usage demands (e.g., Middle East, South America), should prioritize IP ratings and supplier certifications to ensure durability. Although these strips carry a premium, their longevity and reliability justify the investment for demanding environments.

High Lumen LED Strip

High lumen LED strips feature densely packed LEDs that deliver intense brightness suitable for task-oriented settings like warehouses, factories, and large commercial spaces. For B2B buyers, evaluating the heat dissipation mechanisms and energy consumption is critical to avoid operational issues and additional cooling costs. These strips enable businesses to replace traditional high-power lighting with more efficient and longer-lasting alternatives, supporting sustainability goals and reducing maintenance overhead.

Smart LED Strip

Smart LED strips integrate connectivity options such as Wi-Fi or Bluetooth, allowing for remote control, automation, and integration with building management systems. This type is increasingly popular in smart buildings, retail innovation projects, and experiential marketing campaigns across Europe and technologically advanced markets. Buyers should assess supplier expertise in IoT compatibility, software support, and after-sales service. While smart strips demand a higher initial investment, they offer future-proofing and enhanced functionality that can drive long-term value.

Related Video: LED Strip Lighting Installs: Beginner, Intermediate and Expert Level

Key Industrial Applications of led strip lamp

| Industry/Sector | Specific Application of led strip lamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Accent and ambient lighting in stores, display cases, and signage | Enhances product visibility, attracts customers, reduces energy costs | Requires customizable color and brightness; durable and safe for high-traffic areas; compliance with local electrical standards |

| Hospitality & Events | Mood and decorative lighting in hotels, restaurants, and event venues | Creates immersive atmospheres, flexible design options, energy-efficient | Waterproof and flexible strips for varied environments; ease of installation and control systems integration |

| Manufacturing & Warehousing | Task lighting for workstations, conveyor belts, and storage areas | Improves worker productivity and safety, lowers maintenance costs | High-lumen output, robust construction, and long lifespan; compatibility with industrial control systems |

| Automotive & Transportation | Interior ambient lighting, dashboard illumination, and exterior accents | Enhances vehicle aesthetics and safety, lightweight and low power consumption | Heat-resistant and vibration-proof strips; certifications for automotive use |

| Agriculture & Horticulture | Supplemental lighting for plant growth in greenhouses and vertical farms | Optimizes photosynthesis, increases crop yield, reduces electricity use | Specific wavelength options (e.g., red and blue LEDs), waterproof and dustproof design |

In the retail and commercial sector, LED strip lamps are widely used to enhance product displays and create inviting store environments. These strips provide even, customizable lighting that highlights merchandise effectively, drawing customer attention and boosting sales. For international buyers, especially in regions like Europe and South America, sourcing LED strips with adjustable color temperatures and energy-efficient certifications is crucial to meet local regulations and consumer preferences.

Within hospitality and events, LED strip lamps offer versatile lighting solutions for hotels, restaurants, and event spaces. They enable dynamic mood settings and decorative effects that can be easily adjusted for different occasions. Buyers from the Middle East and Africa should prioritize waterproof and flexible LED strips that withstand diverse climates and enable quick installation, reducing downtime during event setups.

In manufacturing and warehousing environments, LED strip lamps serve as essential task lighting to improve visibility and safety on production lines and storage areas. High-lumen, durable strips reduce worker fatigue and maintenance needs. For B2B buyers in industrial hubs such as the UK and Mexico, sourcing LED strips compatible with existing industrial control systems and featuring robust construction is vital for operational efficiency.

The automotive and transportation industry leverages LED strip lamps for interior ambient lighting, dashboard illumination, and aesthetic exterior accents. These strips must endure heat, vibration, and comply with automotive standards. International buyers should seek suppliers offering certified, heat-resistant LED strips with proven reliability to ensure safety and performance in diverse driving conditions.

Finally, in agriculture and horticulture, LED strip lamps provide supplemental lighting that enhances plant growth in controlled environments like greenhouses and vertical farms. Specific LED wavelengths optimize photosynthesis, boosting yields while conserving energy. Buyers from regions with emerging agricultural technologies, such as parts of Africa and South America, should focus on sourcing waterproof, dustproof LED strips with customizable spectrum options tailored to crop requirements.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for led strip lamp

Aluminum

Key Properties: Aluminum is widely used for LED strip lamp housings and heat sinks due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. It typically withstands temperatures up to 150°C and offers good resistance to oxidation, making it suitable for various environmental conditions.

Pros & Cons: Aluminum’s high thermal conductivity helps dissipate heat efficiently, extending LED lifespan and maintaining performance. It is relatively cost-effective and easy to manufacture into extrusions or profiles. However, aluminum can be prone to surface scratching and requires anodizing or powder coating for enhanced corrosion resistance in harsh environments.

Impact on Application: Aluminum is ideal for indoor and outdoor LED strip installations where heat dissipation is critical, such as commercial lighting, retail displays, and architectural lighting. Its corrosion resistance makes it suitable for moderate outdoor exposure but may require additional protective coatings in coastal or high-humidity regions.

International B2B Considerations: Buyers from Africa, South America, the Middle East, and Europe should ensure aluminum components comply with regional standards such as ASTM B209 (USA), EN 573 (Europe), or JIS H4000 (Japan). In regions with high UV exposure or saline atmospheres (e.g., coastal Africa or Middle East), anodized or powder-coated aluminum is preferred to prevent premature corrosion. European buyers often prioritize materials with RoHS compliance for environmental safety.

Flexible PCB (Polyimide or PET substrate)

Key Properties: Flexible PCBs used in LED strip lamps are typically made from polyimide or PET substrates, offering excellent flexibility, chemical resistance, and thermal stability up to 130°C. These materials allow the LED strips to bend and conform to irregular surfaces without damage.

Pros & Cons: Polyimide offers superior heat resistance and mechanical strength compared to PET but is more expensive. PET is cost-effective and suitable for less demanding applications. Both substrates provide good electrical insulation and moisture resistance but can be vulnerable to UV degradation if exposed outdoors without protective coatings.

Impact on Application: Flexible PCBs are essential for applications requiring curved or intricate installations, such as automotive lighting, signage, or decorative lighting in retail and hospitality sectors. For outdoor or industrial environments, additional waterproofing or UV-resistant coatings are necessary to ensure longevity.

International B2B Considerations: Buyers should verify compliance with IPC-6013 standards for flexible PCBs and check for certifications like UL or CE marking, especially for markets in Europe and the Middle East. In South America and Africa, where environmental conditions can be extreme, selecting PCBs with enhanced moisture and chemical resistance is crucial. Customization options for thickness and adhesive backing are often requested by European and Middle Eastern clients for specific installation requirements.

Silicone (Encapsulation and Waterproofing)

Key Properties: Silicone is commonly used as an encapsulant and waterproofing material for LED strip lamps, providing excellent flexibility, UV resistance, and thermal stability up to 200°C. It offers superior protection against moisture, dust, and chemical exposure.

Pros & Cons: Silicone encapsulation significantly enhances durability and outdoor suitability, making LED strips resistant to water ingress (IP65 to IP68 ratings). It maintains flexibility in extreme temperatures but increases manufacturing complexity and cost. Silicone coatings can also affect light diffusion and color temperature if not precisely formulated.

Impact on Application: Silicone-encapsulated LED strips are ideal for outdoor lighting, marine environments, and industrial applications where exposure to water, chemicals, or harsh weather is common. They are preferred in regions with high humidity or frequent rainfall, such as parts of Africa, South America, and the Middle East.

International B2B Considerations: Buyers should ensure silicone materials meet international standards such as ASTM D2240 for hardness and ISO 10993 for biocompatibility where applicable. In Europe, compliance with REACH and RoHS regulations is critical. For Middle Eastern and African markets, silicone encapsulation is often a requirement to withstand dust storms and high temperatures. Suppliers offering customized hardness and thickness options cater well to diverse regional needs.

Copper (Conductive Traces and Connectors)

Key Properties: Copper is the standard material for conductive traces and connectors in LED strip lamps due to its excellent electrical conductivity and thermal performance. It typically has a melting point of 1085°C and good corrosion resistance when properly treated.

Pros & Cons: Copper ensures efficient current flow and heat dissipation, which is vital for LED performance and longevity. It is relatively affordable but can be susceptible to oxidation and corrosion if exposed to moisture without protective coatings like tin or gold plating. Manufacturing complexity increases with the need for precise etching and plating processes.

Impact on Application: Copper traces are fundamental for all LED strip lamps, especially in high-power or long-run installations where voltage drop and heat buildup are concerns. Protective coatings are essential for outdoor or humid environments to prevent corrosion-related failures.

International B2B Considerations: Buyers should verify that copper materials and plating processes comply with IPC standards and regional regulations such as RoHS in Europe and similar directives in other markets. In humid or coastal regions of South America and Africa, corrosion-resistant plating is highly recommended. European and Middle Eastern buyers often require traceability and certification of copper purity and plating quality to meet stringent quality standards.

Summary Table

| Material | Typical Use Case for led strip lamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks and housing for indoor/outdoor LED strips | Excellent thermal conductivity and lightweight | Requires surface treatment for corrosion resistance | Medium |

| Flexible PCB (Polyimide/PET) | Flexible circuit substrate for curved or irregular installations | High flexibility and chemical resistance | UV degradation risk without protective coating | Medium |

| Silicone | Encapsulation and waterproofing for outdoor/industrial LED strips | Superior waterproofing and UV resistance | Increases manufacturing complexity and cost | High |

| Copper | Conductive traces and connectors within LED strips | Excellent electrical and thermal conductivity | Susceptible to corrosion without plating | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for led strip lamp

Manufacturing Processes for LED Strip Lamps

The production of LED strip lamps involves a series of carefully controlled stages to ensure high performance, durability, and safety. For B2B buyers, understanding these manufacturing steps helps in selecting suppliers capable of delivering consistent quality products tailored to diverse international markets.

-

Material Preparation

The process begins with sourcing and preparing raw materials such as LED chips, flexible printed circuit boards (FPCBs), resistors, capacitors, and connectors. High-quality LED chips from reputable manufacturers ensure brightness and longevity. The FPCB is typically made from copper-clad polyimide or polyester film, chosen for flexibility and heat resistance. Materials undergo initial inspections to verify specifications and compliance with supplier agreements. -

Forming the Circuit

After material prep, the copper layers on the FPCB are etched or printed to create precise circuit paths. This step uses photolithography or chemical etching techniques to ensure accurate electrical pathways. Automated machinery typically performs this to maintain uniformity. Subsequent solder mask application protects circuits from oxidation and short circuits. -

Component Assembly

The LED chips and other electronic components are mounted onto the FPCB using Surface Mount Technology (SMT). This involves applying solder paste, placing components via pick-and-place machines, and reflow soldering to secure them. Precision is critical here to avoid defects such as cold solder joints or misaligned LEDs, which can affect light output and reliability.

Illustrative Image (Source: Google Search)

- Finishing and Encapsulation

Post-assembly, the strips are coated or encapsulated to protect against moisture, dust, and mechanical damage. Common finishing methods include silicone or epoxy resin coating, which also enhances waterproof ratings (e.g., IP65, IP67). Finally, the strips are cut into standard or custom lengths, with connectors attached as required by client specifications.

Quality Assurance in LED Strip Lamp Production

Effective quality control (QC) throughout the manufacturing process is essential to meet international standards and customer expectations. B2B buyers should prioritize suppliers with robust QC systems aligned with global certifications and industry best practices.

International and Industry Standards

- ISO 9001: This is the cornerstone quality management system standard, ensuring that manufacturers maintain consistent processes and continuous improvement. Suppliers certified with ISO 9001 demonstrate a commitment to product quality and operational excellence.

- CE Marking: For buyers in Europe and other markets recognizing CE, this certification confirms conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restriction of hazardous substances is critical, especially for European and UK markets, ensuring the LED strips are free from lead, mercury, cadmium, and other harmful materials.

- UL Certification: Particularly important for North America and some Middle Eastern countries, UL ensures electrical safety and fire hazard prevention.

- IP Ratings (Ingress Protection): International buyers focused on outdoor or industrial applications should verify IP ratings that guarantee resistance to dust and water.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

Raw materials and components undergo thorough inspections upon arrival. IQC includes visual checks, dimensional measurements, and functional testing of LED chips and PCBs to prevent defective inputs from entering production. -

In-Process Quality Control (IPQC)

During assembly, IPQC monitors soldering quality, component placement accuracy, and circuit integrity. Automated optical inspection (AOI) machines and manual sampling are common methods. This stage minimizes defects early, reducing costly rework. -

Final Quality Control (FQC)

Completed LED strips are subjected to rigorous testing before shipment. Key tests include:

- Electrical Testing: Verifying voltage, current, and power consumption to ensure adherence to specifications.

- Light Output Testing: Measuring brightness (lumens), color temperature, and color rendering index (CRI) for consistency.

- Environmental Testing: Assessing resistance to moisture, heat, and UV exposure, particularly for outdoor-rated products.

- Mechanical Inspection: Checking physical dimensions, flexibility, and connector integrity.

- Safety Tests: Confirming compliance with electrical safety standards (e.g., insulation resistance, dielectric strength).

How B2B Buyers Can Verify Supplier Quality Control

- Factory Audits: Conduct on-site or virtual audits focusing on manufacturing processes, QC procedures, and compliance with certifications. Audits assess supplier capability, traceability systems, and workforce training.

- Review of QC Documentation: Request detailed QC reports, including incoming material inspections, in-process checks, and final test results. Look for evidence of statistical process control (SPC) and defect rates.

- Third-Party Inspections: Engage independent inspection agencies to perform random batch testing or full pre-shipment inspections. This adds an unbiased layer of assurance, especially when sourcing from distant suppliers.

- Sample Testing: Obtain product samples for in-house or third-party laboratory testing. This helps verify performance claims and compliance with international standards.

- Certification Verification: Confirm the authenticity and validity of ISO, CE, RoHS, UL, and other relevant certifications through official registries or certification bodies.

Quality Assurance Considerations for International B2B Buyers

- Regional Regulatory Requirements: Buyers from Africa, South America, the Middle East, and Europe must consider local import regulations and safety standards. For example, the UK requires UKCA marking post-Brexit, while Mexico may require NOM certification for electrical products.

- Environmental Conditions: In regions with high humidity or extreme temperatures, waterproof and robust LED strip lamps with appropriate IP ratings are essential to ensure product longevity.

- Supply Chain Transparency: Buyers should insist on clear traceability of components and production batches to facilitate recalls or warranty claims if needed.

- Customization and Compliance: When ordering customized LED strips (e.g., specific lengths, colors, or packaging), verify that suppliers maintain quality standards for these bespoke products without compromising overall performance.

- After-Sales Support: Assess the supplier’s warranty policies, return procedures, and technical support capabilities. Reliable post-purchase service is vital for sustaining business relationships and managing potential quality issues.

Summary

For international B2B buyers seeking LED strip lamps, a deep understanding of the manufacturing process and quality assurance protocols is crucial. Rigorous material preparation, precise assembly techniques, and protective finishing combine to produce durable and efficient lighting solutions. Quality control governed by international standards such as ISO 9001, CE, and RoHS, along with multiple QC checkpoints (IQC, IPQC, FQC), ensures products meet global expectations. Buyers should actively verify supplier QC through audits, sample testing, and third-party inspections, while remaining mindful of region-specific regulatory and environmental requirements. This comprehensive approach mitigates risks, optimizes procurement decisions, and supports successful deployment of LED strip lighting in diverse markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for led strip lamp Sourcing

When evaluating the cost and pricing dynamics of sourcing LED strip lamps for international B2B procurement, understanding the full cost structure and key price influencers is essential. This enables buyers—especially those operating in Africa, South America, the Middle East, and Europe—to make informed decisions that optimize budget and value.

Core Cost Components in LED Strip Lamp Sourcing

- Materials:

The primary cost driver is the quality and type of raw materials used, including LED chips, flexible circuit boards, drivers, and connectors. Higher-grade materials improve longevity and light quality but raise costs. For instance, premium LEDs with advanced color rendering or waterproof coatings add to the base material expense.

-

Labor and Manufacturing Overhead:

Labor costs vary significantly by manufacturing location. Countries with lower labor expenses offer competitive pricing but may require stricter quality controls. Manufacturing overhead includes factory utilities, equipment depreciation, and indirect labor, all contributing to the final unit cost. -

Tooling and Customization:

Initial tooling for custom LED strip designs, lengths, or packaging incurs upfront costs. Customization options like specific color temperatures, branding, or smart functionalities increase tooling and setup expenses but can differentiate products in the market. -

Quality Control (QC):

Rigorous QC processes—testing for durability, color accuracy, and electrical safety—add to costs but reduce returns and enhance supplier reliability. Certifications such as CE, RoHS, or UL often require additional inspection steps. -

Logistics and Shipping:

Freight charges, customs duties, and insurance must be factored in, especially for buyers importing from Asia or Europe. Bulk shipments reduce per-unit logistics costs but require capital investment and storage capacity. -

Supplier Margin:

Suppliers build in profit margins reflecting their operational costs, market positioning, and volume discounts. Margins can fluctuate based on demand cycles and supplier competition.

Key Price Influencers for Buyers to Consider

-

Order Volume and Minimum Order Quantity (MOQ):

Larger orders unlock volume discounts, significantly lowering unit prices. Buyers should negotiate MOQs to match project scale, balancing inventory holding costs against price benefits. -

Product Specifications and Customization:

Higher specifications such as IP65 waterproof ratings, higher lumen output, or smart control features increase pricing. Custom packaging or branding also affects costs. -

Material Quality and Certifications:

Certified products with eco-friendly or safety approvals command premium pricing but reduce compliance risks in regulated markets like the EU or UK. -

Supplier Reputation and Location:

Established suppliers with proven quality and reliability may charge higher prices but reduce risk and hidden costs from defects or delays. Local or regional suppliers might offer faster turnaround and lower freight costs. -

Incoterms and Payment Terms:

Understanding Incoterms (e.g., FOB, CIF, DDP) is critical as they determine which party bears shipping and customs costs. Favorable payment terms such as letter of credit or net 60 can improve cash flow.

Practical Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Beyond Price:

Focus on total value including warranty terms, after-sales support, and lead times. Suppliers may offer better pricing in exchange for longer contract commitments or upfront payments. -

Calculate Total Cost of Ownership (TCO):

Evaluate not just unit price but installation costs, energy consumption, lifespan, and maintenance. High-efficiency LEDs may have higher upfront costs but lower operational expenses. -

Leverage Sample Testing:

Request product samples to verify quality before placing large orders. This reduces risk of costly returns and ensures compatibility with local standards and installations. -

Consider Regional Supplier Hubs:

For buyers in Africa, South America, and the Middle East, sourcing from regional warehouses or distributors can reduce shipping times and import duties, improving overall cost efficiency. -

Stay Informed on Market Trends:

Monitor raw material price fluctuations (e.g., copper, semiconductor chips) and geopolitical factors impacting supply chains. Early engagement with suppliers can help lock in favorable pricing.

Disclaimer: Pricing for LED strip lamps varies widely based on specifications, order size, and supplier agreements. The insights provided are indicative and should be validated through direct supplier quotations and market research tailored to your specific sourcing context.

By carefully analyzing these cost components and price influencers, international B2B buyers can strategically negotiate and optimize their LED strip lamp sourcing, ensuring competitive pricing without compromising on quality or service.

Spotlight on Potential led strip lamp Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘led strip lamp’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for led strip lamp

Critical Technical Properties of LED Strip Lamps

Understanding the key technical specifications of LED strip lamps is essential for making informed purchasing decisions in international B2B trade. These properties directly impact product performance, compatibility, and longevity, which are crucial for large-scale projects and resale.

Illustrative Image (Source: Google Search)

-

LED Chip Quality and Type

The LED chip is the core light source in the strip. High-quality chips (such as those from reputable brands like Cree or Samsung) provide better brightness, color consistency, and longer lifespan. For B2B buyers, sourcing strips with premium chips ensures reliability and reduces post-sale issues, particularly important in markets with demanding standards like Europe or the Middle East. -

IP Rating (Ingress Protection)

This rating indicates the strip’s resistance to dust and water. For example, IP20 is suitable for indoor dry areas, while IP65 or higher is needed for outdoor or humid environments. Understanding the IP rating helps buyers select the right product for specific applications, avoiding costly failures or returns due to environmental incompatibility. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) defines the warmth or coolness of the light—ranging from warm white (~2700K) to daylight (~6500K). CRI measures how accurately the light reveals colors compared to natural light, with values above 80 preferred for retail or hospitality sectors. These parameters are vital for buyers targeting markets with strict aesthetic or functional lighting requirements. -

Power Consumption and Luminous Efficiency

Power consumption (watts per meter) combined with luminous efficiency (lumens per watt) determines the energy efficiency of the LED strip. Lower power consumption with high lumens output means cost savings on electricity and cooling, a compelling factor for large commercial projects in energy-conscious regions like the EU. -

Cutting and Connection Points

LED strips are designed with specific cutting intervals, usually marked every few centimeters. Knowing these intervals is important for customization and installation flexibility. Additionally, connection types (soldered wires, connectors, or plug-and-play systems) affect ease of assembly and maintenance. -

Material and PCB Quality

The substrate or printed circuit board (PCB) material impacts heat dissipation and durability. High-grade flexible PCBs with copper layers enhance thermal management, prolonging LED life. For B2B buyers, investing in quality PCBs reduces failure rates and supports warranty claims.

Key Trade Terminology for LED Strip Lamp Transactions

Familiarity with common industry terms streamlines communication and negotiation in international B2B purchasing, minimizing misunderstandings and optimizing procurement processes.

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce LED strips that can be branded and customized for resellers or project owners. OEM partnerships allow buyers to offer unique products with tailored specifications or branding, enhancing market differentiation. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is crucial for budgeting and inventory planning, especially for buyers in emerging markets who need to balance order size with cash flow and storage capacity. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for detailed pricing, lead times, and product specifications. RFQs are the foundation of transparent supplier evaluation and help buyers secure competitive terms. -

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities, risks, and costs between buyers and sellers during shipping (e.g., FOB, CIF, DDP). Clear knowledge of Incoterms enables buyers to negotiate shipping logistics, cost allocation, and customs clearance efficiently. -

Lead Time

The total time from order placement to product delivery. Lead time affects project scheduling and inventory turnover. Buyers should confirm lead times upfront to align procurement with installation or sales plans. -

Dimmable and RGB

These terms describe functional features of LED strips. “Dimmable” indicates the strip’s compatibility with brightness control systems, while “RGB” refers to strips capable of producing multiple colors. Such features may be essential for specific markets or applications, influencing product selection.

By grasping these technical properties and trade terms, international B2B buyers can confidently navigate supplier offerings, ensure product suitability, and optimize procurement strategies for LED strip lamps tailored to diverse regional markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the led strip lamp Sector

Market Overview & Key Trends

The global LED strip lamp market is experiencing robust growth driven by escalating demand for energy-efficient, versatile lighting solutions across residential, commercial, and industrial sectors. Key growth drivers include government initiatives promoting energy conservation, rising urbanization, and the expanding smart lighting ecosystem. For international B2B buyers—especially in Africa, South America, the Middle East, and Europe—understanding these dynamics is crucial for strategic sourcing.

Regional Market Dynamics:

– Africa & South America: Rapid urban infrastructure development and increasing adoption of LED technology in retail and hospitality sectors are fueling demand. However, buyers must navigate challenges such as inconsistent supply chains and variable import regulations. Partnering with suppliers that offer reliable logistics and local support enhances procurement efficiency.

– Middle East: The region’s focus on luxury commercial developments and smart city projects creates demand for customizable, high-performance LED strips, including RGB and waterproof variants. Suppliers providing tailored solutions and compliance with regional standards hold a competitive edge.

– Europe (UK and beyond): Stringent energy efficiency regulations and sustainability mandates push buyers to prioritize LED strips with certifications like CE and RoHS. The UK market particularly values smart LED strips compatible with IoT platforms, aligning with growing smart building trends.

Emerging B2B Sourcing Trends:

– Customization & Scalability: Bulk buyers increasingly seek suppliers offering bespoke LED strip lengths, colors, and packaging to align with branding and project-specific needs.

– Technology Integration: The rise of app-controlled, dimmable, and color-changing LED strips supports dynamic lighting applications, enhancing value propositions in retail and events.

– Supply Chain Resilience: Given recent global disruptions, diversification of suppliers and establishing direct manufacturer partnerships are becoming standard to reduce lead times and mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a decisive factor in LED strip lamp procurement. Buyers globally are prioritizing products that minimize environmental impact throughout their lifecycle—from raw material extraction to manufacturing, usage, and end-of-life disposal.

Environmental Impact Considerations:

– LED strip lamps inherently offer significant energy savings compared to traditional lighting, lowering carbon footprints. However, responsible sourcing of raw materials—such as conflict-free metals and recyclable components—is critical to reduce ecological harm.

– Selecting suppliers that employ eco-friendly manufacturing processes, including waste minimization and low-emission operations, aligns with corporate sustainability goals.

Ethical Supply Chains:

– Transparency and traceability in the supply chain are increasingly demanded by international B2B buyers. Ethical sourcing policies ensure compliance with labor standards and reduce risks associated with forced labor or unsafe working conditions.

– Certifications such as ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and Energy Star provide credible assurance of sustainable practices. Buyers should require these certifications as part of supplier qualification.

Green Materials & Innovations:

– The adoption of biodegradable or recyclable substrates and halogen-free components in LED strips is gaining traction. Such innovations not only reduce environmental footprints but also appeal to environmentally conscious clients and end-users.

– Incorporating smart controls that optimize energy consumption further enhances sustainability credentials and operational savings.

Brief Evolution of LED Strip Lamps

LED strip lamps have evolved from simple, single-color light sources to highly versatile, programmable lighting systems. Initially developed in the early 2000s as flexible, low-power decorative lighting, technological advancements have since enabled high-lumen outputs, color-changing capabilities, and integration with smart home and commercial automation systems.

For B2B buyers, this evolution translates into a broader spectrum of applications—from ambient retail lighting to industrial task illumination and dynamic architectural accents. Understanding this progression helps buyers appreciate the growing value LED strips offer beyond basic lighting, including improved energy efficiency, enhanced user experience, and greater design flexibility.

This nuanced perspective on market dynamics, sourcing trends, and sustainability equips international B2B buyers with actionable insights to optimize procurement strategies and align with evolving industry standards in the LED strip lamp sector.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of led strip lamp

-

How can I effectively vet LED strip lamp suppliers for international B2B purchases?

To ensure reliability, start by verifying the supplier’s business registration and years of operation. Check for positive customer reviews, especially from buyers in your region (Africa, South America, Middle East, Europe). Request product samples to assess quality firsthand. Confirm the supplier’s certifications (e.g., CE, RoHS, UL) that comply with your country’s standards. Engage in direct communication to evaluate responsiveness and transparency. Using platforms with verified trade assurance or escrow services can add an extra layer of security for international transactions. -

What customization options are typically available when ordering LED strip lamps wholesale?

Wholesale LED strip lamp suppliers often offer customization on length, color temperature, LED density, waterproof rating, and packaging. For branding purposes, custom packaging and labeling are common. Some suppliers provide options for specific connectors or dimming capabilities tailored to your market needs. It’s important to clarify customization lead times and minimum order quantities (MOQs) upfront, as bespoke products may require longer production cycles and higher MOQs. Clear technical specifications should be shared to avoid misunderstandings. -

What are standard minimum order quantities (MOQs) and lead times for bulk LED strip lamp orders?

MOQs vary widely depending on the supplier and customization level but typically range from 500 to 5,000 meters per model. For standard products, lead times usually span 2 to 6 weeks, while customized orders might take 4 to 12 weeks. Buyers should negotiate MOQs and lead times early, especially when importing to regions like Africa or South America where shipping times can add delays. Consolidating orders can reduce per-unit costs and expedite processing. Always request a production and delivery timeline before confirming orders. -

Which payment terms and methods are advisable for international B2B buyers of LED strip lamps?

Common payment methods include wire transfers (T/T), Letters of Credit (L/C), and escrow services via platforms like Alibaba. For new suppliers, a deposit (30%-50%) upfront with balance paid upon shipment or after inspection is standard. Letters of Credit provide security by involving banks but may incur additional costs. For buyers in regions with currency volatility, negotiating fixed payment terms and currency options can mitigate financial risk. Always ensure payment terms are clearly documented in the sales contract. -

What quality assurance measures and certifications should I expect from reputable LED strip lamp suppliers?

Quality assurance typically involves in-line testing during production and final product inspections before shipment. Look for certifications such as CE (Europe), RoHS (restriction of hazardous substances), UL (North America), and ISO 9001 (quality management). These ensure compliance with safety, environmental, and performance standards. Request test reports for electrical safety, waterproof ratings (IP65 or higher for outdoor use), and lumen output consistency. Some suppliers offer third-party inspection services for added confidence before shipment. -

How should I approach logistics and shipping for bulk LED strip lamp imports?

Choose suppliers experienced in international shipping and familiar with your destination country’s import regulations to avoid delays. Options include sea freight for cost efficiency on large orders and air freight for urgent shipments. Negotiate who handles customs clearance and duties—typically, suppliers offer FOB (Free On Board) or CIF (Cost, Insurance, and Freight) terms. Packaging should protect fragile components during transit. Use reliable freight forwarders with tracking capabilities and consider insurance to cover potential damage or loss. -

What steps can I take to resolve disputes or product issues with international LED strip lamp suppliers?

First, document all communications and agreements. If product quality or delivery issues arise, notify the supplier immediately with photographic evidence. Utilize dispute resolution mechanisms provided by trade platforms or escrow services if used. For direct contracts, refer to the arbitration clause or governing law specified. Maintaining good supplier relationships can facilitate amicable solutions. In cases of repeated issues, consider third-party mediation or legal counsel familiar with international trade laws. -

Are there specific considerations for LED strip lamp buyers from Africa, South America, the Middle East, and Europe?

Yes, regional factors include compliance with local electrical standards and certifications, climate considerations (e.g., waterproof ratings for humid or desert environments), and import regulations. Buyers should verify voltage compatibility and warranty coverage valid in their countries. Currency fluctuations and import duties may affect pricing, so factoring these into total landed cost is essential. Building relationships with suppliers who understand your regional market can improve customization, logistics, and after-sales support tailored to your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for led strip lamp

Key Takeaways for B2B Buyers

Strategic sourcing of LED strip lamps is essential for international businesses aiming to optimize cost, quality, and supply chain resilience. Bulk purchasing unlocks significant price advantages while providing access to a diverse range of customizable products tailored to specific market needs—whether for outdoor durability in harsh climates or advanced smart lighting solutions. Prioritizing partnerships with reputable suppliers and LED module manufacturers ensures consistent product performance and reduces risks associated with supply disruptions.

The Value of Strategic Sourcing

A well-planned sourcing strategy enables buyers to balance inventory levels, minimize lead times, and enhance delivery reliability. Leveraging technology and maintaining diversified supplier relationships can further strengthen procurement agility and responsiveness. This approach is especially vital for buyers across Africa, South America, the Middle East, and Europe, where varying infrastructure and regulatory landscapes demand adaptable sourcing solutions.

Looking Ahead

As LED technology continues to evolve with innovations in energy efficiency and smart connectivity, international B2B buyers are encouraged to adopt proactive sourcing practices. Engaging early with trusted suppliers to explore emerging products and scalable solutions will position businesses to meet growing market demands confidently. Embrace strategic sourcing today to secure competitive advantages in the dynamic global LED strip lamp market.